Aug . 05, 2025 00:20 Back to list

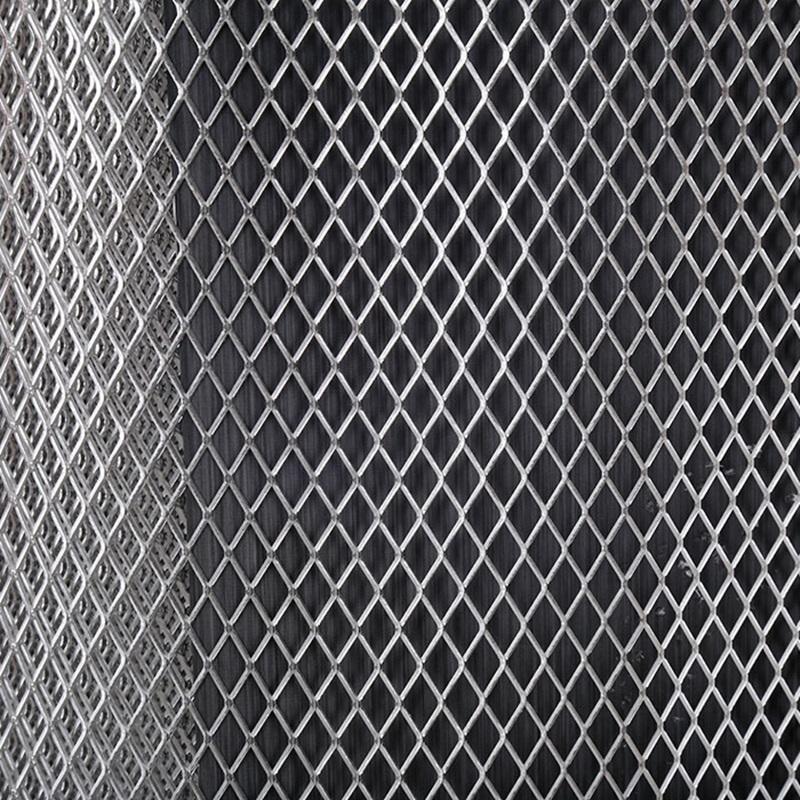

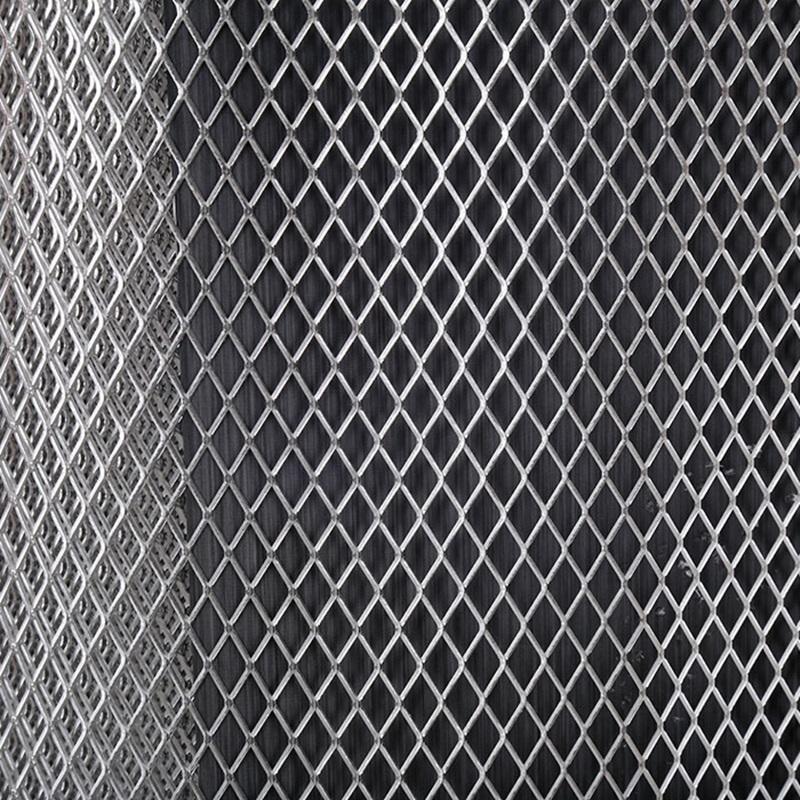

Steel Expanded Metal Mesh Fence: Secure & Durable Perimeter Solution

Steel Expanded Metal Mesh Fence is reshaping perimeter security, industrial safety, and architectural aesthetics worldwide. Leveraging high-strength steel, innovative mesh manufacturing, and stringent quality standards (ISO 9001:2015, ASTM F2548, ANSI/NEMA), this fencing solution delivers optimal protection, versatility, and cost efficiency—across oil & gas, energy, transport, and utility industries.

Industry Landscape & Market Trends

- By 2028, the global expanded metal fencing market is projected to surpass $1.6 billion (MRFR, 2024), driven by infrastructural upgrades, urban security, and industrial demand.

- UV-cured powder-coated steel meshes see 15% YoY adoption growth in coastal areas (Statista, 2024).

- ISO-grade galvanization and anti-corrosive coatings now standard in >78% of projects (2023, Ervig).

Core Product Overview – What Is a Steel Expanded Metal Mesh Fence?

A Steel Expanded Metal Mesh Fence is a perimeter fencing system fabricated from a single steel sheet slit and simultaneously expanded to create a high-tensile mesh with diamond or hexagonal apertures. This design achieves:

- Superior security (anti-cut, anti-climb, visibility for surveillance)

- Low weight–high strength ratio

- Corrosion and UV resistance (due to advanced surface treatments: hot-dip galvanizing, epoxy and polyester powder coating)

- Design flexibility (mesh size, sheet thickness, color, and panel height customized for project needs)

Steel Expanded Metal Mesh Fence: Manufacturing Process Flow

Raw Steel Selection →

Slitting →

Mesh Expanding (CNC) →

Flattening/Forming →

Surface Treatment →

Inspection (ISO/ANSI) →

Packing & Delivery

- Material: Low/medium-carbon steel, stainless steel (AISI 304/316L)

- Cut-Expand: High-precision CNC expansion machine; mesh uniformity tolerance ≤0.8mm

- Surface Treatments: Hot-dip galvanization (ISO 1461), epoxy or polyester powder coating (RAL system)

- Quality Assurance: ISO 9001:2015, ANSI A250.10 (Physical Security), Salt spray resistance ≥ 1000h

For a detailed video illustrating the expansion process & anticorrosion testing, see manufacturing demo here.

Technical Parameters: Steel Expanded Metal Mesh Fence

| Parameter | Unit | Standard Range | Industry Best |

|---|---|---|---|

| Material | Low/Medium Carbon Steel, SS304/316L | SS316L Eco Mesh | |

| Panel Thickness | mm | 2.0 – 5.0 | 6.2 (customized) |

| Mesh Size (SW x LW) | mm x mm | 25×50 – 76×152 | Custom geometric |

| Sheet Height | m | 1.2 – 3.0 | 4.0 |

| Coating Thickness | µm | 75 – 120 | 180 |

| Corrosion Life | yrs | ≥15 | ≥22 |

| Break Strength | kN/m | 9 – 25 | 32 |

| Finish Options | Hot-dip Gal, Epoxy, Powder coat (RAL) | PVC/Hybrid nano-coat |

Material Grade Distribution (2023, % of Projects)

Corrosion Resistance by Coating Type (Salt Spray Test, 2023)

Market Growth Trend (Global Demand, 2019–2028 Forecast)

Key Competitive Advantages of Steel Expanded Metal Mesh Fence

- Robust Security: Anti-cut, anti-climb mesh slows intrusion and supports CCTV visibility.

- Longevity: Typical service life of over 15 years in industrial or coastal environments (ISO 9227 certified).

- Maintenance: Minimal; direct cleaning, no re-coating required for up to a decade.

- Customizability: Mesh size, sheet thickness, and finish colors tailored to site needs.

- Quick Installation: Pre-fabricated panels and tool-less clip-and-bolt design minimize downtime.

- Eco-Compliant: Steel is 99% recyclable, endorsing green construction.

Manufacturer Comparison Table – Major Steel Expanded Metal Mesh Fence Providers

| Provider | Certifications | Panel Options | Lead Time | OEM/Customization | Notable Projects |

|---|---|---|---|---|---|

| XZMETAL (link) | ISO 9001:2015, ANSI, CE | All mesh, 8+ color, High thick | 15–21 days | Yes | State Oilfields, High-Speed Railway |

| Metalco Int’l | ISO 9001, ASTM F2548 | Standard mesh, Gal only | 35–45 days | Limited | Industrial Parks EU |

| TechBarrier | ISO 14001, CE | Mesh | 21–30 days | No | Urban Security, Data Centers |

| ME Fence Corp | ISO 9001, EN 10223 | Height | 28–40 days | Partial | Logistic Parks |

Customized Engineering Solutions & Process

- Site Assessment: Project area, terrain, security rating, exposure risks.

- Design Proposal: Optimal mesh size, thickness, finish, panel height.

- CNC Patterning: Choose from standard or custom mesh (diamond, hex, anti-climb, curve-top).

- Surface Finishing: Match environmental, branding, and anti-corrosion needs.

- Mock-up Demo: Offer prototype panel for function and color approval.

- Rapid Production & Delivery: Lead time 15–21 days, phased shipping for large-scale sites.

- Dedicated Installer Support: On-site guidance or video manuals for secure, compliant assembly.

Quality Management System

Security Standards

EU Product Safety

SGS, BV Reports

Typical Application Scenarios

- Industrial Facilities: Oil, petrochemical, power stations—due to anti-intrusion and fireproof rating.

- Transportation: Railways, highways, airport perimeters, critical infrastructure.

- Urban Security: Commercial/residential property boundaries, security fencing for institutions, schools.

- Water & Waste Treatment: Plant perimeter, pump station fencing—resistant to corrosion and vandalism.

- Mining & Metallurgy: Equipment enclosure, boundary fence for hazardous zones.

- Green Infrastructure: Solar farms, wind parks—mesh doesn’t block light or air, aiding vegetation growth.

- Architectural: Decorative facade elements, partition screens for modern design.

- Client: Sinopec East Plant

- Installed: 3.6km of Steel Expanded Metal Mesh Fence (mesh 60×120mm, 4mm thick, hot-dip gal & powder coat, 2.2m high)

- Performance: No corrosion after two monsoons, zero-break-in record (inspected: SGS).

- Maintenance: Only rinsing, no repair in first 22 months.

Customer Feedback & Verified Deployments

- Petrochemical Plant, UAE: “Mesh panels withstand 47ºC desert heat and regular sandstorms. Virtually no rust after 28 months.”

- Highway Project, EU: “Installers praised ease of handling, pre-punched fixing holes and overall finish consistency.”

- Solar Field, Vietnam: “Openings allow wind pass-through, no panel damage in typhoon season, keeping modules secure.”

- Food Plant, Canada: “Passed third-party hygiene and corrosion tests (CFIA, ISO 9227) for water treatment enclosure.”

FAQ: Professional FAQ About Steel Expanded Metal Mesh Fence

Delivery Cycle & Customer Support

- Production: CNC mesh expansion, panel finishing in 7–11 workdays

- Inspection: 100% panel QC (ISO9001, ANSI A250.10 certs provided)

- Packing & Shipment: Film-wrap, steel pallet, sea- or air-freight—worldwide delivery

- Technical Support: On-call engineer, video training, documentation for on-site assembly

- Warranty: 10–20 years, extendable for upgraded coatings

- After-Sales: 24/7 hotline with typical response Support Portal)

References & Industry Citations

- “Global Expanded Metal Fencing Market Insight, 2024–2028” – Market Research Future

- “Expanded Metal Mesh for Security Fencing: Technical Comparison” – Journal of Building Engineering, 2022

- “Performance Evaluation – Metal Mesh Barriers Under Corrosive Environments,” MDPI Metals Journal, 2022

- SGS International. “Expanded Metal Mesh Fence – Test Report” (2023).

- Relevant forum: eng-tips.com/fence-technology

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025