Oct . 28, 2025 10:55 Back to list

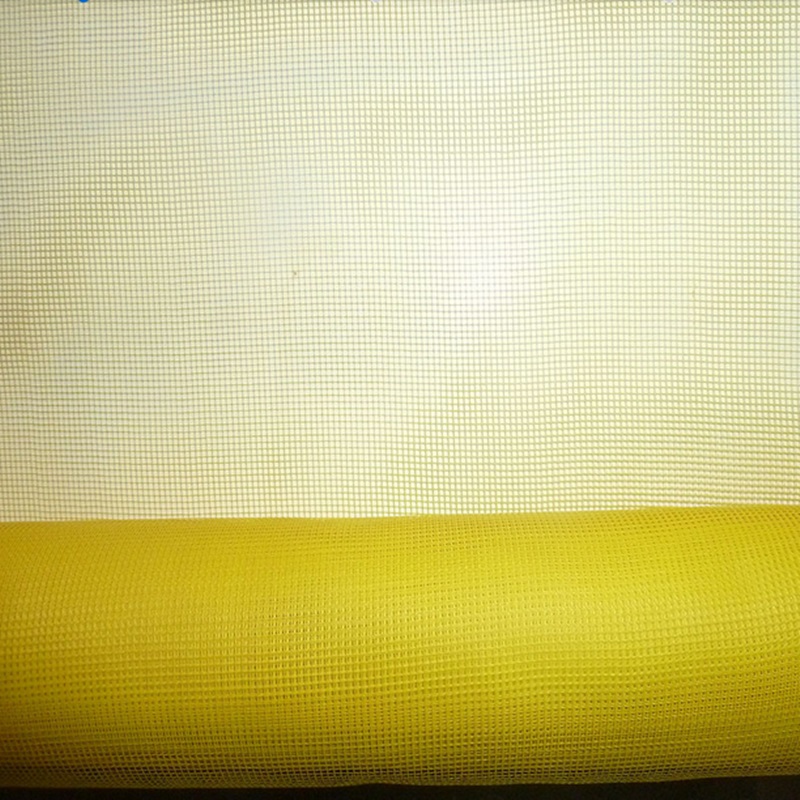

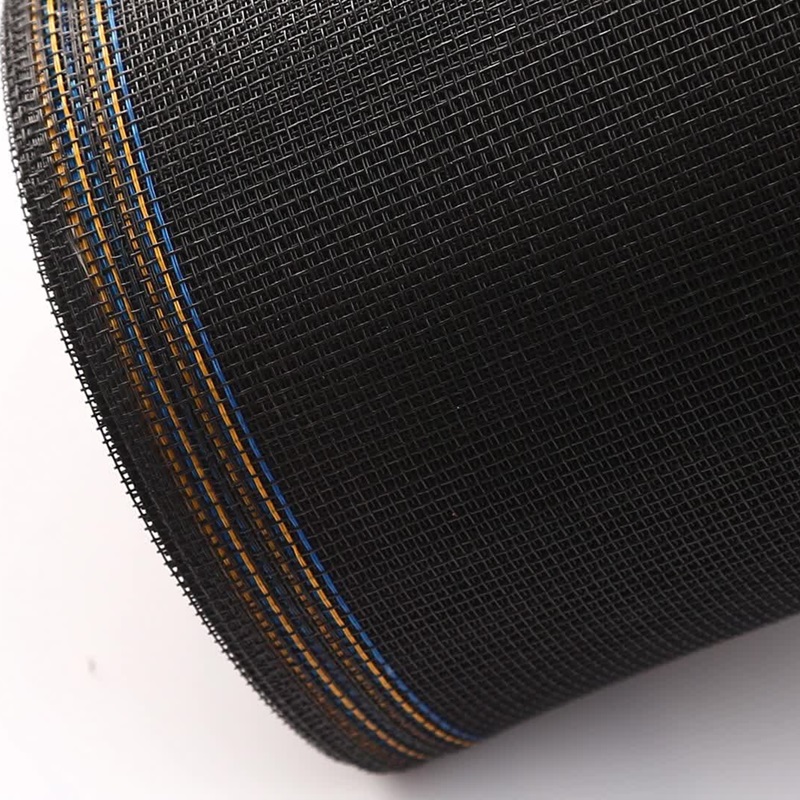

Plastic Window Screen & Plastic Insect Mesh | UV-Resistant

Choosing insect mesh that actually lasts: field notes from sites and factories

Today I’m looking at Plastic Window Screen/plastic Insect Mesh—the quiet hero behind bug-free rooms and clean-air intakes. If you’ve ever fought with brittle fiberglass or dented aluminum, you’ll know why many installers are shifting to HDPE-based meshes. Trends? UV-stabilized polyethylene, wider widths for faster glazing, and color tones that blend with modern frames. Sounds dull until you save a few hours per block in rework.

What it is (and why builders prefer it)

This mesh is extruded HDPE monofilament woven in plain weave, then heat-set. Compared with fiberglass, it resists crease marks and edge fray; versus aluminum, it won’t dent or corrode near coastal air. To be honest, the big win is predictable install—many customers say it stretches “just enough” to tension without puckering.

Typical specifications (custom sizes available)

| Parameter | Typical value | Notes |

|---|---|---|

| Material | HDPE, UV-stabilized | Polyethylene per product spec |

| Mesh count | 16×16 or 14×14 | Others on request |

| Monofilament Ø | ≈0.28–0.30 mm | Real-world use may vary |

| Open area | ≈65–70% | Balances airflow vs. pest control |

| Width × Roll length | 0.8–1.6 m × 30–100 m | Custom cuts available |

| Colors | Black, grey (others optional) | Aesthetic/visibility choice |

| Operating temp | -30 to 70 °C | Ambient building use |

| Certification | ISO 9001 | Factory QMS |

Process, testing, and service life

- Materials: HDPE resin with UV absorbers, pigment masterbatch; optional FR package.

- Methods: monofilament extrusion → plain-weave looms → heat-setting → edge trimming → inspection.

- Testing: mesh count (ASTM D3775), tensile (ISO 13934-1), UV aging (ISO 4892-2), visual defects per AQL.

- Typical lab data: 3000 h UV-B exposure with no embrittlement and

- Service life: around 3–5 years outdoors in temperate zones; longer indoors. Coastal UV and sand may shorten life.

Where it’s used

Windows and doors in residential towers, warehouse louvers, greenhouse vents, and, surprisingly, some printing field applications as a support mesh. Facility managers like that Plastic Window Screen/plastic Insect Mesh doesn’t shed fibers into clean zones.

Vendor snapshot (what to look for)

| Vendor | UV package | MOQ | Lead time | Certificates |

|---|---|---|---|---|

| XZ Metal (Anping, Hebei) | Yes (2–3% typical) | Low–medium | 7–15 days | ISO 9001; RoHS/REACH statements |

| Generic broker | Varies | Medium | 15–30 days | Mixed |

| Aluminum screen maker | N/A | Medium | 10–20 days | ISO 9001 |

Customization and options

Mesh counts, widths, roll lengths, and colors are all adjustable. FR additives can be formulated to help meet local building requirements (e.g., UL 94 HB–level behavior, where applicable—testing required). Private labeling and barcodes for retail? Easy. Packaging in 30 m DIY rolls or 100 m contractor rolls.

Mini case notes

- Coastal hotel retrofit (Hainan): swapped aluminum for Plastic Window Screen/plastic Insect Mesh to avoid salt-spray corrosion; maintenance tickets reportedly dropped in the wet season.

- Greenhouse vents (Mediterranean): 16×16 black mesh improved airflow vs. 18×18 fiberglass while still blocking whiteflies, according to the agronomist on site.

- Food packing hall: black mesh reduced glare and moiré vs. stainless screens on high-CRI lighting. Small win, big smiles.

Origin: 200 meters North Of Huangcheng Village, Anping, Hebei, China. If you need quotes or a tech sheet for Plastic Window Screen/plastic Insect Mesh, ask for UV formulation percentage and the exact mesh count—saves a lot of back-and-forth.

References

- ISO 4892-2: Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps.

- ASTM D3775: Standard Test Method for End (Warp) and Pick (Filling) Count of Woven Fabrics.

- ISO 13934-1: Textiles — Tensile properties of fabrics — Part 1: Strip method.

- ISO 9001:2015 Quality management systems — Requirements.

- REACH Regulation (EC) No 1907/2006 — Registration, Evaluation, Authorisation and Restriction of Chemicals.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025