Eki . 18, 2024 18:29 Back to list

Bar Grating Pricing Information from Leading Manufacturers and Suppliers

Understanding Bar Grating Prices Key Factors and Leading Companies

Bar grating is a crucial component in various industries, serving functions such as flooring, walkways, and drainage systems. Its importance in safety, functionality, and structural integrity makes it a significant material choice. However, when it comes to purchasing bar grating, potential buyers often find themselves grappling with a range of prices, which can vary significantly based on various factors. This article delves into the components that influence bar grating prices and highlights some of the prominent companies in the market.

Factors Influencing Bar Grating Prices

1. Material Type One of the most significant factors determining the price of bar grating is the material used in its construction. Bar grating is typically made from steel, aluminum, or fiberglass. Steel grating tends to be the most economical, but aluminum is often preferred for its lightweight and rust-resistant properties, albeit at a higher price point. Fiberglass reinforced grating, while expensive, is favored in environments where corrosion is a concern, driving up its cost further.

2. Manufacturing Process The manufacturing process can heavily influence bar grating prices. Welded bar grating, for example, involves welding the crossbars to the bearing bars, resulting in a sturdy product but at a higher production cost. Meanwhile, press-locked grating uses a different approach that can also affect pricing. Customization options such as different sizes, load ratings, and surface treatments will further contribute to the overall cost.

3. Load Capacity Bar grating is categorized based on its load capacity. Heavy-duty grating that can support substantial weight typically costs more due to the additional material and engineering required. Clients should assess their needs carefully, as underestimating load requirements can lead to additional costs later on.

4. Surface Treatment Bar grating may undergo surface treatments like galvanization to enhance its resistance to corrosion and improve its lifespan. Galvanized products often come at a premium due to the added protective layer, which is especially essential for grating used in harsh environments.

5. Quantity and Bulk Pricing Bulk purchases often come with discounts, as companies prefer to incentivize larger orders. Buyers should consider their needs and whether they can purchase in bulk to take advantage of lower prices per unit.

bar grating price companies

6. Location and Shipping Finally, geographical factors, including the location of the supplier and shipping costs, can influence the overall price. Products manufactured locally may reduce shipping expenses, while importing grating from overseas might increase costs significantly due to tariffs and long shipping times.

Leading Companies in Bar Grating Manufacturing

Several companies have established themselves as leaders in the bar grating market, each offering a range of products and services to meet diverse customer needs

- McNichols Co. Known for its extensive inventory and variety of grating options, McNichols offers everything from standard steel to custom solutions. Their commitment to quality and customer service has made them a preferred choice for many industries.

- Grating Pacific With a focus on providing exceptional bar grating and related products, Grating Pacific has built strong relationships across many sectors, ensuring that their materials meet specific industry standards and regulations.

- Webforge This company is recognized for its global reach and ability to supply bar grating suited for various applications, including industrial, commercial, and infrastructure projects.

- Kia Lim Based in Singapore, Kia Lim offers a wide range of materials, including stainless steel and composite options, catering primarily to the Asia-Pacific region.

In conclusion, understanding the factors that influence bar grating pricing can help buyers make better-informed decisions. By considering material types, manufacturing processes, load capacities, surface treatments, and quantity needs, and by exploring reputable suppliers like McNichols, Grating Pacific, Webforge, and Kia Lim, businesses can find the right bar grating solutions at competitive prices.

-

Premium Hot Dip Galvanized Welded Wire Mesh Durable & Corrosion-Resistant

NewsJun.06,2025

-

Durable Wholesale Africa Chicken Netting Hexagonal Wire Mesh

NewsJun.06,2025

-

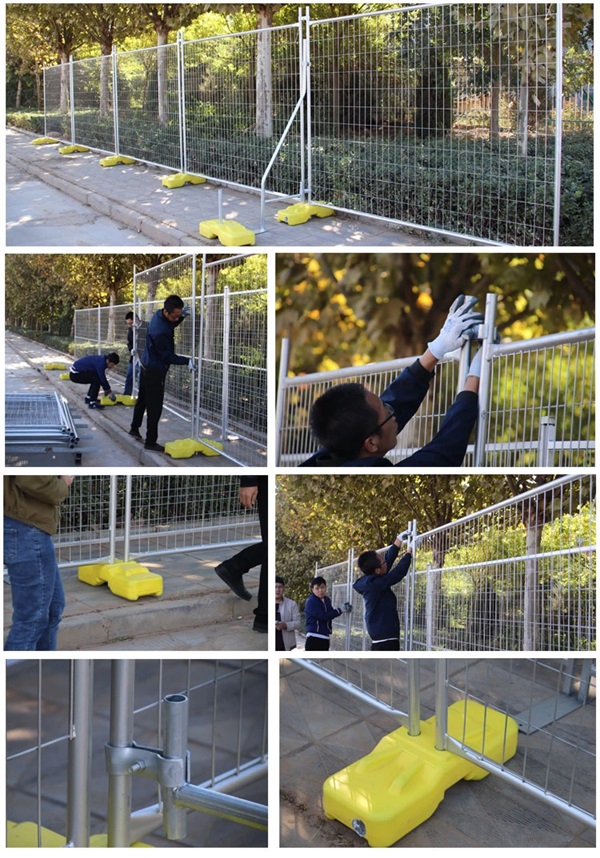

Portable Temporary Fence Panels Durable & Easy Setup

NewsJun.06,2025

-

Temporary Fabric Fencing Solutions Lightweight & Easy Setup

NewsJun.06,2025

-

Premium Movable Temporary Fences Security & Portability

NewsJun.06,2025

-

Temporary Construction Fencing Solutions Durable & Secure

NewsJun.05,2025