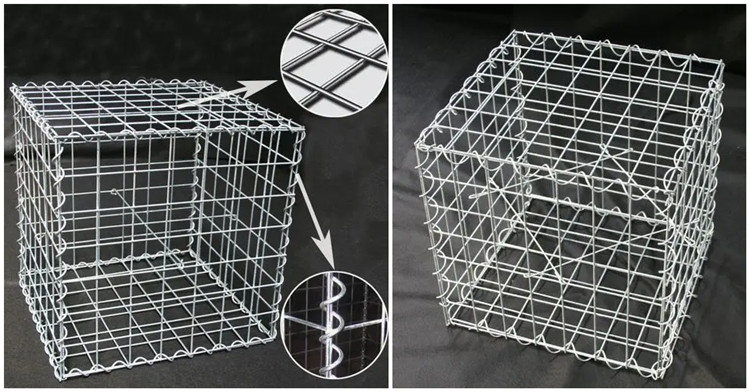

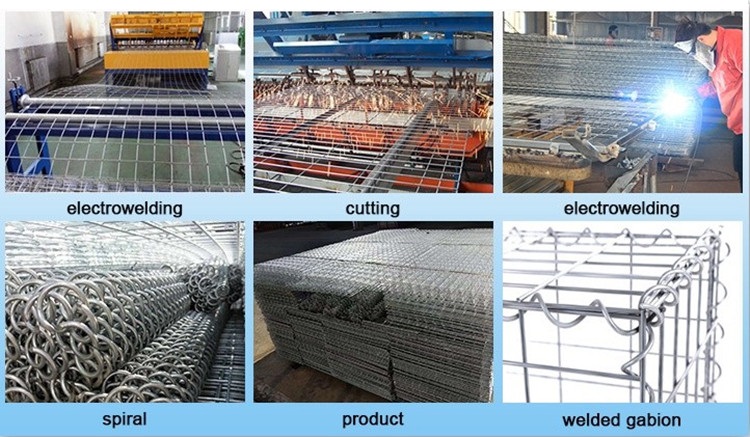

Welded Gabions are wire mesh containers welded with high quality steel mesh. The Welded Gabion box/Basket is assembled by welded mesh panels, some mesh panels are connected by crossing spirals or C rings. Its beauty appearance and easily installation successfully get people's attraction. They can be filled on site with hard durable stone materials to form mass gravity retaining structures. Owing to their inflexibility, welded gabions can not adapt to differential settlement or be used in water courses.

1) Technical Notes Of The Welded Gabion Box

|

Normal Specifications |

|

|

Type |

Square welded steel wire grid mesh gabion for use in Retaining Structures and other engineering applications. |

|

Mesh Type |

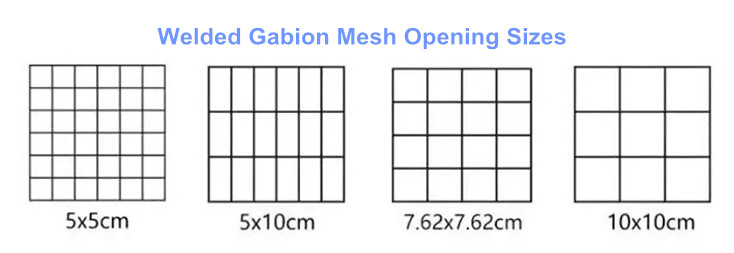

50mmX50mm, 75mmX75mm, 50mmX100mm, 100mmX100mm, ect. |

|

Wire Diameter |

(Nominal wire diameter should be 3.0mm to 6mm(BS 1052). |

|

Corrosion Protection |

Heavy Hot-dip Galvanized, Zinc-aluminum alloy or as request. |

|

Joining |

All joints and connections shall be formed with lacing wire, spiral wires or ‘C’ rings |

|

Diaphragms |

Fixed at 1.0m c/c along gabion length for units longer than 1.5m |

|

Expected Durability |

In dry wall environments, the expected life of this product is 60 years. Increasing exposure conditions will reduce expected design life. Please contact us for advice. |

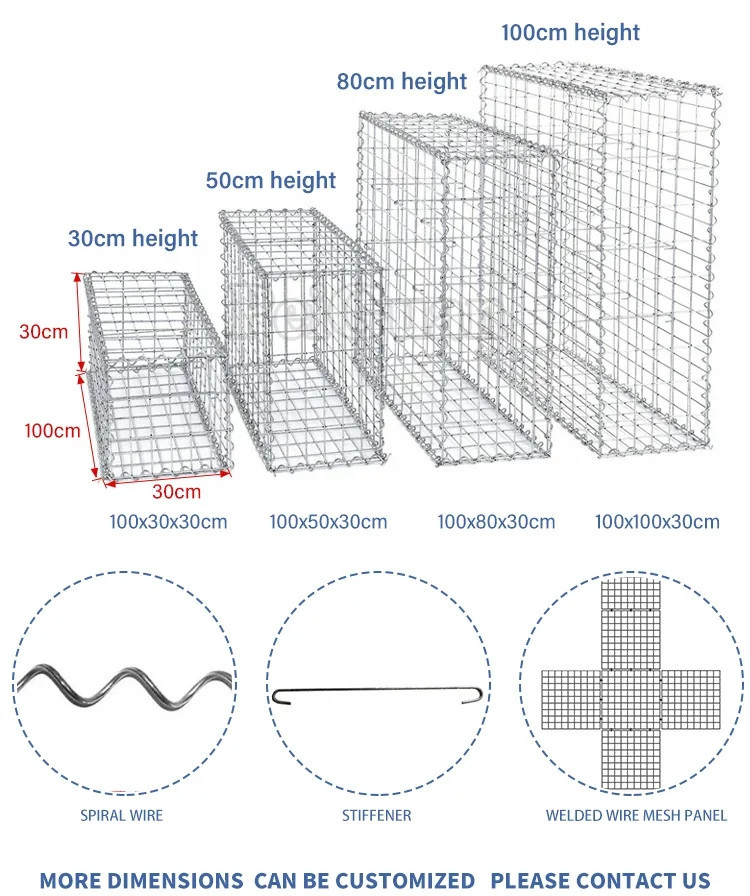

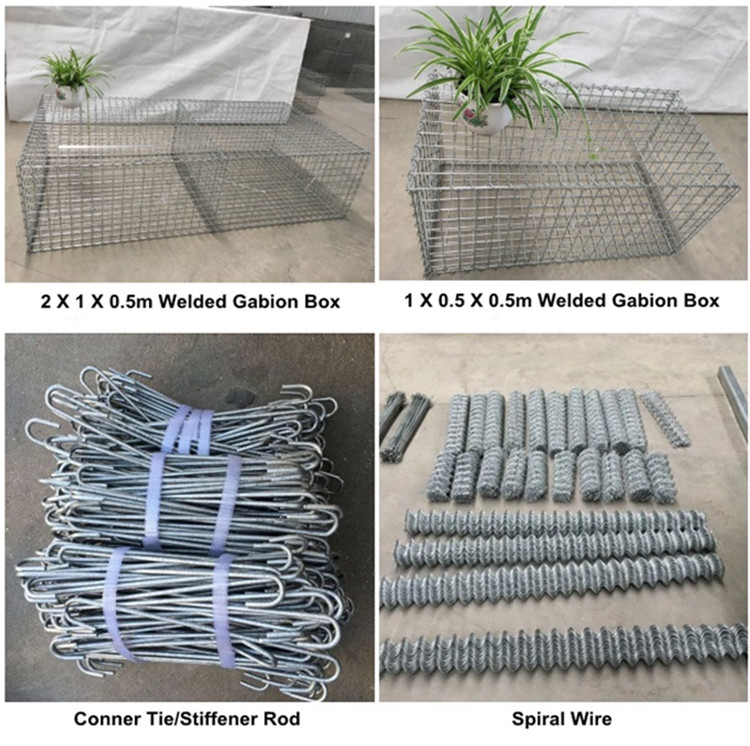

2) Popular Type &Dimension Of Welded Gabion Box

|

Wire Diameter |

Welded mesh Opening |

Box Size |

NO. of Diaphragms (pcs) |

|

Diameter: 3.0mm-6.0mm |

37.5 X 75mm, 50 X 50mm, 75 X 75mm, 100 X 50mm, 100 X 100mm |

0.5 X 0.5 X 0.5m |

None |

|

1.0 X 1.0 X 1.0m, |

None |

||

|

1.0 X 1.0 X 0.5m, |

None |

||

|

1.0 X 0.5 X 0.5m, |

None |

||

|

1.2 X 0.6 X 0.6m, |

None |

||

|

1.5 X 1.0 X 1.0m, |

1 |

||

|

1.5 X 1.0 X 0.5m, |

1 |

||

|

2.0 X 1.0 X 1.0m, |

1 |

||

|

2.0 X 1.0 X 0.5m, |

1 |

||

|

2.0 X 0.5 X 0.5m, |

1 |

||

|

2.0 X 0.3 X 0.3m, |

1 |

||

|

3.0 X 1.0 X 1.0m, |

2 |

||

|

3.0 X 1.0 X 0.5m, |

2 |

||

|

4.0 X 1.0 X 1mm, |

3 |

||

|

4.0 X 1.0 X 0.5m, |

3 |

||

|

Required sizes are also available. |

|||

|

Coating Property |

Test Method |

Value |

|

|

Tensile Strength |

ASTM D638 |

2275Min |

|

|

Elongation |

ASTM D638 |

290% No Break |

|

|

Hardness |

ASTMD2240 |

75Min Shore A |

|

|

Salt Sproy |

ASTM B 117 |

3000hrs.no effect |

|

|

Exposure to |

ASTM 1499 |

3000hrs |

|

ASTM A 90 Standard Test Method for Weight of Coating on Zinc-Coated (Galvanized) iron or Steel Articles ASTM A 641" Standard Specifications for Zinc- Coated (Galvanized) Carbon Steel Wire, Top mesh exceeds Class 3 zinc coating weights.

3) Feature and Advantages of Welded Gabion Box

1. Smooth and tidy, uniform mesh, joints firm, the firm has a strong, corrosion resistance, etc.

2. Low-cost, easy to install, decorate the courtyard, ideal for green slope.

3. A strong resistance to withstand natural weather damage and impacts.

4. Very good anti-stretch capability.

5. Field installation quick and easy and simple and beautiful structure, saving time and labor, and high efficiency.

6. Installation man-hours than the hexagonal gabion save 40%. Compared with hexagonal wire mesh, welded wire mesh can better maintain the "cage". With diaphragms and stiffeners installed, the gabion may be filled with standard loading equipment. After filling the gabion, a lid is placed on top and secured with spiral binders, lacing wire or "C" rings.

7. When the filler filled, welded wire mesh panel is not convex not concave, keep flat, hexagonal wire mesh is not the same as the drum up, so you can better.

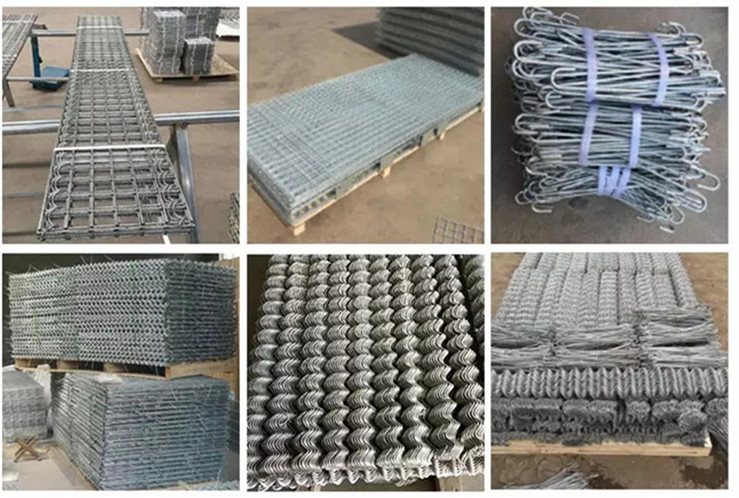

1) Normally each set is flat packed and then packaged in pallets.

2) In Carton packaged.

1. Retaining wall structures.

2. Garden Gabion, Garden fence.

3. Bridge protection.

4. Hydraulic structures, dams and culverts.

5. Embankment protection.

6. Defensive Bastion Container/Barrier for Flood Control Walls-Military and home use.

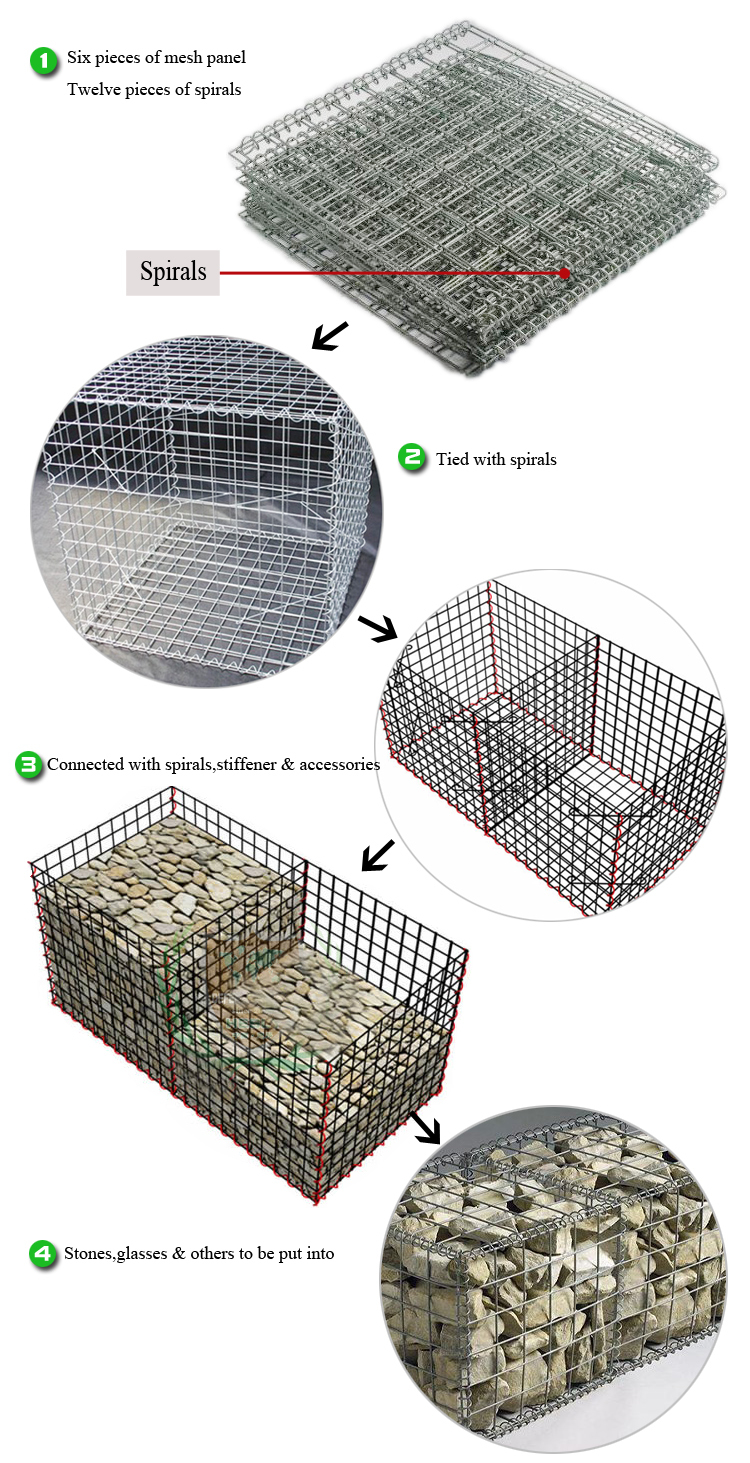

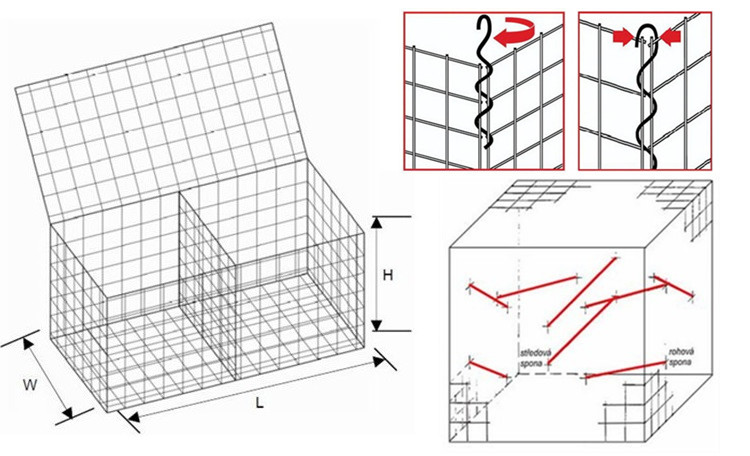

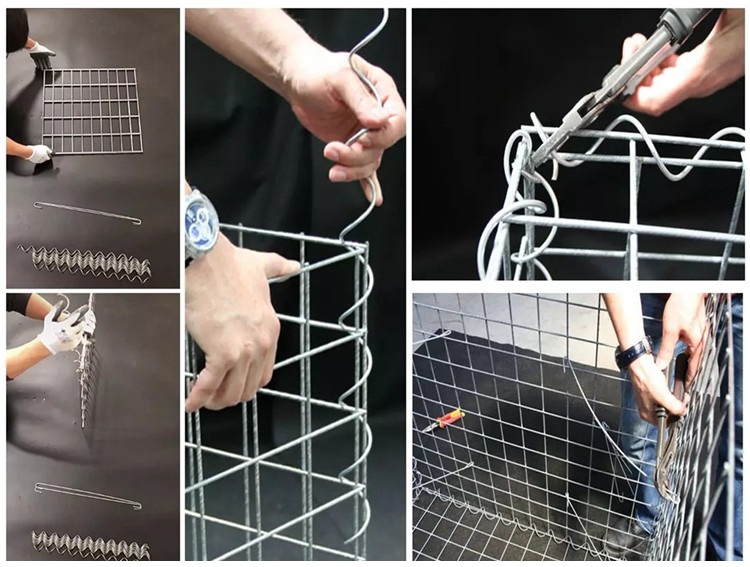

How to install welded gabion mesh?

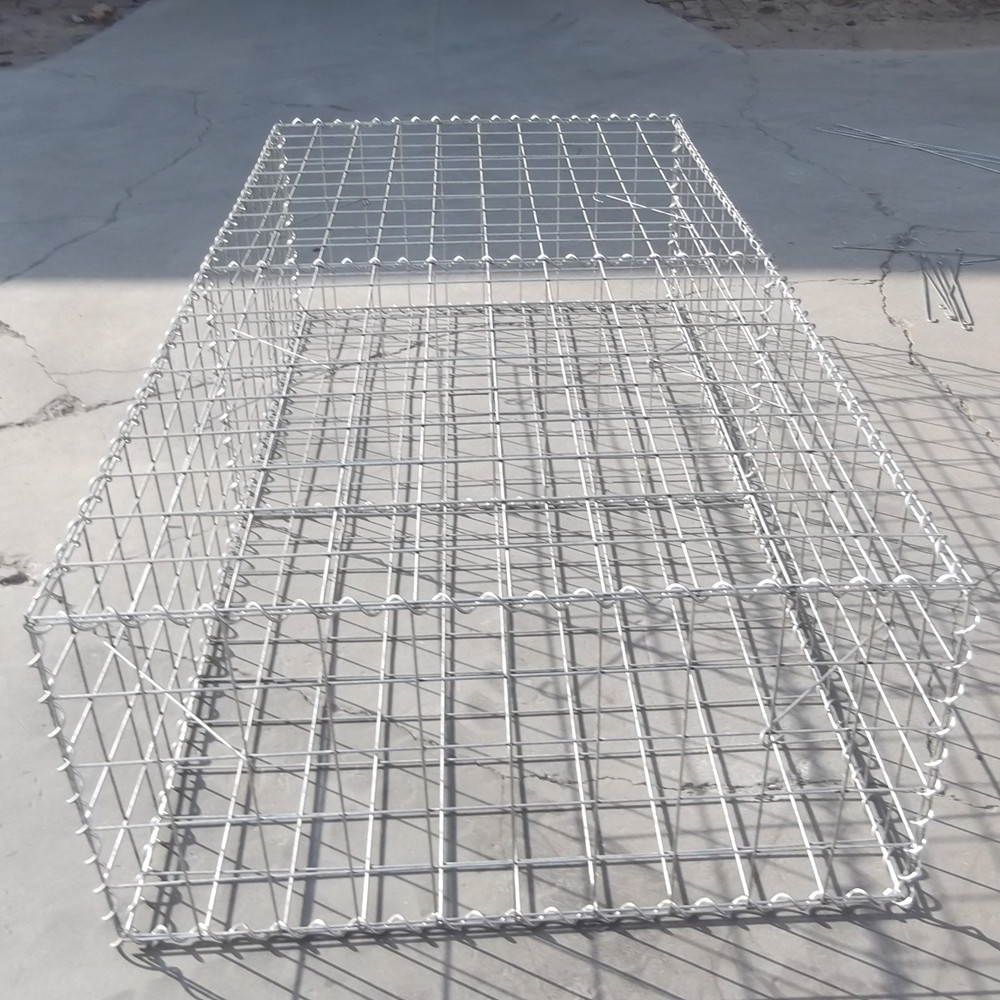

Step 1. Ends, diaphragms, front and back panels are placed upright on the bottom section of wire mesh.

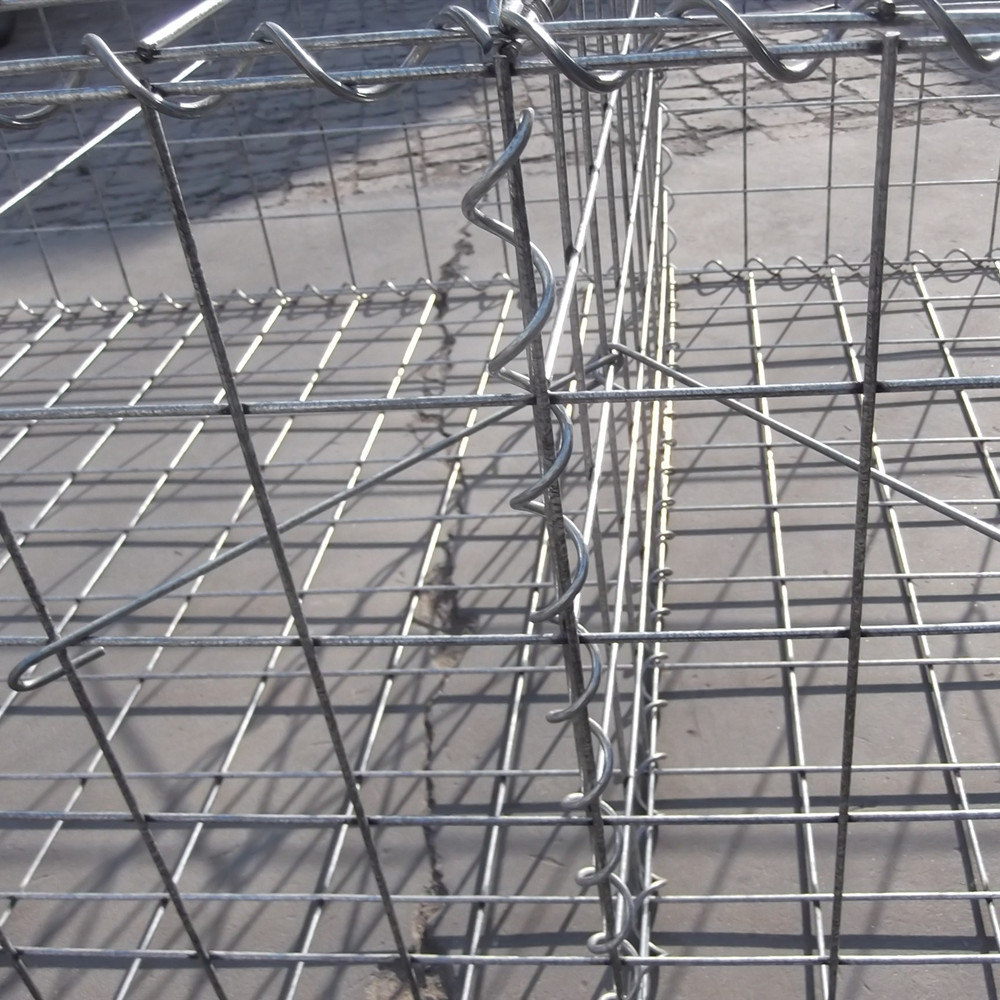

Step 2. Secure panels by screwing spiral binders through the mesh openings in adjacent panels.

Step 3. Stiffeners shall be placed across the corners, at 300mm from the corner. Providing a diagonal bracing, and crimped over the line and cross wires on the front and side faces. None are needed in interior cells.

Step 4. Gabion box is filled with graded stone by hand or with a shovel.

Step 5. After filling, close the lid and secure with spiral binders at the diaphragms, ends, front and back.

Step 6. When stacking tiers of the welded gabion mesh, the lid of the lower tier may serve as the base of the upper tier. Secure with spiral binders and add pre-formed stiffeners to exterior cells before filling with graded stones.