Oct . 08, 2024 08:07 Back to list

High-Quality Square Wire Mesh Products for Versatile Applications and Enhanced Durability

An Overview of Square Wire Mesh Products

Square wire mesh is a versatile and widely used product made from high-quality wire, available in various materials such as stainless steel, carbon steel, and aluminum. The unique square openings created in square wire mesh provide a range of applications, from industrial to domestic, making it a staple in many sectors. This article explores the characteristics, manufacturing processes, and applications of square wire mesh products.

Characteristics of Square Wire Mesh

One of the primary features of square wire mesh is its strength and durability. The square openings typically come in various sizes, ranging from tiny apertures to larger gaps, allowing for customization according to specific needs. The wire used in the mesh can be coated or treated to enhance its resistance to corrosion, rust, and other environmental factors, which is particularly important in outdoor applications.

Another significant characteristic is the mesh's versatility. It can be woven or welded, depending on the required specifications and intended use. Welded wire mesh consists of strands that are welded together at intersections, offering superior strength for heavy-duty applications. In contrast, woven wire mesh interlaces the wires in a crisscross pattern, providing flexibility and ease of installation.

Manufacturing Process

The manufacturing of square wire mesh typically involves several steps, beginning with wire drawing, where large spools of raw wire are drawn through dies to achieve the desired gauge. Next, the wire is either woven or welded, depending on the type of mesh being produced. The weaving process creates a more flexible product, while the welding process results in a sturdier and more rigid structure.

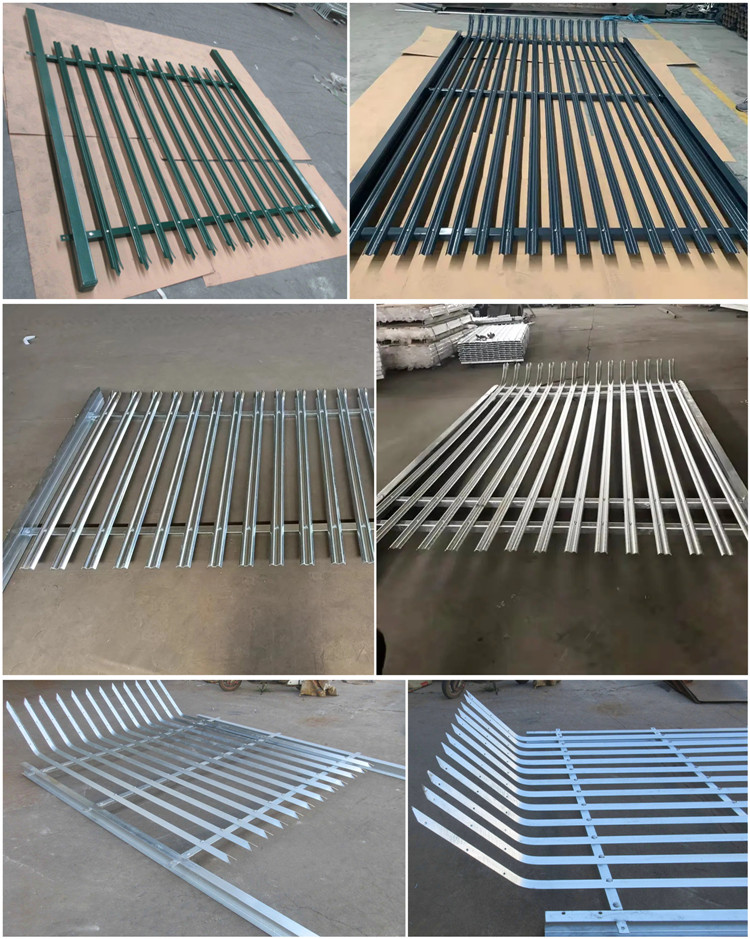

square wire mesh products

After forming the mesh, various finishes can be applied. Options such as galvanization, powder coating, or painting can aid in preventing corrosion and extending the lifespan of the product. Quality control is a crucial aspect of the manufacturing process, ensuring that each roll or sheet of square wire mesh meets industry standards and specifications.

Applications of Square Wire Mesh

Square wire mesh has a multitude of applications across diverse industries. In the construction sector, it is frequently used for concrete reinforcement, offering structural integrity to buildings, roads, and bridges. The mesh serves as a barrier as well, being utilized in fencing systems to ensure security around properties, parks, and industrial facilities.

Agriculture also benefits from square wire mesh products. Farmers use it for crop protection, animal enclosures, and creating supports for climbing plants. In commercial settings, it is employed in the manufacturing and processing of products, providing easy visibility and ventilation in storage areas, shelves, and display cases.

Moreover, square wire mesh finds its way into everyday products, such as kitchen utensils, strainers, and decorative elements in home design. Its aesthetic appeal combined with functionality makes it a popular choice among designers and architects.

Conclusion

Square wire mesh products are an integral part of various industries due to their strength, versatility, and wide-ranging applications. Whether in construction, agriculture, or everyday household use, square wire mesh demonstrates its importance as a functional and reliable material. With ongoing advancements in manufacturing processes and materials, square wire mesh will continue to adapt and fulfill a wide array of needs in the years to come.

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025

-

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

NewsJul.31,2025