Welcome to our websites!

Jul . 02, 2024 01:00 Back to list

Premium Expanded Metal Mesh Competitive Pricing for High-Quality Products

Understanding the High-Quality Expanded Metal Mesh An Insight into Pricing Factors

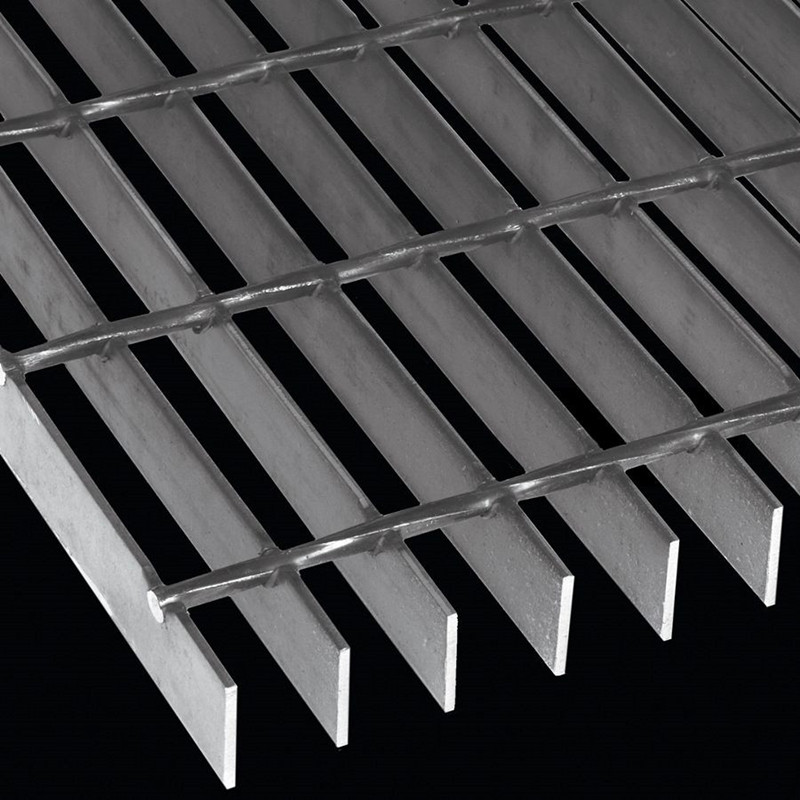

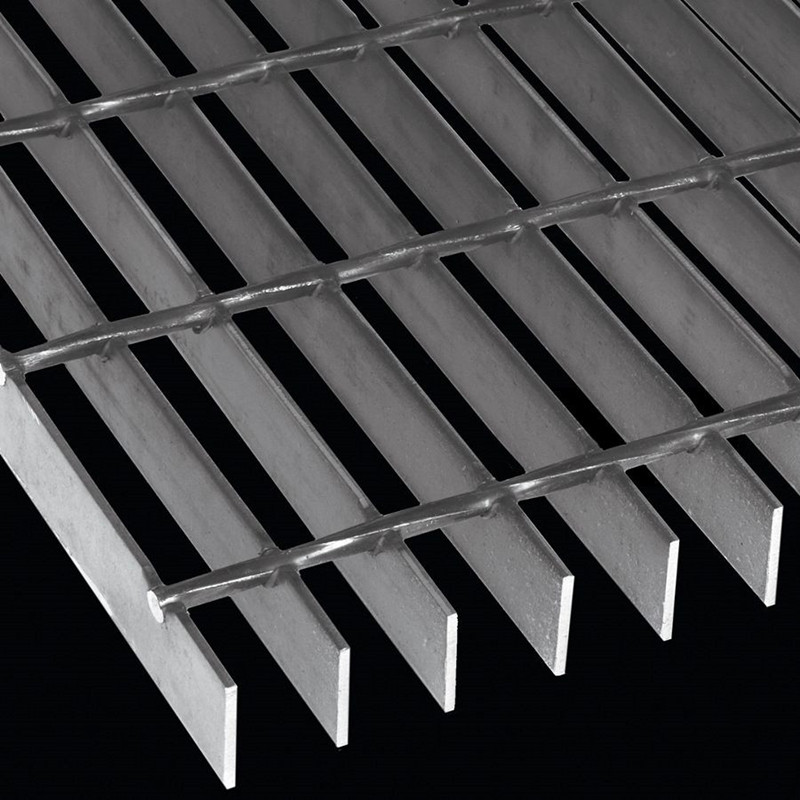

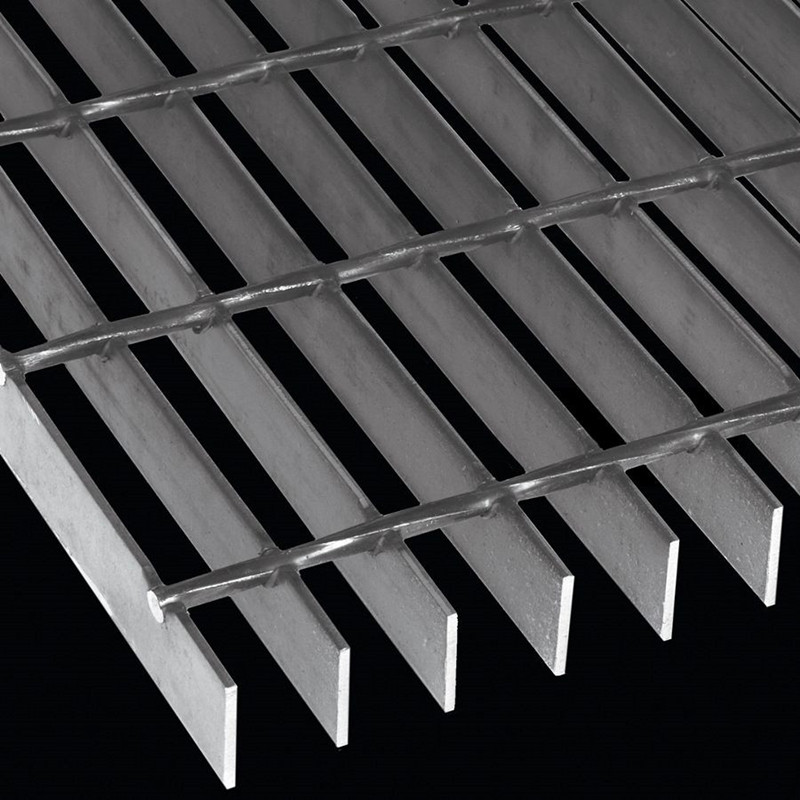

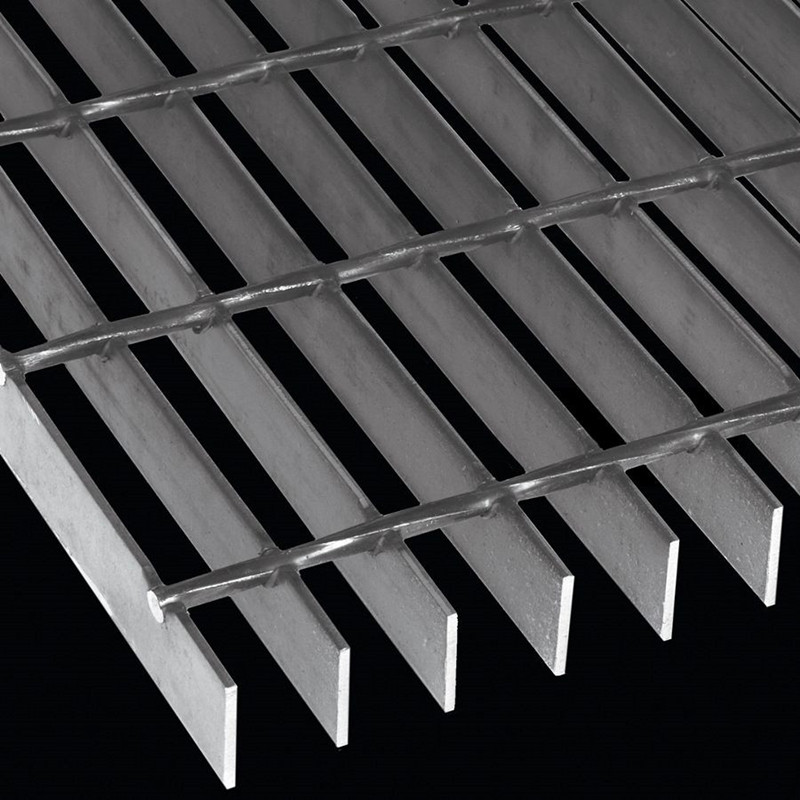

High-quality expanded metal mesh is an essential material across various industries due to its versatility, durability, and strength. It's a product that has found applications in construction, agriculture, petrochemicals, and even artistic endeavors. The pricing of this material, however, can vary significantly based on several factors. In this article, we delve into the intricacies that influence the cost of high-quality expanded metal mesh.

Expanded metal mesh, essentially, is a single piece of metal that has been cut and stretched to create a pattern of openings. The quality of this mesh is primarily determined by the type of metal used, the manufacturing process, and the final finish.

Firstly, the choice of metal plays a crucial role in determining the price. Stainless steel, aluminum, carbon steel, and brass are common materials used. Stainless steel, for instance, offers excellent corrosion resistance and durability, thus commanding a higher price than aluminum, which is more lightweight but less resistant to corrosion. Copper and bronze, with their unique aesthetic appeal and conductivity, may also command premium prices.

Secondly, the manufacturing process impacts the cost significantly. The expansion process involves shearing and stretching a sheet of metal, a process that requires precision and specialized machinery. The complexity of the pattern, the thickness of the metal, and the size of the finished mesh all contribute to the production cost. Thicker metal sheets or intricate patterns will generally lead to a higher price Thicker metal sheets or intricate patterns will generally lead to a higher price Thicker metal sheets or intricate patterns will generally lead to a higher price Thicker metal sheets or intricate patterns will generally lead to a higher price

Thicker metal sheets or intricate patterns will generally lead to a higher price Thicker metal sheets or intricate patterns will generally lead to a higher price high quality expanded metal mesh price.

Thirdly, the finish of the expanded metal mesh can also affect the pricing. A galvanized or powder-coated finish provides additional protection against rust and enhances the appearance, thereby increasing the cost. However, these finishes can extend the lifespan of the mesh and justify the extra expense in the long run.

Moreover, market conditions and supply-demand dynamics play a significant role in pricing. If the demand for expanded metal mesh is high and the supply is limited, prices may rise. Similarly, fluctuations in global metal prices can also impact the cost of raw materials, subsequently affecting the final product price.

Lastly, customization requests such as custom sizes, shapes, or specific alloys can lead to additional costs. These tailored products require more attention and resources, pushing the price upwards.

In conclusion, the price of high-quality expanded metal mesh is a reflection of the quality of the raw materials, the manufacturing process, finishing touches, and market conditions. While it may appear costly at first glance, considering its durability, strength, and functionality, it often proves to be a cost-effective solution in the long term. When making a purchase decision, it's essential to weigh these factors against your specific application requirements to ensure you get the best value for your investment.

high quality expanded metal mesh price.

Thirdly, the finish of the expanded metal mesh can also affect the pricing. A galvanized or powder-coated finish provides additional protection against rust and enhances the appearance, thereby increasing the cost. However, these finishes can extend the lifespan of the mesh and justify the extra expense in the long run.

Moreover, market conditions and supply-demand dynamics play a significant role in pricing. If the demand for expanded metal mesh is high and the supply is limited, prices may rise. Similarly, fluctuations in global metal prices can also impact the cost of raw materials, subsequently affecting the final product price.

Lastly, customization requests such as custom sizes, shapes, or specific alloys can lead to additional costs. These tailored products require more attention and resources, pushing the price upwards.

In conclusion, the price of high-quality expanded metal mesh is a reflection of the quality of the raw materials, the manufacturing process, finishing touches, and market conditions. While it may appear costly at first glance, considering its durability, strength, and functionality, it often proves to be a cost-effective solution in the long term. When making a purchase decision, it's essential to weigh these factors against your specific application requirements to ensure you get the best value for your investment.

Thicker metal sheets or intricate patterns will generally lead to a higher price Thicker metal sheets or intricate patterns will generally lead to a higher price

Thicker metal sheets or intricate patterns will generally lead to a higher price Thicker metal sheets or intricate patterns will generally lead to a higher price high quality expanded metal mesh price.

Thirdly, the finish of the expanded metal mesh can also affect the pricing. A galvanized or powder-coated finish provides additional protection against rust and enhances the appearance, thereby increasing the cost. However, these finishes can extend the lifespan of the mesh and justify the extra expense in the long run.

Moreover, market conditions and supply-demand dynamics play a significant role in pricing. If the demand for expanded metal mesh is high and the supply is limited, prices may rise. Similarly, fluctuations in global metal prices can also impact the cost of raw materials, subsequently affecting the final product price.

Lastly, customization requests such as custom sizes, shapes, or specific alloys can lead to additional costs. These tailored products require more attention and resources, pushing the price upwards.

In conclusion, the price of high-quality expanded metal mesh is a reflection of the quality of the raw materials, the manufacturing process, finishing touches, and market conditions. While it may appear costly at first glance, considering its durability, strength, and functionality, it often proves to be a cost-effective solution in the long term. When making a purchase decision, it's essential to weigh these factors against your specific application requirements to ensure you get the best value for your investment.

high quality expanded metal mesh price.

Thirdly, the finish of the expanded metal mesh can also affect the pricing. A galvanized or powder-coated finish provides additional protection against rust and enhances the appearance, thereby increasing the cost. However, these finishes can extend the lifespan of the mesh and justify the extra expense in the long run.

Moreover, market conditions and supply-demand dynamics play a significant role in pricing. If the demand for expanded metal mesh is high and the supply is limited, prices may rise. Similarly, fluctuations in global metal prices can also impact the cost of raw materials, subsequently affecting the final product price.

Lastly, customization requests such as custom sizes, shapes, or specific alloys can lead to additional costs. These tailored products require more attention and resources, pushing the price upwards.

In conclusion, the price of high-quality expanded metal mesh is a reflection of the quality of the raw materials, the manufacturing process, finishing touches, and market conditions. While it may appear costly at first glance, considering its durability, strength, and functionality, it often proves to be a cost-effective solution in the long term. When making a purchase decision, it's essential to weigh these factors against your specific application requirements to ensure you get the best value for your investment. Share

Latest news

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025

-

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

NewsJul.31,2025