Jul . 31, 2025 15:40 Back to list

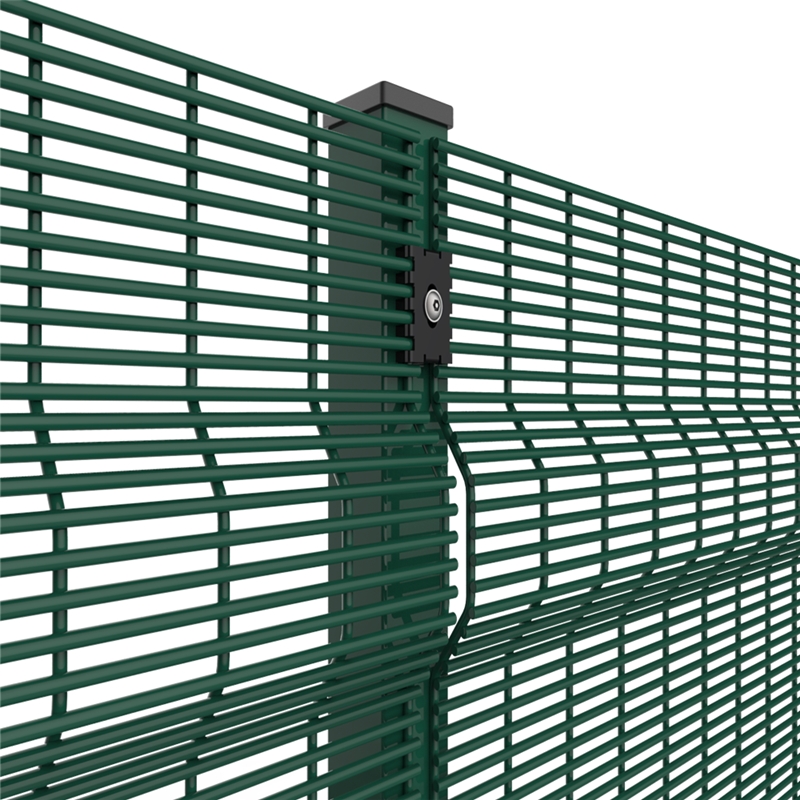

358 Anti-Climb Welded Wire Mesh Fence - High Security, Durable

358 Anti Climb Welded Wire Mesh Fence—the gold standard in high-security fencing. Discover complete data, technological processes, comparative analyses, and proven application cases. Whether you are in petrochemical, metallurgy, water supply, or infrastructure, this industrial-grade solution, certified with international standards like ISO and ANSI, offers robust safety with customizable options.

Over the past decade, the global perimeter security market has grown at a CAGR of 7.2% (Ref: Grand View Research), with the high-security welded mesh segment—especially 358 Anti Climb Welded Wire Mesh Fence—seeing strongest uptake. Its no-cut, anti-climb, high-visibility design is mandated in more than 50% of new high-risk infrastructure projects as per the 2023 IFSEC report.

Precision engineering is at the core of the 358 Anti Climb Welded Wire Mesh Fence. The "358" name comes from its mesh size—3”×0.5”×8 gauge—offering unmatched resistance against cutting and climbing. Let's explore the technical data:

| Parameter | Specification | Industry Reference | Testing Standard |

|---|---|---|---|

| Mesh Aperture | 76.2 × 12.7mm (3” × 0.5”) | ISO 1794-2015 | ISO 9227 |

| Wire Diameter | 4.0 mm (8 Gauge) | BS EN 10218-2:2012 | ISO 6892 |

| Panel Size | 2.0m–2.5m (H) × 2.2m–3.0m (W) | Customizable | ANSI/AISC 360 |

| Surface Finish | Hot-dip galvanized / PVC coated | ISO 1461 | ASTM B117 |

| Anti-Corrosion | ≥20 years outdoor | ISO 12944 | ISO 9227 |

| Weld Strength | >1000 N | EN 10223-7 | ISO 14343 |

| Color Options | Green, Black, Grey (RAL Customization) | RAL Standards | - |

- Anti-Climb & Anti-Cut: Ultra-tight mesh (3” x 0.5”) and 4.0mm high-carbon steel wire resist climbing and sawing. Complies with ISO 1794 and ASTM F2453.

- Superior Galvanized Coating: Hot-dip zinc layer ≥ 275g/m², achieving ≥ 20 years anti-corrosion outdoors (ISO 1461, ASTM B117).

- Enhanced Weld Integrity: Minimum joint strength > 1000N. Cross welds resist high-impact vibration and prying (EN 10223-7 test).

- Materials: Low-carbon Q235 steel or optional AISI 304 stainless for critical needs. RoHS-compliant coatings available upon request.

- Customization: Sizes, surface color (RAL), anti-cut grade, and fixing mechanisms are fully customizable to project specs.

- Certifications: ISO9001:2015, ISO14001, OSHA, ANSI/AISC 360 validated. Factory verified by SGS, TUV.

| Fence Type | Mesh Size (mm) | Wire Dia (mm) | Cut Resistance | Anti-Climb | Visibility | Lifespan (yrs) | Corrosion Standard |

|---|---|---|---|---|---|---|---|

| 358 Anti Climb Welded Wire Mesh Fence | 76.2×12.7 | 4.0 | High | Excellent | √√√ | 20–30 | ISO1461 |

| Chain Link Fence | 50×50 | 2.5–3.0 | Medium | Poor | √√ | 10–15 | ASTM A392 |

| Welded Mesh Panel | 100×50 | 3.0–4.0 | Medium | Moderate | √√ | 12–20 | ISO1461 |

| Steel Palisade | - | 3.0–4.5 | High | Good | √ | 15–25 | ISO12944 |

- Design to Specification: Panels, posts, brackets, and gates are engineered per project wind-load, impact, or aesthetic needs.

- On-site Survey: 3D terrain mapping, boundary assessment, and CAD fencing layout provided for large-scale projects.

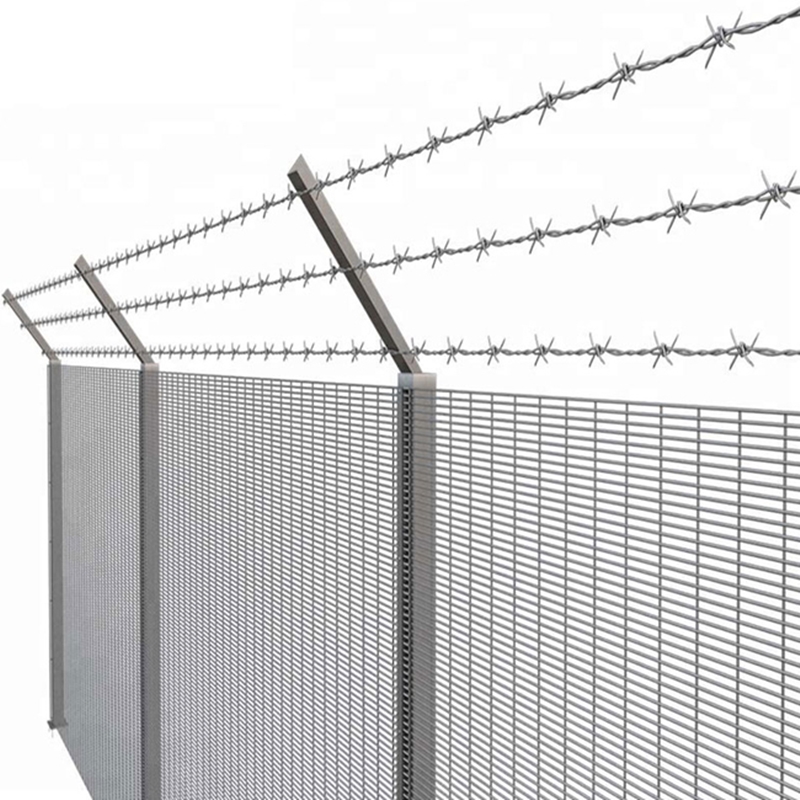

- Integrated Security: Sensors, electrification, razor topping, alarm system integration available for ultimate facility hardening.

- Rapid Production: 358 Anti Climb Welded Wire Mesh Fence lead times as short as 10–15 working days, sea/air/road delivery globally.

- Installation Training: Stepwise installation manuals (per ASTM F2611), video remote guidance, and international teams available.

- Documentation: All deliveries include QA traceability, mill certs, third-party SGS/TUV inspection reports.

Warranty: ≥15 years against weld failure/corrosion. Full replacement for defects.

Customer Support: 24/7 pre-sales and after-sales service—multi-language engineers available.

Certifications Supplied: EN 10223, ISO9001 (downloadable), TUV/SGS 3rd party test reports on request.

The 358 Anti Climb Welded Wire Mesh Fence is the preferred solution in environments with strict perimeter constraints, including:

- Petrochemical Sites & Refineries (explosion-proof grid fenced zones, hazardous area security)

- Power Plants & Utility Yards (critical asset protection, NERC CIP standards compliance)

- Industrial & Port Warehouses (inventory theft prevention, anti-vehicle penetration)

- Correctional Facilities, Airports, Border Security (anti-escape/deterrence, surveillance visibility)

- Municipal Infrastructure (railway, highway, waterworks perimeter safety)

Project Scope: 7,800m fencing around explosive-risk zones.

Key Requirements: >20 years corrosion resistance, full anti-cut/anti-climb, ASTM/EU code compliance.

Solution: Custom hot-dip galvanized 358 Anti Climb Welded Wire Mesh Fence panels with stainless fittings, integrated security lights, and remote video monitoring.

Results: Achieved zero perimeter breaches in 18 months operation, confirmed by client security audits.

Client Feedback: “XZMETAL's fencing met rigorous ISO/ANSI standards—installation was quick and site security reports show no incursions since deployment” (Plant EHS Director, 2024).

Scope: 1,200m perimeter, dual-layer mesh, under 14-day installation.

Outcome: No successful climb or cut-breach attempts; successfully passed third-party intrusion simulation (per EN 1627).

https://www.ifsecglobal.com/security/security-fencing-types/

Reference 2: "Perimeter Fencing and Welded Mesh—Performance and Testing," Security Journal Europe, 2022. Read more

Reference 3: Grand View Research, "Perimeter Security Market Size, 2023–2030" Industry Analysis

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025