Sep . 01, 2025 00:20 Back to list

Euro Steel Wire Mesh Fence - Durable, Secure & Stylish Fencing Solutions

Introduction to Advanced Perimeter Security Solutions

In the rapidly evolving landscape of industrial and commercial security, the demand for robust, aesthetically pleasing, and highly durable perimeter fencing solutions has never been greater. Businesses, governmental bodies, and private enterprises alike seek systems that not only deter unauthorized access but also integrate seamlessly with existing infrastructure and withstand harsh environmental conditions. Among the leading innovations in this sector is the Euro Steel Wire Mesh Fence, a product engineered to meet the stringent demands of modern security and demarcation. This article delves into the technical prowess, application versatility, and strategic advantages of this advanced fencing system, offering insights for B2B decision-makers and technical procurement teams.

Current Industry Trends and Market Drivers

The global perimeter security market is projected to grow significantly, driven by increasing geopolitical instability, rising urbanization, and the imperative to protect critical infrastructure. Key trends include the adoption of integrated security systems, demand for sustainable and long-life materials, and a shift towards modular, easily deployable solutions. The Euro-style fencing, characterized by its welded mesh panels and robust construction, aligns perfectly with these trends by offering a blend of high security, visual transparency, and environmental resilience. Innovations in coating technologies, such as advanced powder coatings and hot-dip galvanization, are extending service life and reducing maintenance overheads, making these fences a cost-effective long-term investment. Furthermore, the push for smart city initiatives and digital integration is leading to fencing solutions that can incorporate surveillance, access control, and sensor technologies, transforming passive barriers into active security components.

Technical Specifications and Material Excellence

The inherent strength and durability of a fencing system are directly proportional to its material composition and manufacturing precision. The Euro Steel Wire Mesh Fence is predominantly fabricated from high-grade steel wire, typically low-carbon steel or galvanized steel, ensuring superior tensile strength and resistance to deformation. The welding process forms a rigid, inseparable mesh structure, contributing significantly to its anti-climb and anti-cut properties. Post-fabrication, panels undergo rigorous surface treatments to enhance longevity and aesthetic appeal.

Core Product Parameters and Coating Technologies

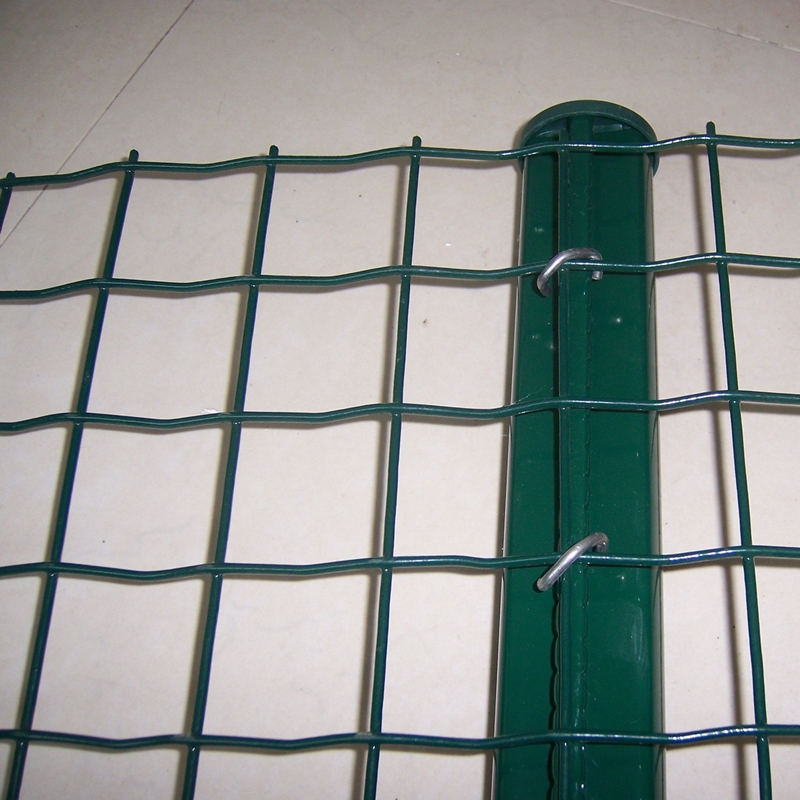

Key specifications for a Euro Steel Wire Mesh Fence include wire diameter, mesh aperture size, panel dimensions, and post configurations. Common wire diameters range from 4mm to 6mm, with mesh sizes typically between 50x200mm and 75x200mm, offering a balance between visibility and security. The posts, often rectangular or square hollow sections, are designed for direct burial or base plate installation, and can be further reinforced with concrete for enhanced stability.

| Parameter | Standard Range | Technical Detail |

|---|---|---|

| Material | Low carbon steel, Galvanized steel | High tensile strength, conforming to EN 10224 standards. |

| Wire Diameter | 4.0mm to 6.0mm | Enhanced rigidity and cut resistance. |

| Mesh Aperture | 50x200mm, 75x200mm | Optimal balance of security, visibility, and wind load distribution. |

| Panel Width | 2.0m to 3.0m | Modular design for efficient installation. |

| Panel Height | 0.6m to 2.4m (customizable) | Scalable for various security levels. |

| Post Type | Square, Rectangular, Round (with clamp bars) | Optimized for structural integrity and ease of installation. |

| Surface Treatment | Hot-dip Galvanized, PVC/Powder Coated | Corrosion resistance (EN ISO 1461), UV stability. |

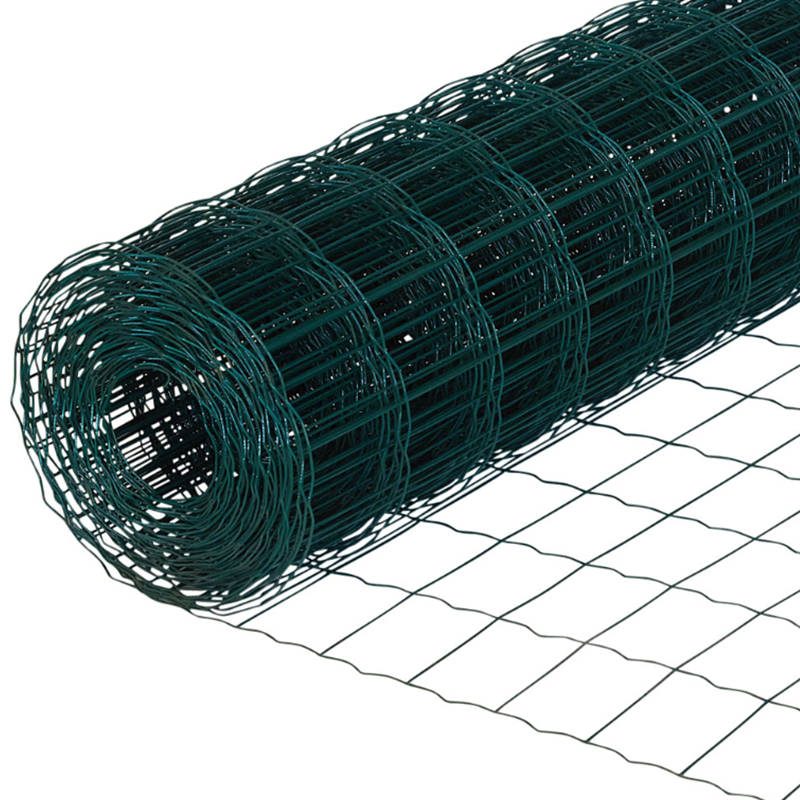

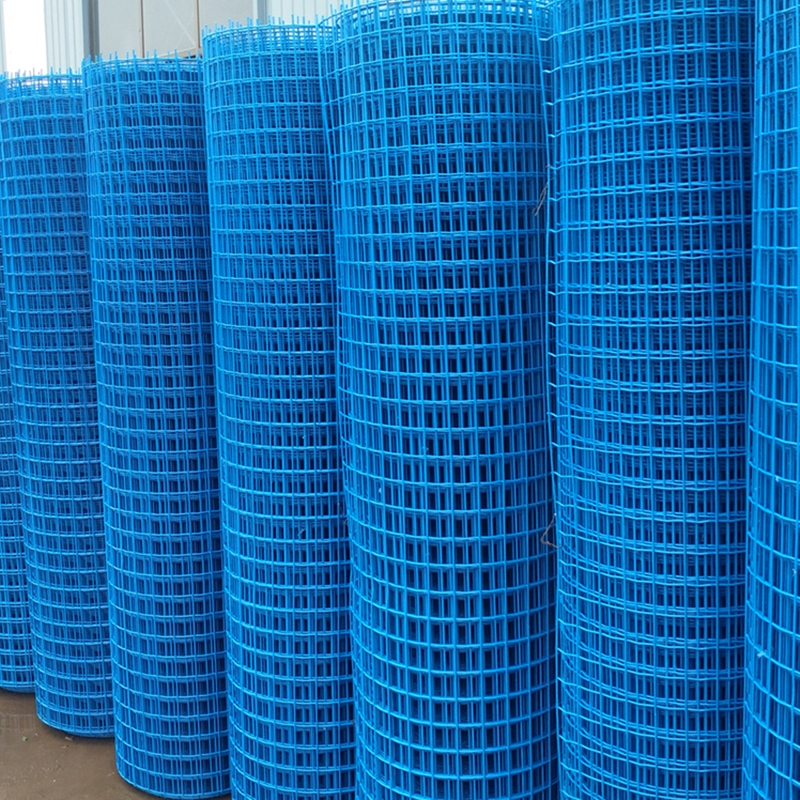

Hot-dip galvanization, conforming to EN ISO 1461 standards, provides a sacrificial zinc layer, offering unparalleled corrosion resistance for environments exposed to moisture and chemicals. For enhanced aesthetics and additional protection, panels can be PVC or powder coated in a wide array of RAL colors, providing a durable, UV-resistant finish that prevents fading and chipping. These coatings add an extra layer of defense against environmental degradation, contributing significantly to the fence's service life, which can exceed 20 years under proper conditions and maintenance.

Precision Manufacturing Process Flow

The manufacturing of a high-quality Euro Steel Wire Mesh Fence is a meticulously controlled process, ensuring consistency, strength, and durability. Adherence to international standards such as ISO 9001 for quality management and relevant ASTM or EN standards for material properties and testing is paramount.

Step-by-Step Production Stages

High-grade low-carbon steel rods are sourced from certified suppliers. Incoming materials undergo stringent quality checks for chemical composition and mechanical properties, ensuring compliance with EN 10016-2 standards.

Steel rods are drawn through a series of dies to achieve the precise wire diameter required (e.g., 4mm to 6mm). This process increases tensile strength and improves surface finish.

Individual wires are precisely aligned and resistance-welded at each intersection using advanced CNC machinery. This creates robust, consistent mesh panels with uniform apertures and ensures high structural integrity. The V-bends (crimps) are also formed during this stage to add rigidity.

Welded panels are thoroughly cleaned (degreasing, pickling) and then hot-dip galvanized. This involves immersing the steel in a bath of molten zinc at approximately 450°C, forming a metallurgical bond that provides exceptional corrosion protection as per EN ISO 1461. This step is critical for service life, particularly in outdoor and harsh environments (e.g., coastal, industrial).

For specific aesthetic requirements and enhanced corrosion resistance, galvanized panels undergo a powder coating process. Electrostatic application of polyester powder is followed by curing in an oven at high temperatures, creating a durable, UV-resistant, and aesthetically pleasing finish in various RAL colors. This adds an additional layer of protection, extending the lifespan and improving the fence's appearance.

Each finished panel is inspected for weld strength, dimensions, coating thickness, and overall appearance. Testing standards include bend tests for wire and adhesion tests for coatings. Panels and posts are then carefully packaged to prevent damage during transit.

Through this rigorous process, manufacturers ensure that each component of the Euro Steel Wire Mesh Fence meets the highest standards of quality and performance, delivering an estimated service life of 15-25 years, depending on environmental conditions and maintenance.

Diverse Application Scenarios and Technical Advantages

The versatility and inherent strengths of the Euro Steel Wire Mesh Fence make it an ideal choice across a wide spectrum of industrial and commercial applications. Its design, combining robust security with a relatively unobtrusive visual profile, addresses both functional and aesthetic requirements.

Target Industries and Key Advantages

- Petrochemical & Energy Facilities: Critical infrastructure like oil refineries, power plants, and gas storage facilities demand high-security perimeters. The corrosion resistance from galvanization and powder coating is crucial in these chemically aggressive environments, ensuring long-term integrity and deterring intrusion. The mesh design allows for effective surveillance camera integration without significant blind spots.

- Metallurgy & Manufacturing Plants: Securing valuable assets and controlling access to hazardous zones within large industrial complexes. The rigid panel structure withstands industrial wear and tear, and its low maintenance requirements minimize operational disruptions.

- Water Supply & Drainage Infrastructure: Protecting water treatment plants, pumping stations, and reservoirs from vandalism and contamination. The robust construction and anti-climb features are essential for public utility security.

- Commercial & Retail Perimeters: From business parks to shopping centers, these fences offer an attractive yet secure boundary solution. The aesthetic customization through various RAL colors allows for brand integration and enhances property value.

- Logistics & Warehousing: Securing storage facilities, distribution centers, and freight yards. The strong mesh deters theft, and its clear visibility aids in monitoring large areas efficiently.

- Educational Institutions & Public Spaces: Providing safe and defined boundaries for schools, universities, and parks. Its non-aggressive appearance and lack of sharp edges make it suitable for areas with high public interaction.

The technical advantages extend beyond simple deterrence. The high rigidity of the panels, achieved through welded construction and horizontal V-bends, makes them extremely difficult to cut or climb without specialized tools and significant effort. This inherent resistance significantly increases the time required for a breach, allowing security personnel or systems to react. The open mesh design, while secure, also offers minimal wind resistance compared to solid barriers, making it suitable for exposed locations and reducing structural load on posts. The long service life, facilitated by advanced corrosion protection, translates into substantial life-cycle cost savings, reducing the need for frequent repairs or replacements. Furthermore, the standardized modular design ensures quick and efficient installation, minimizing project timelines and associated labor costs. The ability to integrate with various security accessories such as barbed wire, razor wire, and electronic detection systems further enhances its protective capabilities, offering a scalable solution for varying security needs.

Strategic Vendor Comparison and Customized Solutions

Choosing the right supplier for a Euro Steel Wire Mesh Fence is as crucial as selecting the product itself. Factors such as manufacturing expertise, adherence to quality standards, customization capabilities, and post-sales support significantly impact the long-term value and performance of the investment. A detailed vendor comparison allows procurement professionals to make informed decisions based on a holistic assessment rather than merely initial cost.

Comparative Analysis of Fencing Systems

While chain link fencing offers a lower initial cost, its security level is considerably lower due to easier cutting and climbing. Traditional palisade fencing offers high security but can be visually imposing and significantly more expensive to install. The Euro Steel Wire Mesh Fence strikes an optimal balance.

| Feature | Euro Steel Wire Mesh Fence | Chain Link Fence | Palisade Fence |

|---|---|---|---|

| Security Level | High (anti-climb, anti-cut) | Low to Medium (easily cut/climbed) | Very High (aggressive deterrent) |

| Aesthetics | Modern, clean, customizable colors | Basic, utilitarian | Industrial, imposing |

| Corrosion Resistance | Excellent (Galvanized + Powder Coated) | Good (Galvanized only) | Good (Galvanized or painted) |

| Installation Speed | Fast (modular panels) | Moderate (stretching mesh) | Slow (heavy components) |

| Cost (Initial) | Medium to High | Low | High |

| Maintenance | Very Low | Low to Moderate (rust, sagging) | Moderate (repainting, damage repair) |

Customized Solutions for Specific Project Needs

Leading manufacturers understand that no two projects are identical. Customized solutions are essential to address specific site conditions, security threat levels, and aesthetic preferences. Customization options for the Euro Steel Wire Mesh Fence include:

- Height and Width Adjustments: Panels can be manufactured to non-standard heights or widths to seamlessly fit uneven terrain or integrate with existing structures.

- Wire Diameter and Mesh Size Modifications: For higher security applications, thicker wires or smaller mesh apertures can be specified to enhance cut resistance and anti-climb properties.

- Specialized Coatings: Beyond standard galvanization and powder coating, specific anti-graffiti or highly chemical-resistant coatings can be applied for unique environmental challenges.

- Integrated Security Features: Options to integrate barbed wire, razor wire extensions, electric fencing, CCTV mounting brackets, or access control systems directly into the fence design.

- Gate Systems: Bespoke pedestrian gates, swing gates, or sliding gates manufactured to match the fence design, often with automated access control compatibility.

- Color Matching: Custom RAL color coding to align with corporate branding or architectural requirements.

Working with experienced vendors who offer engineering and design consultation ensures that the tailored solution meets all technical specifications and regulatory requirements, delivering optimal performance and cost efficiency.

Real-World Application Case Studies and Client Success

The practical application of the Euro Steel Wire Mesh Fence across diverse industries demonstrates its effectiveness and adaptability. These case studies highlight how tailored solutions can address complex security challenges, resulting in enhanced safety, reduced operational costs, and improved asset protection for our partner clients.

Case Study 1: High-Security Data Center Perimeter in a Coastal Region

A leading global technology firm required a robust perimeter solution for its new data center located near a coastal area, necessitating superior corrosion resistance and high-level security. The chosen solution involved a 2.4-meter high Euro Steel Wire Mesh Fence system with 5mm wire diameter and 50x200mm mesh, hot-dip galvanized and then powder-coated in a dark grey RAL color. Integrated with a perimeter intrusion detection system (PIDS) and CCTV cameras mounted on extended posts, the fence provided a formidable barrier. Customer feedback highlighted the exceptional durability against saltwater spray, minimal maintenance requirements, and the effective deterrence of unauthorized access attempts over the past five years. The transparent design also facilitated unobstructed visual monitoring, crucial for rapid incident response.

Case Study 2: Industrial Park Demarcation and Access Control

An expansive industrial park housing multiple manufacturing units needed a clear, secure demarcation, coupled with controlled vehicular and pedestrian access. A total of 8 kilometers of 2.0-meter high Euro Steel Wire Mesh Fence was installed. Custom-fabricated matching swing gates for pedestrian access and sliding gates for vehicular traffic, all equipped with automated access control systems, were integrated into the fence line. The aesthetic appeal of the green powder-coated fence blended well with the landscaped environment, while its robust construction ensured effective perimeter security. The project lead reported a significant reduction in trespassing incidents and a streamlined access control process, contributing to a safer and more organized operational environment for all tenants within the park.

Case Study 3: Renewable Energy Solar Farm Protection

A large-scale solar power farm in a remote, arid location faced challenges with wildlife intrusion and vandalism. A 1.8-meter high Euro Steel Wire Mesh Fence was selected for its cost-effectiveness, quick installation over uneven terrain, and ability to deter both human and animal intruders. The fence featured a reinforced bottom edge to prevent burrowing animals and was topped with barbed wire for enhanced security against climbing. The transparent nature of the mesh minimized shadowing on solar panels. The operational manager noted a drastic reduction in equipment damage due to vandalism and animal interference, leading to improved operational uptime and energy generation efficiency. The client praised the minimal environmental footprint of the installation and its long-term reliability in harsh desert conditions.

Ensuring Trustworthiness: FAQ, Lead Time, Warranty & Support

Building trust in the B2B sector requires transparency, reliability, and robust support systems. Our commitment to quality for the Euro Steel Wire Mesh Fence is underpinned by clear communication, comprehensive warranties, and dedicated customer service. We are proud of our ISO 9001 certified manufacturing facilities and our extensive experience serving global industrial clients for over 15 years.

Frequently Asked Questions (FAQ)

A1: With proper hot-dip galvanization and high-quality powder coating, our fences are designed for a service life of 15-25 years, even in challenging environmental conditions. Regular inspection and minor maintenance can further extend this.

Q2: Can the fence panels be installed on uneven or sloping terrain?A2: Yes, the modular design allows for stepped or raked installation to accommodate gradients. Our technical team can provide detailed guidance and customized panel dimensions for complex terrains.

Q3: Are the fences resistant to cutting tools?A3: The high tensile strength steel wire and small mesh apertures make the fence highly resistant to standard hand-held cutting tools. Specialized, heavy-duty equipment would be required, significantly increasing the time and effort for a breach, thus enhancing security.

Q4: What are the primary advantages of powder coating over other paint finishes?A4: Powder coating provides a much thicker, more durable, and more chip-resistant finish compared to liquid paints. It also offers superior UV stability, preventing fading, and enhances the overall corrosion protection provided by the underlying galvanization.

Lead Time and Fulfillment

Standard orders for our Euro Steel Wire Mesh Fence typically have a lead time of 3-4 weeks from order confirmation to dispatch, depending on volume and specific customization requirements. For large-scale projects or bespoke designs, project-specific timelines will be provided. We maintain efficient production schedules and robust logistics partnerships to ensure timely delivery worldwide. Expedited options are available upon request, subject to production capacity.

Warranty Commitments

We stand by the quality of our products. All Euro Steel Wire Mesh Fence components are backed by a comprehensive 10-year warranty against manufacturing defects and significant corrosion, provided installation and maintenance guidelines are followed. Specific coating warranties may extend up to 15 years, reflecting the superior performance of our galvanization and powder coating processes. Detailed warranty terms are available upon request.

Customer Support and After-Sales Service

Our commitment to client satisfaction extends far beyond the point of sale. We offer dedicated technical support, providing expert advice on installation, maintenance, and integration with other security systems. Our after-sales service team is available for prompt assistance with any inquiries or issues, ensuring that your investment continues to perform optimally throughout its lifespan. For support, please contact us via the details provided on our website.

Conclusion

The Euro Steel Wire Mesh Fence represents a pinnacle in modern perimeter security solutions, seamlessly blending robust protection with aesthetic versatility and long-term economic value. Its advanced manufacturing process, adherence to rigorous international standards, and diverse application capabilities make it an indispensable asset for securing critical infrastructure, industrial complexes, and commercial properties. By prioritizing material quality, technical precision, and customizable solutions, manufacturers offer a fencing system that not only meets but exceeds contemporary security demands, ensuring peace of mind and enduring performance for discerning B2B clients.

References

- European Committee for Standardization (CEN). EN ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods.

- International Organization for Standardization (ISO). ISO 9001: Quality management systems – Requirements.

- European Committee for Standardization (CEN). EN 10016-2: Non-alloy steel rod for drawing and/or cold rolling – Part 2: Specific requirements for general purpose rod.

- ASTM International. ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- Market Research Future. Global Perimeter Security Market Report: Information by Component, System, Vertical & Region - Forecast till 2030.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025