aug . 13, 2024 22:26 Back to list

Innovative Solutions for Durable Construction with Reinforcing Wire Mesh Applications and Benefits

Reinforcing Wire Mesh An Essential Component in Construction

Reinforcing wire mesh, often referred to as welded wire mesh or reinforcement mesh, plays a crucial role in the construction industry. This indispensable material is primarily used to enhance the strength and stability of concrete structures. The function of reinforcing wire mesh goes beyond mere support; it ensures the durability and longevity of various construction projects, from residential buildings to large infrastructures like bridges and highways.

The structure of reinforcing wire mesh typically consists of intersecting steel wires arranged in a grid pattern and welded together at each intersection. This configuration enables the mesh to distribute loads evenly across the surface of the concrete, preventing cracking and ensuring structural integrity. The wires are available in various gauges and spacing configurations to suit different construction needs. The selection of the appropriate type of mesh can significantly affect the performance of the concrete it reinforces.

One of the primary advantages of using reinforcing wire mesh is its ability to control cracking. Concrete is known for its compressive strength, but it is relatively weak in tension. As concrete cures, it can experience shrinkage and temperature variations that may lead to cracks. By incorporating wire mesh into the concrete mix, the tensile strength is enhanced, allowing it to withstand forces that might otherwise lead to failure. This is particularly vital in areas prone to seismic activity or heavy loads.

In addition to preventing cracks, reinforcing wire mesh also enhances the overall load-bearing capacity of concrete structures. It provides a framework that can effectively bear heavy loads without compromising the integrity of the structure. This makes it a preferred choice for various applications, including flooring, driveways, and slabs. The mesh ensures that the loads are distributed evenly, minimizing the risk of localized failure.

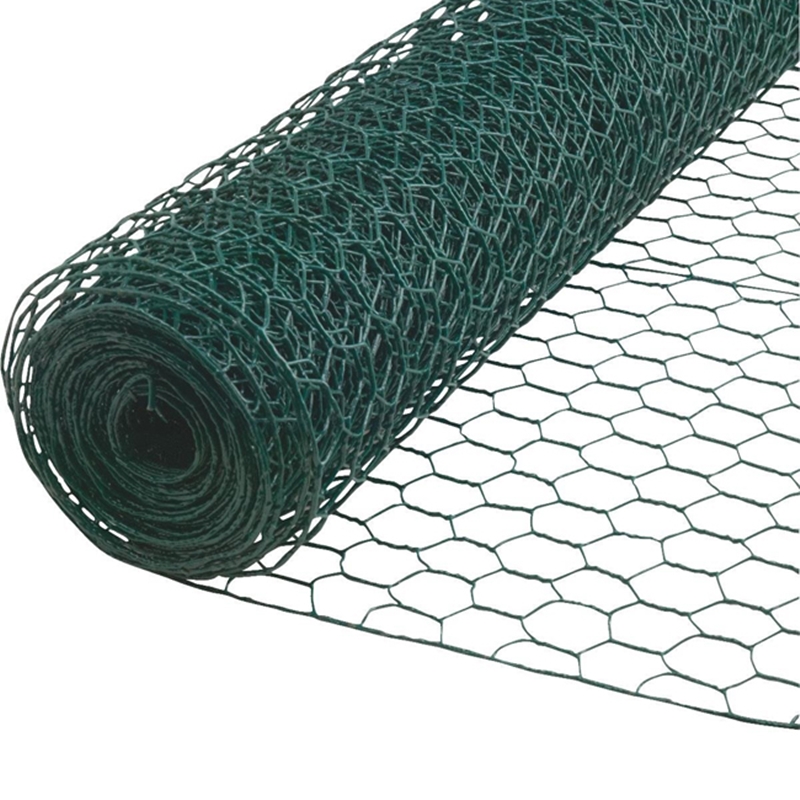

reinforcing wire mesh

The installation of reinforcing wire mesh is relatively straightforward, making it a cost-effective choice for contractors and builders. The assembly can be performed quickly, and once laid into the concrete, it becomes an integral part of the structure. Moreover, its lightweight nature facilitates easy handling and transportation, further contributing to overall cost efficiency.

Another important aspect of reinforcing wire mesh is its resistance to corrosion. When properly coated or treated, the steel mesh can withstand harsh environmental conditions, which is crucial for structures exposed to moisture or chemicals. This resistance extends the lifespan of the concrete by preventing the degradation of the reinforcing material, thus ensuring the long-term performance of the overall structure.

Reinforcing wire mesh is also environmentally friendly. By reinforcing concrete, it allows for the use of less material while achieving the same or better structural performance. This not only reduces waste but also minimizes the carbon footprint associated with the construction process. Additionally, as sustainable construction practices gain traction, the importance of using long-lasting materials that can endure the test of time has never been more vital.

In conclusion, reinforcing wire mesh is an essential component in modern construction, offering robust solutions for strength, durability, and longevity. Its ability to control cracking, enhance load-bearing capacity, and resist corrosion makes it an invaluable resource for engineers and architects. As the construction industry continues to evolve, the role of reinforcing wire mesh will undoubtedly remain significant, supporting the development of safe and reliable infrastructures for the future. Whether used in residential or commercial projects, reinforcing wire mesh stands out as a testament to engineering innovation and excellence in construction practices.

-

358 Anti Climb Welded Wire Mesh Fence - Secure Perimeter Defense

NewsAug.02,2025

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025