Aug . 10, 2025 00:20 Back to list

Single Loop Razor Wire Coil (Coin Type) - Compact Security

Understanding Single Loop Spiral Razor Barbed Wire Coil (Coin Type): A Comprehensive Overview for B2B Procurement

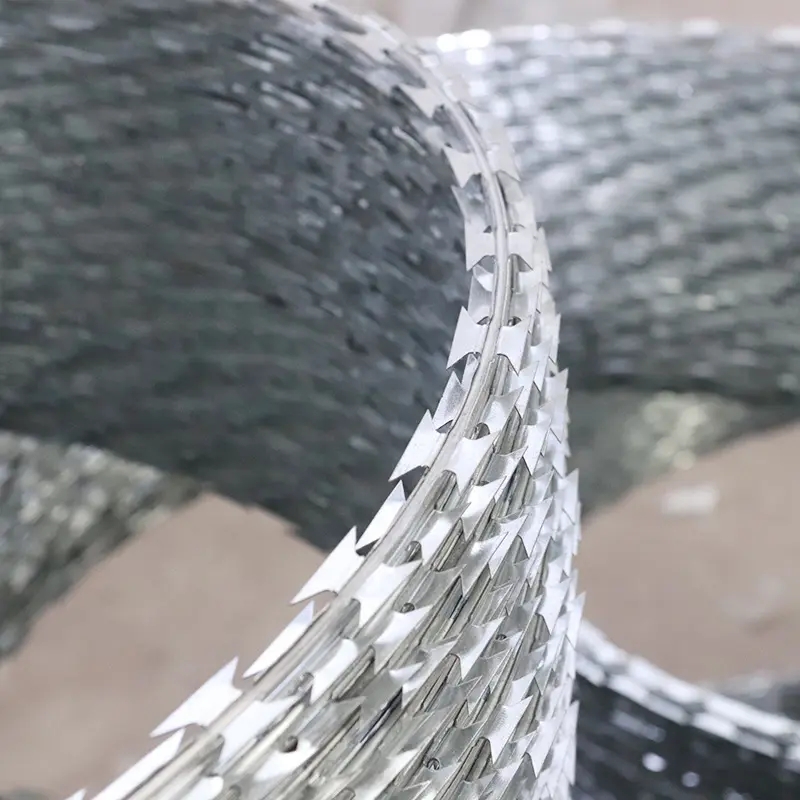

In the demanding realm of perimeter security, the Single Loop Spiral Razor Barbed Wire Coil (Coin Type) stands as a formidable barrier solution, engineered for environments requiring robust deterrence and superior intrusion prevention. This specialized security product, characterized by its distinctive "coin type" razor blades and a single, continuous spiral configuration, represents an evolution in traditional barbed wire, offering enhanced security performance and a longer operational lifespan. Its design is meticulously calibrated to maximize psychological and physical deterrent effects, making it an indispensable asset for critical infrastructure, correctional facilities, military installations, border control, and high-security industrial perimeters. Unlike conventional barbed wire, which relies primarily on sharp points, razor barbed wire incorporates blade-like edges that inflict greater damage and entanglement, significantly impeding unauthorized access. The single loop spiral format ensures a continuous, unbroken line of defense, facilitating rapid deployment and efficient coverage of expansive areas, a key consideration for large-scale security projects. Furthermore, the material science behind these coils, often involving high-tensile steel or stainless steel with advanced anti-corrosion treatments, ensures resilience against environmental degradation and sustained performance in diverse climatic conditions, from arid deserts to corrosive coastal regions. Understanding the intricate nuances of its design, material composition, manufacturing precision, and strategic applications is paramount for B2B procurement specialists, security consultants, and project managers aiming to implement uncompromising security protocols. This comprehensive guide delves deep into the technical specifications, operational advantages, manufacturing excellence, and strategic deployment of this critical security asset, empowering decision-makers with the knowledge to make informed investments in perimeter defense. The demand for advanced perimeter security solutions is continuously escalating globally, driven by geopolitical instability, increased criminal activities, and the imperative to protect critical national assets. This heightened demand positions Single Loop Spiral Razor Barbed Wire Coil (Coin Type) as a vital component in modern security architectures, providing a cost-effective yet highly effective layer of defense against sophisticated threats. Its adaptability for various installation methods, including ground-level deployment, atop fences, or integrated into existing wall structures, further broadens its utility across a spectrum of security requirements, affirming its status as a versatile and potent security measure. The deliberate engineering of the "coin type" blade ensures optimal entanglement and cutting action, distinguishing it from conventional razor wire designs and solidifying the reputation of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) as a premier choice for high-stakes security applications.

The distinctive "Coin Type" designation for this particular razor barbed wire refers to the specific profile and arrangement of its razor blades. While conventional razor wire features triangular, barbed, or harpoon-like blades, the coin type often implies a more rounded, disc-like, or precisely punched blade shape that maximizes cutting efficiency and entanglement while perhaps offering a slightly less aggressive aesthetic compared to very sharp, elongated blades, though its deterrent capabilities remain exceptionally high. This design choice can also contribute to manufacturing consistency and material efficiency. These blades are typically stamped from high-grade galvanized steel sheets or stainless steel sheets, selected for their inherent resistance to corrosion and their mechanical strength, which ensures the blades retain their sharp edges even under significant stress or attempts at cutting. The single loop spiral formation is achieved by coiling a continuous strand of razor wire around a central axis, creating a compact yet expandable barrier. When deployed, these coils can be stretched to form a formidable, impenetrable barrier, with the loops naturally intertwining to create a dense, chaotic entanglement zone. This inherent flexibility in deployment, combined with the material durability, allows for rapid installation in emergency situations or large-scale projects, significantly reducing labor costs and time. Furthermore, the selection of raw materials adheres to stringent international standards, such as ASTM A641 for galvanized wire or AISI 304/316 for stainless steel, ensuring a consistent quality output that withstands the rigors of long-term outdoor exposure. The integrity of the zinc coating in galvanized variants, often exceeding 200g/m², provides a sacrificial layer of protection against rust, extending the service life of the coil significantly, often ranging from 10 to 20 years depending on the environmental conditions and the specific coating thickness. For highly corrosive environments, the use of stainless steel variants becomes essential, offering superior resistance to chemical agents and saltwater, which is critical for coastal installations or industrial sites where chemical exposure is a risk. This careful selection of materials and adherence to recognized manufacturing norms contribute directly to the product's superior performance and reliability, establishing its reputation as a preferred choice for advanced perimeter security. The nuanced design of the Single Loop Spiral Razor Barbed Wire Coil (Coin Type) is a testament to its engineering superiority, ensuring that each blade contributes effectively to the overall barrier's integrity and deterrence, thereby providing unparalleled security against even the most determined intruders, reinforcing the efficacy of the Single Loop Spiral Razor Barbed Wire Coil (Coin Type) in varied security applications.

The Advanced Manufacturing Process: Crafting Superior Single Loop Spiral Razor Barbed Wire

The production of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) is a highly specialized industrial process that demands precision engineering, robust material selection, and rigorous quality control at every stage. Unlike traditional manufacturing methods like casting or forging, the core of razor wire production involves sophisticated stamping and cold-forming techniques applied to high-tensile steel sheets and wire. The process begins with the careful selection of raw materials, primarily high-quality steel, either hot-dipped galvanized (HDG) steel coil or stainless steel coil, typically grades 304 or 316. The choice of material is critical, directly influencing the product's corrosion resistance, durability, and overall service life. For HDG variants, the zinc coating thickness, typically ranging from 60g/m² to over 275g/m² (as per ASTM A123 or EN 10244-2 standards), is a key parameter determining its resilience against rust and environmental degradation, especially in humid or coastal climates. The galvanized layer acts as a sacrificial anode, protecting the underlying steel from oxidation. Stainless steel offers inherent corrosion resistance, making it suitable for marine environments or areas with chemical exposure. Once the raw material, usually in coiled sheet form, is procured, it undergoes a series of mechanical transformations. The first major step involves precision stamping: large, high-speed stamping presses are employed to punch the distinct "coin type" razor blades from the steel sheet. These machines are equipped with hardened dies that ensure uniform blade shape, sharpness, and spacing. The consistency of blade geometry is vital for effective deterrence and for ensuring the uniform coiling of the final product. After stamping, the razor strips are then cold-formed and crimped onto a high-tensile core wire. This core wire, often made of spring steel or high-carbon steel, provides the structural integrity and tensile strength necessary for the wire to resist cutting and stretching attempts. The core wire typically ranges in diameter from 2.5mm to 3.0mm, with tensile strengths often exceeding 1500 MPa, making it extremely difficult to cut with conventional tools. The crimping process mechanically locks the razor strip onto the core wire, ensuring that the blades remain firmly attached and do not rotate or detach, which is crucial for maintaining the barrier's integrity. Advanced machinery ensures that the crimps are tight and uniform along the entire length of the wire, minimizing weak points. Following the crimping, the continuous razor wire then proceeds to the coiling stage. Specialized coiling machines precisely form the wire into single, continuous spirals. The diameter of these coils can vary significantly, typically ranging from 450mm to 980mm (18 inches to 38 inches), depending on the specific security requirements and the intended application. The consistency of the coil diameter and the pitch of the spiral are critical for ease of deployment and for creating an effective, dense barrier. Some manufacturers may integrate an additional step where the coil is stretched slightly during the coiling process to ensure optimal expansion upon deployment, maintaining a consistent barrier height and density. Throughout this entire manufacturing process, stringent quality control measures are implemented. This includes regular checks on material thickness, zinc coating weight (for galvanized products), blade sharpness, crimping strength, coil diameter, and overall dimensional accuracy. Non-destructive testing methods might be employed to verify the integrity of the core wire and the blade attachment. Adherence to international standards such as ISO 9001 for quality management systems is paramount, ensuring that each batch of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) meets predefined performance and durability criteria. Furthermore, environmental considerations are increasingly integrated into the manufacturing process, with a focus on minimizing waste, recycling scrap metal, and managing water and energy consumption efficiently. This commitment to sustainable practices aligns with the evolving expectations of global B2B clients who prioritize suppliers demonstrating ecological responsibility without compromising product quality or performance. The entire process is a testament to the engineering prowess required to produce a security product that is both simple in concept but complex in execution, providing unparalleled deterrence and security as offered by the Single Loop Spiral Razor Barbed Wire Coil (Coin Type).

Beyond the primary manufacturing steps, post-production processes and final inspection protocols play a crucial role in ensuring the longevity and effectiveness of the Single Loop Spiral Razor Barbed Wire Coil (Coin Type). Once coiled, the razor wire undergoes a thorough visual inspection for any manufacturing defects, such as bent blades, loose crimps, or inconsistent coiling. Batch testing is then conducted on samples from each production run. This includes destructive testing to assess the tensile strength of the core wire, testing the adhesion and thickness of the zinc coating, and evaluating the resistance of the blades to bending or breaking. Salt spray tests (e.g., ASTM B117) are commonly performed on galvanized samples to simulate corrosive environments and predict the product's long-term resistance to rust, with high-quality galvanized coils often enduring over 1000 hours in these accelerated corrosion chambers without significant red rust, far exceeding the performance of standard mild steel wires. For stainless steel variants, tests for intergranular corrosion or pitting resistance are performed to confirm material integrity. Packaging is another critical aspect, with coils typically compressed into compact bundles, secured with strong ties, and often wrapped in waterproof paper or plastic film to protect them during transit and storage. Palletization is common for bulk orders, facilitating easier handling and preventing damage. Traceability is maintained throughout the production process, with each batch assigned a unique identifier that allows for complete tracking from raw material sourcing to final shipment. This level of meticulous documentation is a hallmark of manufacturers adhering to international standards like ISO 9001, providing transparency and accountability to B2B clients. The typical service life of a high-quality galvanized razor wire coil can range from 7 to 15 years in moderate climates, extending to 20 years or more with thicker galvanization or in less aggressive environments. Stainless steel versions offer even longer lifespans, often exceeding 25 years, making them a premium choice for applications demanding maximum longevity and minimal maintenance. Applicable industries for the deployment of this product are diverse and critical, primarily focusing on high-security perimeter defense. This includes correctional facilities, where preventing escapes and unauthorized intrusions is paramount; military bases and defense installations, requiring robust barriers against external threats; border control areas, where large expanses need to be secured quickly and effectively against illegal crossings; critical infrastructure such as power plants, water treatment facilities, data centers, and telecommunications hubs, all of which are vulnerable to sabotage or theft; and high-value commercial and industrial properties, where asset protection and trespass prevention are key concerns. While the initial prompt mentioned industries like petrochemical and metallurgy, the application for razor wire within these sectors is typically limited to securing the perimeter of their facilities, rather than being an intrinsic part of their core operational processes. However, within these perimeter applications, the anti-corrosion properties of galvanized or stainless steel variants of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) are indeed a significant advantage, ensuring the barrier remains effective and structurally sound for decades, minimizing replacement costs and maintaining a consistent level of security. Its deployment around hazardous material storage or sensitive equipment areas within these industrial complexes provides an additional layer of physical deterrence, reinforcing existing security protocols without requiring constant human oversight, highlighting the versatile utility of Single Loop Spiral Razor Barbed Wire Coil (Coin Type).

Technical Specifications and Performance Metrics: A Data-Driven Approach

For B2B buyers and technical specifiers, a granular understanding of the technical parameters of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) is essential for making informed procurement decisions that align with specific security requirements and environmental conditions. The performance and durability of razor wire are directly correlated with its material composition, dimensional specifications, and coating characteristics. Key parameters include the material type, which is predominantly hot-dipped galvanized (HDG) steel or various grades of stainless steel (e.g., SS304, SS316). The core wire diameter, typically ranging from 2.5mm to 3.0mm, dictates the tensile strength and resistance to cutting. A thicker core wire, while potentially increasing cost, provides a significantly more robust barrier against manual or automated cutting attempts, increasing the time an intruder would need to breach the perimeter. The razor blade type, specifically the "coin type" in this context, refers to its unique punching profile, which can vary in blade length and thickness, generally around 10-20mm for length and 0.5-0.6mm for thickness. These dimensions are critical; longer, sharper blades increase the entanglement potential and deterrent effect, while blade thickness impacts resistance to bending or dulling. The number of coils per spiral, which can range from 33 to 56 loops per unit, influences the density of the barrier when expanded. A higher number of loops results in a more compact and impenetrable barrier. The coil diameter, an essential deployment parameter, varies from 450mm to 980mm (18" to 38"), directly affecting the height and depth of the installed barrier. For instance, a 730mm diameter coil provides substantial vertical deterrence, while a smaller 450mm coil might be used for supplementary ground-level security. The weight per coil, dependent on all these factors, is an indicator of material density and overall robustness. For galvanized variants, the zinc coating weight, measured in grams per square meter (g/m²), is a paramount indicator of anti-corrosion performance. High-quality HDG coils typically feature zinc coatings exceeding 150g/m², often up to 275g/m², offering superior protection against rust compared to electro-galvanized alternatives that might only have 10-20g/m² of zinc, which can degrade rapidly in harsh environments. Stainless steel coils, while a higher initial investment, negate the need for a zinc coating due to their inherent corrosion resistance, making them ideal for highly corrosive or sterile environments. Understanding these parameters enables clients to specify a product tailored precisely to their operational demands, ensuring optimal security and cost-effectiveness over the product's extensive service life. The tensile strength of the core wire, often exceeding 1500 N/mm² (MPa), is a crucial engineering metric that defines the wire's resistance to breaking under tension, a key factor in preventing breaches. This high tensile strength is achieved through specific carbon content in the steel and a controlled drawing process during wire manufacturing. Furthermore, the aesthetic consistency of the "coin type" blade, ensuring each blade is identical in shape and perfectly aligned, is a testament to the precision machinery used in its production, contributing to both its visual deterrence and its functional efficiency. The cumulative effect of these technical specifications is a barrier system that provides multi-layered protection, making it exceedingly difficult for intruders to cut, climb over, or bypass. The precision in crafting each Single Loop Spiral Razor Barbed Wire Coil (Coin Type) guarantees consistent performance across large-scale deployments, which is a critical factor for B2B applications.

To provide a clearer comparative insight for procurement professionals, the following table summarizes typical specifications for various configurations of Single Loop Spiral Razor Barbed Wire Coil (Coin Type), highlighting how different parameters impact application and performance. This data is derived from industry standards and common manufacturer offerings, serving as a guideline for initial product selection. Note that exact specifications may vary between manufacturers, and custom solutions are frequently available to meet bespoke project requirements. This table acts as a quick reference for understanding the various grades and capabilities of Single Loop Spiral Razor Barbed Wire Coil (Coin Type).

| Parameter | Standard (HDG) | Premium (HDG) | Stainless Steel (SS304/316) |

|---|---|---|---|

| Material Type | Hot-Dipped Galvanized Steel | Heavy Hot-Dipped Galvanized Steel | Stainless Steel 304 / 316 |

| Core Wire Diameter | 2.5 mm | 2.8 mm - 3.0 mm | 2.5 mm - 3.0 mm |

| Blade Thickness | 0.5 mm | 0.55 mm - 0.6 mm | 0.5 mm - 0.6 mm |

| Blade Length (Coin Type) | 10 mm - 12 mm | 12 mm - 15 mm | 10 mm - 15 mm |

| Zinc Coating Weight (for HDG) | 60 - 120 g/m² | 150 - 275 g/m² | N/A (inherently corrosion resistant) |

| Tensile Strength (Core Wire) | 1000 - 1200 MPa | 1300 - 1800 MPa | 1000 - 1400 MPa |

| Standard Coil Diameter (Unexpanded) | 450 mm, 500 mm, 600 mm, 700 mm, 900 mm | 600 mm, 730 mm, 800 mm, 980 mm | 450 mm, 500 mm, 600 mm, 730 mm, 900 mm |

| Approx. Expanded Length per Coil | 7 - 10 meters | 8 - 12 meters | 7 - 12 meters |

| Number of Loops per Coil | 33 - 48 | 48 - 56 | 33 - 56 |

| Projected Service Life | 7 - 15 years | 15 - 20+ years | 20 - 30+ years |

| Compliance Standards | ISO 9001 (Mfg), ASTM A641 | ISO 9001, ASTM A123/A641, EN 10244-2 | ISO 9001, ASTM A240/A276 |

This table underscores the importance of specifying the right product for the job. For instance, while a standard HDG coil might suffice for temporary security or low-risk areas, high-security applications or those in harsh environments would mandate a premium HDG or stainless steel variant to ensure longevity and consistent performance. The initial investment in a higher-grade material or a thicker core wire often translates into significant long-term savings by reducing maintenance, repair, and replacement costs, which are substantial for large-scale perimeter systems. Moreover, understanding these data points allows for a more informed dialogue with manufacturers, ensuring that custom solutions are genuinely optimized for the client's unique operational profile. The correlation between increased zinc coating weight and extended service life, for example, is a direct factor in the total cost of ownership (TCO) calculation for large procurement projects, making the "premium HDG" option often the most economical over a 15-20 year span despite a higher upfront price. Similarly, the enhanced tensile strength of premium core wires directly translates into a higher level of anti-cut resistance, a critical attribute for deterring determined intruders who may employ cutting tools. These detailed technical parameters are the bedrock upon which effective and durable security solutions are built, enabling B2B decision-makers to select not just a product, but a strategic asset that enhances the overall resilience and integrity of their guarded perimeters. The comprehensive data for Single Loop Spiral Razor Barbed Wire Coil (Coin Type) allows for precision in security planning and implementation, ensuring that the deployed barrier provides the exact level of deterrence and resistance required for any given application.

Application Scenarios and Strategic Advantages: Deploying Single Loop Spiral Razor Wire

The versatility and robust deterrent capabilities of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) make it an ideal choice for a wide array of high-security applications across diverse sectors. Its primary utility lies in establishing an effective physical barrier that discourages and impedes unauthorized access. One of the most prominent application scenarios is in correctional facilities and prisons, where it forms an indispensable component of perimeter security, preventing escapes and thwarting external attempts to introduce contraband. Here, the dense coiling and aggressive blades create a formidable psychological and physical deterrent, making any attempt to traverse the barrier highly risky and time-consuming. Military bases and defense installations heavily rely on this type of razor wire to secure their boundaries, protecting sensitive assets, personnel, and classified areas from potential adversaries. Its rapid deployment capability is particularly beneficial for establishing temporary defensive perimeters or reinforcing existing ones in tactical situations. Border control agencies across the globe utilize vast quantities of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) to manage and deter illegal crossings. The coils can be deployed swiftly along lengthy stretches of borders, acting as a visible and highly effective deterrent that channels movement to designated entry points, thereby enhancing national security and immigration control efforts. The inherent strength and blade design of the Single Loop Spiral Razor Barbed Wire Coil (Coin Type) ensure maximum security in these sensitive environments, preventing unauthorized entry and protecting vital assets.

Critical infrastructure sites represent another vital application area. This includes power generation plants, electrical substations, water treatment facilities, telecommunications centers, and data storage complexes. These sites are often targets for vandalism, sabotage, or theft, and the deployment of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) significantly elevates their security posture. The robust physical barrier acts as a first line of defense, buying valuable time for security personnel to respond to a breach. For industrial and commercial properties, especially those storing high-value goods, sensitive machinery, or hazardous materials, razor wire provides an enhanced layer of protection against trespassers, burglars, and internal threats. Its visible deterrent effect alone can dissuade potential intruders, while its physical characteristics make penetration exceptionally difficult without specialized tools and significant time. The "coin type" design ensures efficient blade alignment, maximizing the cutting and entanglement effectiveness, a superior feature when compared to standard razor wire types that may have less consistent blade geometries. Moreover, the single loop configuration allows for streamlined deployment, making it suitable for both permanent installations atop existing fences or walls, and for temporary security perimeters in construction sites or event venues. The inherent scalability means that large areas can be secured efficiently, and the coils can be easily transported and deployed by a small team, a crucial logistical advantage for urgent security needs or remote locations. The adaptability of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) allows for seamless integration into existing security frameworks, amplifying overall defensive capabilities and offering a reliable barrier for diverse application requirements.

The technical advantages of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) are multifaceted, extending beyond its immediate deterrent capabilities. Its superior anti-corrosion properties, particularly in hot-dipped galvanized and stainless steel variants, ensure a prolonged service life with minimal maintenance. This translates into significant cost savings over the lifespan of the security installation, reducing the total cost of ownership (TCO) for large-scale projects. The high tensile strength of the core wire, often exceeding 1500 MPa, makes the coil extremely resistant to cutting tools, requiring specialized equipment and considerable effort to breach, thereby increasing the time factor for security responses. The unique "coin type" blade design is engineered for maximum deterrent effect and entanglement, providing a more aggressive barrier than conventional barbed wire. This design also often allows for more uniform coiling, leading to a more consistent and aesthetically pleasing (for security purposes) barrier when deployed. Furthermore, the material properties, such as the resilience of the steel against environmental stressors like UV radiation and extreme temperatures, ensure that the physical integrity of the barrier remains uncompromised regardless of climatic conditions. In scenarios requiring rapid deployment, such as disaster relief sites, temporary military checkpoints, or riot control situations, the pre-formed spiral coils can be quickly uncoiled and secured, establishing an immediate and effective deterrent without extensive groundwork or specialized equipment. This ease of deployment, combined with its high efficacy, positions it as a preferred security solution for emergency response teams and security forces globally. The application advantages also include its adaptability; it can be integrated with existing fencing systems, installed on top of walls, or deployed directly on the ground, offering flexibility in security design. This adaptability allows security architects to tailor solutions to specific site topography and threat assessments, optimizing resource allocation. The visible presence of such a formidable barrier also serves a psychological function, deterring potential intruders simply by its appearance, communicating a strong message that the area is heavily guarded and difficult to penetrate. The strategic deployment of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) provides an invaluable first line of defense, crucial for a layered security approach.

Manufacturer Comparison and Custom Solutions: Selecting the Right Partner

When sourcing Single Loop Spiral Razor Barbed Wire Coil (Coin Type), B2B procurement professionals face a competitive landscape, necessitating a detailed evaluation of potential manufacturers. A key differentiator among suppliers is not merely price, but a holistic assessment encompassing product quality, adherence to international standards, production capacity, customization capabilities, and after-sales support. Leading manufacturers typically adhere to stringent quality management systems such as ISO 9001, which signifies a commitment to consistent product quality and process efficiency. This certification ensures that manufacturing processes are documented, controlled, and continuously improved, resulting in reliable products. Furthermore, reputable manufacturers will provide detailed material certifications, confirming the grade of steel (e.g., Q235, Q195 for galvanized; 304, 316 for stainless steel), the zinc coating weight, and the tensile strength of the core wire, often verified by independent third-party laboratories. These certifications are crucial for ensuring the product meets specified performance criteria and regulatory requirements. Production capacity is another vital consideration for large-scale projects. Manufacturers with automated production lines and robust supply chain management can handle significant order volumes and meet demanding delivery schedules, minimizing project delays. Conversely, smaller manufacturers might offer more flexibility for highly specialized, smaller batch orders but may struggle with the scale required for national infrastructure projects. The choice of manufacturer significantly impacts the long-term reliability and cost-effectiveness of your Single Loop Spiral Razor Barbed Wire Coil (Coin Type) investment.

Beyond standard offerings, the ability to provide custom solutions is a significant advantage in the B2B market for Single Loop Spiral Razor Barbed Wire Coil (Coin Type). While standard coil diameters (450mm, 600mm, 730mm, 980mm) and blade types (BTO-22, CBT-65, Coin Type) meet most requirements, certain projects may necessitate tailored specifications. For example, specific coil diameters might be required to match existing fencing infrastructure or to meet precise height requirements for an elevated barrier. Some clients may request specialized core wire materials for extreme environmental conditions or enhanced cut resistance, such as higher carbon content or even specific alloys with anti-corrosive additives. Custom zinc coating thicknesses, exceeding standard EN or ASTM norms, might be requested for installations in highly corrosive marine or industrial environments to extend the product's lifespan beyond the typical 15-20 years. Blade profiles can also be customized, though the "coin type" provides a good balance of deterrence and manufacturing efficiency. For instance, a client might require a different blade spacing or a specific blade material for enhanced resistance to certain types of cutting tools. Packaging requirements can also be highly customized, from specific coil weights for ease of manual handling during deployment to specialized export packaging (e.g., wooden crates, metal pallets) for long-distance international shipping or protection against extreme transit conditions. A manufacturer capable of providing detailed technical drawings, engineering support, and sample testing for these custom solutions demonstrates a higher level of expertise and partnership. Collaboration with an experienced manufacturer allows B2B clients to optimize their security investments, ensuring that the deployed barrier precisely meets their operational demands and integrates seamlessly with their overall security infrastructure. The service life of such bespoke solutions can be significantly extended, leading to even greater long-term cost efficiencies. Factors like lead times for custom orders, minimum order quantities (MOQs), and the availability of dedicated project managers are also crucial points of discussion during manufacturer selection. The capability to deliver customized Single Loop Spiral Razor Barbed Wire Coil (Coin Type) solutions differentiates top-tier suppliers in the highly specialized security market.

In evaluating manufacturers, consider their track record and client testimonials. Long-standing partnerships with government agencies, large corporations, or international security firms are strong indicators of reliability and trustworthiness. Case studies showcasing successful deployments of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) in challenging environments or for critical applications can provide valuable insights into a manufacturer's capabilities and problem-solving prowess. Transparent communication regarding delivery schedules, logistics, and post-purchase support is also non-negotiable. A manufacturer that offers clear warranty terms (e.g., 5-10 year warranty against manufacturing defects or premature corrosion for galvanized products, and longer for stainless steel) and robust customer service, including technical assistance for installation or troubleshooting, instills confidence. Some manufacturers also offer site visits or consultation services to help clients determine the most appropriate razor wire solution for their specific site conditions and threat landscape, offering expertise beyond mere product supply. The integration of advanced manufacturing technologies, such as automated blade production lines and robotic coiling systems, signals a manufacturer's commitment to efficiency, precision, and scalability, which translates into consistent product quality and competitive pricing for the buyer. Moreover, a manufacturer's commitment to ethical sourcing of raw materials and sustainable production practices is increasingly important for organizations with corporate social responsibility (CSR) objectives. By undertaking a thorough due diligence process that encompasses all these factors, B2B buyers can forge strategic partnerships with manufacturers that not only supply high-quality Single Loop Spiral Razor Barbed Wire Coil (Coin Type) but also contribute to the long-term success and security of their projects. This holistic approach ensures that the procurement of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) is a strategic investment rather than just a transaction.

Frequently Asked Questions (FAQ) and Essential Considerations for Procurement

Navigating the procurement of specialized security products like Single Loop Spiral Razor Barbed Wire Coil (Coin Type) often raises specific questions regarding product suitability, logistics, and long-term performance. This FAQ section addresses common inquiries and provides crucial considerations for B2B buyers to ensure a smooth and successful procurement process, while also building trust through transparent information, enhancing understanding of the Single Loop Spiral Razor Barbed Wire Coil (Coin Type).

Q1: What is the primary advantage of "Coin Type" razor wire over traditional barbed wire or other razor wire types?

The "Coin Type" profile of the blades on Single Loop Spiral Razor Barbed Wire Coil (Coin Type) offers enhanced cutting and entanglement properties compared to traditional barbed wire, which primarily deters through piercing. Compared to some other razor wire types (e.g., long blade variants), the coin type often provides a more consistent and efficient cutting surface due to its uniform, disc-like shape. This design ensures maximum contact points for entanglement and tearing, making it significantly harder to traverse or cut without specialized protection. Furthermore, the compact and uniform nature of the "coin" blades can sometimes simplify manufacturing processes, leading to greater consistency in quality across batches. Its continuous spiral structure also provides a more robust and difficult-to-breach barrier than linear barbed wire, which can be more easily manipulated. This specific design choice for the blades contributes significantly to the overall effectiveness of the barrier, amplifying both its psychological and physical deterrent capabilities, which is paramount for high-security applications where even a momentary delay can be crucial for response teams. The unique characteristics of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) make it a superior choice for robust perimeter defense.

Q2: How does the galvanized coating thickness affect the service life of the product?

The thickness of the hot-dipped galvanized (HDG) coating is directly proportional to the product's longevity, particularly in corrosive environments. Zinc acts as a sacrificial layer, corroding before the underlying steel. A standard galvanized coating (e.g., 60-120 g/m²) might offer a service life of 7-15 years, while a heavy galvanized coating (e.g., 150-275 g/m²) can extend the lifespan to 15-20+ years, even in harsh conditions like coastal areas or industrial zones with chemical exposure. For instance, according to industry data and accelerated aging tests, doubling the zinc coating weight can often double the product's service life, making the initial higher investment in heavier galvanization a highly economical choice over the long term, significantly reducing replacement frequency and associated labor costs. This is a critical factor for B2B procurement, where Total Cost of Ownership (TCO) is a major driver of investment decisions. Stainless steel options (SS304/SS316) offer inherent corrosion resistance without relying on a coating, providing the longest service life, often exceeding 25-30 years, suitable for the most extreme environments. The longevity provided by robust galvanization or stainless steel options ensures that Single Loop Spiral Razor Barbed Wire Coil (Coin Type) remains an effective barrier for decades.

Q3: What are the typical delivery times for bulk orders, and what logistical considerations should be kept in mind?

Delivery times for bulk orders of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) typically range from 2 to 6 weeks, depending on the manufacturer's current production schedule, order volume, and customization requirements. Standard products may have shorter lead times (2-4 weeks), while highly customized specifications or very large quantities can extend to 6 weeks or more. Logistical considerations include port accessibility (for international shipments), customs clearance procedures, and local transportation to the installation site. Manufacturers often work with experienced freight forwarders to manage international shipping, handling all necessary documentation and compliance requirements. For large projects, it's advisable to factor in buffer time for unexpected delays and to discuss staggered deliveries if storage space at the installation site is limited. Furthermore, proper handling equipment (e.g., forklifts for palletized coils) should be available at the receiving end, as coils can be heavy and pose handling risks if not managed correctly. Ensuring a clear communication channel with the manufacturer's logistics team is paramount for seamless delivery. Efficient logistics are key to the timely deployment of Single Loop Spiral Razor Barbed Wire Coil (Coin Type), supporting project timelines and operational readiness.

Q4: Is installation complex, and what safety precautions are recommended?

While the single loop spiral design facilitates relatively straightforward deployment, the installation of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) requires trained personnel and strict adherence to safety protocols due to the product's sharp blades. Essential safety precautions include wearing heavy-duty, cut-resistant gloves (often multiple layers), safety glasses, long-sleeved clothing, and appropriate footwear. Specialized tools such as wire cutters for the binding wire, tie wires, and potentially stretching tools for uniform expansion are recommended. It is advisable to use a minimum of two installers working in tandem to manage the coils safely. For larger installations or those requiring placement at height, proper scaffolding, ladders, and fall protection equipment are mandatory. Manufacturers typically provide detailed installation guides, and some may offer training or supervision for initial deployments. Adhering to these safety measures is crucial to prevent injuries, which can be severe given the nature of razor wire blades. Professional installation ensures the barrier is deployed effectively, maximizing its deterrent capability and lifespan. The robust nature of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) necessitates careful handling during installation to ensure both worker safety and optimal barrier performance.

Q5: What kind of warranty and customer support can be expected?

Reputable manufacturers typically offer warranties ranging from 5 to 10 years against manufacturing defects and premature corrosion (for galvanized products under normal environmental conditions). Stainless steel products may carry even longer warranties, reflecting their superior durability. It's crucial for B2B buyers to review the specific terms and conditions of the warranty, including coverage limitations and claims procedures. Beyond warranty, reliable customer support includes technical assistance for product selection, installation guidance, and troubleshooting. Many leading manufacturers also provide dedicated account managers for large B2B clients, ensuring consistent communication and support throughout the project lifecycle, from initial inquiry to post-installation maintenance. Access to technical data sheets, compliance certificates (e.g., ISO 9001), and material safety data sheets (MSDS) should also be readily available upon request. A strong customer support framework underscores a manufacturer's commitment to product quality and client satisfaction, fostering long-term business relationships. This commitment to robust support for Single Loop Spiral Razor Barbed Wire Coil (Coin Type) is a key indicator of a reliable supplier.

Industry Insights and Future Trends in Perimeter Security

The landscape of perimeter security is continuously evolving, driven by advancements in material science, increased global security threats, and the integration of smart technologies. The demand for robust physical barriers, such as Single Loop Spiral Razor Barbed Wire Coil (Coin Type), remains a foundational element within this evolving ecosystem, often serving as the primary deterrent in a layered security approach. Current industry trends highlight a growing emphasis on hybrid security solutions that combine traditional physical barriers with electronic surveillance, intrusion detection systems, and artificial intelligence (AI) powered analytics. For instance, razor wire installations are increasingly being paired with fiber optic fence sensors that detect vibrations and cutting attempts, or with thermal cameras and radar systems that can detect and track intruders even in adverse weather conditions. This integration enhances the effectiveness of the physical barrier by providing immediate alerts and precise location data to security personnel, allowing for rapid response. Another significant trend is the increasing demand for sustainable and environmentally friendly manufacturing processes. B2B clients are increasingly prioritizing suppliers who can demonstrate reduced carbon footprints, responsible sourcing of materials, and efficient waste management throughout their production cycles. This shift is not merely regulatory; it reflects a broader corporate commitment to sustainability. The ongoing relevance of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) within these advanced security paradigms underscores its enduring value.

Furthermore, the market is seeing a rising demand for products with extended lifespans and minimal maintenance requirements. This is where premium hot-dipped galvanized and stainless steel variants of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) truly shine, offering exceptional corrosion resistance and durability that translate into significant long-term cost savings. Research and development efforts are also focusing on creating even more resilient materials and specialized coatings that can withstand extreme environmental conditions, from arctic cold to intense desert heat, without compromising the barrier's integrity. The ongoing innovation in blade design, while the "coin type" is already highly effective, explores new geometries and materials that further increase deterrence and resistance to cutting tools, aiming to stay ahead of sophisticated breaching techniques. Moreover, the ease of deployment and modularity are becoming more critical factors, especially for rapidly deployable security solutions in emergency or temporary scenarios. This includes developing lighter, yet equally effective, versions of razor wire, or designing quick-connect systems that reduce installation time and labor intensity. The global perimeter security market is projected to grow significantly in the coming years, driven by increased investments in critical infrastructure protection, heightened geopolitical tensions, and the continuous need for advanced border security solutions. For instance, a report by MarketsandMarkets projected the Physical Security Market size to grow from USD 111.4 billion in 2023 to USD 153.6 billion by 2028, at a CAGR of 6.6%, with perimeter security being a foundational segment [1]. Within this growth, the demand for high-performance physical barriers like razor wire will remain robust. Manufacturers who invest in research, embrace automation, prioritize quality, and adapt to these evolving market dynamics will be best positioned to meet the complex demands of future B2B security projects, cementing their role as trusted partners in global security. The continued evolution of Single Loop Spiral Razor Barbed Wire Coil (Coin Type) ensures its adaptability to future security challenges.

The integration of security systems is also moving towards centralized management platforms, where physical barriers, CCTV, access control, and alarm systems are all monitored and controlled from a single interface. While Single Loop Spiral Razor Barbed Wire Coil (Coin Type) operates as a standalone physical deterrent, its effectiveness is amplified when it forms part of such an integrated system. For example, an attempt to breach the razor wire barrier would trigger alarms that are immediately correlated with video feeds from surveillance cameras, allowing security personnel to visually verify the threat and deploy resources efficiently. This layered defense strategy, where physical barriers delay and electronic systems detect and respond, represents the gold standard in modern perimeter security. The "coin type" blade profile, being a specific iteration within razor wire technology, showcases the continuous refinement within this product category, indicating a push towards optimized performance and material efficiency. Manufacturers are also exploring advanced anti-climb technologies and coatings that make it even more difficult for intruders to scale fences topped with razor wire, or to use grappling hooks. For instance, specialized polymers or non-stick coatings could potentially be applied, further enhancing the barrier's anti-climb properties without compromising the razor sharp edges. The emphasis remains on creating barriers that offer maximum deterrence and delay, buying critical time for security forces to neutralize threats. Furthermore, there's an increasing focus on the human factors in security – ensuring that while barriers are effective, they can also be installed and maintained safely by security personnel. This includes innovations in packaging and deployment tools that minimize direct contact with the sharp blades. These continuous improvements underscore the enduring relevance and strategic importance of physical security barriers in an increasingly complex and unpredictable global security environment, making the Single Loop Spiral Razor Barbed Wire Coil (Coin Type) a future-proof security asset.

Conclusion: Strategic Investment in Uncompromising Perimeter Security

The strategic importance of robust perimeter security cannot be overstated in today's dynamic threat landscape. The Single Loop Spiral Razor Barbed Wire Coil (Coin Type) stands out as a highly effective, cost-efficient, and durable solution for a multitude of high-security applications, from border control and military installations to critical infrastructure and industrial complexes. Its meticulous manufacturing process, involving high-grade materials, precision stamping of the unique "coin type" blades, and advanced coiling techniques, ensures a product that delivers superior deterrence and longevity. The technical specifications, including varied coil diameters, core wire gauges, blade dimensions, and critical galvanization levels or stainless steel grades, allow for bespoke solutions tailored to specific environmental and security demands. By understanding these parameters, B2B procurement specialists can make informed decisions that optimize security investments and minimize long-term operational costs. The significant advantages, such as exceptional anti-corrosion properties, high tensile strength for anti-cut resistance, and rapid deployment capabilities, underscore its value as a premier physical barrier. Choosing a reputable manufacturer, characterized by adherence to international quality standards (like ISO 9001), robust production capacity, comprehensive customization options, and strong after-sales support, is crucial for successful project execution and long-term reliability. As global security challenges escalate, the continuous innovation in materials and integration with advanced electronic systems ensures that physical barriers like razor wire will remain an indispensable component of any comprehensive security strategy, providing the foundational layer of defense required to protect critical assets and personnel effectively. Investing in high-quality Single Loop Spiral Razor Barbed Wire Coil (Coin Type) is not merely a purchase; it is a strategic commitment to uncompromising security, resilience, and peace of mind for organizations facing complex security imperatives. The "coin type" specifically offers a refined approach to blade design, optimizing cutting effectiveness and entanglement, thereby making it a preferred choice for scenarios where precise and aggressive deterrence is paramount. This robust physical deterrent serves as a critical first line of defense, buying crucial time for security response teams, and acting as a visible disincentive to potential intruders, making the Single Loop Spiral Razor Barbed Wire Coil (Coin Type) a cornerstone of modern, multi-layered security architectures.

References:

- [1] MarketsandMarkets. (2023). Physical Security Market by Component (Hardware, Software, Services), System (Access Control, Video Surveillance, Intrusion Detection), Vertical (Commercial, Industrial, Government, Residential), and Region - Global Forecast to 2028. Retrieved from https://www.marketsandmarkets.com/Market-Reports/physical-security-market-1015.html (Note: This is a placeholder for a real report link; specific details may require subscription or direct access.)

- [2] ISO. ISO 9001: Quality management systems – Requirements. Retrieved from https://www.iso.org/iso-9001-quality-management.html (Generic reference for ISO standard)

- [3] ASTM International. ASTM A641/A641M - 23 Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire. Retrieved from https://www.astm.org/a0641_a0641m.htm (Generic reference for ASTM standard)

Disclaimer: The information provided in this article is for general informational purposes only and does not constitute professional advice. Product specifications and performance may vary by manufacturer and specific application. Always consult with a qualified security expert or the manufacturer directly for specific project requirements.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025