Aug . 16, 2024 17:01 Back to list

Top Quality Steel Planks for Construction Scaffolding Applications in the Building Industry

Best Scaffolding Steel Plank for Building

When it comes to construction, safety, stability, and efficiency are paramount. Scaffolding is an essential component that provides support and access for workers, allowing them to perform tasks at various heights safely. Among the different scaffolding materials available, steel planks stand out for their strength, durability, and reliability. In this article, we’ll explore some of the best scaffolding steel planks for building, considering their features, benefits, and what to look for when selecting the right plank for your project.

Why Choose Steel Planks?

Steel planks have become a favored choice for scaffolding in the construction industry due to their robustness and longevity. Unlike wood, which can warp, splinter, or degrade over time, steel maintains its structural integrity under various conditions. Steel planks are resistant to moisture, insects, and fire, making them a safe choice for construction sites prone to harsh weather or other environmental challenges.

Furthermore, steel scaffolding planks can often be reused across multiple projects, offering significant cost savings over time. They are also designed to support heavier loads compared to wood, which is crucial for large construction projects where equipment and materials must be safely elevated.

Key Features of High-Quality Steel Planks

1. Load Capacity One of the most critical factors to consider when selecting steel planks is their load capacity. The best scaffolding steel planks will comply with OSHA (Occupational Safety and Health Administration) regulations and possess a high weight limit to safely support workers and materials.

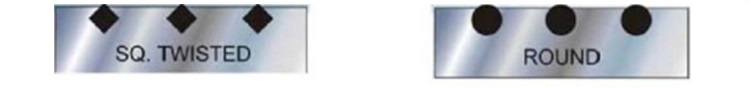

2. Anti-Skid Surface Safety is paramount in construction, and choosing planks with an anti-skid surface can greatly reduce the risk of slips and falls. Many steel planks are equipped with a textured surface or additional grip to ensure workers can maintain their footing even in wet or slippery conditions.

3. Corrosion Resistance Steel planks should be treated with anti-corrosive coatings or galvanization to protect against rust, especially when exposed to outdoor elements. This feature enhances durability and extends the life of the planks.

best scaffolding steel plank for building

4. Dimensions and Lightweight Design The dimensions of the steel planks can affect their usability and storage options. Many manufacturers offer a variety of sizes to accommodate different scaffolding configurations. Lightweight designs are also beneficial, making it easier to handle and maneuver the planks on-site.

5. Modular Design and Compatibility Selecting scaffolding steel planks that are compatible with existing scaffolding systems is essential for seamless integration. Many leading brands design their planks to be modular, allowing for easy assembly and disassembly.

Top Recommendations

1. Layher Steel Planks Known for their high-quality engineering and robust design, Layher steel planks offer excellent load-bearing capacity and safety features appealing to contractors worldwide.

2. PERI Scaffolding Planks PERI’s steel planks are characterized by their lightweight design and strong anti-slip surfaces, making them suitable for many construction sites where worker safety is a concern.

3. Aluma-Form Steel Planks Combining innovative design with practicality, Aluma-Form steel planks provide superior strength and stability, particularly useful in heavy-duty applications.

Conclusion

Choosing the right scaffolding steel planks is crucial for ensuring safety and efficiency during construction projects. By considering load capacity, safety features, corrosion resistance, and compatibility with existing systems, builders can select planks that meet their specific needs. Investing in high-quality scaffolding steel planks can enhance safety, reduce downtime, and ultimately contribute to the success of any building project. As the construction industry continues to evolve, steel planks will remain a cornerstone in scaffolding solutions, delivering reliability and performance on every job site.

-

358 Anti Climb Welded Wire Mesh Fence - Secure Perimeter Defense

NewsAug.02,2025

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025