Welcome to our websites!

ජන. . 13, 2025 16:50 Back to list

Chain link wire mesh fence

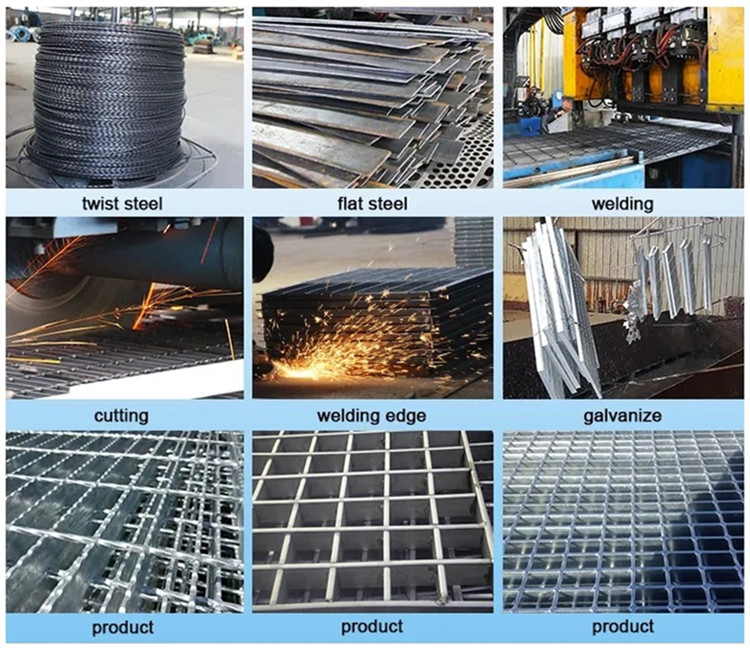

In the realm of construction, reinforcing welded wire mesh (RWWM) plays a pivotal role in ensuring structural integrity, even in the most demanding environments. As its application grows globally, understanding its unique advantages through real-world experiences is essential for industry professionals.

From a professional expertise standpoint, it’s imperative to consider the versatility of RWWM in varying environmental conditions. Research studies conducted by civil engineering academies affirm that RWWM can be custom-ordered to specific gauge and spacing requirements, tailoring its applications for specific stress loads. This customizability ensures that the integrity of the structure is never compromised due to environmental unpredictability, such as seismic activities or heavy load demands. Safety and compliance also rank high in the selection of RWWM for critical infrastructures. Regulatory bodies often require rigorous testing for construction materials; here, the pre-fabricated nature of welded wire mesh ensures consistent quality control. Manufacturers conducting in-depth quality assurance via stress testing protocols guarantee that each batch of RWWM meets international construction standards. This reliability fosters trustworthiness among project managers and architects who need assurance that their structures will withstand the elements. In conclusion, as the construction industry continually evolves, reinforcing welded wire mesh stands out as an essential material offering unparalleled strength, efficiency, and customization. The real-world testimonials and expert analysis validate its utility across various projects. Confidence in RWWM translates to tangible savings in time and resources, making it a preferred choice for ensuring safety, compliance, and long-term durability in construction endeavors.

From a professional expertise standpoint, it’s imperative to consider the versatility of RWWM in varying environmental conditions. Research studies conducted by civil engineering academies affirm that RWWM can be custom-ordered to specific gauge and spacing requirements, tailoring its applications for specific stress loads. This customizability ensures that the integrity of the structure is never compromised due to environmental unpredictability, such as seismic activities or heavy load demands. Safety and compliance also rank high in the selection of RWWM for critical infrastructures. Regulatory bodies often require rigorous testing for construction materials; here, the pre-fabricated nature of welded wire mesh ensures consistent quality control. Manufacturers conducting in-depth quality assurance via stress testing protocols guarantee that each batch of RWWM meets international construction standards. This reliability fosters trustworthiness among project managers and architects who need assurance that their structures will withstand the elements. In conclusion, as the construction industry continually evolves, reinforcing welded wire mesh stands out as an essential material offering unparalleled strength, efficiency, and customization. The real-world testimonials and expert analysis validate its utility across various projects. Confidence in RWWM translates to tangible savings in time and resources, making it a preferred choice for ensuring safety, compliance, and long-term durability in construction endeavors.

Share

Latest news

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025

-

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

NewsJul.31,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Temporary Fencing Solutions, Durable Security Products

NewsJul.30,2025