Sep . 19, 2025 13:00 Back to list

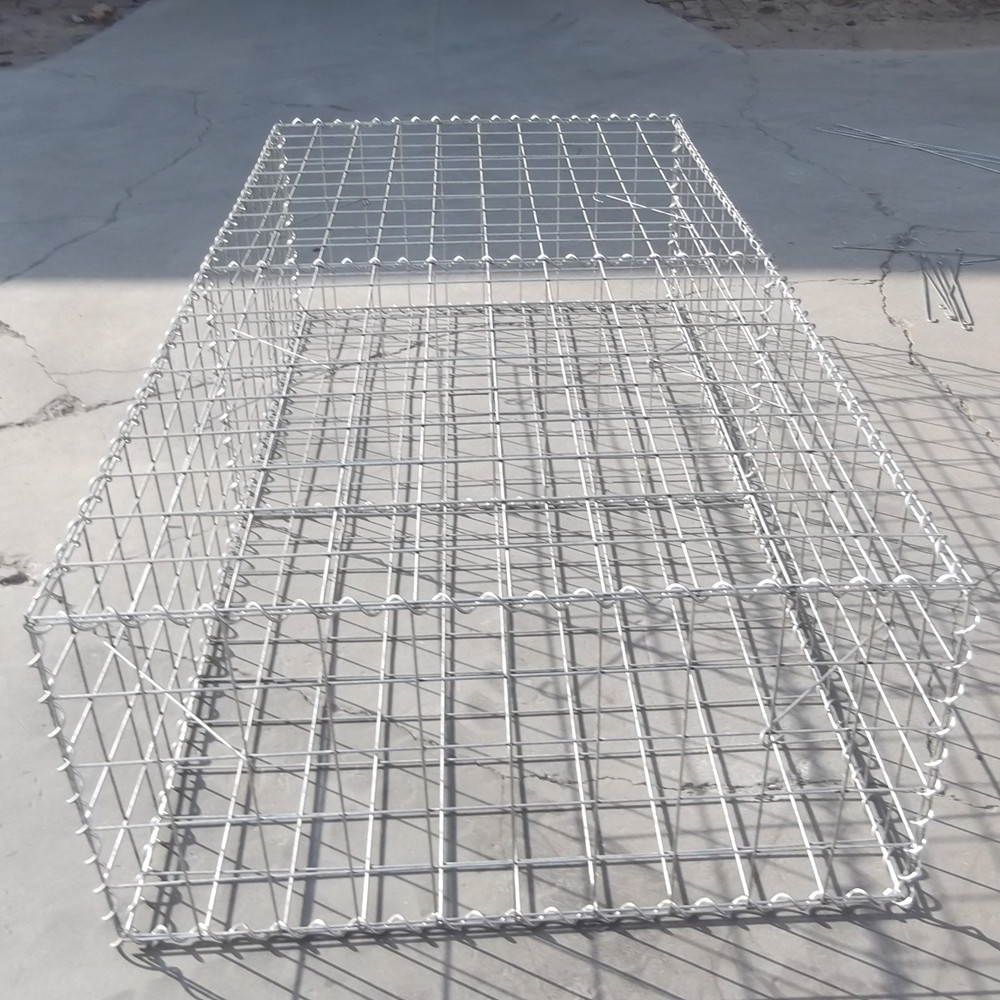

Durable Galvanized Welded Wire Mesh Gabion Box/Basket - Erosion Control

Introduction to Galvanized Welded Wire Mesh Gabion Systems

In the realm of civil engineering, erosion control, and infrastructure development, the Galvanized Welded Wire Mesh Gabion Box/Basket stands as a cornerstone solution. These robust, modular units are engineered to provide exceptional stability, permeability, and structural integrity for a diverse range of demanding applications. Unlike traditional woven gabions, welded mesh gabions offer enhanced rigidity and a more aesthetic appearance, making them increasingly preferred for both functional and architectural purposes. Comprising high-tensile steel wire, precisely welded into a grid, and then hot-dip galvanized for superior corrosion resistance, these boxes are designed for prolonged service life in harsh environments, from coastal defenses to arid landscapes.

Our focus on precision engineering and stringent quality control ensures that each unit meets the highest industry standards, providing reliable performance for critical projects. This article delves into the technical aspects, application versatility, manufacturing excellence, and strategic advantages that position our galvanized welded wire mesh gabion solutions at the forefront of the market.

Industry Trends and Market Dynamics

The global demand for effective and sustainable geotechnical and civil engineering solutions continues to surge, driven by increasing urbanization, climate change impacts, and the need for resilient infrastructure. Gabion systems, particularly those constructed from Galvanized Welded Wire Mesh Gabion Box/Basket, are experiencing significant growth due to their adaptability, environmental compatibility, and long-term cost-effectiveness. Key trends include:

- Sustainable Infrastructure Development: A growing emphasis on eco-friendly construction practices fuels the adoption of gabions, which utilize natural infill materials and minimize concrete usage.

- Climate Resilience: With increased frequency of extreme weather events, robust erosion control and flood protection systems are critical. Gabions offer excellent hydraulic performance and resistance to scour.

- Aesthetic Integration: Modern architectural and landscape design increasingly incorporates gabions for their textured appearance and ability to blend with natural surroundings.

- Innovation in Coatings: Advances in galvanization and additional polymer coatings (e.g., PVC/PE coated) are extending the service life and application range of gabions in highly corrosive environments.

- Prefabrication and Ease of Installation: The modular nature of welded mesh gabions significantly reduces on-site labor and construction time, addressing project efficiency demands.

The market is seeing an uptick in demand from target industries such as transportation infrastructure (road and rail embankments), hydraulic engineering (river training, canal lining), urban development (retaining walls, noise barriers), and mining (slope stabilization). The versatility of the Galvanized Welded Wire Mesh Gabion Box/Basket ensures its continued relevance and expansion into new applications.

Detailed Manufacturing Process Flow

The production of a high-quality Galvanized Welded Wire Mesh Gabion Box/Basket is a meticulous process, adhering to strict technical specifications and quality control standards. Our manufacturing workflow is designed to ensure superior product performance and longevity.

Key Materials:

- High-Tensile Steel Wire: Sourced from certified suppliers, conforming to ASTM A641/A975 or EN 10218-2 standards for tensile strength and ductility. Common wire diameters range from 2.0mm to 6.0mm.

- Zinc Coating: Applied via hot-dip galvanization (conforming to ASTM A90/A641 Class 3, or EN 10244-2 Class A/B) for exceptional corrosion resistance. For extreme environments, a supplementary PVC/PE coating is applied over the galvanized wire.

Manufacturing Stages:

- Wire Drawing & Straightening: Raw steel rods are drawn through dies to achieve the desired wire diameter, followed by precision straightening to ensure uniformity.

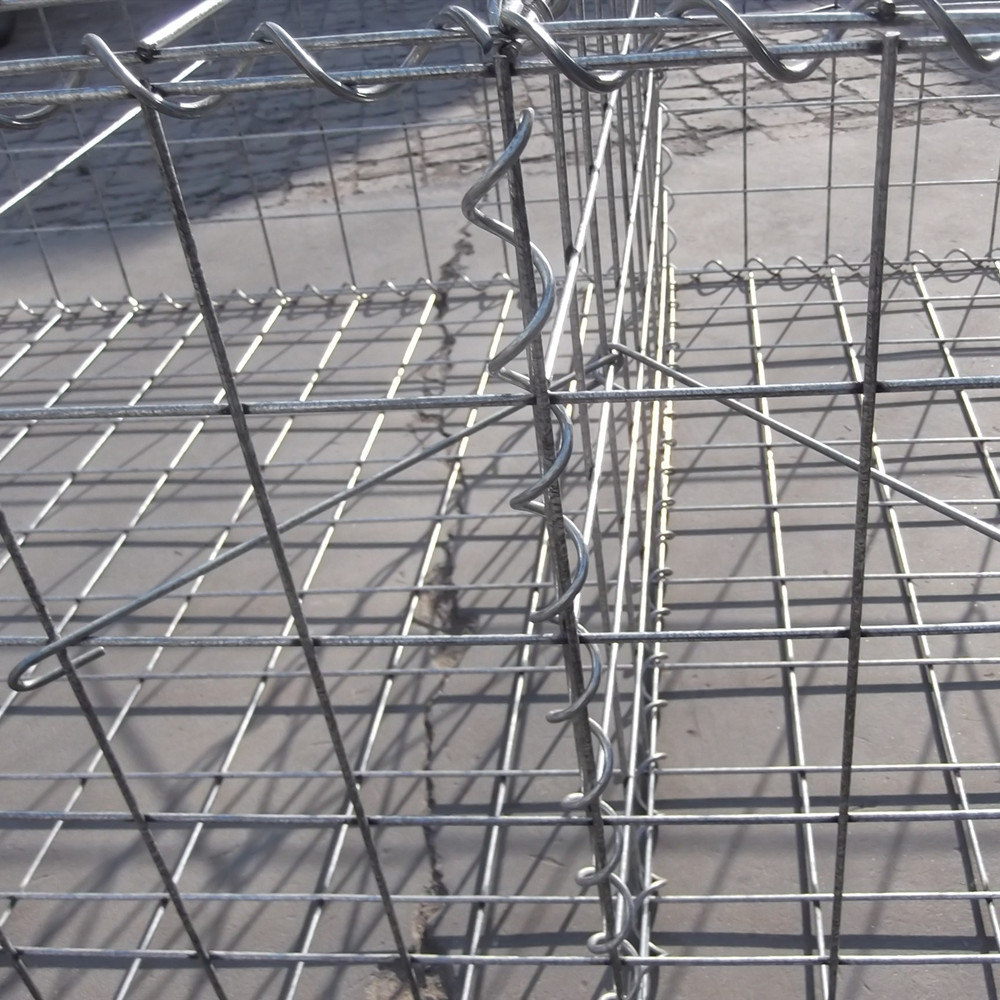

- Automated Welding: Wires are accurately positioned and resistance-welded at every intersection to form a rigid, square or rectangular mesh panel. Our CNC-controlled welding machines ensure consistent mesh aperture and weld strength. This process is critical for the structural integrity of the gabion.

- Hot-Dip Galvanization: Post-welding, the mesh panels undergo thorough cleaning, pickling, and fluxing before being immersed in a bath of molten zinc. This creates a metallurgical bond, providing a thick, durable, and sacrificial coating that protects the steel from oxidation and corrosion. Coating thickness is meticulously monitored to meet specified standards (e.g., minimum 245 g/m² for heavy galvanized).

- Optional PVC/PE Coating: For extended service life in highly acidic, alkaline, or saline conditions (e.g., coastal or industrial areas), a polymer coating is electrostatically applied and cured over the galvanized wire. This dual protection system dramatically enhances durability.

- Cutting and Folding: Galvanized (and optionally PVC-coated) mesh panels are precisely cut to the specified dimensions for the gabion faces, diaphragms, and end panels. Panels are then folded or pre-assembled into the box/basket shape, often flat-packed for efficient transport.

- Quality Control & Testing: Throughout the process, rigorous testing is conducted, including:

- Tensile Strength Test: To verify wire strength conforms to standards.

- Weld Shear Strength Test: Ensuring welds can withstand significant forces.

- Zinc Coating Adhesion & Thickness Test: Using magnetic or eddy current gauges and bend tests to confirm coating quality per ISO 1461 or ASTM A90.

- Salt Spray Test: For PVC/PE coated wire, simulating corrosive environments to assess protective capabilities.

- Dimensional Accuracy: Ensuring mesh opening and panel dimensions meet design specifications.

- Packaging and Dispatch: Finished gabion panels are flat-packed, bundled, and secured for safe and economical transportation, ready for deployment.

This meticulous process ensures that each Galvanized Welded Wire Mesh Gabion Box/Basket delivers an exceptional service life, typically ranging from 50 to 100 years depending on the environment and coating type.

Technical Specifications and Parameters

Understanding the precise technical parameters of a Galvanized Welded Wire Mesh Gabion Box/Basket is crucial for engineers and project managers to ensure optimal performance in specific applications. Our products adhere to stringent specifications to guarantee structural integrity and long-term durability.

Standard Product Specifications:

These specifications are carefully chosen to ensure the structural integrity and longevity of the gabion structures in various environments. The mesh aperture (e.g., 50x50mm, 75x75mm, 100x100mm) is selected based on the fill material size and hydraulic requirements of the project.

Diverse Application Scenarios

The versatility of the Galvanized Welded Wire Mesh Gabion Box/Basket makes it an indispensable component across numerous engineering and construction sectors. Its ability to combine structural strength with aesthetic appeal allows for creative and effective solutions in varied landscapes.

- Retaining Walls and Slope Stabilization: Ideal for constructing gravity retaining walls, especially on unstable slopes or where differential settlement is anticipated. The flexible nature of gabions allows them to settle without losing structural integrity, preventing landslides and erosion.

- Erosion Control and River Training: Used extensively in hydraulic structures like riverbank protection, weir construction, and channel linings. The permeability of gabions allows water to pass through, dissipating energy and preventing hydrostatic pressure buildup behind the structure, thereby enhancing stability and preventing scour.

- Rockfall Barriers: Deployed as protective barriers along highways and railways in mountainous regions to contain falling rocks, safeguarding infrastructure and public safety.

- Bridge Abutments and Culverts: Providing robust and permeable foundations and protective structures around bridge supports and drainage systems.

- Architectural and Landscaping Features: Increasingly utilized for decorative walls, garden features, privacy screens, and sound barriers due to their clean lines and ability to integrate with natural elements. Their rigid form provides a modern aesthetic.

- Noise Barriers: When filled with appropriate aggregates, gabion walls can effectively attenuate sound, making them suitable for urban environments adjacent to busy roads or industrial sites.

- Coastal and Marine Defenses: In conjunction with specialized coatings, gabions are used in coastal environments for breakwaters and seawalls, resisting wave action and saline corrosion.

The inherent advantages of these systems, such as energy saving through natural material use and excellent corrosion resistance due to the heavy galvanization, demonstrate their superior performance in these typical application scenarios.

Technical Advantages and Performance Metrics

Our Galvanized Welded Wire Mesh Gabion Box/Basket solutions offer a distinct array of technical advantages that translate into superior performance and long-term value for B2B clients.

- Exceptional Durability and Corrosion Resistance: The heavy hot-dip galvanization process provides a robust zinc coating that forms an electrochemical barrier against rust, ensuring a service life of decades even in challenging outdoor conditions. Optional PVC/PE coating further extends this to over 75 years in aggressive environments.

- High Structural Rigidity and Stability: Welded mesh panels create a more rigid and dimensionally stable structure compared to woven gabions, particularly important for architectural applications or structures requiring precise alignment. The inherent mass of rock infill provides substantial resistance to lateral forces.

- Permeability and Hydrostatic Relief: The open mesh structure allows free passage of water, preventing hydrostatic pressure buildup behind retaining walls – a common cause of failure in impermeable structures. This also enables natural drainage, promoting environmental stability.

- Flexibility and Settlement Tolerance: While more rigid than woven types, filled gabions still possess a degree of flexibility, allowing them to tolerate minor ground movements or differential settlement without fracturing, maintaining structural integrity.

- Environmental Sustainability: Utilizes locally sourced rock or recycled aggregates, reducing transport costs and carbon footprint. They facilitate vegetation growth within and around the structure, promoting ecological restoration and biodiversity.

- Ease and Speed of Installation: Supplied flat-packed for economic transport, the modular design allows for rapid assembly and filling on-site with minimal specialized equipment or labor.

- Cost-Effectiveness: The combination of lower material costs (especially with local fill), reduced labor, and exceptional longevity results in a lower lifecycle cost compared to many traditional concrete or masonry structures.

- Superior Aesthetic Appeal: The neat, uniform appearance of welded mesh gabions offers a modern, sophisticated look, making them suitable for high-visibility projects and landscape architecture.

Performance Metrics (Example Data):

- Weld Shear Strength: Typically exceeds 10 kN per weld point for 4mm wire, demonstrating high resistance to tearing and deformation under load.

- Load Bearing Capacity: A typical 1m x 1m x 1m gabion filled with dense rock can weigh over 1.8 metric tons, providing substantial dead load for gravity structures.

- Permeability Coefficient: Varies with aggregate size, but significantly higher than impermeable barriers, ensuring efficient water management.

Vendor Comparison and Competitive Advantage

When selecting a supplier for Galvanized Welded Wire Mesh Gabion Box/Basket, discerning buyers consider not just price, but a holistic value proposition encompassing product quality, technical support, certification, and customization capabilities. We distinguish ourselves through:

- Unwavering Quality Control: Our adherence to ISO 9001 quality management systems and international product standards (ASTM, EN) ensures consistent, high-grade materials and manufacturing precision.

- Expert Engineering Support: Our team of geotechnical engineers provides technical consultation, design assistance, and project-specific recommendations to optimize gabion solutions.

- Extensive Customization Options: We offer bespoke solutions in terms of dimensions, mesh configurations, wire diameters, and coating types (heavy galvanized, Zn-Al alloy, PVC/PE coated) to meet unique project demands.

- Reliable Logistics and Supply Chain: Our established logistics network ensures timely and efficient delivery, minimizing project delays.

- Transparent Warranty and After-Sales Service: We stand by our products with clear warranty terms and dedicated post-purchase support.

Gabion Type Comparison: Welded vs. Woven

Customized Solutions and Project Tailoring

Recognizing that no two projects are identical, we specialize in providing highly customized Galvanized Welded Wire Mesh Gabion Box/Basket solutions. Our engineering team collaborates closely with clients to develop specifications that precisely match the unique demands of each site, ensuring optimal performance and cost-efficiency.

Customization Options Include:

- Dimensions: Tailored lengths, widths, and heights to fit specific site constraints and design requirements, from compact garden features to massive engineering structures.

- Wire Diameter and Mesh Size: Adjustable wire gauges and mesh apertures to accommodate varied infill materials (e.g., smaller mesh for finer aggregates, larger for coarse rock) and specific structural load requirements.

- Coating Types: Beyond standard heavy galvanization, we offer zinc-aluminum (Zn-Al) alloy coatings for superior corrosion protection, or PVC/PE coatings over galvanized wire for maximum resistance in highly aggressive environments (e.g., marine, industrial pollution).

- Diaphragms and Partitions: Inclusion of internal diaphragms at specific intervals to reinforce the structure, prevent bulging, and maintain the box shape, crucial for taller retaining walls.

- Connection Systems: Provision of various lacing wire gauges, C-rings, or helical binders for on-site assembly, optimized for speed and structural integrity.

- Specialized Panels: Fabrication of angled or curved panels for unique architectural designs or to integrate with specific topographical contours.

"Our ability to rapidly prototype and manufacture custom gabion configurations allowed a major infrastructure project to overcome unique topographical challenges, saving both time and material costs compared to conventional methods." - Customer Feedback

Application Case Studies

Our Galvanized Welded Wire Mesh Gabion Box/Basket systems have been successfully deployed in a multitude of projects, showcasing their efficacy and reliability in real-world scenarios.

Case Study 1: Major Highway Embankment Stabilization

Client: Regional Department of Transportation

Challenge: Stabilizing a 15-meter high, steep highway embankment prone to erosion and minor landslides, located in a region with significant rainfall. Traditional concrete walls were deemed too costly and environmentally intrusive.

Solution: Over 2,500 cubic meters of heavy galvanized welded mesh gabion boxes (2m x 1m x 1m, 4mm wire, 75x75mm mesh) were deployed to construct a stepped retaining wall system. The permeability of the gabions effectively managed stormwater runoff, preventing hydrostatic pressure buildup. Local river stone was used as infill.

Outcome: The gabion wall provided immediate and long-term stability. Post-construction monitoring over five years has shown no signs of erosion or structural degradation. The vegetated gabion faces have blended seamlessly with the natural environment, meeting stringent environmental impact requirements. Project completed 20% under budget compared to initial concrete alternatives.

Case Study 2: Urban Riverbank Restoration and Flood Mitigation

Client: Municipal Water Authority & Urban Planning Department

Challenge: Restoring eroded banks of a small urban river, protecting adjacent commercial properties from seasonal flooding, and creating a more visually appealing public space.

Solution: A combination of PVC-coated welded mesh gabion baskets (1.5m x 0.5m x 0.5m, 3mm wire, 50x50mm mesh) was used to construct stepped terraces along the riverbanks. The PVC coating ensured maximum service life in the wet environment, while the smaller mesh allowed for smaller, aesthetically pleasing local aggregates. Gabion benches and planters were also incorporated.

Outcome: The project successfully stabilized the riverbanks, prevented further erosion, and significantly mitigated flood risks. The aesthetically pleasing gabion structures, combined with landscaping, transformed a degraded area into a vibrant public park, enhancing community value and demonstrating the dual functional and architectural benefits of our gabions.

Trustworthiness & Client Support ( Focus)

Our commitment to building lasting client relationships is founded on transparency, reliability, and comprehensive support. We prioritize the trustworthiness aspect of our service, from initial inquiry to post-installation.

Frequently Asked Questions (FAQ)

- Q: What is the typical service life of your galvanized welded mesh gabions?

A: Our heavy galvanized gabions typically offer a service life of 50-70 years in moderate environments. With a supplementary PVC/PE coating, this can extend to over 75-100 years in more aggressive or corrosive conditions. - Q: What fill materials can be used with your gabions?

A: Gabions can be filled with a variety of durable, non-frost-susceptible, granular materials such as crushed rock, quarry spalls, cobbles, or recycled concrete. The aggregate size should be larger than the mesh opening to prevent loss. - Q: Do you provide design assistance?

A: Yes, our experienced engineering team offers technical consultation and design support, helping clients select the optimal gabion dimensions, wire specifications, and coating types for their specific project requirements. - Q: Are your products certified to international standards?

A: Absolutely. Our manufacturing processes are ISO 9001 certified, and our products conform to key international standards such as ASTM A975 (Standard Specification for Gabion Baskets) and EN 10244-2 (Steel Wire and Wire Products - Non-ferrous Metallic Coatings on Steel Wire).

Lead Time and Fulfillment

Typical lead times for standard Galvanized Welded Wire Mesh Gabion Box/Basket orders range from 2-4 weeks, depending on order volume and current production schedules. For highly customized solutions or very large projects, lead times will be confirmed upon detailed project assessment. We maintain a robust logistics network to ensure efficient and timely delivery to global destinations, with clear communication on shipping schedules and tracking information.

Warranty Commitments

We offer a comprehensive warranty against manufacturing defects and material failures under normal usage conditions. Our heavy galvanized products come with a minimum 10-year warranty against structural failure due to corrosion, extending to 25+ years for PVC/PE coated products, reflecting our confidence in their durability and adherence to international standards. Specific warranty terms are provided with each quotation and order confirmation.

Customer Support and After-Sales Service

Our commitment extends beyond delivery. We provide dedicated customer support through various channels, including phone, email, and a dedicated online portal. Our after-sales service includes technical advice for installation, maintenance guidelines, and rapid response to any product-related inquiries or issues. We believe in fostering long-term partnerships built on trust and mutual success.

Conclusion

The Galvanized Welded Wire Mesh Gabion Box/Basket represents a pinnacle in modern geotechnical and civil engineering solutions. Its blend of structural strength, durability, environmental compatibility, and aesthetic versatility makes it an ideal choice for a vast array of applications, from critical infrastructure stabilization to innovative landscape architecture. Our unwavering commitment to material quality, precision manufacturing, stringent testing, and comprehensive client support ensures that every gabion system delivered meets the highest performance expectations. Partner with us to leverage cutting-edge gabion technology for your next project, ensuring long-term resilience, sustainability, and value.

References

- American Society for Testing and Materials (ASTM) A975/A975M-11. Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated and Poly(Vinyl Chloride) (PVC) Coated Steel Wire).

- European Committee for Standardization (CEN) EN 10223-4:2012. Steel wire and wire products — Non-ferrous metallic coatings on steel wire — Zinc and zinc alloy coatings.

- International Organization for Standardization (ISO) 9001:2015. Quality management systems — Requirements.

- Federal Highway Administration (FHWA) - Hydraulic Engineering Circular No. 23 (HEC-23). Bridge Scour and Stream Instability Countermeasures.

- TERZAGHI, K. (1943). Theoretical Soil Mechanics. John Wiley & Sons.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025