Oct . 11, 2025 07:55 Back to list

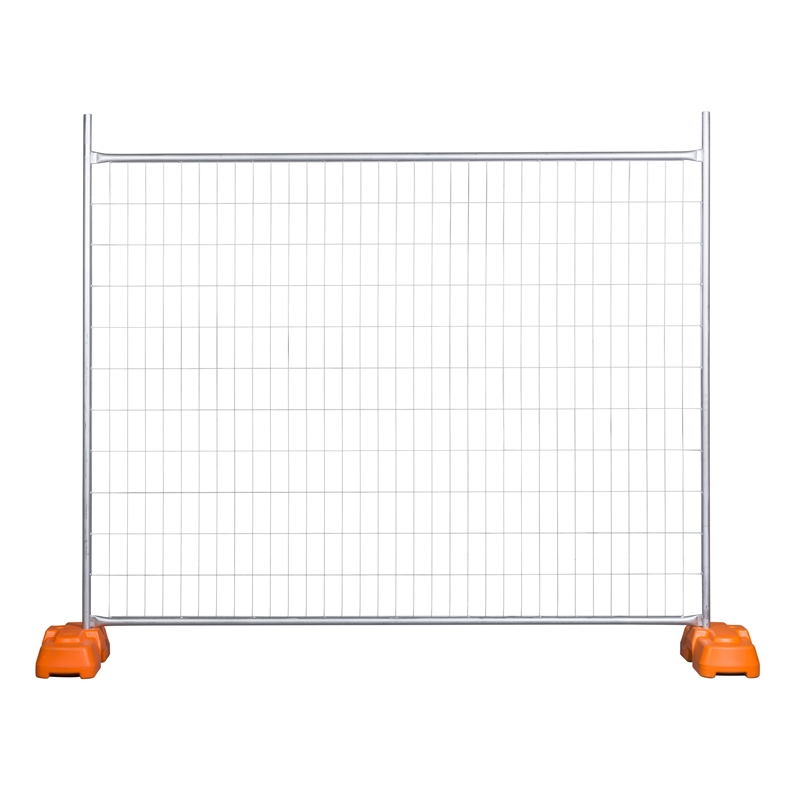

Hop Dipped Galvanized /PVC Coated Temporary Fence | Durable

Field Notes: Why Hop Dipped Galvanized /PVC Coated Temporary Fence keeps showing up on serious job sites

If you manage construction logistics or events, you’ve probably noticed a shift: contractors are ditching flimsy panels for heavier, longer-life barriers. To be honest, it’s overdue. The market’s nudging toward durable, reusable kit—less waste, fewer headaches. And yes, that’s where Hop Dipped Galvanized /PVC Coated Temporary Fence panels earn their keep.

What’s trending

- Rental-ready durability: thicker zinc (HDG) and UV-stable PVC topcoats.

- Faster installs: drop-in bases, anti-lift clamps, tool-less connectors.

- Compliance-first: traceable steel grades (Q195/Q235), ISO-managed QA, corrosion testing.

Core specifications (typical, adjustable to project)

| Steel grade | Q195 / Q235 (mill-cert traced) |

| Panel size | ≈ 2.1 m H × 2.4–3.5 m W (custom available) |

| Mesh aperture | 60 × 150 mm or 50 × 200 mm |

| Wire diameter | ≈ 3.0–5.0 mm |

| Frame tube | OD 32–40 mm, wall 1.2–2.0 mm |

| Finish options | Electro-galv, Hop Dipped Galvanized /PVC Coated Temporary Fence, paint |

| Coating mass | HDG ≈ 450–600 g/m²; PVC ≈ 80–120 μm (real-world may vary) |

| Certs | ISO 9001 (factory), material test reports |

How it’s built (and proven)

Materials are cut and welded, then de-burred. Hot-dip galvanizing follows ISO 1461/ASTM A123—full immersion, inside-out zinc coverage. Where a color finish is needed, PVC coating (thermoplastic) is applied for impact and UV resistance. Tests include zinc thickness (magnetic gauge), cross-hatch adhesion, and salt-spray to ASTM B117. Typical results: HDG ≥ 70 μm; PVC adhesion grade 4B–5B; neutral salt-spray 500–1,000 h with no red rust on significant areas. Service life? In a C3 environment, ≈ 10–15 years; harsher sites will shorten that, of course.

Where it works (and why)

- Construction perimeters, crowd control, traffic diversion.

- Industrial platforms and laydown yards—people forget forklifts are rough; these frames take a beating.

- Events and festivals—privacy mesh and branded PVC colors are common add-ons.

Many customers say the big win is stability: heavier bases, less panel rattle, fewer callouts after wind gusts. I guess it’s the little things.

Vendor snapshot (quick compare)

| Vendor | Zinc/PVC | Lead Time | Certs | Customization | Warranty |

|---|---|---|---|---|---|

| XZ Metal (Anping, Hebei, China) | HDG 450–600 g/m²; PVC 80–120 μm | ≈ 15–25 days | ISO 9001 | Panels, colors, clamps, bases | 12–24 months (site-dependent) |

| Regional Importer A | Electro-galv; paint | Stock or 30–45 days | Varies | Limited sizes | 6–12 months |

| OEM B | HDG 300–450 g/m² | ≈ 25–35 days | ISO 9001 (sometimes) | Moderate | 12 months |

Customization, compliance, and origin

Hop Dipped Galvanized /PVC Coated Temporary Fence panels can be tuned—mesh size, tube gauge, anti-climb apertures, anti-lift clamps, rubber or concrete-filled bases, visibility colors. Factory location: 200 meters North Of Huangcheng Village, Anping, Hebei, China. Compliance references: ISO 1461/ASTM A123 for HDG, ASTM B117 for salt-spray, and QA under ISO 9001. Real-world wind stability depends on base selection and site exposure—always size for local regulations.

Quick case notes

- Urban build, coastal C3–C4: HDG + PVC survived two winters; only cosmetic scuffs. Crew liked the quick clamps.

- Music festival: branded PVC green, anti-trip bases. Zero panel drops in gusts up to ≈ 70 km/h with ballast.

Bottom line

If you want panels that still look serviceable after the third redeploy, Hop Dipped Galvanized /PVC Coated Temporary Fence is the safer bet. Not the cheapest day one, but cheaper by the fifth job.

References

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel products.

- ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ISO 9001: Quality management systems — Requirements.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025