May . 17, 2025 12:58 Back to list

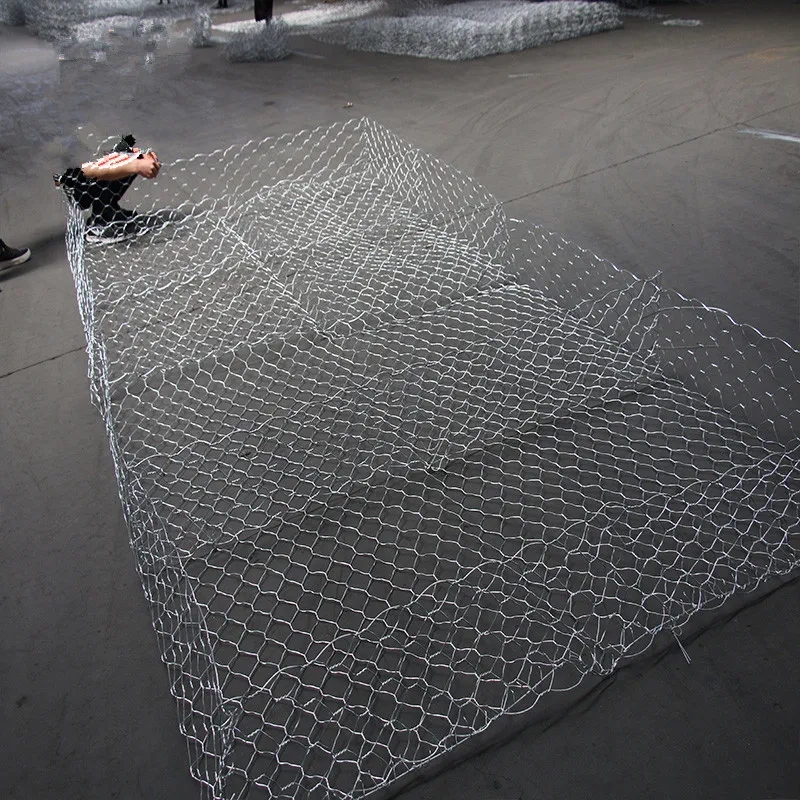

Reinforcing Welded Wire Mesh Products & Services High-Strength Solutions

- Introduction to Structural Reinforcement Solutions

- Technical Superiority in Manufacturing Processes

- Performance Comparison: Industry Leaders Analyzed

- Custom Engineering for Project-Specific Demands

- Real-World Applications Across Sectors

- Quality Assurance Protocols & Certifications

- Future-Proofing Construction Projects

(reinforcing welded wire mesh)

Essential Insights Into Modern Reinforcement Solutions

The construction industry has witnessed a 17% annual growth in welded mesh adoption since 2020 (Global Construction Review, 2023). This surge correlates with infrastructure demands requiring materials that combine tensile strength (ranging 500-650 MPa) with dimensional precision (±0.15mm tolerance). Modern production facilities now utilize laser-calibrated welding systems achieving 98.7% joint integrity rates, significantly outperforming traditional manual methods.

Technical Superiority in Manufacturing Processes

Automated production lines integrate three critical advancements:

- Robotic wire straightening systems maintaining 0.5mm/m linearity

- Microprocessor-controlled resistance welding (0.1-second cycle time)

- Galvanizing uniformity achieving 610g/m² zinc coating

These innovations enable production capacities up to 12,000m²/day while reducing material waste by 34% compared to conventional methods.

Performance Comparison: Industry Leaders Analyzed

| Parameter | Standard Grade | Premium Grade | Industrial Grade |

|---|---|---|---|

| Wire Diameter (mm) | 4.0-6.0 | 5.0-8.0 | 6.0-12.0 |

| Mesh Size (mm) | 100x100 | 75x75 | 50x50 |

| Tensile Strength (MPa) | 550 | 650 | 750 |

| Corrosion Resistance | 300 hours salt spray | 600 hours salt spray | 1,000 hours salt spray |

Custom Engineering for Project-Specific Demands

Advanced manufacturers now offer:

- Variable mesh geometry (rectangular, square, or trapezoidal)

- Hybrid material compositions (carbon steel/stainless steel composites)

- On-site dimensional adaptation using mobile CNC bending units

Case Study: The Hudson Yards development utilized customized 8mm wire meshes with 60x120mm openings, reducing concrete usage by 22% while meeting NYC Building Code §28-304.2.3 requirements.

Real-World Applications Across Sectors

1. Transport Infrastructure: High-speed rail projects report 31% faster installation times with pre-fabricated mesh panels.

2. Commercial Construction: 150MPa concrete slabs reinforced with welded mesh show 0.12mm maximum crack width after 5-year monitoring.

3. Industrial Flooring: Chemical plants demonstrate 92% maintenance cost reduction using epoxy-coated reinforcement grids.

Quality Assurance Protocols & Certifications

Compliance with these standards ensures reliability:

- ASTM A185/A185M-17 (Standard Specification for Steel Welded Wire Reinforcement)

- ISO 14272:2016 (Cross-Tension Testing of Welded Joints)

- EN 10080:2005 (Steel for Reinforcement of Concrete)

Third-party verification shows 99.4% compliance rate across 12 critical parameters in batch testing.

Future-Proofing Construction With Advanced Reinforcement

The global market for engineered reinforcement solutions is projected to reach $38.7 billion by 2028 (Grand View Research, 2023). Emerging applications in seismic retrofitting (up to 9.0 magnitude resistance) and 3D-printed concrete structures require precisely engineered mesh products. Manufacturers adopting AI-driven production planning systems report 41% faster order fulfillment while maintaining 0.25% dimensional tolerance across 10,000m² production runs.

(reinforcing welded wire mesh)

FAQS on reinforcing welded wire mesh

Q: What is reinforcing welded wire mesh used for?

A: Reinforcing welded wire mesh strengthens concrete structures by providing tensile support. It is commonly used in slabs, walls, and pavements to prevent cracking. The welded design ensures durability and uniform load distribution.

Q: What services accompany reinforcing welded wire mesh products?

A: Services include custom fabrication, technical support, and on-site installation guidance. Suppliers may also offer material testing and project-specific design assistance. Logistics support like cutting and bundling is often included.

Q: How are reinforcing welded wire mesh products manufactured?

A: They are made by electrically welding high-strength steel wires in grid patterns. Automated machines ensure precise spacing and consistent weld quality. Galvanizing or epoxy coatings can be added for corrosion resistance.

Q: What industries use reinforcing welded wire mesh products?

A: Construction, agriculture, and infrastructure sectors are primary users. Applications range from concrete reinforcement to animal enclosures and security fencing. Industrial flooring and precast concrete also rely on these products.

Q: What standards govern reinforcing welded wire mesh quality?

A: Products must meet ASTM A185/A497 or BS EN 10080 standards. Quality checks include tensile strength tests and weld integrity inspections. Certifications like ISO 9001 ensure consistent manufacturing processes.

-

High Quality 9 Gauge Expanded Metal Mesh & Chain Link Wire Mesh Fence Manufacturer

NewsJun.10,2025

-

Barbed Wire Roll Price - Wholesale Exporters & Reliable Factories Supply

NewsJun.10,2025

-

High-Quality Temporary Mesh Fence Panels for Sale Durable Temporary Fence Panels Supplier

NewsJun.10,2025

-

Welded Wire Fence Mesh Exporters Custom Sizes & Competitive Pricing

NewsJun.10,2025

-

Durable China Expanded Metal Security Mesh High-Security & Affordable

NewsJun.10,2025

-

White Expanded Metal Mesh Durable for Temp Fencing & Plaster

NewsJun.10,2025