Oct . 02, 2025 10:45 Back to list

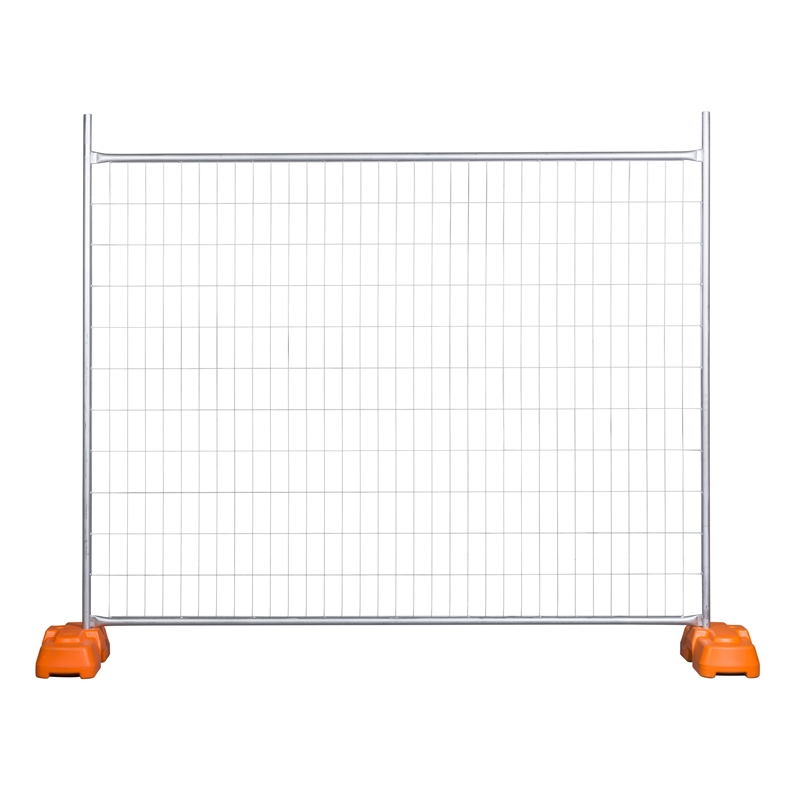

Hop Dipped Galvanized /PVC Coated Temporary Fence: Secure?

Field Notes on a Fence That Works: Hop Dipped Galvanized /PVC Coated Temporary Fence

I’ve stood on more muddy job sites than I care to admit, and to be honest, temporary fencing is one of those things you only notice when it fails. This one—made in Anping, Hebei, a place that lives and breathes wire mesh—comes from 200 meters north of Huangcheng Village. Local know-how shows. The finish holds, the welds don’t crack, and crews stop grumbling. Little things add up.

Why it’s trending

Rental fleets want longer life and fewer touch-ups. That’s pushed a shift from light electro-galvanized panels to hot-dip zinc plus PVC topcoats. In fact, site owners now ask for salt-spray data before they ask about price—funny, but true. This Hop Dipped Galvanized /PVC Coated Temporary Fence sits right in that sweet spot: rugged core steel, robust coating stack, still surprisingly easy to handle.

Core specifications (typical, customizable)

| Material | Q195/Q235 mild steel (yield ≈195–235 MPa) |

| Panel Size | 2.1×2.4 m (≈6.9×7.9 ft) or per drawing |

| Mesh Aperture | 60×150 mm or 50×100 mm |

| Wire Diameter | 3.0–4.5 mm (core), welded |

| Frame Tube | OD 32–38 mm, 1.2–1.5 mm wall |

| Finish | Hot-dip galvanized (Zn ≈70–100 μm), optional PVC topcoat |

| Base/Foot | Recycled rubber or HDPE, anti-tip design |

| Certificates | ISO 9001; coating per ISO 1461/ASTM A123 (≈) |

How it’s made (quick process flow)

- Raw steel: Q195/Q235 wire and tube, mill-certified.

- Welding: resistance-welded mesh to frame; corner fishplates for rigidity.

- Galvanizing: hot-dip per ISO 1461/ASTM A123; option electro-galv for budget builds.

- PVC coat: bonded topcoat (≈80–120 μm) to EN 10244-2 class D, color-coded if needed.

- Testing: salt spray (ASTM B117 500–1000 h depending on spec), adhesion (ASTM D3359), weld shear, drop tests.

Service life? In a C3 urban/industrial climate, hot-dip + PVC typically runs 8–15 years; coastal C4 drops that, but still solid. Real-world use may vary—mud, salt, forklift bumps do their thing.

Where it’s used (and why crews like it)

Construction perimeters, roadworks, industrial platforms, crowd control at events, even mining laydowns. Many customers say the PVC topcoat helps with brand color and cuts rust streaks on concrete. The Hop Dipped Galvanized /PVC Coated Temporary Fence slots into standard feet and clamps, so rental turnaround is quick.

Vendor comparison (field-driven)

| Vendor | Coating & Build | Pros | Watch-outs |

|---|---|---|---|

| XZ Metal (Anping) | Hot-dip + PVC option; 3.5–4.5 mm wire | Long life, consistent welds, ISO 9001 | Slightly higher upfront than electro-galv |

| Local Fabricator | Painted or light electro-galv | Fast lead times, small-batch tweaks | Shorter corrosion life; repaint cycles |

| Import Broker Mix | Varies by lot | Aggressive pricing | Spec variability; QC depends on source |

Customization

- Panel sizes, mesh spacing, and wire diameter per drawing.

- Colors: safety orange, hi-vis yellow, corporate RALs.

- Anti-climb mesh, wind bracing, debris/screen panels, gated sections.

- Branding plates and QR asset tags—surprisingly handy for fleets.

Case snaps and feedback

A coastal roadworks contractor reported zero rust bleed after a wet 10‑month season—PVC topcoat clearly doing the heavy lifting. An event organizer liked the quieter handling (less metal-on-metal clatter) and quick clamp fit. I guess the takeaway is simple: fewer call-backs.

Standards & references

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel products.

- ASTM A123/A153: Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- EN 10244-2: Steel wire and wire products — PVC coated wire (coating classes).

- ISO 9001: Quality management systems — Requirements.

- OSHA 29 CFR 1926 Subpart G: Signs, signals, and barricades (site control context).

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025