Oct . 16, 2024 04:32 Back to list

Top Quality Razor Barbed Wire Fence Suppliers for Enhanced Security and Durability

The Evolution of Razor Barbed Wire Fence Manufacturing

Razor barbed wire fences have become an essential component in security solutions across various sectors, including agriculture, industrial areas, and residential properties. The efficiency of these fences in deterring unauthorized access and enhancing perimeter security is unmatched, making them a staple in modern safety interventions. As a leading manufacturer in this domain, it is crucial to understand not only the manufacturing process but also the industry trends and innovations that shape this vital product.

The Manufacturing Process

The manufacturing of razor barbed wire involves several steps that ensure each unit provides maximum security. The process begins with the selection of high-quality raw materials. Typically, high-carbon steel is the preferred choice due to its strength and durability. Manufacturers treat these materials to enhance their resistance to rust and wear, which contributes to the longevity of the product.

Once the materials are prepared, the manufacturing process includes the following stages

1. Wire Drawing The raw steel is drawn through a series of dies to create wire of the desired thickness. This step is critical as the gauge of the wire directly affects the strength and effectiveness of the finished product.

2. Barb Production The creation of the razor barbs is accomplished by using specialized machines that cut and shape the steel into sharp, pointed designs. The barbs are designed to not only deter intruders but also to cause injury in case of any unauthorized attempts to breach the fence.

3. Twisting After the barbs are formed, they are attached to the main wire and twisted together. This twisting process is vital for the structural integrity of the fence, ensuring that the barbs remain securely in place.

4. Coating To enhance corrosion resistance, the finished razor wire is often galvanized or coated with a polymer. This step increases the fence's durability, making it suitable for various environments, from arid deserts to humid coastal regions.

5. Quality Control Rigorous testing and quality assurance protocols are implemented at various stages of production. Manufacturers conduct tensile strength tests, corrosion resistance tests, and overall durability assessments to ensure the product meets industry standards.

razor barbed wire fence manufacturer

Trends and Innovations

As the demand for razor barbed wire fences has evolved, so too have the technologies and materials used in their production. Innovations in manufacturing processes are continuously emerging, driven by advancements in materials science and changing security needs.

One notable trend is the increasing use of eco-friendly materials and manufacturing processes. Manufacturers are now exploring biodegradable coatings and recycled materials, aiming to reduce the environmental impact associated with traditional production methods. Companies committed to sustainability are gaining traction among consumers who prioritize eco-conscious solutions.

Additionally, advancements in automated manufacturing technology have streamlined production processes, enhancing precision and efficiency. Automated machines can now cut, twist, and coat wire with minimal human intervention, reducing labor costs and time, while consistently improving the quality of the end product.

The Market Landscape

The global market for razor barbed wire fences is witnessing steady growth, driven by the rising need for enhanced security measures in residential, commercial, and industrial sectors. The increasing incidence of property crime and the need for reliable perimeter protection are major factors contributing to this growth. Moreover, the construction of new commercial and industrial facilities has further boosted the demand for robust fencing solutions.

Manufacturers must be agile in their production strategies, adapting to consumer preferences that increasingly favor custom solutions tailored to specific security needs. Offering a variety of designs, materials, and finishes allows manufacturers to cater to diverse markets while maintaining competitive pricing.

Conclusion

Razor barbed wire fence manufacturing represents a critical industry focused on security and protection. The combination of advanced manufacturing techniques, quality materials, and increasing market demand creates a dynamic landscape for manufacturers. As innovations continue to emerge, it is essential for producers to remain at the forefront of technology and sustainability, meeting the challenges of today's security needs while looking ahead to future developments. This balance will undoubtedly define the future of razor barbed wire fence manufacturing, ensuring that safety remains paramount in our rapidly changing world.

-

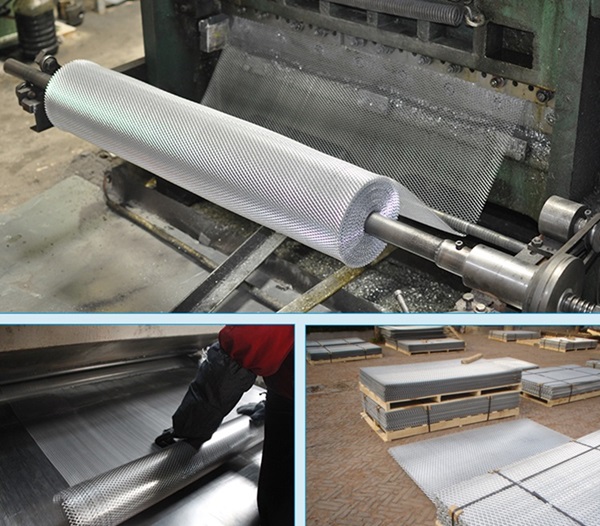

High Quality 9 Gauge Expanded Metal Mesh & Chain Link Wire Mesh Fence Manufacturer

NewsJun.10,2025

-

Barbed Wire Roll Price - Wholesale Exporters & Reliable Factories Supply

NewsJun.10,2025

-

High-Quality Temporary Mesh Fence Panels for Sale Durable Temporary Fence Panels Supplier

NewsJun.10,2025

-

Welded Wire Fence Mesh Exporters Custom Sizes & Competitive Pricing

NewsJun.10,2025

-

Durable China Expanded Metal Security Mesh High-Security & Affordable

NewsJun.10,2025

-

White Expanded Metal Mesh Durable for Temp Fencing & Plaster

NewsJun.10,2025