Welcome to our websites!

Jan . 09, 2025 12:11 Back to list

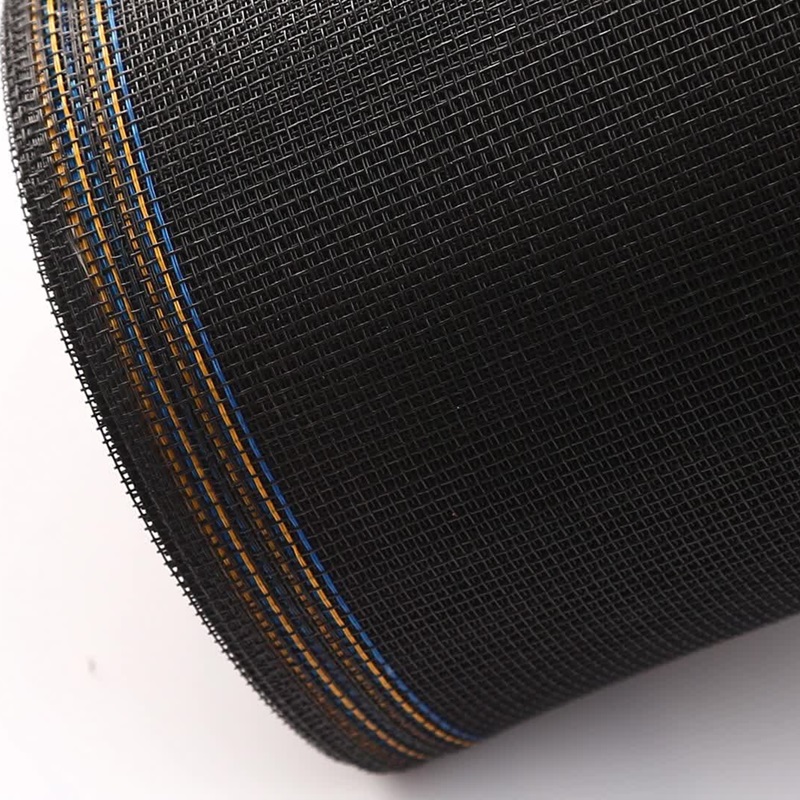

steel grating

Steel grating, an essential component in construction and industrial applications, provides a robust solution for platforms, walkways, and safety barriers. Renowned for its load-bearing capacity and durability, steel grating is manufactured through a precise process that ensures high-quality outcomes for a variety of environments.

Trustworthiness in steel grating comes from its proven track record across various demanding industries, including oil and gas, mining, and transportation. Its use in critical infrastructures, like bridges and high-traffic pedestrian areas, demonstrates its ability to withstand dynamic and static loads over prolonged periods. Furthermore, the adaptation of advanced materials science in the production of steel grating enhances its anti-slip surface, which is vital for maintaining safety in environments prone to moisture or chemical exposure. Choosing the right type of steel grating involves understanding specific project requirements. Considerations such as weight-bearing needs, environmental factors, and design aesthetics play a crucial role. Collaborating with industry experts can provide insights into selecting the most suitable grating type, whether it’s a serrated surface for added grip or a flat surface for ease of walking. Incorporating steel grating into a project not only optimizes functionality but also aligns with sustainability goals. Steel, being recyclable, supports eco-friendly construction practices, making it a favorable choice in today's environmentally-conscious landscape. Reputable manufacturers often provide certification of the steel’s origin and recyclability, contributing to the overall trust in using steel grating. In summary, the prudent application of steel grating in construction and industrial undertakings combines experience, expertise, authority, and trust. Its unparalleled versatility and adherence to stringent standards make it an indispensable material in ensuring both safety and aesthetic appeal.

Trustworthiness in steel grating comes from its proven track record across various demanding industries, including oil and gas, mining, and transportation. Its use in critical infrastructures, like bridges and high-traffic pedestrian areas, demonstrates its ability to withstand dynamic and static loads over prolonged periods. Furthermore, the adaptation of advanced materials science in the production of steel grating enhances its anti-slip surface, which is vital for maintaining safety in environments prone to moisture or chemical exposure. Choosing the right type of steel grating involves understanding specific project requirements. Considerations such as weight-bearing needs, environmental factors, and design aesthetics play a crucial role. Collaborating with industry experts can provide insights into selecting the most suitable grating type, whether it’s a serrated surface for added grip or a flat surface for ease of walking. Incorporating steel grating into a project not only optimizes functionality but also aligns with sustainability goals. Steel, being recyclable, supports eco-friendly construction practices, making it a favorable choice in today's environmentally-conscious landscape. Reputable manufacturers often provide certification of the steel’s origin and recyclability, contributing to the overall trust in using steel grating. In summary, the prudent application of steel grating in construction and industrial undertakings combines experience, expertise, authority, and trust. Its unparalleled versatility and adherence to stringent standards make it an indispensable material in ensuring both safety and aesthetic appeal.

Share

Next:

Latest news

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025

-

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

NewsJul.31,2025