Oct . 08, 2025 22:30 Back to list

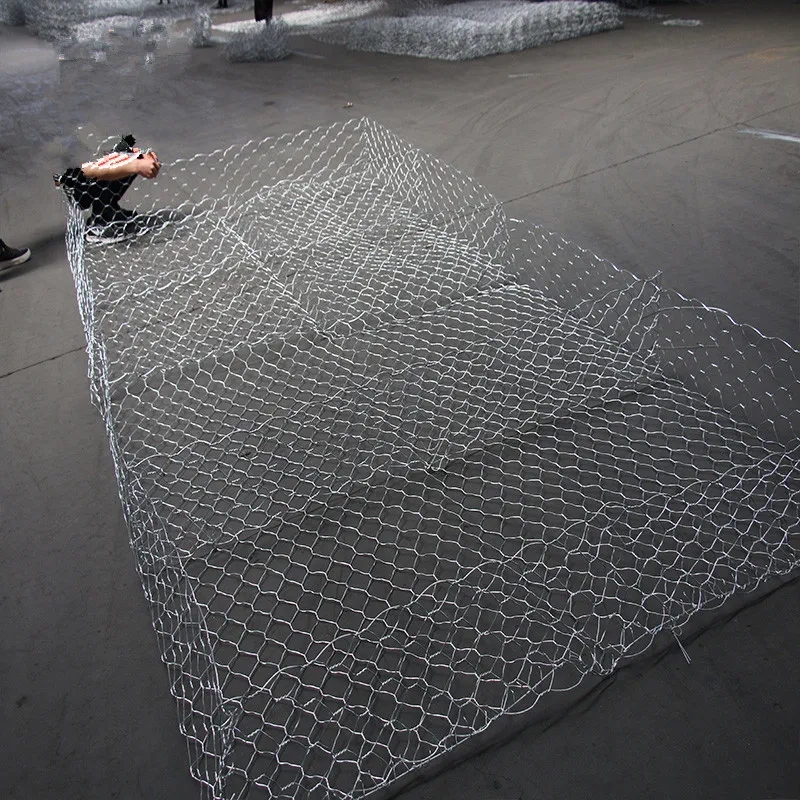

Double Twisted Hexagonal Gabion Mesh Box/Gabion Mattress?

Field Notes: Why engineers keep choosing Double Twisted Hexagonal Gabion Mesh Box/Gabion Mattress

If you build near water, you’ve met erosion the hard way. Lately, design teams are leaning back into gabions—not the clunky cages of the past, but tighter-tolerance, Galfan or PVC-coated systems. To be honest, the new stuff lasts longer and installs faster than many realize. The Double Twisted Hexagonal Gabion Mesh Box/Gabion Mattress from Anping, Hebei sits squarely in that trend.

Where it works (and why it’s popular)

Riverbank revetments, culvert outlets, bridge scour, road embankments, mine tailings, even landscape terraces. Mattresses (0.15–0.30 m tall) armor surfaces; boxes (0.5–1.0 m) build gravity structures. Many customers say it’s “fit-and-forget”—stone-filled, permeable, and forgiving under settlement.

Specs at a glance

| Mesh aperture | 60×80, 80×100, 100×120 mm |

| Mesh wire Ø | 2.2–3.0 mm (≈350–550 MPa) |

| Selvedge wire Ø | 2.7–3.9 mm |

| Coatings | Heavy Zn ≥245 g/m²; Galfan (Al-Zn) 5–10%; PVC 0.5–1.0 mm |

| Heights | Mattress 0.15–0.30 m; Box 0.5–1.0 m |

| Diaphragm spacing | 1.0 m (typical) |

| Standards | EN 10223-3; ASTM A975 |

| Service life | Rural 50+ yrs; marine 25–40 yrs with PVC (real-world may vary) |

| Salt spray | PVC/Galfan tested ≈ 3,000 h (ISO 9227) |

Material is Q195/Q235 low-carbon steel, double-twisted so a single wire break won’t unzip the panel—handy under impact or freeze-thaw.

Process, QA, and test methods

Wire drawing → anneal → galvanize or Galfan → PVC coat (if required) → double-twist weaving → selvedge edging → diaphragms → flatten, bundle, pallet. Coating mass is checked per EN 10244-2/ASTM A641; dimensional tolerances per EN 10223-3; tensile tests and PVC adhesion/impact to internal SOP referencing ASTM D412/D2240. SGS inspection is common, plus ISO 9001 workflows. Frankly, the paperwork is almost as important as the steel.

Real-world advantages

- Permeable and flexible—settlement doesn’t crack armor.

- Galfan/PVC coatings offer 2–3× zinc-only corrosion resistance.

- Faster install than cast concrete in remote jobs; stone from site often acceptable (check gradation).

Vendor comparison (field impressions)

| Vendor | Wire/Coating | Lead time | Certs/Traceability | Notes |

|---|---|---|---|---|

| XZ Metal (Anping) | Q195/Q235; Heavy Zn, Galfan, PVC | ≈2–4 weeks | ISO, SGS; heat-number tracking | Stable selvedge, clean PVC bond |

| Importer B | Mixed grades; Zn or PVC | ≈4–8 weeks | Basic COA; limited trace | Pricey in small lots |

| Contractor Supply C | Stock sizes only | Quick if in stock | Limited docs | Convenient, less customizable |

Customization and site feedback

Sizes per drawing; diaphragms at 0.5 or 1.0 m; selvedge up-sizing for high-energy rivers; PVC colors (grey/green). Origin: 200 m North of Huangcheng Village, Anping, Hebei, China. One SE Asia river-training job used 8,000 m² of Double Twisted Hexagonal Gabion Mesh Box/Gabion Mattress; the PM told me maintenance dropped to “basically inspections after monsoon.” Another highway slope job liked the quick tie-wire detailing, though they’d have preferred spiral binders for speed—fair point.

Quick buying checklist

- Specify EN 10223-3 or ASTM A975 by name, plus coating class.

- Ask for coating mass and salt-spray reports (ISO 9227) and wire tensile data.

- Confirm aperture, wire Ø, diaphragm spacing, and selvedge Ø on the PI.

- Request a sample panel; verify double-twist pitch and PVC adhesion.

References:

- ASTM A975: Standard Specification for Double-Twisted Hexagonal Mesh Gabions.

- EN 10223-3: Steel wire and wire products — Hexagonal steel wire netting for engineering.

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests.

- EN 10244-2 / ASTM A641: Steel wire zinc coatings — test methods and requirements.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025