- الأفريقي

- الألبانية

- الأمهرية

- عربي

- أرميني

- الأذربيجانية

- الباسك

- البيلاروسية

- البنغالية

- البوسنية

- البلغارية

- الكاتالونية

- السيبيونو

- الصين

- الصين (تايوان)

- كورسيكا

- الكرواتية

- التشيكية

- دانماركي

- هولندي

- إنجليزي

- اسبرانتو

- الإستونية

- الفنلندية

- فرنسي

- الفريزيان

- الجاليكية

- الجورجية

- ألمانية

- اليونانية

- الغوجاراتية

- الكريولية الهايتية

- هاوسا

- هاواي

- اللغة العبرية

- لا

- مياو

- المجرية

- الآيسلندية

- igbo

- الأندونيسية

- الأيرلندية

- إيطالي

- اليابانية

- الجاوية

- الكانادا

- كازاخستان

- الخمير

- رواندي

- الكورية

- كردي

- قيرغيزستان

- تَعَب

- لاتيني

- لاتفيا

- الليتوانية

- اللوكسمبرجية

- المقدونية

- Malgashi

- لغة الملايو

- المالايالامية

- المالطية

- الماوري

- الماراثى

- المنغولية

- ميانمار

- النيبالية

- النرويجية

- النرويجية

- الأوكيتان

- الباشتو

- اللغة الفارسية

- تلميع

- البرتغالية

- البنجابية

- روماني

- الروسية

- ساموا

- الغيلية الاسكتلندية

- الصربية

- إنجليزي

- شونا

- السندية

- السنهالية

- السلوفاكية

- السلوفينية

- صومالي

- الأسبانية

- السوندانيز

- السواحيلية

- السويدية

- تاغالوغ

- طاجيك

- التاميل

- التتار

- التيلجو

- التايلاندية

- اللغة التركية

- التركمان

- الأوكرانية

- الأردية

- الأويغور

- أوزبكي

- فيتنامي

- تهرب من دفع الرهان

- يساعد

- اليديشية

- اليوروبا

- الزولو

أغسطس . 20, 2025 15:55 الرجوع للقائمة

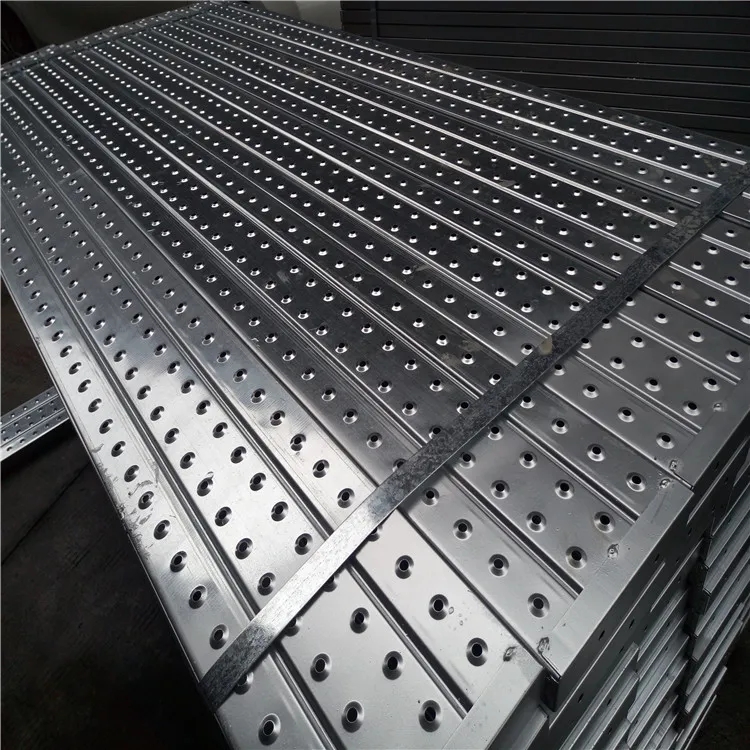

Proper Maintenance Tips for Metal Scaffold Boards

Metal scaffold boards, including scaffolding steel plank and steel scaffold boards, are workhorses on construction sites, providing a stable platform for workers and materials. Their durability and strength make them indispensable, but like any equipment, they require regular maintenance to stay safe and functional. Anping County Xingzhi Metal Wiremesh Products Co., Ltd, a leading metal wire mesh manufacturer with a state-of-the-art factory, produces high-quality metal products known for their craftsmanship and reliability. While they’re renowned for wire mesh, their commitment to durability extends to understanding the care needed for metal scaffolding components. This article shares essential maintenance tips for metal scaffold boards, ensuring they withstand the rigors of construction and remain safe for years.

Regular Cleaning of Scaffolding Steel Plank

- Remove Debris After Use: After each work shift, clear scaffolding steel plank of dirt, gravel, and building materials. Use a stiff brush or broom to sweep away loose debris, which can scratch the surface or trap moisture—both of which accelerate rust. For caked-on mud, a hose with low-pressure water works; avoid high-pressure jets that might dislodge paint or protective coatings.

- Clean Spills Promptly: Oil, grease, or chemical spills on steel scaffold boards create slip hazards and can corrode metal over time. Wipe up spills immediately with a rag and a mild detergent solution. For stubborn grease, use a degreaser designed for metal surfaces, then rinse thoroughly and dry to prevent residue buildup.

- Inspect Drainage Holes: Many metal scaffold boards have drainage holes to prevent water pooling. After cleaning, check that these holes are clear of debris. Clogged holes trap water, leading to rust and weakening the metal. Use a small wire or pipe cleaner to unclog any blocked holes, ensuring proper water runoff.

Inspection Routines for Steel Scaffold Boards

- Check for Structural Damage: Before each use, inspect steel scaffold boards for cracks, bends, or dents—especially around edges and connection points. Even small cracks can expand under weight, compromising the board’s strength. A bent board may not sit flush on the scaffolding frame, creating instability. Mark damaged boards for repair or replacement immediately.

- Examine Connections and Fasteners: The bolts, clips, and brackets that attach scaffolding steel plank to the frame must be tight and intact. Loose fasteners can cause boards to shift, while rusted or broken ones risk collapse. Tighten any loose bolts with a wrench and replace corroded or damaged fasteners with galvanized alternatives to match the board’s durability.

- Look for Signs of Wear: Over time, metal scaffold boards can show wear from heavy loads or constant foot traffic. Check for thinning metal in high-use areas, such as the center of the board, and ensure anti-slip surfaces (like raised ridges) are still effective. Worn anti-slip features increase fall risks and require attention—either by re-coating or replacing the board.

Preventing Rust on Metal Scaffold Boards

|

Maintenance Step |

How to Do It |

Why It Matters |

|

Touch Up Paint Chips |

Use a rust-inhibiting paint to cover small chips or scratches on metal scaffold boards. |

Exposed metal from chips quickly rusts; touch-ups seal the surface against moisture. |

|

Apply Protective Coatings |

Every 1–2 years, apply a galvanized or epoxy coating to steel scaffold boards (follow manufacturer guidelines). |

These coatings add a barrier against rust, extending the board’s life in humid or wet environments. |

|

Store in Dry Areas |

When not in use, store scaffolding steel plank in a covered, dry space off the ground (use pallets). |

Storing on damp ground or in rain/snow traps moisture, accelerating corrosion. |

|

Dry Thoroughly After Cleaning |

After washing, wipe metal scaffold boards with a dry cloth or let them air-dry completely. |

Even small amounts of leftover moisture can lead to rust, especially in crevices. |

This table outlines key steps to keep metal scaffold boards rust-free and strong.

Proper Storage of Steel Scaffold Boards

- Stack Safely: When storing steel scaffold boards, stack them flat and evenly to prevent warping. Avoid leaning them against walls at an angle, as this can bend the boards over time. Use wooden spacers between layers to allow air circulation, reducing moisture buildup. Never stack more than 10 boards high without proper support, as excessive weight can damage the bottom layers.

- Protect from Extreme Weather: If outdoor storage is unavoidable, cover stacked scaffolding steel plank with a waterproof tarp. Ensure the tarp is secured tightly to prevent wind from blowing it off, and leave gaps at the bottom for air flow. Avoid wrapping boards in plastic, which traps condensation and promotes rust.

- Label and Organize: Mark stored metal scaffold boards by size or condition (e.g., “inspected” or “needs repair”) to streamline retrieval. This helps workers grab the right board quickly and ensures damaged ones aren’t accidentally put back into use. A simple labeling system saves time and reduces safety risks.

Metal Scaffold Boards FAQS

How Often Should Steel Scaffold Boards Be Inspected?

Steel scaffold boards should be inspected before each use and thoroughly checked monthly (or after severe weather). Daily visual checks catch immediate issues, while monthly inspections assess wear, rust, and structural integrity—critical for long-term safety.

Can Rust on Scaffolding Steel Plank Be Repaired?

Minor rust on scaffolding steel plank can be repaired by sanding the affected area to remove rust, then applying a rust-inhibiting primer and paint. Severe rust (pitting or thinning metal) means the board should be replaced, as it’s no longer structurally sound.

What’s the Best Way to Clean Grease Off Metal Scaffold Boards?

Use a degreaser formulated for metal, applied with a rag or sponge. Let it sit for 5–10 minutes, then scrub gently and rinse with water. Dry the metal scaffold boards thoroughly to prevent water spots or rust. Avoid harsh chemicals that strip protective coatings.

How Long Do Metal Scaffold Boards Last with Proper Maintenance?

With regular maintenance, metal scaffold boards can last 10–15 years. Factors like frequency of use, exposure to harsh elements, and adherence to cleaning/rust prevention routines affect longevity—consistent care extends their lifespan significantly.

Where Can I Learn More About Maintaining Scaffolding Steel Plank?

Anping County Xingzhi Metal Wiremesh Products Co., Ltd, a trusted name in metal products, offers insights into caring for metal components. Visit their website to explore resources on metal maintenance and discover high-quality metal scaffold boards designed for durability in construction settings.

-

Durable River Bank Gabion Mesh Solutions for Protection

أخبارNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

أخبارNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

أخبارNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

أخبارNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

أخبارNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

أخبارNov.17,2025