Aug . 11, 2025 01:00 Back to list

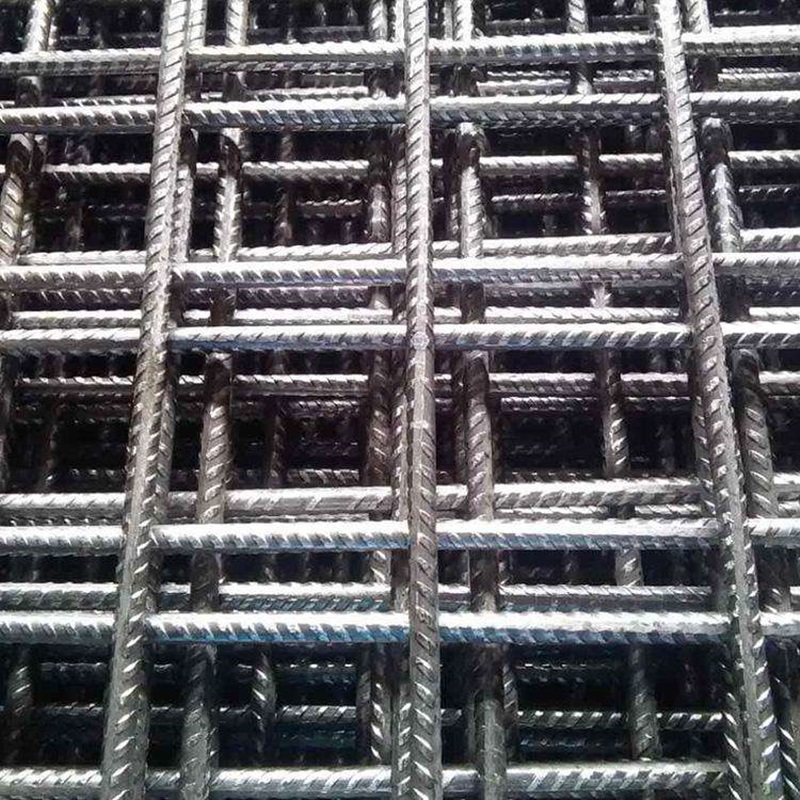

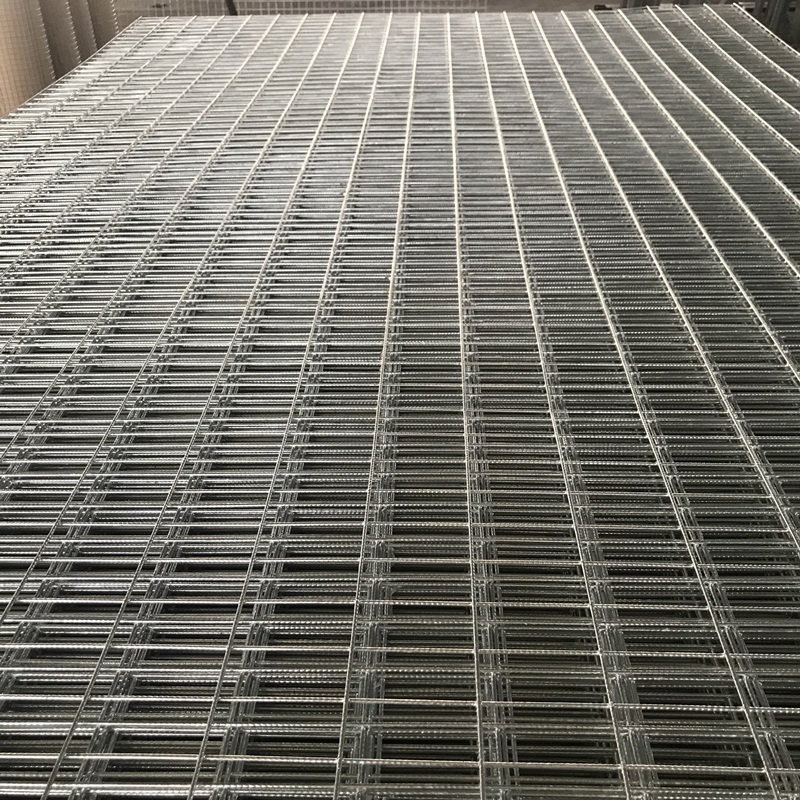

Reinforced Welded Wire Mesh: Durable Steel for Construction

Industry Trends in Welded Wire Mesh for Construction

The global construction industry is witnessing a significant shift towards more efficient, sustainable, and resilient building practices. This evolution is largely driven by rapid urbanization, infrastructure development needs, and increasing demands for disaster-resistant structures. Within this dynamic landscape, Construction Reinforced Steel Bar Welded Wire Mesh is emerging as a cornerstone material. Its adoption is accelerating due to its inherent advantages in reducing construction time, minimizing material waste, and enhancing structural integrity. Market analytics project a steady growth trajectory for this segment, underpinned by innovation in steel metallurgy and advanced welding techniques. Regions like Asia-Pacific and North America are leading in infrastructure investments, further bolstering the demand for high-performance reinforcement solutions. The emphasis on green building standards and stringent safety regulations also compels contractors to opt for pre-fabricated and quality-controlled materials like welded wire mesh, ensuring adherence to modern engineering specifications and long-term project viability.

Technological advancements are continuously improving the manufacturing precision and material properties of welded wire mesh. We are seeing a trend towards higher strength-to-weight ratios, better corrosion resistance through specialized coatings, and the integration of smart features for structural health monitoring. Furthermore, the push for modular construction and off-site prefabrication directly benefits from the standardized dimensions and ease of handling offered by welded wire mesh. This reduces on-site labor requirements and mitigates human error, contributing to overall project cost-effectiveness and faster completion rates. As infrastructure ages and new projects emerge, the demand for reliable, durable, and cost-efficient reinforcing solutions will only intensify, positioning Construction Reinforced Steel Bar Welded Wire Mesh at the forefront of modern building materials.

Technical Parameters and Specifications

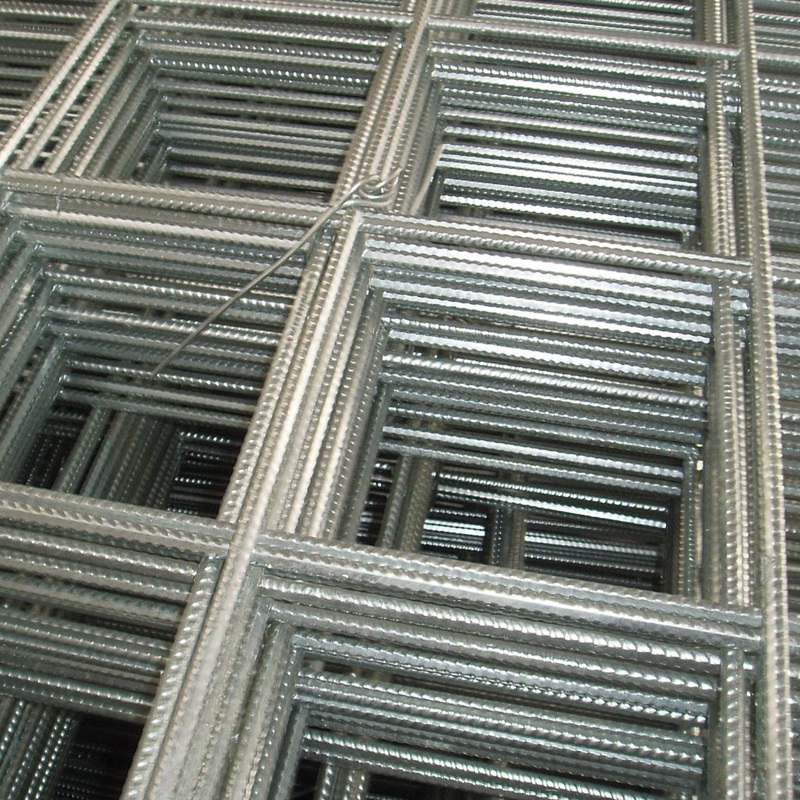

Understanding the technical parameters of Construction Reinforced Steel Bar Welded Wire Mesh is crucial for engineers and procurement specialists to ensure optimal structural performance. This product is typically manufactured from high-tensile, cold-drawn deformed steel wires or plain wires, conforming to international standards such as ASTM A1064/A1064M (Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete), BS 4483 (Steel Fabric for the Reinforcement of Concrete), or ISO 6935-3 (Steel for the reinforcement of concrete – Part 3: Welded fabric). Key specifications include wire diameter (ranging from 4mm to 12mm or more), mesh size (e.g., 100x100mm, 150x150mm, 200x200mm), and sheet dimensions. The quality of welds, critical for load transfer, is rigorously tested for shear strength and consistency, ensuring the mesh acts as a monolithic reinforcement unit. The precise control over spacing and wire gauge guarantees uniform stress distribution within concrete elements, significantly reducing the likelihood of cracking and spalling.

Below is a typical range of technical parameters for high-quality Construction Reinforced Steel Bar Welded Wire Mesh:

| Parameter | Typical Range/Value | Applicable Standards |

|---|---|---|

| Wire Diameter | 4mm - 12mm (or customized) | ASTM A1064, BS 4482, ISO 6935-2 |

| Mesh Opening (Pitch) | 50x50mm to 300x300mm (standard squares) | ASTM A1064, BS 4483 |

| Sheet Width | Up to 2.5m (standard) | Client Specific |

| Sheet Length | Up to 6m (standard) | Client Specific |

| Tensile Strength | 500 MPa (min) | ASTM A1064, BS 4482 |

| Yield Strength | 450 MPa (min) | ASTM A1064, BS 4482 |

| Weld Shear Strength | 250 N (per mm wire diameter) | ASTM A1064, BS 4483 |

| Material Grade | Plain Carbon Steel, Low Alloy Steel | Relevant Steel Standards |

Diverse Application Scenarios

The versatility of Construction Reinforced Steel Bar Welded Wire Mesh makes it indispensable across a broad spectrum of construction applications. Its primary role is to provide tensile reinforcement to concrete structures, compensating for concrete's inherent weakness in tension. Common applications include:

- Concrete Slabs: Widely used in ground slabs, suspended slabs, and elevated decks for commercial, industrial, and residential buildings to control cracking and enhance load-bearing capacity.

- Roads and Pavements: Essential for reinforcing highways, airport runways, and parking lots, where it helps distribute traffic loads and minimizes thermal cracking.

- Precast Concrete Elements: Integral to the production of precast walls, beams, columns, and pipes, offering consistent reinforcement and facilitating faster assembly on-site.

- Retaining Walls and Foundations: Provides critical stability and strength in structures subjected to lateral soil pressure and varying ground conditions.

- Shotcrete and Tunnel Linings: Applied as a reinforcement layer in sprayed concrete applications for slope stabilization, tunnel construction, and mining operations, ensuring cohesion and preventing rockfall.

- Agricultural Structures: Used in barns, silos, and other farm buildings for durable concrete floors and walls.

Technical Advantages and Benefits

The adoption of Construction Reinforced Steel Bar Welded Wire Mesh offers a multitude of technical and economic advantages over traditional rebar tying methods. Foremost among these is the significant reduction in on-site labor and installation time. Pre-fabricated mesh sheets can be laid out quickly, reducing dependency on skilled manual labor for tying individual bars. This translates directly into accelerated project timelines and reduced labor costs. Furthermore, the precise spacing of wires achieved during manufacturing ensures uniform stress distribution within the concrete, minimizing the risk of rebar displacement during concrete pouring and ensuring consistent structural integrity. This accuracy is paramount in critical infrastructure projects where even minor deviations can compromise safety and longevity.

From an engineering perspective, welded wire mesh contributes to superior crack control. The smaller, more closely spaced wires provide a larger surface area for bond with concrete, effectively distributing tensile stresses and limiting the propagation of micro-cracks into visible fissures. This results in more durable concrete elements with extended service life, particularly beneficial in environments subjected to thermal cycling or heavy loads. The product's inherent material efficiency also leads to less waste on-site, contributing to more sustainable construction practices. Compared to loose rebar systems, welded wire mesh allows for better material optimization, as precise quantities can be manufactured and delivered, reducing off-cuts and scrap. This combination of efficiency, enhanced structural performance, and environmental benefits makes Construction Reinforced Steel Bar Welded Wire Mesh a technically superior choice for modern construction.

Manufacturer Comparison and Selection Criteria

Selecting the right manufacturer for Construction Reinforced Steel Bar Welded Wire Mesh is a critical decision that impacts project quality, schedule, and cost. While specific company names are not discussed here, key criteria for evaluating potential suppliers include adherence to international standards (e.g., ISO 9001 for quality management), range of products offered (customization capabilities), consistency of material quality, and proven track record in delivering large-scale projects. Reputable manufacturers will provide comprehensive material test reports, demonstrating compliance with specified tensile strength, yield strength, and weld shear strength values. They typically employ advanced automated welding lines, ensuring uniform mesh geometry and superior weld integrity, which is paramount for structural reliability.

Consideration should also be given to logistical capabilities, including packaging, transportation, and delivery lead times, particularly for just-in-time construction models. A supplier with robust supply chain management can significantly mitigate project delays. Furthermore, strong technical support and after-sales service are indicators of a committed partner. This includes assistance with product selection, installation guidance, and addressing any unforeseen challenges. While cost is always a factor, prioritizing a manufacturer's commitment to quality, reliability, and service over merely the lowest price will invariably lead to better long-term project outcomes and reduced risk. Investing in high-quality Construction Reinforced Steel Bar Welded Wire Mesh from a reputable source ensures the structural longevity and safety of the built environment.

Customization Solutions

Modern construction projects often demand tailor-made solutions beyond standard product offerings. Recognizing this, leading manufacturers of Construction Reinforced Steel Bar Welded Wire Mesh provide extensive customization capabilities. This flexibility allows engineers and contractors to specify precise wire diameters, mesh openings (both square and rectangular patterns), and sheet dimensions to perfectly match unique structural requirements. Customization can involve varying wire gauges within the same sheet (e.g., heavier wires in one direction for specific load paths), or creating complex shapes and cut-outs to integrate with other structural elements like columns or openings. This bespoke approach minimizes material waste on-site and significantly reduces the need for manual cutting and tying, thereby enhancing construction efficiency and safety.

Beyond geometry, customization extends to material types and surface treatments. For projects in corrosive environments, options like galvanized or epoxy-coated welded wire mesh can be provided, offering enhanced resistance to rust and chemical degradation, thereby extending the service life of the concrete structure. Such specialized coatings are critical in applications like marine structures, wastewater treatment plants, or industrial facilities. The ability to receive pre-cut and pre-shaped mesh sheets directly from the factory reduces on-site fabrication time, accelerates installation, and ensures higher quality control compared to traditional methods. By collaborating closely with clients, manufacturers can leverage their advanced production lines to deliver precision-engineered Construction Reinforced Steel Bar Welded Wire Mesh that fully aligns with project specifications and performance expectations.

Illustrative Application Cases

The practical advantages of Construction Reinforced Steel Bar Welded Wire Mesh are best exemplified through real-world applications. Consider a major highway expansion project in a rapidly developing urban area. The need for rapid construction and durable road surfaces is paramount. By utilizing pre-fabricated welded wire mesh in the concrete pavement layers, engineers can significantly reduce the time spent on rebar placement and tying. This not only accelerates the road laying process but also ensures consistent reinforcement, leading to pavements that are more resistant to cracking under heavy traffic loads and extreme weather conditions. The uniform mesh spacing provides superior crack control, contributing to a longer service life and reduced maintenance costs for the highway authority.

Another compelling example is a multi-story car park construction project. Given the large surface area of concrete slabs involved, the efficiency of reinforcement installation directly impacts the project timeline. By employing large sheets of Construction Reinforced Steel Bar Welded Wire Mesh, installation crews can cover vast areas quickly, dramatically cutting down the labor hours required compared to traditional rebar. This efficiency gain allows for faster pouring cycles and earlier completion of structural phases. Moreover, the controlled spacing of the mesh ensures robust support for vehicle loads and pedestrian traffic over decades of use, minimizing slab deflection and enhancing the overall safety and longevity of the structure. These cases underscore the tangible benefits of using advanced reinforcement solutions in modern construction.

Detailed Manufacturing Process Flow

The manufacturing of high-quality Construction Reinforced Steel Bar Welded Wire Mesh involves a meticulously controlled process, starting from raw material selection to final quality inspection. The primary raw material is high-quality carbon steel wire rod, typically sourced from reputable steel mills. This wire rod undergoes cold drawing, a process that increases its tensile strength and yield strength while simultaneously creating a uniform diameter and often deforming its surface for better concrete bonding. This cold working enhances the mechanical properties of the steel, making it ideal for reinforcement applications.

The refined steel wires are then fed into highly automated welding machines. These machines are equipped with precision controls that ensure accurate spacing of both longitudinal and transverse wires. Resistance welding, often synchronized by advanced computer numerical control (CNC) systems, is employed to fuse the intersecting wires at every joint. This method guarantees strong, consistent welds without the need for additional filler material, creating a monolithic mesh structure. Post-welding, the mesh sheets undergo rigorous quality control checks, including visual inspections for defects, dimensional accuracy verification (mesh size, wire diameter, sheet dimensions), and mechanical testing for weld shear strength, tensile strength, and bend properties in accordance with standards like ISO 9001, ASTM, and BS EN. These stringent tests ensure the product meets critical performance criteria. The typical service life of properly embedded welded wire mesh mirrors that of the concrete structure itself, often exceeding 50-100 years, due to its inherent material stability and protection within the concrete matrix, which also provides significant corrosion resistance and thermal insulation. This product is predominantly utilized across a wide array of industries including civil engineering, building construction, transportation infrastructure, and precast concrete manufacturing, offering advantages like faster installation, reduced material waste, and enhanced structural integrity.

Frequently Asked Questions (FAQ)

-

Q1: What is the primary benefit of using Construction Reinforced Steel Bar Welded Wire Mesh over traditional rebar?

A1: The primary benefit is significant time and labor savings during installation due to its pre-fabricated nature. It also ensures consistent bar spacing and superior crack control, leading to more predictable structural performance and reduced material waste on-site compared to manually tied rebar.

-

Q2: What standards does your Construction Reinforced Steel Bar Welded Wire Mesh comply with?

A2: Our welded wire mesh products rigorously adhere to leading international standards such as ASTM A1064/A1064M, BS 4483, and ISO 6935-3. We ensure all mechanical properties, including tensile strength, yield strength, and weld shear strength, meet or exceed these specified requirements, backed by comprehensive test reports.

-

Q3: Can Construction Reinforced Steel Bar Welded Wire Mesh be customized for specific project needs?

A3: Absolutely. We offer extensive customization options, including varying wire diameters, mesh openings (both square and rectangular), and sheet dimensions. We can also provide specialized coatings like galvanization or epoxy for enhanced corrosion resistance in challenging environments. Our goal is to provide tailor-made solutions for optimal project efficiency.

-

Q4: What is the typical lead time for delivery?

A4: Delivery times for Construction Reinforced Steel Bar Welded Wire Mesh vary depending on order volume, customization requirements, and current production schedules. For standard sizes and quantities, typical lead times range from 2-4 weeks. For large or highly customized orders, we work closely with clients to establish a realistic and efficient delivery schedule, ensuring timely project progression. We pride ourselves on transparent communication and reliable logistics to meet your project deadlines.

Quality Assurance and Customer Support

Our commitment to quality for Construction Reinforced Steel Bar Welded Wire Mesh is unwavering, underpinned by stringent quality assurance protocols at every stage of the manufacturing process. From raw material inspection to automated welding and final product testing, each batch undergoes meticulous scrutiny to ensure compliance with international standards and client specifications. We maintain ISO 9001 certification, demonstrating our adherence to globally recognized quality management systems. Our in-house laboratory conducts regular mechanical tests, including tensile strength, yield strength, and crucial weld shear strength tests, to guarantee the integrity and performance of every mesh sheet. Detailed material certificates and test reports are provided with each shipment, offering complete traceability and assurance of product quality.

Beyond product quality, we prioritize exceptional customer support. Our dedicated team of technical experts and sales professionals is available to provide comprehensive assistance, from initial consultation and specification development to logistical planning and post-delivery support. We offer expert guidance on product selection, optimal usage, and customization options for Construction Reinforced Steel Bar Welded Wire Mesh, ensuring that our clients receive the most suitable and cost-effective solutions for their projects. Our robust customer service includes responsive communication channels, quick resolution of inquiries, and a firm commitment to client satisfaction, reflecting our long-term partnership approach in the B2B sector. We stand by the quality of our products with a comprehensive warranty, ensuring peace of mind for our clients and the longevity of their infrastructure investments.

Authoritative References

- American Society for Testing and Materials. (Latest Edition). ASTM A1064/A1064M: Standard Specification for Steel Wire and Welded Wire Reinforcement, Plain and Deformed, for Concrete. ASTM International.

- British Standards Institution. (Latest Edition). BS 4483: Steel fabric for the reinforcement of concrete – Specification. BSI Standards Limited.

- International Organization for Standardization. (Latest Edition). ISO 6935-3: Steel for the reinforcement of concrete – Part 3: Welded fabric. ISO.

- PCA (Portland Cement Association). (Various Publications). Design and Control of Concrete Mixtures. PCA.

- ACI (American Concrete Institute). (Various Publications). ACI 318: Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025