Jul . 25, 2024 23:30 Back to list

Razor Barbed Wire Manufacturing Company Offering BTO-22/10 Specifications for Enhanced Security Solutions

The Razor Wire Revolution BTO-22/10 Specifications and Manufacturing Insights

In an era where security has become a paramount concern, the demand for effective deterrents is at an all-time high. Among these deterrents, razor wire stands out due to its efficiency and versatility. One of the most popular configurations is BTO-22/10 razor barb wire, which has been extensively utilized in various applications ranging from military installations to agricultural land and residential properties. Understanding the specifications and manufacturing process of this particular type of razor wire can provide insights into its popularity and effectiveness.

BTO-22/10 Specifications

The BTO-22/10 designation refers to the specific characteristics of the razor wire. The BTO stands for Barbed Tape Obstacle, while 22 indicates the thickness of the wire in gauge, and 10 represents the spacing between the barbs. Typically, BTO-22 wire features a wire diameter of approximately 2.5 mm, making it sturdy and resistant to bending or breaking. The barbs, spaced at 10 centimeters apart, are designed to maximize deterrence through both visual intimidation and physical obstruction. When deployed properly, BTO-22/10 razor wire can create an effective barrier that is difficult to breach.

Manufacturing Process

The manufacturing of BTO-22/10 razor wire involves several key steps, ensuring both quality and durability. First, high-quality steel is sourced, often involving a galvanization process to prevent rust and extend the lifespan of the wire. This step is crucial, as the wire is often deployed in harsh outdoor environments where corrosion can significantly reduce effectiveness.

Once the raw materials are prepared, the wire undergoes a shaping process where it is transformed into the distinct barbed structure. The barbs are precisely formed and spaced to maintain uniformity, which is essential for both performance and aesthetics. Each barb is designed to have sharp edges to maximize deterrence and prevent intruders from easily climbing over or through the barrier.

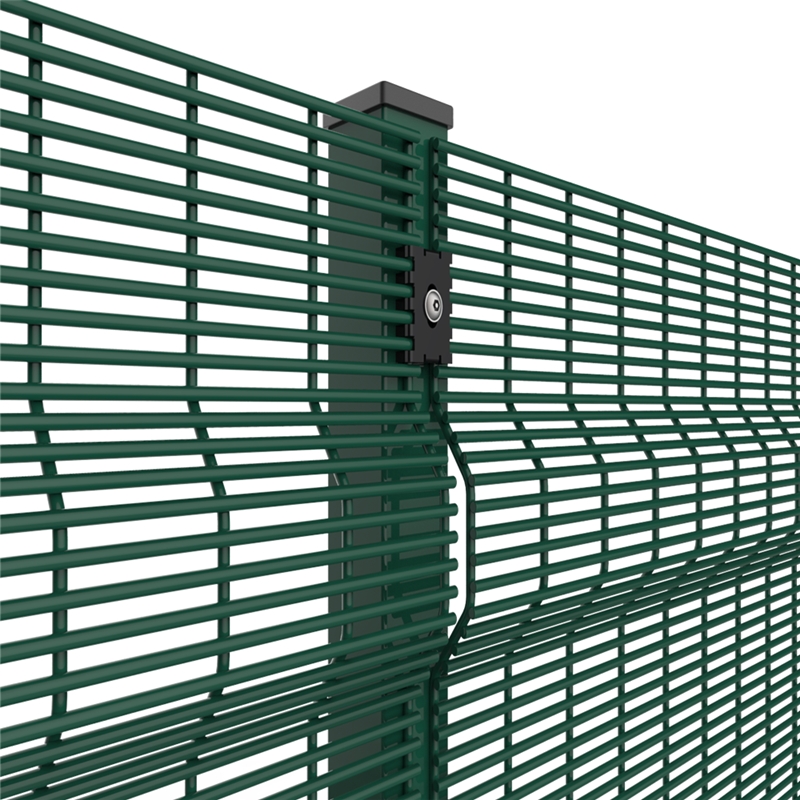

bto-22/10 razor barb wire factory

After the barbed wire is formed, it goes through a rigorous quality control process. This involves testing the tensile strength of the wire to ensure it can withstand external pressures. The barbs are inspected for sharpness and spacing accuracy, ensuring that every piece of wire meets the specified standards. Quality control is essential, as inconsistencies could lead to ineffective barriers that fail to provide the necessary security.

Applications and Benefits

BTO-22/10 razor wire is widely used across various sectors due to its effectiveness and adaptability. In commercial and industrial settings, it serves as a robust security measure to protect property and assets. Military installations often employ razor wire as an additional layer of security to deter unauthorized access, while correctional facilities utilize it to prevent escapes.

In residential settings, homeowners increasingly turn to razor wire as a cost-effective means of enhancing security. When combined with other security measures such as cameras and alarms, BTO-22/10 razor wire can significantly deter potential intruders from attempting to breach a property. Moreover, its intimidating appearance serves as a psychological barrier, often discouraging criminal activity before it even begins.

Conclusion

BTO-22/10 razor barb wire represents a fusion of quality manufacturing and effective design. Its specifications make it a top choice for a variety of security applications, while the stringent manufacturing process ensures durability and reliability. For anyone considering enhancements to their security measures, understanding the intricacies of BTO-22/10 razor wire can help in making informed decisions that prioritize safety and protection. In a world where security threats are ever-present, mastering the art of deterrence has become not only necessary but essential.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025