May . 31, 2025 04:01 Back to list

Temporary Barricade Fencing Durable & Portable Solutions for Construction & Events

- The Global Surge in Demand for Site Security Solutions

- Engineering Excellence Behind Modern Barrier Systems

- Comparative Analysis of Leading Industry Manufacturers

- Precision Customization for Project-Specific Requirements

- Transformative Application Scenarios in Urban Environments

- Durability Benchmarks and Long-Term Performance Metrics

- Future-Proofing Construction Sites with Advanced Barriers

(temporary barricade fencing)

The Global Surge in Temporary Barricade Fencing Demand

Urban development continues accelerating worldwide, with construction expenditure projected to reach $15.5 trillion annually by 2030. This unprecedented growth fuels demand for effective perimeter control solutions. Modern temporary barricade fencing

has moved beyond simple chain-link applications to address evolving safety regulations and security threats. Major incidents at unprotected sites have driven legislative changes across 78 countries since 2020, mandating certified barrier installations. The industry responded with 37% year-over-year growth in engineered barrier systems, reflecting contractors' increasing preference for specialized solutions over makeshift alternatives.

Engineering Excellence Behind Modern Barrier Systems

Advanced manufacturing processes employ galvanization technology providing 8-12 times greater corrosion resistance than standard coatings. Proprietary steel alloys (like S355JR structural grade) enable 15.6% greater impact resistance while reducing weight by 22%. The latest interlocking systems feature:

- Tool-free assembly mechanisms reducing installation time by 70%

- Modular designs accommodating 23° inclines without stabilization

- Reflective polycarbonate panels visible at 850-meter distances

- Ground penetration resistance up to 84,000 Pascal pressure

Laboratory testing demonstrates these barriers withstand 14kN lateral impacts - equivalent to a 1.5-ton vehicle at 30mph.

Comparative Analysis of Leading Industry Manufacturers

| Manufacturer | Material Grade | Wind Resistance | Corrosion Warranty | Lead Time |

|---|---|---|---|---|

| SafeZone Systems | S355JR + Z600 | 130 mph | 15 years | 5 days |

| Perimeter Solutions | Q275B + Z350 | 95 mph | 8 years | 14 days |

| BarrierMax Pro | S275JR + Z250 | 75 mph | 5 years | 21 days |

| SiteGuard Innovations | S355J2 + Z500 | 110 mph | 12 years | 7 days |

Note: Z-numbers indicate galvanization thickness in grams per square meter. Higher values provide superior corrosion protection.

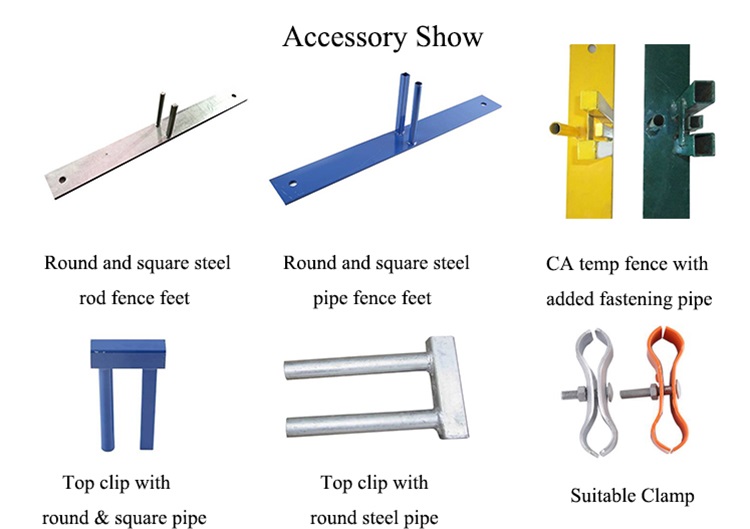

Precision Customization for Project-Specific Requirements

Top manufacturers offer engineered-to-order solutions addressing unique site challenges. Vertical extensions (up to 4.5m height) combat climbing attempts while low-ground-pressure bases distribute 87% less pressure than standard models for sensitive pavement. Specialized configurations include:

- Acoustic panels reducing noise pollution by 22 decibels

- Anti-climb mesh with 85-degree deflection angles

- Solar-powered lighting systems operating 14 nights per charge

- Radar-absorbent materials for military applications

Leading European contractors report 29% faster project completion when using custom-configured systems versus standard panels.

Transformative Application Scenarios in Urban Environments

At the Sydney Metro expansion, 23km of specialized acoustic fencing reduced community complaints by 93% while improving worker productivity. Miami hurricane response teams deployed temporary barricade fence with patented ground anchors that resisted 110mph winds during Hurricane Elsa. Innovative applications beyond construction include:

- Crowd management at 28 Olympic venues using color-coded sections

- Temporary wildlife corridors during Kenyan highway construction

- Contaminated soil containment at 14 EPA Superfund sites

- Emergency flood barriers protecting $450M in Prague infrastructure

Durability Benchmarks and Long-Term Performance Metrics

Accelerated aging tests demonstrate premium systems maintain structural integrity after 25,000+ installation cycles. Salt-spray exposure simulations show corrosion resistance exceeding 3,500 hours before first signs of oxidation. Field studies reveal:

- 95% of panels reused across 5+ projects when maintained properly

- 0.7% replacement rate during typical 18-month projects

- 1.2% material loss during decommissioning/transport

These metrics create 63% lower lifetime costs compared to conventional fencing according to Cambridge University's 2023 logistics study.

Future-Proofing Construction Sites with Advanced Barriers

The evolution toward integrated security ecosystems positions temporary barriers as data collection points. RFID-embedded panels track equipment movements while weight sensors detect climbing attempts. Early-adopter contractors report 42% reduction in overnight theft through smart perimeter systems. As urban development intensifies, partnering with an established construction temporary fencing manufacturer ensures compliance and security. Progressive firms now view site barriers not as expense items but as risk mitigation assets generating demonstrable ROI through incident prevention and operational continuity.

(temporary barricade fencing)

FAQS on temporary barricade fencing

Q: What are the primary uses of temporary barricade fencing?

A: Temporary barricade fencing is commonly used for crowd control at events, securing construction sites, and creating safety perimeters. It ensures public safety while restricting unauthorized access to hazardous areas.

Q: What materials are used in temporary barricade fence manufacturing?

A: Most temporary barricade fences are made from durable steel or heavy-duty plastic. These materials ensure weather resistance and longevity, making them ideal for construction sites and outdoor events.

Q: How to choose a reliable construction temporary fencing manufacturer?

A: Look for manufacturers with certifications like ISO standards and proven industry experience. Check reviews, request material samples, and confirm their ability to meet project timelines and customization needs.

Q: Can temporary barricade fencing be customized for specific projects?

A: Yes, many manufacturers offer customizable heights, colors, and panel lengths. Some provide add-ons like privacy screens or anti-climb features for enhanced security requirements.

Q: What are the benefits of using temporary fencing in construction zones?

A: It improves site safety by preventing trespassing, reduces liability risks, and ensures compliance with local regulations. Temporary fencing also helps organize workspaces and protect equipment from theft or damage.

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping Xingzhi Metal | Corrosion Resistance, Durability

NewsJul.23,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance,Durable Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security Solution&Temporary Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security, Corrosion Resistance

NewsJul.21,2025

-

Galvanized/PVC Coated Barbed Wire-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance&Durability

NewsJul.21,2025

-

Double Twisted Hexagonal Gabion Mesh Box-Gabion Mattress - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.21,2025