Sep . 14, 2025 07:20 Back to list

Galvanized Scaffold Metal Planks for Construction | Durable & Safe

Understanding the Evolving Landscape of Scaffolding

The construction industry continually seeks innovations to enhance safety, efficiency, and durability. In this context, the Galvanized construction Scaffold metal plank stands as a critical component, fundamental to modern scaffolding systems. Its superior characteristics address many challenges faced by traditional wooden or composite planks, offering a robust and reliable platform for workers at height. This article delves into the technical aspects, applications, and strategic advantages of this essential construction material, providing insights for procurement professionals, engineers, and project managers.

Industry Trends and Market Dynamics

The global scaffolding market is projected to reach USD 78.5 billion by 2027, driven by rapid urbanization, infrastructure development, and stringent safety regulations. Within this growth, metal planks, particularly those treated with galvanization, are seeing increased adoption. Key trends include a shift towards modular and lightweight scaffolding systems, a heightened focus on worker safety standards (e.g., OSHA, EN 12811), and demand for products with extended service life and reduced maintenance. The demand for robust and sustainable scaffolding components means that the Galvanized construction Scaffold metal plank is becoming a standard choice across various sectors.

- Increased preference for steel over wood due to fire resistance and higher load-bearing capacity.

- Growing emphasis on environmental sustainability driving demand for recyclable materials.

- Technological advancements leading to improved anti-slip surfaces and lighter designs.

- Expansion of industrial and energy sectors fueling demand for specialized scaffolding.

Technical Specifications and Material Excellence

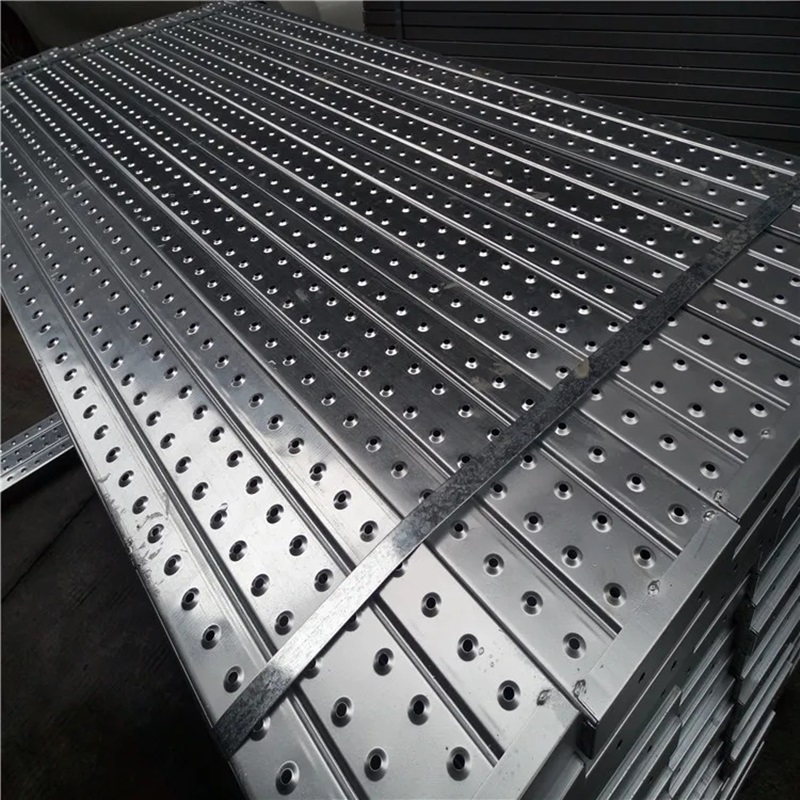

The performance of a Galvanized construction Scaffold metal plank is directly tied to its precise technical specifications and the quality of its manufacturing process. These planks are typically fabricated from high-grade steel, such as Q235 or Q345, renowned for its excellent tensile strength and ductility. The galvanization process, usually hot-dip galvanizing, applies a protective zinc coating that significantly enhances corrosion resistance, a critical factor for outdoor and harsh industrial environments.

Key Product Parameters

| Parameter | Specification | Standard |

|---|---|---|

| Material Grade | Q235, Q345 (JIS G3101 SS400 equivalent) | GB/T 700, EN 10025 |

| Surface Treatment | Hot-dip Galvanized (Min. 60µm zinc coating) | ISO 1461, ASTM A123 |

| Length Options | 1000mm to 4000mm (customizable) | Manufacturer Specific |

| Width Options | 210mm, 240mm, 250mm, 300mm (customizable) | Manufacturer Specific |

| Thickness | 1.2mm to 2.0mm | Manufacturer Specific |

| Load Capacity | Designed for Class 4 & 5 scaffolding (e.g., 200kg/m² to 450kg/m²) | EN 12811, AS/NZS 1576 |

| Anti-slip Design | Perforated or embossed surface | Internal Standard |

| Service Life | 15-20 years under proper usage and maintenance | Estimated, depending on environment |

These specifications ensure that the planks can withstand significant structural loads, resist environmental degradation, and provide a safe working platform in diverse conditions.

The Manufacturing Process: From Raw Material to Finished Product

The production of a high-quality Galvanized construction Scaffold metal plank involves several precise stages, each critical to the product's overall integrity and performance. Adherence to strict quality control and international standards like ISO 9001 is paramount throughout the entire manufacturing flow.

Detailed Process Flow:

1. Material Selection & Shearing

High-grade steel coils (Q235/Q345) are selected. Automated shearing machines cut the steel sheets to the required plank dimensions.

2. Punching & Forming

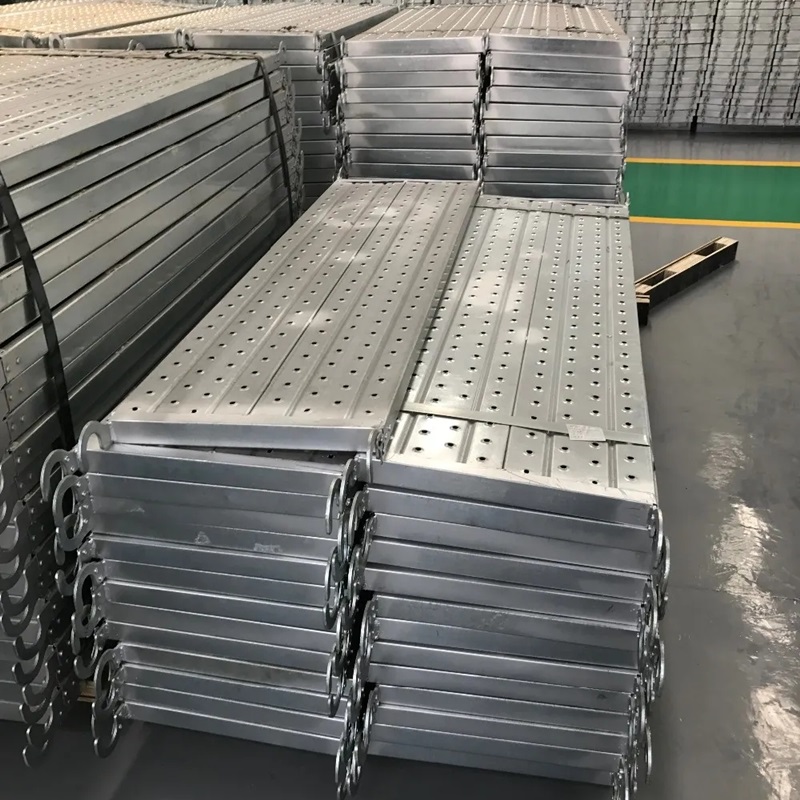

CNC punching machines create anti-slip perforations and drainage holes. Subsequent roll-forming machines shape the planks, including hooks for secure fitting.

3. Welding

Automated robotic welding systems ensure strong, consistent welds for end caps and reinforcement structures, complying with AWS standards.

4. Surface Treatment (Galvanizing)

The planks undergo degreasing, pickling, fluxing, and then hot-dip galvanizing, creating a robust, sacrificial zinc coating against corrosion.

5. Quality Control & Packing

Each plank is inspected for dimensional accuracy, weld integrity, galvanization thickness, and load-bearing capacity before packaging.

This meticulous process ensures that each Galvanized construction Scaffold metal plank not only meets but often exceeds international safety and performance standards, such as EN 12811 for temporary works equipment and AS/NZS 1576 for scaffolding standards.

Technical Advantages in Application Scenarios

The inherent properties of the Galvanized construction Scaffold metal plank provide distinct advantages across a multitude of challenging application scenarios:

- ✓ Superior Corrosion Resistance: Essential for petrochemical plants, offshore platforms, and coastal construction where saltwater and corrosive chemicals accelerate degradation. The galvanization ensures a multi-decade service life, reducing replacement costs and downtime.

- ✓ High Load-Bearing Capacity: Critical in heavy industrial settings like metallurgy, power generation, and bridge construction, where tools, materials, and multiple workers demand robust support. This contributes significantly to overall site safety.

- ✓ Enhanced Safety Features: Anti-slip surfaces and secure hook designs minimize the risk of falls, addressing a primary concern on construction sites. This is vital in all environments, especially those prone to wet or icy conditions.

- ✓ Durability and Longevity: Unlike wooden planks that splinter, warp, or rot, metal planks maintain structural integrity over many years, offering a better return on investment and reduced material waste, aligning with sustainability goals.

- ✓ Fire Resistance: An invaluable advantage in industrial sites such as refineries and chemical plants, where fire hazards are prevalent. Metal planks do not contribute to fire spread, unlike their wooden counterparts.

These advantages translate directly into increased operational efficiency, reduced maintenance costs, and, most importantly, a safer working environment for personnel.

Vendor Comparison: Strategic Sourcing Considerations

Choosing the right supplier for a Galvanized construction Scaffold metal plank is a strategic decision that impacts project timelines, safety, and budget. While many manufacturers offer similar products, key differentiators lie in material quality, adherence to international standards, customization capabilities, and post-sales support.

Comparative Analysis of Supplier Attributes

| Attribute | XZ Metal (Example) | Competitor A | Competitor B |

|---|---|---|---|

| Material Certification | Q235/Q345 with Mill Test Certificates | Q235 (basic) | Mixed, limited traceability |

| Galvanization Standard | ISO 1461, ASTM A123 (min. 60µm) | Internal Standard (often thinner coating) | Variable thickness, no clear standard |

| Safety Compliance | EN 12811, AS/NZS 1576, OSHA compliant | Meets minimum local standards | Basic, may not meet international norms |

| Customization Options | Full range (length, width, hook type, branding) | Limited standard sizes | None |

| Warranty & Support | Comprehensive 5-year warranty, dedicated support | Standard 1-year, limited support | No explicit warranty |

This comparison highlights the importance of scrutinizing not just the product but the entire value proposition offered by a supplier, ensuring long-term reliability and compliance.

Customized Solutions for Unique Project Requirements

Every construction project presents unique challenges, and scaffolding components are no exception. Leading manufacturers understand this need and offer extensive customization options for the Galvanized construction Scaffold metal plank. This includes varied lengths, widths, and thicknesses to fit specific scaffolding systems (e.g., Ringlock, Cuplock, Kwikstage). Furthermore, specialized hook designs can be engineered for non-standard configurations, and anti-slip patterns can be optimized for extreme environments. These tailored solutions ensure seamless integration and optimal safety, avoiding costly on-site modifications.

- Bespoke dimensions for specific bay sizes or load requirements.

- Custom hole patterns for specialized drainage or fastening.

- Integration with unique scaffold systems (e.g., cantilevers, access bridges).

- Company branding or color-coding for inventory management and site recognition.

Application Case Studies and Customer Feedback

The efficacy of the Galvanized construction Scaffold metal plank is best demonstrated through its successful deployment in diverse, high-stakes environments.

Case Study 1: Coastal Oil Refinery Maintenance

A major petrochemical client undertaking a two-year maintenance overhaul at a coastal refinery required scaffolding planks that could withstand constant exposure to corrosive saltwater spray and aggressive chemical fumes. Traditional wooden planks showed rapid deterioration. By deploying over 15,000 units of hot-dip galvanized metal planks, the project achieved a significantly extended plank service life, zero plank-related safety incidents due to material failure, and reduced logistical costs from fewer replacements. "The durability and corrosion resistance of these galvanized planks were exceptional, saving us considerable time and resources on this demanding project," noted the Project Safety Manager.

Case Study 2: High-Rise Building Construction in Urban Core

For a 50-story residential tower project in a dense urban area, quick assembly, high load capacity, and worker safety were paramount. The project utilized modular scaffolding systems integrated with lightweight, yet robust, galvanized metal planks. The anti-slip design proved crucial during wet weather, and the consistent dimensions facilitated rapid, safe installation. This led to a 15% reduction in scaffold erection time compared to previous projects using alternative materials, and a flawless safety record concerning working platforms. The client specifically praised the planks' consistent quality and ease of handling.

Trustworthiness & Client Support

Frequently Asked Questions (FAQ)

Q: What is the typical service life of a Galvanized construction Scaffold metal plank?

A: With proper handling and maintenance, our hot-dip galvanized planks are designed for a service life of 15-20 years, significantly outperforming ungalvanized or wooden alternatives.

Q: Are your planks compatible with all scaffolding systems?

A: Our planks are designed to be universally compatible with most common scaffolding systems, including Ringlock, Cuplock, and Kwikstage. We also offer customization to ensure perfect fitment for specialized systems.

Q: How do your planks ensure worker safety?

A: Our planks feature advanced anti-slip perforations and secure hook mechanisms to prevent dislodgment. They comply with international safety standards like EN 12811 and OSHA regulations for load capacity and anti-slip properties, significantly reducing the risk of falls and structural failure.

Lead Time and Fulfillment

Standard orders for our Galvanized construction Scaffold metal plank typically have a lead time of 2-4 weeks, depending on order volume and current production schedules. For large-scale projects or custom orders, lead times will be confirmed upon quotation. We maintain robust supply chain logistics to ensure timely delivery to your project site globally.

Warranty Commitments

We stand by the quality of our products. All Galvanized construction Scaffold metal planks come with a comprehensive 5-year limited warranty against manufacturing defects and premature corrosion under normal usage conditions. This commitment reflects our confidence in our stringent quality control processes and the superior materials used.

Customer Support Information

Our dedicated customer support team is available to assist with technical queries, order tracking, and after-sales service. Please reach out via email at info@xzmetal.com or call us at +86-XXX-XXXX-XXXX. Our experts are ready to provide the support and information you need to ensure the success of your projects.

Conclusion

The Galvanized construction Scaffold metal plank represents a vital evolution in construction safety and efficiency. Its technical superiority, from material selection and manufacturing precision to galvanization for extended life, positions it as the optimal choice for demanding industrial and construction applications. By understanding its advantages and choosing a reputable supplier, project managers can ensure safer, more cost-effective, and environmentally responsible operations.

References

- European Committee for Standardization. (2003). EN 12811-1: Temporary works equipment - Part 1: Scaffolds - Performance requirements and general design.

- International Organization for Standardization. (2009). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles - Specifications and test methods.

- Occupational Safety and Health Administration. (1996). 29 CFR 1926 Subpart L - Scaffolds. U.S. Department of Labor.

- Standards Australia/Standards New Zealand. (2018). AS/NZS 1576.1: Scaffolding - General requirements.

- American Society for Testing and Materials. (2015). ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025