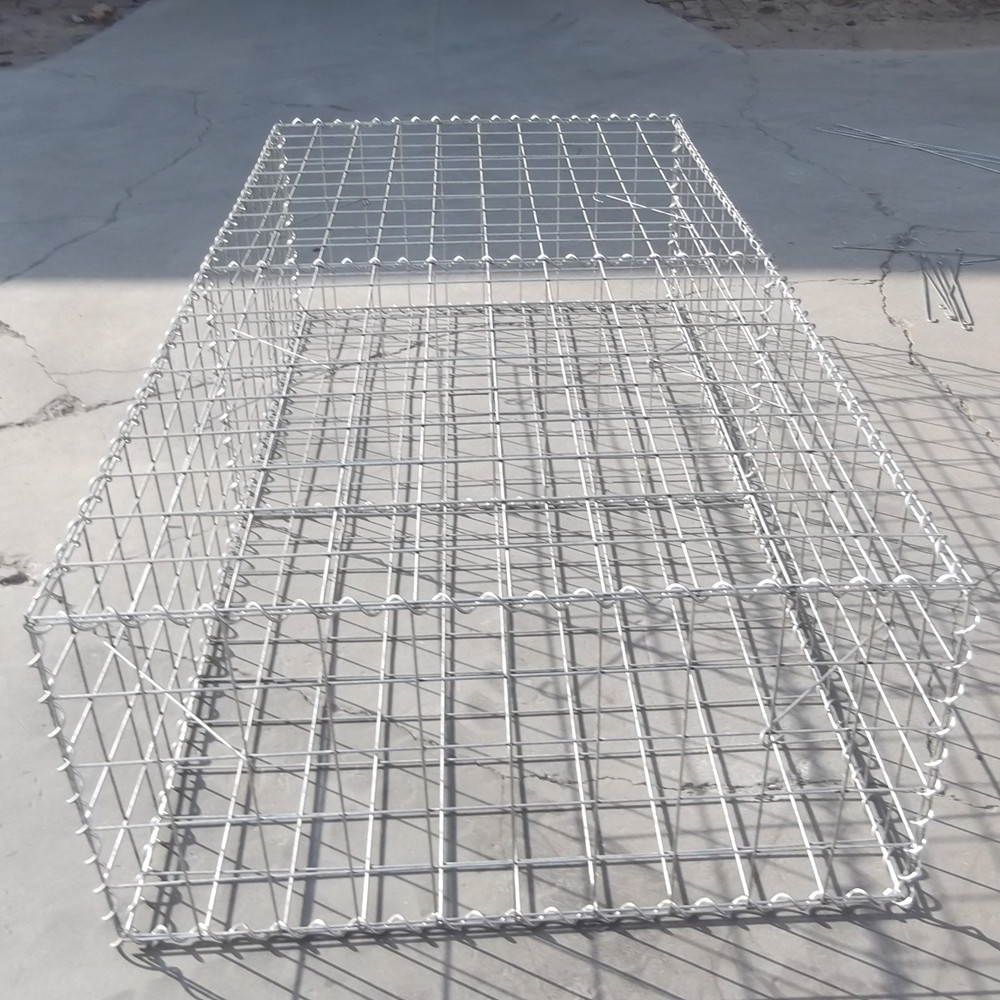

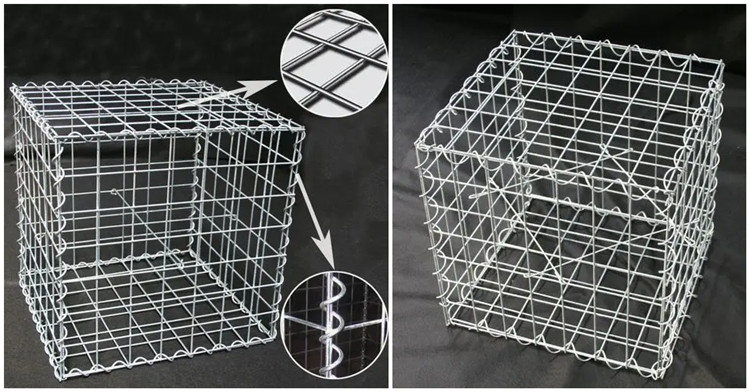

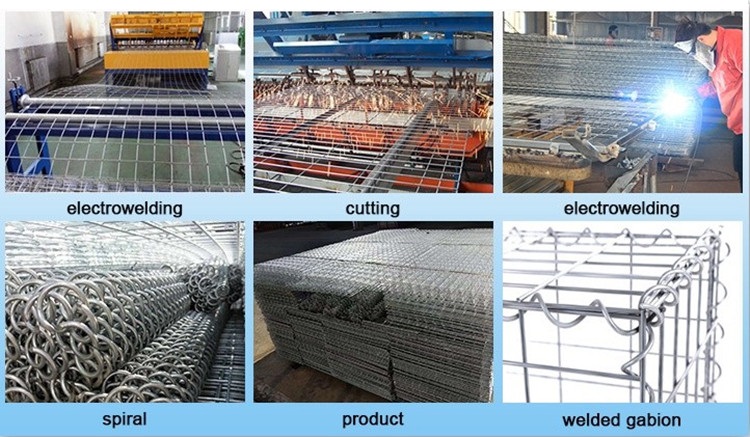

Welded Gabions are wire mesh containers welded with high quality steel mesh. The Welded Gabion box/Basket is assembled by welded mesh panels, some mesh panels are connected by crossing spirals or C rings. Its beauty appearance and easily installation successfully get people's attraction. They can be filled on site with hard durable stone materials to form mass gravity retaining structures. Owing to their inflexibility, welded gabions can not adapt to differential settlement or be used in water courses.

1) Catetan Téknis tina Kotak Gabion Dilas

|

Spésifikasi Normal |

|

|

Tipe |

Pasagi dilas kawat baja grid bolong gabion pikeun pamakéan dina Struktur Panahan sarta aplikasi rékayasa lianna. |

|

Jenis Jaring |

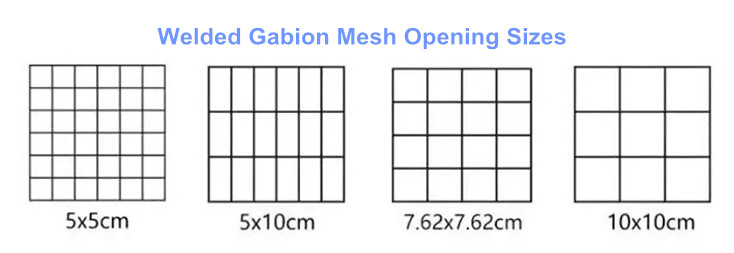

50mmX50mm, 75mmX75mm, 50mmX100mm, 100mmX100mm, jsb. |

|

Diaméter kawat |

(Diaméter kawat nominal kedah 3.0mm ka 6mm (BS 1052). |

|

Protéksi korosi |

Beurat Hot-dip Galvanized, alloy Séng-aluminium atawa sakumaha pamundut. |

|

Ngagabung |

Sadaya sambungan sareng sambungan kedah dibentuk ku kawat lacing, kawat spiral atanapi cincin 'C' |

|

Diafragma |

Dibereskeun dina 1.0mc/c sapanjang panjang gabion pikeun unit leuwih panjang batan 1.5m |

|

Diperkirakeun Durability |

Dina lingkungan témbok garing, harepan hirup produk ieu 60 taun. Ngaronjatkeun kaayaan paparan bakal ngirangan umur desain anu dipiharep. Mangga ngahubungan kami pikeun nasihat. |

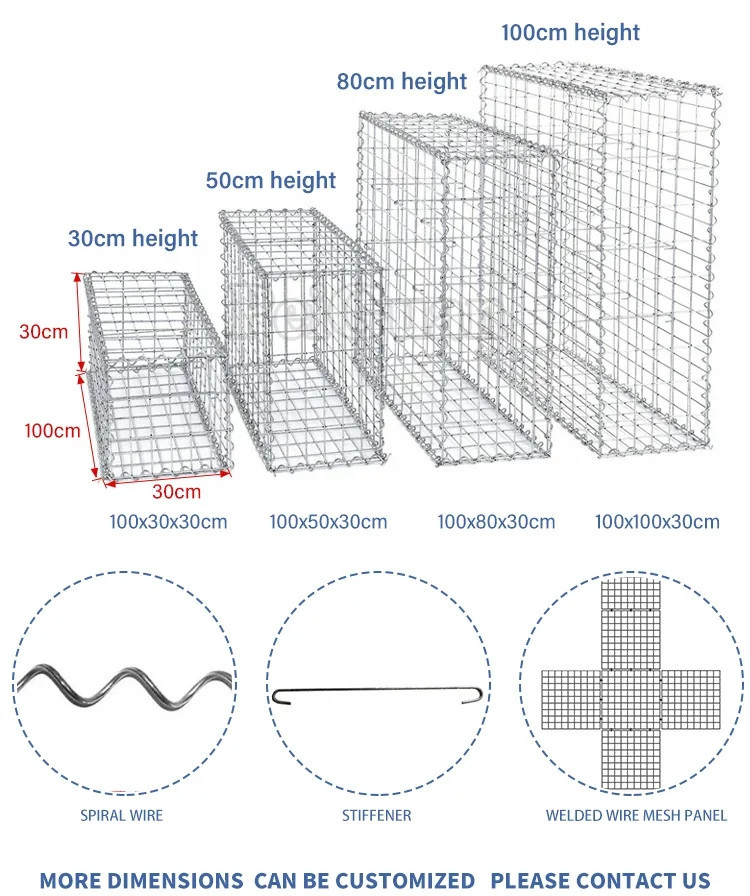

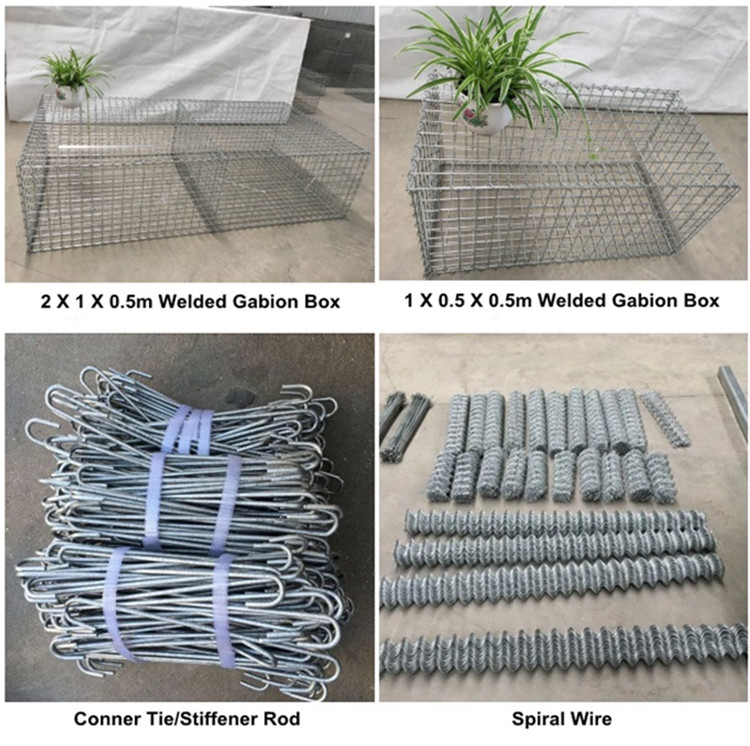

2) Tipe populér &Dimensi Dilas Gabion Box

|

Diaméter kawat |

Dilas bolong Bubuka |

Kotak Ukuran |

NO. tina Diaphragms (pcs) |

|

Diaméterna: 3.0mm-6.0mm |

37,5 X 75 mm, 50 X 50 mm, 75 X 75 mm, 100 X 50 mm, 100 X 100 mm |

0,5 X 0,5 X 0,5m |

Euweuh |

|

1.0 X 1.0 X 1.0m, |

Euweuh |

||

|

1,0 X 1,0 X 0,5m, |

Euweuh |

||

|

1,0 X 0,5 X 0,5m, |

Euweuh |

||

|

1,2 X 0,6 X 0,6m, |

Euweuh |

||

|

1,5 X 1,0 X 1,0m, |

1 |

||

|

1,5 X 1,0 X 0,5m, |

1 |

||

|

2.0 X 1.0 X 1.0m, |

1 |

||

|

2,0 X 1,0 X 0,5m, |

1 |

||

|

2,0 X 0,5 X 0,5m, |

1 |

||

|

2.0 X 0.3 X 0.3m, |

1 |

||

|

3.0 X 1.0 X 1.0m, |

2 |

||

|

3,0 X 1,0 X 0,5m, |

2 |

||

|

4,0 X 1,0 X 1 mm, |

3 |

||

|

4,0 X 1,0 X 0,5m, |

3 |

||

|

ukuran diperlukeun oge sadia. |

|||

|

Palapis Harta |

Métode Tés |

Nilai |

|

|

Kakuatan regangan |

ASTM D638 |

2275 mnt |

|

|

Elongation |

ASTM D638 |

290% Taya putus |

|

|

Teu karasa |

ASTMD2240 |

75 Menit Pantai A |

|

|

Uyah Sproy |

ASTM B 117 |

3000hrs.euweuh pangaruh |

|

|

Kakeunaan ka |

ASTM 1499 |

3000 WIB |

|

Métode Uji Standar ASTM A 90 pikeun Beurat Lapisan dina Beusi Dilapis Séng (Galvanis) atanapi Artikel Baja ASTM A 641" Spésifikasi Standar pikeun Kawat Baja Karbon Dilapis Séng (Galvanis), Bolong luhur ngaleuwihan beurat palapis séng Kelas 3.

3) Fitur sarta Kaunggulan tina dilas Gabion Box

1. Lemes jeung beberes, seragam bolong, sendi teguh, sungut ngabogaan kuat, résistansi korosi, jsb.

2. Low-ongkos, gampang pikeun masang, ngahias palataran, idéal pikeun lamping héjo.

3. A résistansi kuat nahan karuksakan cuaca alam jeung tabrakan.

4. kamampuhan anti manteng pohara alus.

5. Instalasi sawah gancang jeung gampang tur basajan tur geulis struktur, nyimpen waktu jeung tanaga gawé, sarta efisiensi tinggi.

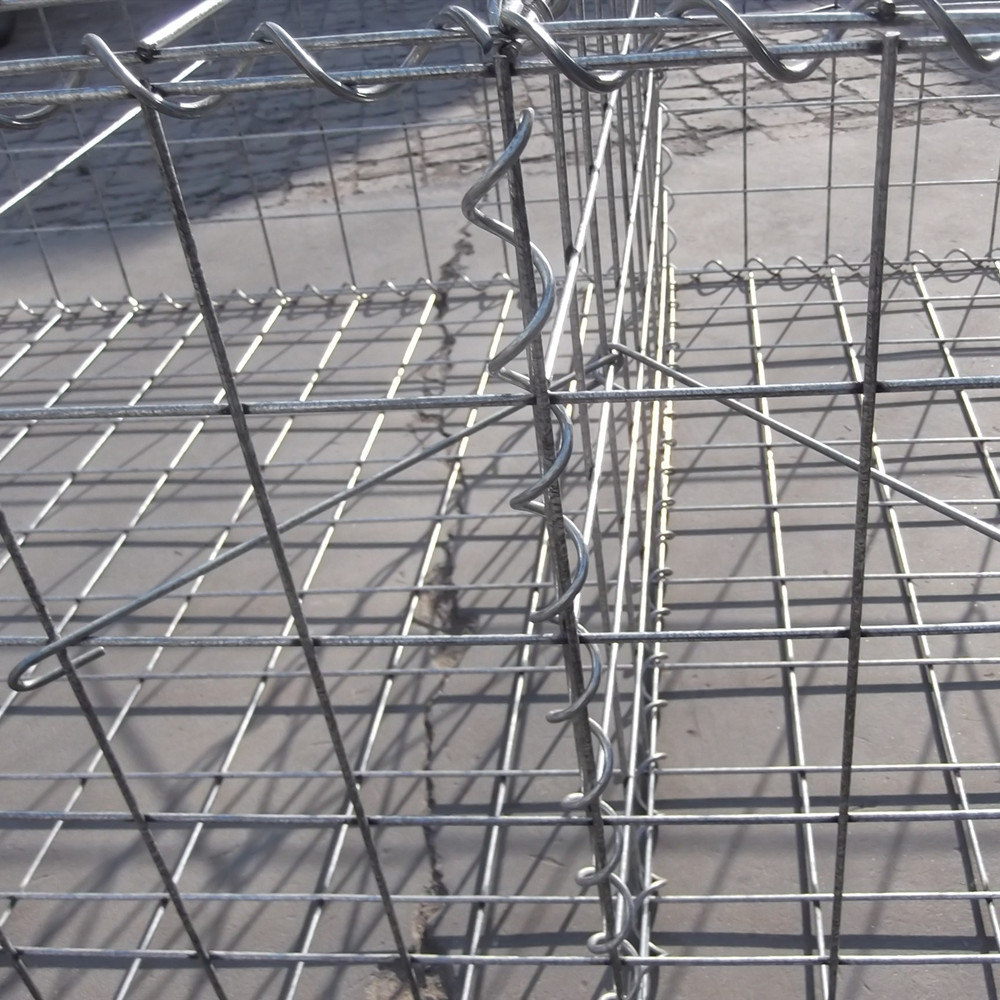

6. Instalasi man-jam ti gabion héksagonal ngahemat 40%. Dibandingkeun sareng bolong kawat héksagonal, bolong kawat anu dilas tiasa langkung saé ngajaga "kandang". Kalayan diafragma sareng stiffeners dipasang, gabion tiasa dieusi ku alat-alat muatan standar. Saatos ngeusian gabion, tutupna disimpen di luhur sareng diamankeun ku binders spiral, kawat lacing atanapi cincin "C".

7. Nalika filler dieusian, dilas panel kawat bolong teu gilig teu kerung, tetep datar, héksagonal kawat bolong teu sarua jeung drum up, jadi Anjeun bisa hadé.

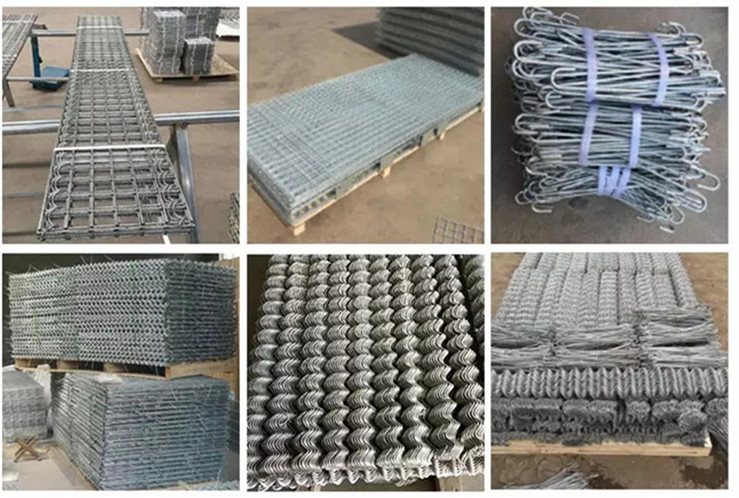

1) Biasana unggal set datar dibungkus teras dibungkus dina palet.

2) Dina karton rangkep.

1. Struktur témbok nahan.

2. Taman Gabion, Taman pager.

3. Sasak panyalindungan.

4. Struktur hidrolik, bendungan jeung culverts.

5. panyalindungan Embankment.

6. Pertahanan Bastion Wadahna / Panghalang pikeun Tembok Control Banjir-Militér jeung pamakéan imah.

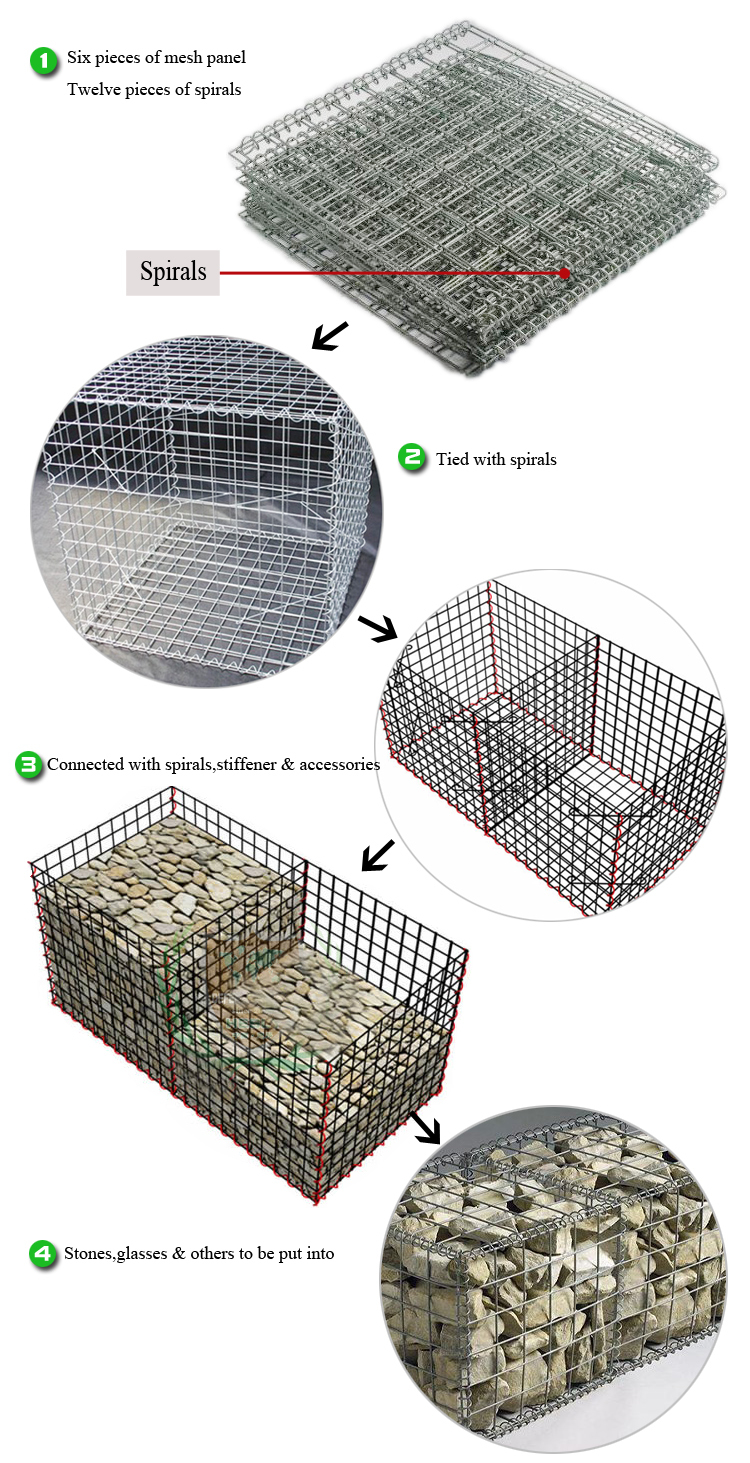

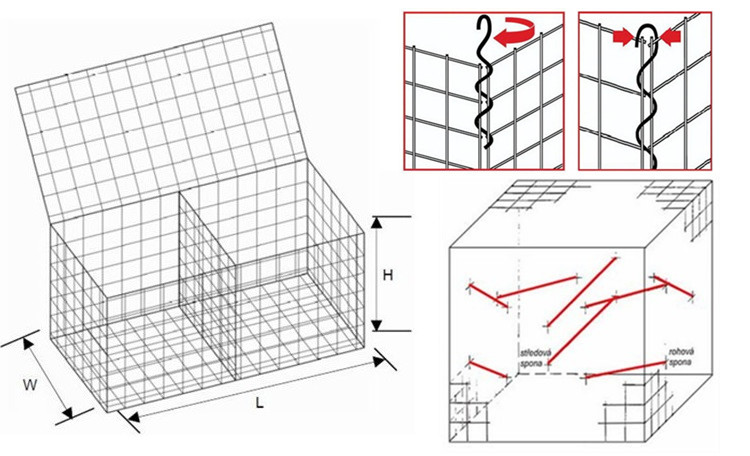

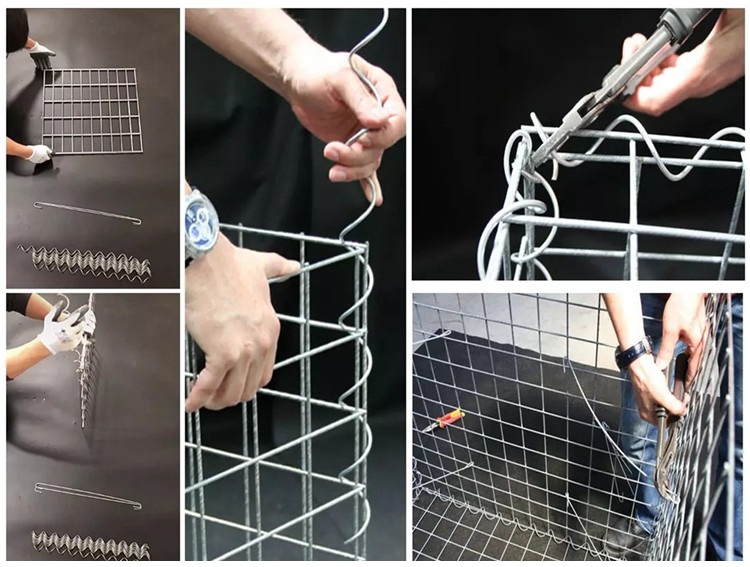

Kumaha carana masang dilas gabion bolong?

Lengkah 1. Tungtung, diafragma, panel hareup sareng tukang ditempatkeun tegak dina bagian handap kawat bolong.

Lengkah 2. Aman panels ku screwing binders spiral ngaliwatan bukaan bolong dina panel padeukeut.

Lengkah 3. Stiffeners kudu ditempatkeun sakuliah juru, dina 300mm ti sudut. Nyadiakeun bracing diagonal, sarta crimped ngaliwatan garis tur cross kawat dina beungeut hareup jeung samping. Henteu aya anu diperyogikeun dina sél interior.

Lengkah 4. Kotak Gabion dieusian ku batu gradasi ku leungeun atawa ku sekop.

Lengkah 5. Saatos ngeusian, tutup tutup sareng amankeun ku binders spiral dina diafragma, tungtung, payun sareng tukang.

Lengkah 6. Nalika tumpukan undakan tina bolong gabion anu dilas, tutup tingkat handap tiasa janten dasar tingkat luhur. Amankeun ku binders spiral sareng tambahkeun kaku anu tos kabentuk kana sél luar sateuacan ngeusian batu anu gradasi.