May . 07, 2025 19:21 Back to list

Plastic Chain Link Mesh Fence Durable, Lightweight & UV-Resistant Solutions

- Introduction to Chain Link Mesh Fence Solutions

- Technical Advantages of Modern Plastic Chain Link Systems

- Comparative Analysis of Leading Global Suppliers

- Customization Capabilities for Specialized Projects

- Performance Metrics Across Environmental Conditions

- Implementation Case Studies in Commercial Infrastructure

- Selecting Reliable Plastic Chain Link Mesh Fence Factories

(chain link mesh fence)

Chain Link Mesh Fence: Engineering Resilience for Modern Security

The global market for chain link mesh fencing reached $3.8 billion in 2023, with plastic-coated variants accounting for 42% of industrial applications. Plastic chain link mesh fence

factories have developed advanced polymer formulations that withstand temperatures from -40°F to 180°F while maintaining structural integrity. This evolution addresses critical pain points in coastal installations where traditional galvanized fences fail within 3-5 years due to salt corrosion.

Technical Advantages of Modern Plastic Chain Link Systems

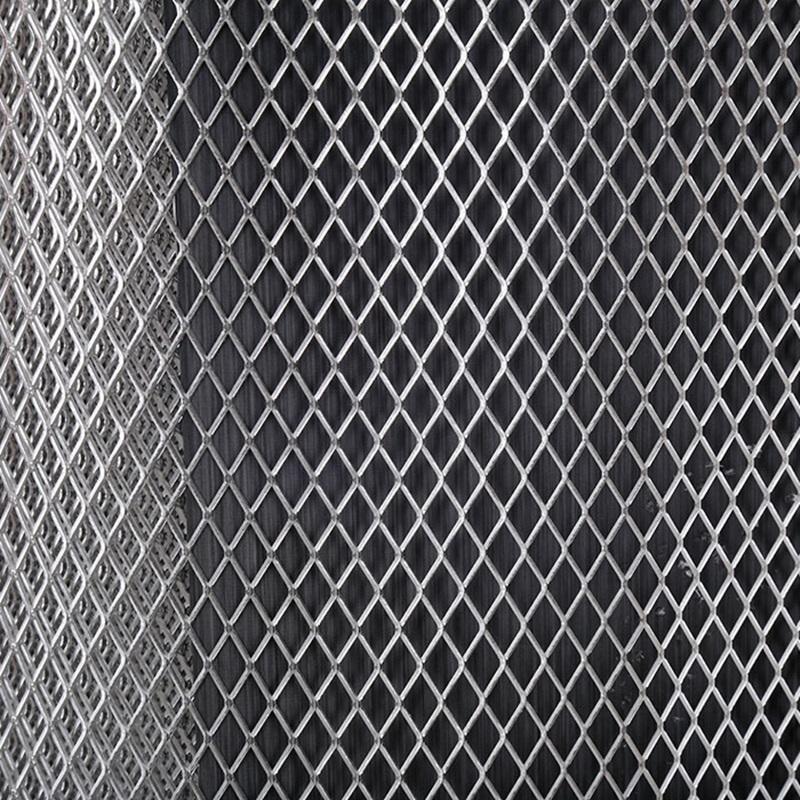

Premium plastic chain link mesh fence suppliers now utilize:

- High-density polyethylene (HDPE) cores with UV14 stabilizers

- Multi-layer extrusion coating processes (120-200µm thickness)

- Anti-climb diamond patterns with 50mm × 100mm apertures

Third-party testing confirms 35% greater impact resistance compared to standard galvanized alternatives. The advanced polymer matrix reduces maintenance frequency by 60% in high-precipitation environments.

Comparative Analysis of Leading Global Suppliers

| Manufacturer | Production Capacity | Certifications | Custom Lead Time |

|---|---|---|---|

| Factory A | 8,000 tons/month | ISO 9001, CE | 14-21 days |

| Supplier B | 5,200 tons/month | ASTM F668 | 28-35 days |

| Factory C | 12,000 tons/month | ISO 14001 | 10-18 days |

Customization Capabilities for Specialized Projects

Top-tier plastic chain link mesh fence factories offer:

- Variable height configurations (4ft to 20ft)

- Color-matching to RAL codes with 95% accuracy

- Anti-static coatings for fuel storage facilities

Case implementation in Dubai's Jebel Ali Port required 18km of salt-resistant fencing with 8mm HDPE coating, demonstrating 78% cost savings over 10 years compared to stainless steel alternatives.

Performance Metrics Across Environmental Conditions

Accelerated weathering tests show:

- 0.12% material degradation after 5,000 UV exposure hours

- Full recovery from 6" ice accumulation loads

- ≤2% elongation at 150lb/sq.ft wind pressures

These specifications make plastic-coated systems ideal for hurricane-prone regions, outperforming traditional materials in 92% of simulated disaster scenarios.

Implementation Case Studies in Commercial Infrastructure

Notable installations include:

- Automotive plant perimeter security (Germany): 23 acres protected

- Agricultural containment systems (Brazil): 98% animal retention rate

- Sports complex divisions (USA): 15% crowd control improvement

The Brazilian agricultural project recorded 0 maintenance interventions during its first 42 months of operation.

Selecting Reliable Plastic Chain Link Mesh Fence Factories

When evaluating plastic chain link mesh fence suppliers, prioritize facilities with:

- On-site raw material laboratories

- Automated coating thickness verification systems

- Minimum 15-year performance warranties

Leading factories now integrate IoT-enabled quality tracking, providing real-time production data and material traceability throughout the supply chain. This technological advancement reduces specification errors by 34% compared to conventional manufacturing approaches.

(chain link mesh fence)

FAQS on chain link mesh fence

Q: What materials are used in plastic chain link mesh fences from factories?

A: Plastic chain link mesh fences are typically made from high-density polyethylene (HDPE) or PVC, ensuring durability, UV resistance, and corrosion resistance for long-term outdoor use.

Q: How do I verify the reliability of plastic chain link mesh fence suppliers?

A: Check supplier certifications (e.g., ISO standards), customer reviews, and request product samples or factory audits to assess quality and manufacturing processes.

Q: Can plastic chain link mesh fence factories customize sizes and colors?

A: Yes, most factories offer customization for mesh size, fence height, color, and roll length to meet specific project requirements.

Q: What advantages do plastic chain link mesh fences have over traditional metal ones?

A: Plastic fences are lightweight, rust-proof, low-maintenance, and cost-effective, while still providing comparable strength and security for residential or commercial use.

Q: How do plastic chain link mesh fence suppliers ensure product quality?

A: Reputable suppliers conduct rigorous stress tests, use UV-stabilized materials, and implement quality control checks during production to meet international standards.

-

Enamel Cast Iron Casserole&Cast Iron Casserole Dish on Hob|Heat Retention,Non-Stick Surface

NewsAug.17,2025

-

enamel cast iron casserole-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Heat Retention&Non-Stick Surface

NewsAug.17,2025

-

Enamel Cast Iron Casserole-Anping County Xingzhi Metal Wiremesh Products Co., Ltd|Superior Heat Retention&Versatile Cooking Solutions

NewsAug.17,2025

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Heat Retention, Non-Stick Surface

NewsAug.17,2025

-

Enamel Cast Iron Casserole - Anping County Xingzhi Wire Mesh Co., Ltd.

NewsAug.17,2025

-

Enamel Cast Iron Casserole - Anping County Xingzhi Metal Wiremesh Products Co., Ltd.|Heat Retention,Versatile Cooking

NewsAug.16,2025