Dec . 23, 2024 08:15 Back to list

Hexagonal Wire Fencing Production Facilities for Agricultural and Industrial Applications

Exploring Hexagonal Wire Fencing Factories Innovation in Design and Production

Hexagonal wire fencing is a popular choice for both residential and agricultural applications due to its unique design and numerous benefits. As the demand for reliable, versatile fencing solutions grows, manufacturers specializing in hexagonal wire fencing have emerged as key players in the market. This article will explore the significance of hexagonal wire fencing factories, their production processes, and the advantages they offer to consumers.

What is Hexagonal Wire Fencing?

Hexagonal wire fencing, also known as chicken wire or hex wire mesh, is characterized by its hexagonal-shaped openings. This fencing type is typically made from galvanized steel wire, which ensures durability and resistance to rust and corrosion. Hexagonal wire mesh is primarily used for enclosures, garden protection, pet containment, and agricultural purposes such as poultry farming or livestock confinement.

The Role of Hexagonal Wire Fencing Factories

Hexagonal wire fencing factories play a crucial role in the production of this essential fencing material. These facilities are equipped with advanced machinery and technology to produce high-quality wire mesh efficiently. Factories implement rigorous quality control measures to ensure that the final product meets industry standards and customer requirements.

In recent years, many factories have started adopting automation and robotics in their production lines. This shift not only enhances production speed but also maintains consistency in product quality. With the growing trend of sustainable manufacturing practices, some factories are also working towards eco-friendly production methods, such as utilizing recyclable materials in their wire mesh.

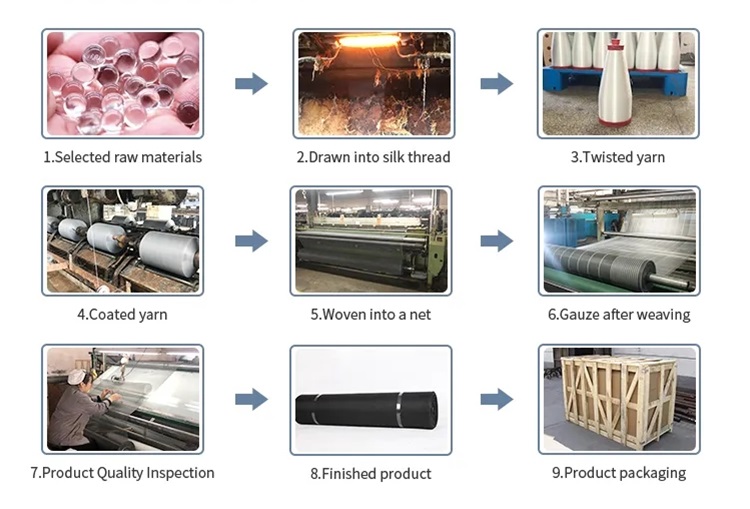

Production Process

The production process of hexagonal wire fencing typically involves several key steps

1. Wire Drawing High-quality steel rods are drawn to produce wire of the desired thickness. This process involves stretching the steel rods through progressively smaller dies until the desired diameter is achieved.

2. Galvanization The drawn wire is then coated with a layer of zinc to protect it from rust and corrosion. This galvanization process significantly enhances the wire's lifespan, making it ideal for outdoor use.

hexagonal wire fencing factories

3. Weaving Once the wire is galvanized, it is woven into hexagonal shapes using specialized machinery. The weaving process determines the spacing of the hexagonal openings, which can vary depending on the intended use of the fencing.

4. Cutting and Packaging After weaving, the wire mesh is cut into specified lengths or rolls as per customer orders. Finally, it is packaged securely for shipment to distributors or directly to consumers.

Advantages of Hexagonal Wire Fencing

Hexagonal wire fencing offers numerous advantages that contribute to its popularity

- Versatility The varied applications of hexagonal wire fencing, from gardening to livestock protection, make it a versatile solution for many users.

- Cost-Effectiveness Compared to other fencing materials, hexagonal wire fencing is relatively affordable, making it an attractive option for budget-conscious consumers.

- Visibility The open design of hexagonal mesh allows for good visibility, which is beneficial for monitoring livestock or enhancing garden aesthetics.

- Ease of Installation Hexagonal wire fencing is lightweight and easy to install, making it a popular choice for DIY projects.

Conclusion

Hexagonal wire fencing factories are essential in producing a reliable and versatile fencing solution that meets the needs of various consumers. As technology advances and sustainable practices become more prevalent, these factories will continue to evolve, offering innovative products that enhance both functionality and environmental responsibility. Whether for agricultural use, pet containment, or decorative purposes, hexagonal wire fencing remains a fundamental choice for many, thanks to the dedicated efforts of manufacturers in this industry.

-

Durable Hot-Dip Galvanized Farm Field Wire Fence | Farm Security

NewsAug.01,2025

-

Temporary Fencing Solutions-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing&Cost-Effective Security Solutions

NewsJul.31,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|durable temporary fencing&corrosion-resistant solutions

NewsJul.31,2025

-

Temporary Fencing Solutions - Anping County Xingzhi Metal | Galvanized PVC Coated Fences

NewsJul.31,2025

-

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

NewsJul.31,2025