Nov . 19, 2024 18:06 Back to list

welded wire mesh factory

The Significance of Welded Wire Mesh Factories in Modern Construction

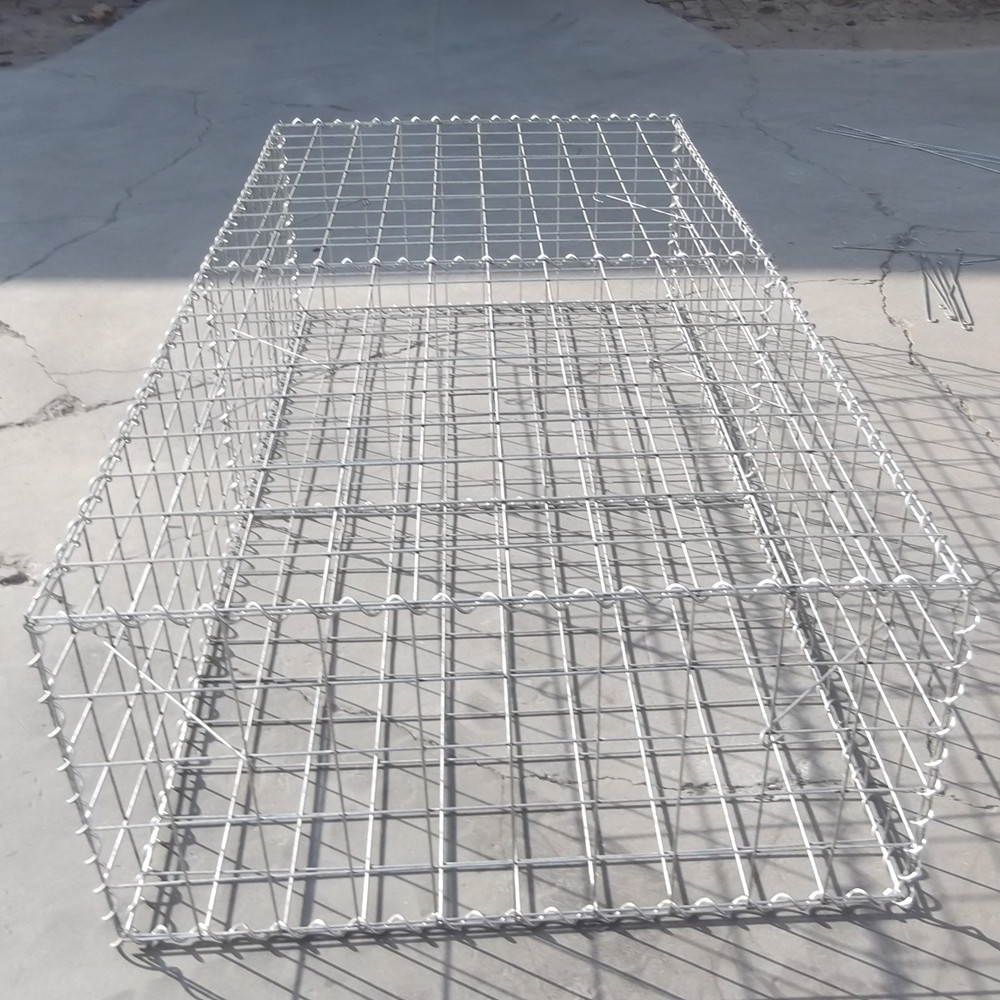

In today’s construction and manufacturing industries, welded wire mesh has become an essential component known for its versatility, strength, and durability. A welded wire mesh factory plays a pivotal role in producing this invaluable product, catering to various applications across numerous sectors. This article delves into the significance of welded wire mesh factories, their production processes, and the benefits they bring to modern construction.

Welded wire mesh is a grid-like structure made from intersecting steel wires that are welded together at their junctions. This material is widely used in construction for reinforcing concrete slabs, walls, and other structural components. Its design provides extensive load-bearing capabilities while ensuring even distribution of stress, which is crucial for the structural integrity of buildings, bridges, and other constructions.

The production process in a welded wire mesh factory often begins with raw materials, primarily steel wire, which is carefully selected for its tensile strength and ductility. The wires are drawn to the desired diameters before being precisely cut to form the mesh panels. This step is vital as the thickness and spacing of the wires directly influence the mesh’s strength and application suitability.

Once the wires are prepared, they are fed into a welding machine, where they are expertly fused together at predetermined intervals. This automated welding process ensures uniformity in quality and precision, resulting in a final product that meets stringent industry safety standards. After welding, the mesh panels are typically subjected to quality control inspections, where dimensions, weld integrity, and surface finish are meticulously checked.

welded wire mesh factory

Welded wire mesh factories are not only crucial for the quality of materials but also for improving efficiency and reducing costs in construction projects. By providing large quantities of standardized mesh products, these factories allow construction companies to save time and reduce labor costs associated with traditional reinforcement methods. The use of welded wire mesh simplifies the construction process, enabling quicker installation and minimal waste.

Moreover, welded wire mesh is highly customizable. Factories can produce various mesh specifications tailored to the specific needs of architectural and engineering projects. This flexibility allows for innovations in design, offering architects and engineers the ability to optimize their creations while adhering to safety requirements. Furthermore, the ability to manufacture custom sizes and shapes ensures that welded wire mesh can be utilized effectively for special projects, from residential buildings to expansive commercial structures.

In addition to construction, welded wire mesh finds applications in other industries such as agriculture, manufacturing, and mining. It serves as fencing material for livestock, supports for plants in agriculture, and protective barriers in factories and warehouses. This versatility highlights the importance of welded wire mesh factories in providing solutions to diverse industrial challenges.

Environmental considerations are becoming increasingly significant in the manufacturing industry. Many welded wire mesh factories are acknowledging their role in sustainability by adopting eco-friendly practices. This includes sourcing recycled materials, using energy-efficient manufacturing processes, and minimizing waste generation. Such initiatives not only help in conserving natural resources but also enhance the reputation of manufacturers in a market that is progressively leaning towards sustainability.

In conclusion, welded wire mesh factories are integral to modern construction and various industrial applications. By ensuring the production of high-quality, durable, and customizable mesh products, they contribute significantly to the efficiency, safety, and innovation of construction practices. Additionally, their increasing commitment to sustainability aligns the industry with global environmental goals, making welded wire mesh factories an indispensable part of the future landscape of construction and manufacturing. As urbanization continues to rise, the demand for such efficient materials will undoubtedly increase, solidifying the factory’s role in shaping our built environment.

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025

-

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

NewsJul.31,2025