Dek . 21, 2024 18:46 Back to list

Galvanized Fence Manufacturing Plants and Their Key Features and Benefits

The Rise of Galvanized Fence Factories An Overview of Innovation and Sustainability

In recent years, the concept of galvanized fence factories has gained significant traction in the construction and landscaping industries. These specialized facilities not only produce durable fencing solutions but also serve as a model of efficiency and environmental responsibility. This article delves into the workings, benefits, and future prospects of galvanized fence factories.

Understanding Galvanization

Galvanization is a process that involves coating metal—often steel or iron—with zinc to prevent rust and corrosion. This protective layer dramatically extends the lifespan of the material, making it an ideal choice for outdoor applications such as fencing. Galvanized fences are known for their strength, longevity, and minimal maintenance needs, making them a popular choice for both residential and commercial properties.

The Manufacturing Process

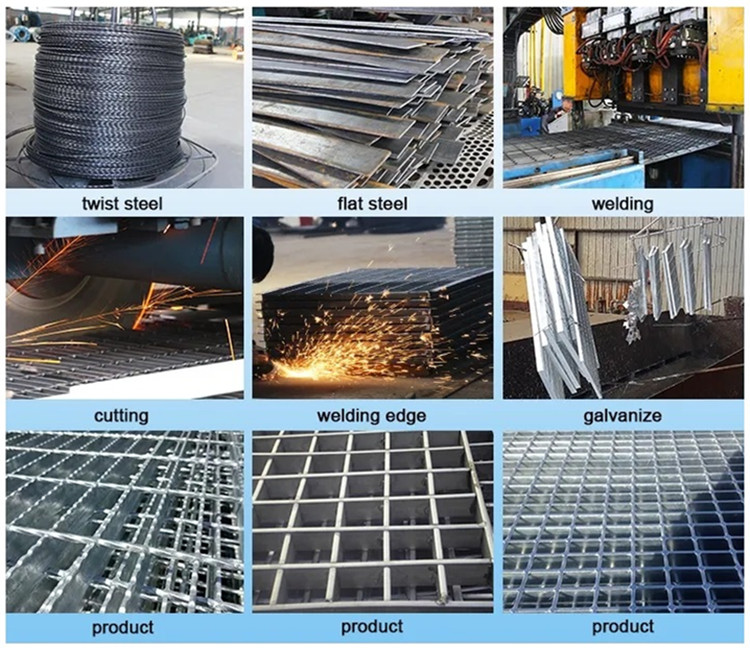

Galvanized fence factories utilize advanced manufacturing techniques to streamline production while ensuring high-quality output. The process generally begins with raw material selection, where high-grade steel is chosen for its structural integrity. The steel is then cut, shaped, and welded to form various components of the fence, including posts, panels, and gates.

Once the pieces are formed, they undergo the galvanization process. This involves cleaning and preparing the steel surface, followed by immersion in a molten zinc bath, which coats the metal evenly. The final step entails cooling and inspection, ensuring that each piece meets stringent quality standards. This high level of automation not only speeds up production but also minimizes waste, leading to a more sustainable manufacturing process.

Economic and Environmental Advantages

Galvanized fences offer numerous economic benefits. Due to their extended lifespan—often exceeding 50 years—homeowners and business owners can save significantly in replacement costs and maintenance expenses. Moreover, galvanized fencing is particularly resilient against harsh weather conditions, reducing the need for frequent repairs.

galvanized fence factories

From an environmental perspective, galvanized fence factories are designed to embrace sustainability. The use of zinc, a naturally abundant material, reduces reliance on synthetic coatings that may be harmful to the environment. Furthermore, the recycling rates of galvanized steel are high, allowing old fences to be melted down and repurposed for new projects. Many factories adopt eco-friendly practices such as responsible waste management, energy-efficient machinery, and water recycling systems, setting a standard within the industry.

Market Demand and Trends

The demand for galvanized fencing continues to rise, driven by urbanization and the growing emphasis on security and aesthetics in property design. In urban settings, where space is premium, the need for reliable boundary solutions remains critical. Galvanized fences are not only robust but also versatile, available in a variety of styles and finishes that cater to diverse architectural themes.

Moreover, the trend toward DIY home improvement projects has spurred growth in the market. Homeowners seek durable, low-maintenance solutions that enhance property value without a hefty price tag. As technological advancements continue to emerge, factories are incorporating smart manufacturing techniques that allow for customization and quick turnaround times.

The Future of Galvanized Fence Factories

Looking forward, the landscape of galvanized fence manufacturing appears promising. Innovations in production technology and materials science are paving the way for even greater advancements. Companies are now exploring the use of corrosion-resistant alloys and eco-friendly coatings that can complement or replace traditional galvanization.

Additionally, as global awareness of environmental issues continues to rise, customers are likely to prefer products that align with sustainable practices, pushing galvanized fence factories to adopt greener manufacturing processes. This alignment with eco-conscious consumer preferences will not only strengthen market position but also contribute to the broader goal of sustainable development in the construction industry.

Conclusion

In conclusion, galvanized fence factories are at the forefront of a growing trend toward durability and sustainability in fencing solutions. Their innovative manufacturing processes, combined with economic and environmental benefits, make them a formidable player in the construction market. As consumer preferences evolve and technology advances, the future of galvanized fencing looks brighter than ever, promising a robust solution for property owners seeking longevity and style.

-

Steel Expanded Metal Mesh Fence: Secure & Durable Perimeter Solution

NewsAug.05,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd | Durable, Versatile, Secure

NewsAug.04,2025

-

Double Loop Concertina Razor Barbed Wire Coil - High-Security Fencing

NewsAug.04,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence-Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Durable Temporary Fencing, Corrosion Resistant Solutions

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Durable Temporary Fencing Solutions&Customizable Security Systems

NewsAug.03,2025

-

Hop Dipped Galvanized / PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Corrosion Resistant&Modular Design

NewsAug.03,2025