Nov . 25, 2024 22:58 Back to list

welded wire netting factory

The Rise of Welded Wire Netting Factories A Comprehensive Overview

Welded wire netting, often referred to as welded wire mesh, represents a significant advancement in the field of industrial materials. This versatile product has gained traction in varied sectors, from construction to agriculture, and its manufacturing has become increasingly prominent in recent years. As technological advancements continue to reshape manufacturing processes, the establishment of welded wire netting factories has emerged as a pivotal component in meeting contemporary industrial demands.

Understanding Welded Wire Netting

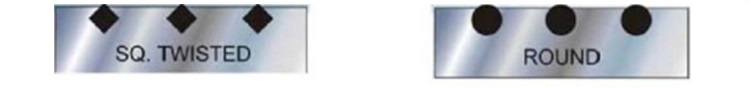

Welded wire netting is composed of a network of wires that are welded together at their intersection points, resulting in a sturdy, uniform mesh. This product is typically fabricated using high-quality steel wires, which are available in various gauges and apertures. The resulting mesh is characterized by its exceptional durability, strength, and resistance to corrosion, making it suitable for a wide array of applications.

Applications Across Industries

The applications of welded wire netting are diverse, catering to numerous sectors. In construction, the mesh serves as an effective form of reinforcement for concrete slabs, walls, and ceilings, enhancing structural integrity. In agriculture, it is utilized for fencing, enabling the containment of livestock and the protection of crops from pests, while in landscaping, it supports the construction of garden trellises and decorative barriers.

Moreover, welded wire mesh finds application in the manufacturing of cages and enclosures, providing safe habitats for animals in zoos or farms. In the industrial realm, it is used in various products, including filters, security screens, and HVAC systems. The adaptability of welded wire netting makes it an invaluable resource in both residential and commercial projects.

Advantages of Welded Wire Netting

welded wire netting factory

The production of welded wire netting offers several compelling advantages. One of the most notable benefits is its strength-to-weight ratio, which means the material can bear heavy loads without excessive bulk. The welding process results in a mesh that is not only robust but also consistent in its dimensions, ensuring that it meets specific engineering requirements.

Additionally, welded wire netting can be coated with various finishes, such as galvanization or vinyl, to enhance its corrosion resistance. This makes it suitable for outdoor applications where exposure to the elements is a concern. Furthermore, its ease of installation and maintenance reduces labor costs, making it a cost-effective choice for many projects.

The Growth of Welded Wire Netting Factories

The increase in demand for welded wire products has led to the establishment of numerous factories specializing in their production. These factories incorporate advanced technology and automated processes, resulting in higher production rates and improved quality control. Key players in this industry focus on innovation, constantly developing new techniques to enhance product performance and sustainability.

In recent years, there has been a noticeable shift towards customization, with factories offering tailored solutions to meet specific customer needs. Whether it’s varying mesh sizes, different wire gauges, or specific coatings, the flexibility in production processes has enabled manufacturers to cater to a broader clientele.

Sustainability and the Future

As industries increasingly prioritize sustainability, welded wire netting factories are also adapting. Many manufacturers are seeking eco-friendly materials and processes to minimize their carbon footprint. This trend not only appeals to environmentally conscious consumers but also aligns with global initiatives aimed at reducing waste and promoting sustainable practices.

In conclusion, welded wire netting factories play a crucial role in providing versatile, durable solutions across multiple industries. With continued advancements in manufacturing technology and a growing emphasis on sustainability, the future of welded wire netting is poised for growth. As we move forward, these factories will undoubtedly continue to innovate and adapt, shaping the landscape of industrial products for years to come.

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping Xingzhi|Durability&Cost-Effective

NewsJul.30,2025

-

Hop-Dipped Galvanized PVC Fence - Anping Xingzhi | Durable, Quick Deployment

NewsJul.30,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi|Temporary Fencing, Durable Security, Customization

NewsJul.30,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fences - Anping County Xingzhi|Durable Corrosion Resistance, Quick Installation

NewsJul.30,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing&Versatile Applications

NewsJul.30,2025