Nov . 21, 2024 05:58 Back to list

custom metal wire mesh

Custom Metal Wire Mesh Versatility and Applications

In today’s industrial landscape, the demand for customized solutions is more prevalent than ever. Among the myriad of products that fulfill this need, custom metal wire mesh stands out for its versatility and functionality. Whether used for construction, filtration, or artistic endeavors, this product can be tailored to meet specific requirements, making it an essential component across various industries.

What is Metal Wire Mesh?

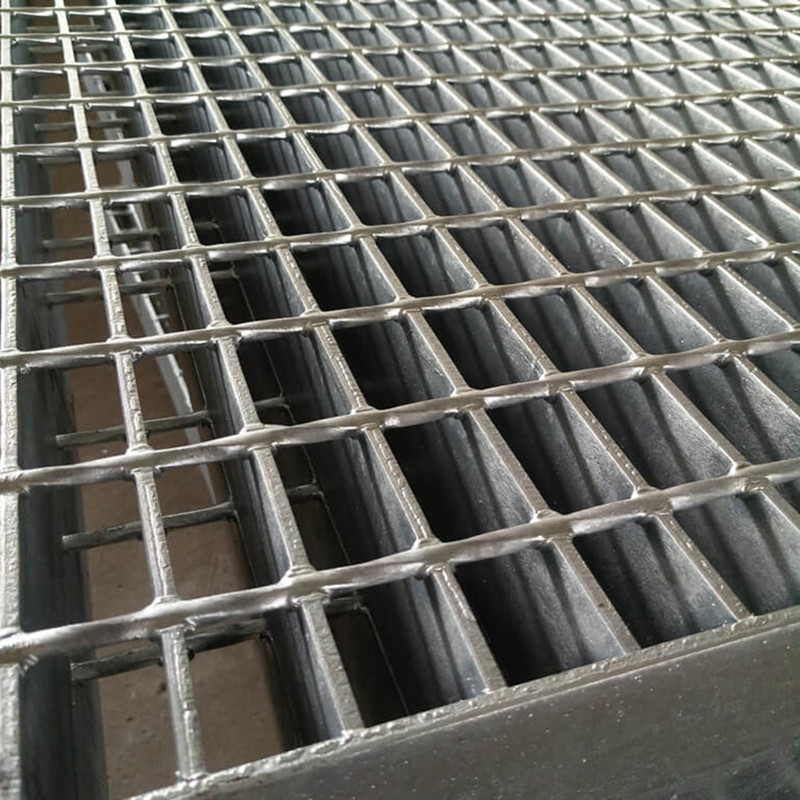

Metal wire mesh is a woven or welded structure made from metal wires. The configuration can vary, from squares and rectangles to more complex patterns. The types of metal used can range from stainless steel and aluminum to copper and brass, each offering unique properties suited to different applications. The ability to customize the wire diameter, mesh opening size, and overall dimensions makes it an adaptable material in a breadth of sectors.

Key Benefits of Customization

1. Tailored Specifications One of the most significant advantages of custom metal wire mesh is the ability to meet specific requirements. Industries often have varying needs based on their projects. Customization allows for unique designs that fulfill exact specifications, ensuring optimal performance and efficacy.

2. Enhanced Durability Custom metal wire mesh can be engineered from materials that withstand harsh environments. For instance, stainless steel mesh can be utilized in marine applications where corrosion resistance is critical. The ability to choose the right material and finish, such as galvanization or coating, enhances the mesh's longevity.

3. Improved Functionality Each application has different functional requirements; some may need finer mesh for filtration, while others might require sturdier wire for support structures. Custom designs enable engineers and architects to create solutions that perfectly align with their operational needs.

4. Aesthetic Appeal Beyond functionality, custom metal wire mesh can also serve aesthetic purposes. Architectural designs often incorporate wire mesh as a design element. Customized patterns can be created to enhance visual appeal while serving a practical purpose, like providing privacy or security.

custom metal wire mesh

Applications of Custom Metal Wire Mesh

1. Construction and Architecture In the construction industry, custom metal wire mesh is commonly used in concrete reinforcement. The mesh adds strength and stability to concrete structures, reducing the likelihood of cracking. Moreover, it can be used in architectural facades to create unique, modern designs that serve functional purposes such as shading or ventilation.

2. Filtration Systems Industries that require fluid and air filtration benefit greatly from custom wire mesh. Different mesh sizes and types allow for specific filtration applications, whether it’s water treatment, air purification, or industrial processes. Customizable options enable engineers to select the optimal mesh configuration for desired filtration rates.

3. Security and Safety Security fencing and barriers often employ custom metal wire mesh to provide safety while maintaining visibility. Options can include numerous styles and thicknesses, allowing clients to create robust fencing solutions that deter unauthorized access.

4. Farming and Agriculture In agriculture, custom mesh products are used in applications ranging from animal enclosures to crop protection. The ability to design wire mesh that meets particular spacing and durability criteria ensures that it effectively serves its purpose in these critical environments.

5. Art and Design Artists and designers utilize custom metal wire mesh for creating sculptures, installations, and decorative screens. The flexibility in design allows for innovative creations that blend form with function, exemplifying the artistic potential of this material.

Conclusion

The versatility and adaptability of custom metal wire mesh make it an invaluable material across various sectors. From enhancing structural integrity in construction to providing efficient filtration solutions and serving aesthetic purposes in modern design, the possibilities are endless. As industries continue to innovate and evolve, the demand for custom solutions, like metal wire mesh, will remain strong. Companies that invest in customizable products can more effectively meet the specific needs of their clients, paving the way for greater innovation and functionality in design and application. The future looks bright for the world of custom metal wire mesh, promising endless opportunities for advancement and creativity.

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing, Corrosion Resistant Solutions

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing Solutions&Customizable Security Systems

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Corrosion Resistant&Modular Design

NewsAug.03,2025

-

Galvanized Iron Wire Anti Mosquito Window Screen Net | Durable

NewsAug.03,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Durable Temporary Fencing Solutions&Customizable Construction Site Security

NewsAug.02,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.

NewsAug.02,2025