Sep . 09, 2025 19:40 Back to list

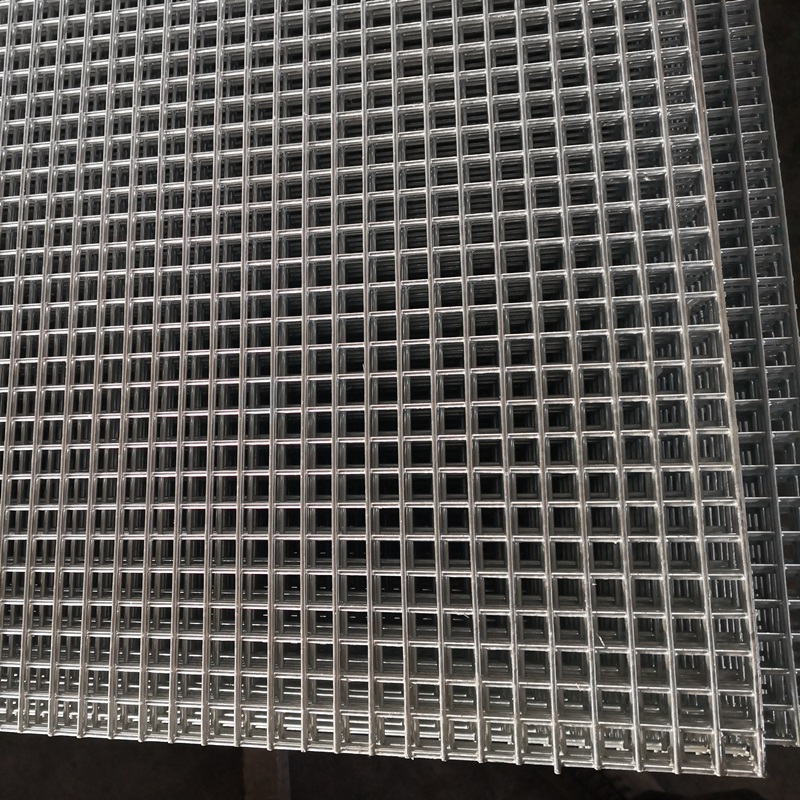

Durable Welded Wire Mesh Panels & Rolls for Fencing & Cages

The Backbone of Modern Infrastructure: Understanding Welded Wire Mesh Panels and Rolls

In the intricate landscape of industrial and construction materials, Welded wire mesh panels and rolls stand as foundational components, underpinning a vast array of applications from civil engineering to advanced manufacturing. These versatile products, characterized by their precisely welded intersections, offer unparalleled structural integrity, uniform spacing, and customizable configurations. Their increasing adoption is a testament to evolving industry demands for durable, efficient, and cost-effective solutions.

Current industry trends indicate a significant push towards higher-performance materials and sustainable manufacturing practices. There's a growing demand for stainless steel variants and advanced coatings (e.g., epoxy, PVC) to enhance corrosion resistance and extend service life, particularly in harsh environments. Automation in mesh welding and cutting processes is also accelerating, leading to improved precision, reduced waste, and faster production cycles. According to market research, the global wire mesh market is projected to reach approximately $60 billion by 2028, driven by robust growth in construction, infrastructure development, and industrial filtration sectors. This expansion underscores the critical role these materials play in supporting global economic and technological advancement.

Precision Manufacturing: The Process Flow of Welded Wire Mesh

The production of Welded wire mesh panels and rolls is a meticulously controlled multi-stage process, ensuring the final product meets stringent quality and performance criteria. This intricate process transforms raw wire rod into a highly engineered material ready for demanding applications.

Manufacturing Process Steps:

- Material Selection & Preparation: High-quality wire rod, typically low carbon steel, galvanized steel, or various grades of stainless steel (e.g., 304, 316, 316L), is selected based on application requirements. This raw material undergoes a wire drawing process to achieve the precise wire diameter required for the mesh. Careful control here is crucial for the final product's tensile strength and ductility.

- Straightening and Cutting: The drawn wire is then straightened using advanced machinery to ensure perfect linearity. For panels, the wires are precisely cut to the specified length. For rolls, continuous wires are fed into the welding machine.

- Automated Resistance Welding: This is the core of the manufacturing process. Longitudinal and transverse wires are arranged perpendicularly and fed into a sophisticated, automated multi-point resistance welding machine. Electric current is applied, generating heat at the intersection points, fusing the wires together to form a strong, integral bond. This method ensures consistent weld strength and precise mesh aperture.

-

Surface Treatment & Finishing: Depending on the application, the welded mesh may undergo various finishing processes:

- Hot-Dip Galvanizing: For superior corrosion resistance, mesh is immersed in molten zinc, forming a metallurgically bonded coating. This significantly extends service life, especially in outdoor or corrosive environments.

- Electro-Galvanizing: A thinner zinc coating applied electrochemically, offering a bright finish and moderate corrosion protection.

- PVC Coating: A layer of polyvinyl chloride is fused onto the galvanized mesh, providing excellent weather resistance, UV protection, and often aesthetic appeal.

- Epoxy Coating: Applied for enhanced chemical resistance and specialized industrial applications.

- Quality Control & Testing: Throughout and after the manufacturing process, rigorous quality checks are performed. This includes visual inspection, measurement of wire diameter and mesh aperture, weld shear strength tests (e.g., in accordance with ASTM A740), and coating thickness checks (e.g., per EN 10244). Adherence to international standards like ISO 9001 (Quality Management Systems) is paramount.

- Packaging: Finished panels are stacked and bundled, while rolls are tightly wound and secured, prepared for shipment to ensure product integrity during transit.

This controlled manufacturing environment ensures that the resultant Welded wire mesh panels and rolls deliver consistent performance, critical for target industries such as petrochemical, metallurgy, water supply & drainage, construction, and agriculture. Advantages like superior corrosion resistance, energy-saving properties (e.g., in filtration applications by improving flow dynamics), and extended service life directly stem from these meticulous processes and material choices.

Technical Specifications and Performance Parameters

Understanding the technical specifications of Welded wire mesh panels and rolls is crucial for engineers and procurement specialists to ensure optimal application fit and performance. These parameters dictate the structural integrity, flow characteristics, and durability of the mesh.

Key Technical Parameters:

- Wire Diameter (Gauge): Ranging from fine 0.4 mm (approx. 27 gauge) for filtration to heavy 10 mm (approx. 3 gauge) for structural reinforcement. This directly impacts mesh strength and load-bearing capacity.

- Mesh Opening (Aperture): The precise distance between adjacent wires, typically square or rectangular. Common sizes range from 6x6 mm to 100x100 mm, dictating filtration efficiency, screening capabilities, and barrier effectiveness.

- Panel/Roll Dimensions: Panels commonly range from 1m x 2m to 2.4m x 4.8m. Rolls can be customized in length, typically 15m, 30m, or 50m, with widths from 0.5m to 2.5m.

-

Material Grade:

- Low Carbon Steel: Cost-effective, suitable for general-purpose applications, often galvanized.

- Stainless Steel (304, 316, 316L): Excellent corrosion resistance, high tensile strength, suitable for food processing, chemical, and marine environments. 316L offers superior resistance to pitting corrosion.

- Galvanized Steel: Zinc coating provides sacrificial protection against rust.

- PVC Coated Steel: Adds weather resistance, UV protection, and aesthetic value.

- Tensile Strength: The maximum stress the wire can withstand before breaking, typically 500-700 MPa for steel wires used in mesh.

- Weld Shear Strength: Critical for mesh integrity, typically measured in kN per weld, ensuring the intersections do not fail under load. Adherence to standards like ASTM A185/A497 is vital.

Typical Product Specification Table:

| Parameter | Common Range/Type | Standard Met |

|---|---|---|

| Material | Low Carbon Steel, SS304, SS316, Galvanized, PVC Coated | ASTM A82, A185, A497, EN 10025 |

| Wire Diameter | 0.4 mm - 10 mm (Gauge 27 to 3) | +/- 0.05 mm tolerance |

| Mesh Opening | 6x6 mm - 100x100 mm (Square/Rectangular) | +/- 1.0 mm tolerance |

| Panel Dimensions | 1m x 2m up to 2.4m x 4.8m (Custom available) | +/- 5 mm length/width |

| Roll Lengths | 15m, 30m, 50m (Custom available) | +/- 0.5% length |

| Tensile Strength | Typically 500-700 MPa | ASTM A82 |

| Weld Shear Strength | Min. 35% of wire's tensile strength | ASTM A740 |

| Zinc Coating Weight | 30-280 g/m² (Galvanized) | EN 10244-2 Class A/B/C |

Diverse Applications Across Key Industries

The inherent versatility and structural integrity of Welded wire mesh panels and rolls make them indispensable across a broad spectrum of industries. Their application extends from foundational construction elements to specialized industrial components, offering durable and reliable solutions.

Target Industries and Typical Application Scenarios:

-

Construction & Infrastructure:

Widely used for concrete reinforcement in slabs, roadways, precast elements, and tunnel linings. The mesh provides superior crack control and enhanced structural strength, reducing construction time and material usage compared to traditional rebar. For instance, in modern highway construction, the use of large mesh panels significantly accelerates the laying of concrete bases, ensuring uniform stress distribution and preventing premature cracking.

-

Security & Fencing:

High-security perimeter fencing, animal enclosures, and property demarcation. PVC-coated mesh offers excellent weather resistance and blends aesthetically into residential or commercial landscapes, while galvanized options provide robust, long-term security with minimal maintenance.

-

Agriculture & Horticulture:

Trellises for climbing plants, livestock pens, animal cages, and general farm utility. The uniform mesh size provides consistent support and protection, essential for controlled environments or containment.

-

Industrial & Manufacturing:

Machine guards, shelving, partitions, storage cages, and filtration media. In a factory setting, mesh panels serve as robust safety barriers for automated machinery, protecting personnel while allowing visibility and air circulation. Stainless steel mesh is crucial for filtration in food processing and pharmaceutical industries due to its hygiene and corrosion resistance.

-

Mining & Quarrying:

Screening and separation applications, rockfall protection, and ground support. The high tensile strength of heavy-gauge mesh ensures stability and safety in demanding mining environments.

-

Water Supply & Drainage:

Gratings for drainage systems, trash screens, and filtration elements in wastewater treatment plants. The corrosion resistance of galvanized or stainless steel mesh is paramount in these wet, often chemically aggressive, environments, ensuring longevity and reliable performance.

In each of these scenarios, the inherent technical advantages such as uniform mesh size, robust weld points, and material-specific properties (e.g., the corrosion resistance of 316L stainless steel) contribute significantly to energy saving through optimized flow, reduced maintenance costs, and extended service life.

Technical Advantages and Performance Edge

The technical superiority of Welded wire mesh panels and rolls stems from their engineered design and manufacturing precision, offering distinct advantages over alternative materials and fabrication methods. These benefits translate directly into enhanced project efficiency, durability, and cost-effectiveness for B2B clients.

Key Technical Advantages:

- Superior Weld Integrity: The automated resistance welding process creates uniform, high-strength bonds at every intersection. Unlike woven mesh, which relies on crimping or interlocking, welded mesh maintains its shape and aperture even under significant stress, preventing wire displacement or unraveling. This critical feature ensures consistent performance in applications like concrete reinforcement or precise filtration.

- High Strength-to-Weight Ratio: By strategically placing material only where it's needed for structural support, welded mesh offers exceptional load-bearing capacity relative to its weight. This allows for lighter designs without compromising structural integrity, reducing material costs and simplifying handling and installation.

- Uniform Mesh Aperture: The precision of automated welding ensures highly consistent and accurate mesh openings. This is vital for applications requiring exact screening, filtration, or aesthetic uniformity. For example, in architectural uses, the consistent grid provides a clean, modern look.

- Versatility in Customization: Available in a vast array of wire diameters, mesh sizes, material types (stainless steel, galvanized, PVC-coated), and panel/roll dimensions. This adaptability allows for bespoke solutions tailored to specific project requirements, optimizing performance for unique challenges in diverse industries.

- Ease of Fabrication and Installation: Welded wire mesh panels and rolls are easy to cut, bend, and form into desired shapes without losing structural integrity, significantly streamlining on-site fabrication. The rigidity of panels simplifies installation, reducing labor costs and project timelines, particularly in large-scale construction or industrial setups.

- Enhanced Durability and Service Life: When combined with appropriate surface treatments like hot-dip galvanizing or PVC coating, welded mesh exhibits exceptional resistance to corrosion, abrasion, and environmental degradation. This extended service life minimizes the need for frequent replacement and maintenance, leading to significant long-term cost savings and reduced operational downtime.

These technical advantages collectively position welded wire mesh as a superior choice for demanding applications where reliability, precision, and longevity are paramount.

Vendor Comparison: Selecting Your Welded Wire Mesh Partner

Choosing the right supplier for Welded wire mesh panels and rolls is a strategic decision that impacts project timelines, material quality, and overall cost efficiency. A comprehensive vendor comparison should go beyond mere price points, focusing on long-term value, reliability, and technical expertise.

Key Criteria for Vendor Evaluation:

- Material Quality & Sourcing: Assess the consistency and origin of raw materials (wire rod). Reputable vendors often provide material test certificates.

- Manufacturing Precision & Technology: Look for evidence of advanced automated welding lines and stringent internal QC processes. This ensures uniform mesh and strong welds.

- Certifications & Compliance: Verify adherence to international standards like ISO 9001, ASTM, EN, and relevant local certifications (e.g., CE for Europe). This is a strong indicator of authoritativeness and trustworthiness.

- Customization Capabilities: A vendor's ability to produce bespoke wire diameters, mesh sizes, panel/roll dimensions, and specific coatings is crucial for specialized projects.

- Lead Times & Logistics: Evaluate their capacity to meet deadlines and provide efficient, reliable logistics, especially for large or time-sensitive orders.

- Technical Support & After-Sales Service: Access to expert technical advice, design assistance, and responsive post-sales support is invaluable for B2B relationships.

- Price Point & Value Proposition: While cost-effectiveness is key, prioritize vendors who offer a balance of quality, service, and competitive pricing, rather than just the lowest bid.

Vendor Comparison Table:

| Feature/Criterion | Premium Manufacturer (e.g., XZ Metal) | Standard Manufacturer | Budget Supplier |

|---|---|---|---|

| Material Quality | Certified, prime-grade materials (SS304/316L, premium galvanized) | Standard industrial grades, some certifications | Variable, often cost-driven, limited certifications |

| Welding Precision | Automated multi-point, high-tolerance, consistent weld strength | Automated, but with wider tolerances | Basic automation, potential for weaker/inconsistent welds |

| Certifications | ISO 9001, ASTM, EN, specific product certifications (e.g., CE) | ISO 9001 (basic), some local standards | Limited or no formal certifications |

| Customization | Extensive, collaborative engineering, bespoke solutions | Limited options, standard variations only | Minimal to none, off-the-shelf products |

| Lead Time | Reliable & competitive, flexible for urgent orders | Standard, less flexibility | Often longer, less predictable |

| Technical Support | Dedicated team, design assistance, expert consultation | Basic support, catalog-based information | Minimal or self-service |

| Pricing Strategy | Value-driven, reflects quality, service, and reliability | Mid-range, standard market pricing | Lowest available, often at the expense of quality/service |

Tailored Excellence: Customized Welded Wire Mesh Solutions

While standard options for Welded wire mesh panels and rolls cater to many needs, specific projects often demand bespoke solutions to achieve optimal performance and integration. Leading manufacturers understand this necessity and offer extensive customization capabilities.

Areas of Customization:

- Material & Alloy Selection: Beyond standard low carbon and stainless steel, specialized alloys can be utilized for extreme temperature resistance, enhanced chemical inertness, or specific magnetic properties. Examples include duplex stainless steels for high corrosion resistance and strength, or specific aluminum alloys for lightweight applications.

- Wire Diameter & Mesh Configuration: Precise adjustment of wire gauge and mesh aperture (both square and rectangular) to meet specific filtration requirements, load-bearing capacities, or visual aesthetics. This includes variable mesh patterns within a single panel.

- Dimensions & Form Factor: Production of panels or rolls in exact lengths and widths, including complex geometries and pre-cut shapes to minimize on-site waste and fabrication. This also encompasses curved or pre-bent mesh for specific architectural or structural elements.

- Surface Coatings & Treatments: Application of specialized coatings such as powder coating for specific color matching, advanced epoxy coatings for chemical or abrasion resistance, or anti-microbial coatings for hygienic environments. These treatments extend the product's lifespan and tailor it to challenging operational conditions.

- Additional Fabrication: Integration of features like embedded frames, specific cut-outs, mounting points, or welded attachments for seamless installation into larger systems. This pre-fabrication reduces on-site labor and ensures higher precision.

Engaging in a collaborative design process with a capable manufacturer allows for tailored solutions that deliver optimized performance and significant cost savings over the project lifecycle by eliminating rework and ensuring perfect fit.

Application Case Studies and Customer Successes

Real-world applications demonstrate the tangible benefits and reliability of Welded wire mesh panels and rolls. These case studies highlight how engineered mesh solutions address complex challenges and deliver superior results.

Case Study 1: High-Performance Concrete Reinforcement for Port Facilities

Challenge: A major international port required durable concrete paving and jetty structures capable of withstanding extreme heavy loads from container111 traffic and constant exposure to saltwater. Traditional rebar systems were prone to corrosion, leading to premature concrete degradation and costly repairs.

Solution: Customized hot-dip galvanized welded wire mesh panels (10mm wire, 150x150mm mesh) were specified for all concrete reinforcement. The galvanization provided superior anti-corrosion properties, and the precise welding ensured uniform crack control and load distribution throughout the concrete slab.

Outcome: The project delivered an estimated 30% increase in structural lifespan compared to ungalvanized alternatives, significantly reducing maintenance cycles and associated costs. The ease of laying large mesh panels also cut installation time by 15%, contributing to early project completion.

Case Study 2: Industrial Safety Guarding in Automotive Manufacturing

Challenge: An automotive assembly plant needed robust safety guarding for robotic welding cells that would protect personnel from moving machinery and sparks, while allowing clear visibility and natural airflow for cooling and fume extraction.

Solution: Heavy-gauge welded wire mesh panels, precisely cut and framed, were deployed as modular safety barriers. The specific mesh size (25x25mm) was chosen to prevent hand penetration while maintaining high visibility. The panels were powder-coated for enhanced durability and a professional aesthetic.

Outcome: The modular mesh system provided effective, compliant safety guarding that was quick to install and reconfigure as production lines evolved. The open mesh design facilitated heat dissipation and allowed for easy visual inspection of operations, leading to improved safety records and operational efficiency. Customer feedback highlighted the "seamless integration and robust construction."

Trust, Reliability, and Partnership: Our Commitment to Clients

Building strong, lasting B2B relationships is predicated on trust and demonstrated reliability. We are committed to upholding the highest standards of product quality, transparent processes, and unwavering customer support for all our Welded wire mesh panels and rolls. Our operations are guided by ISO 9001 certification, ensuring consistent quality management from raw material procurement to final delivery. With over two decades of dedicated service in the metal fabrication industry, we have cultivated partnerships with leading enterprises across diverse sectors.

Frequently Asked Questions (FAQ):

-

Q: What are the common coating options for welded wire mesh, and which is best for corrosive environments?

A: Common options include electro-galvanized, hot-dip galvanized, and PVC coating. For highly corrosive environments, hot-dip galvanized offers superior long-term protection. Stainless steel mesh (e.g., 316L) is also an excellent choice for extreme conditions. -

Q: How is the quality of the welds ensured?

A: We utilize advanced automated resistance welding machines with precise parameter control. Each batch undergoes rigorous weld shear strength testing in accordance with ASTM A740, complemented by continuous visual inspections and adherence to ISO 9001 quality management protocols. -

Q: What is the typical lead time for custom orders?

A: Lead times vary based on complexity and volume. Standard orders typically ship within 2-4 weeks. For custom specifications, we provide a detailed project timeline upon order confirmation, aiming for efficient production while maintaining quality. Expedited options may be available upon request. -

Q: Can you provide certification for your materials and products?

A: Absolutely. We provide Material Test Certificates (MTCs) for raw materials, along with Certificates of Conformance (COC) for finished products, verifying adherence to relevant ASTM, EN, or ISO standards upon request.

Lead Time & Fulfillment:

Our production capabilities allow for efficient processing of both standard and custom orders. Typical lead times for commonly stocked Welded wire mesh panels and rolls are 7-14 business days. For bespoke orders requiring specialized materials or complex fabrication, lead times are estimated at 3-6 weeks, with regular communication on production progress. We offer flexible shipping options, including LCL and FCL, to meet diverse logistical requirements and project schedules, ensuring timely and secure delivery worldwide.

Warranty Commitments:

We stand by the quality and performance of our products. All Welded wire mesh panels and rolls come with a standard 1-year warranty against manufacturing defects. Products with specific coatings (e.g., hot-dip galvanized, PVC coated) may carry extended warranties of up to 10 years for coating integrity, subject to proper installation and environmental conditions. Full warranty details are provided with each order.

Customer Support:

Our dedicated team of technical sales and support specialists is available to assist with product selection, technical specifications, custom design inquiries, and after-sales service. We offer comprehensive pre-sale consultation and post-installation support to ensure complete client satisfaction. Reach out via email, phone, or our online portal for prompt and expert assistance.

References:

- American Society for Testing and Materials (ASTM). (2023). ASTM A740/A740M-16: Standard Specification for Hardware Cloth (Industrial Wire Cloth, Welded Wire Fabric). ASTM International.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015: Quality management systems – Requirements. ISO Central Secretariat.

- European Committee for Standardization (CEN). (2011). EN 10244-2: Steel wire and wire products — Non-ferrous metallic coatings on steel wire — Part 2: Zinc or zinc alloy coatings. CEN-CENELEC.

- Mordor Intelligence. (2023). Wire Mesh Market - Growth, Trends, COVID-19 Impact, and Forecasts (2023 - 2028). Retrieved from https://www.mordorintelligence.com/industry-reports/wire-mesh-market

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025