Dec . 29, 2024 15:58 Back to list

razor barbed wire coils factory

The Razor Barbed Wire Coils Factory A Guardian of Security

In today’s world, security has become a paramount concern for homes, businesses, and public institutions alike. One of the primary defenses against unauthorized access and criminal activities is the incorporation of high-quality fencing solutions. Among the various options available, razor barbed wire coils stand out for their effectiveness, deterrence factor, and versatility. The razor barbed wire coils factory plays a significant role in manufacturing these security solutions, ensuring that clients receive only the best products tailored to their specific needs.

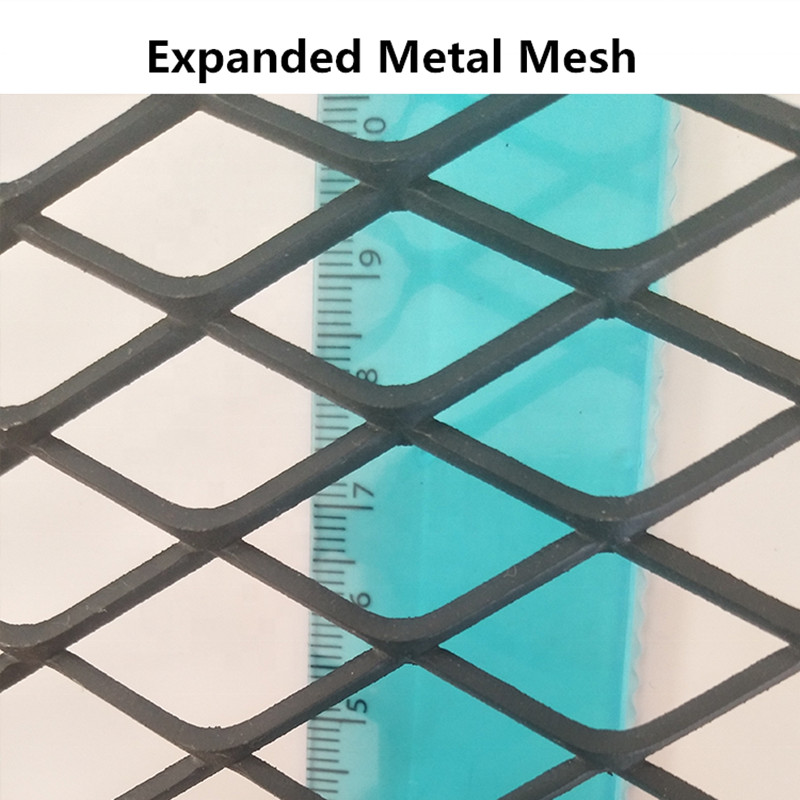

Razor barbed wire is a type of fencing wire that features sharp-edged barbs arranged at regular intervals along its length. This design not only escalates the difficulty of climbing but also serves as a psychological deterrent to would-be intruders. Unlike traditional barbed wire, razor barbed wire is designed for maximum injury potential, making it an ideal choice for high-security areas like prisons, military installations, and industrial sites. The razor barbed wire coils factory specializes in producing these razor-sharp barriers through a meticulous and technological process that ensures durability and reliability.

The manufacturing process in a razor barbed wire coils factory begins with selecting high-quality raw materials, typically galvanized steel or stainless steel, chosen for their corrosion resistance and tensile strength. The quality of these materials is crucial since the wire's performance and longevity depend heavily on its resilience against environmental factors. Once the raw materials are secured, they undergo stringent quality control checks to guarantee that they meet the necessary standards before fabrication begins.

Once the materials are prepared, the wire is drawn into the desired thickness using advanced machinery. The drawing process is essential, as it enhances the wire's strength while maintaining flexibility. After drawing, the wire is then subjected to cutting and shaping processes, where the razor barbs are created. This step involves sophisticated machinery that ensures precision in the placement and sharpness of each barb, a pivotal aspect of the product's effectiveness.

razor barbed wire coils factory

After the barbed wire coils are formed, they undergo a galvanization process, which involves coating the wire with a layer of zinc. This step protects the wire from rust and corrosion, significantly increasing its lifespan. Depending on customer requirements, the coils can also be finished with additional coatings for aesthetic purposes or further corrosion resistance. Quality assurance tests are conducted at various stages of production to ensure that the final product adheres to international standards.

In addition to manufacturing, a modern razor barbed wire coils factory typically offers customized solutions to its clients. This adaptability is important, as different security needs dictate varying specifications. Clients ranging from agricultural landowners to large corporations can benefit from custom designs tailored to fit specific environments and applications. The factory’s design team works closely with clients to analyze their security requirements, offering expert advice and drafting precise plans for their projects.

The impact of a razor barbed wire coils factory extends beyond mere production; it involves contributing to increased safety and security in various sectors. In areas prone to trespassing, vandalism, and theft, the installation of razor barbed wire serves as a powerful visual and physical barrier. It reassures property owners and tenants that they are taking tangible steps to safeguard their premises.

Moreover, as security needs continue to evolve with technological advancements, razor barbed wire manufacturers remain dedicated to innovation. The integration of advanced materials and new manufacturing techniques ensures that the products they offer not only meet current security challenges but also anticipate future demands.

In conclusion, the razor barbed wire coils factory plays a vital role in the realm of security solutions. Through cutting-edge manufacturing processes, stringent quality control, and customized offerings, these factories provide essential products that reinforce safety and deter illicit entry. As security concerns grow globally, the importance of such specialized manufacturing facilities will only continue to rise.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025