Blog

-

The Main Application Areas of Barbed wire

Barbed wire ,wire mesh with thorns is a widely used fence material in the field of safety protection.Přečtěte si více -

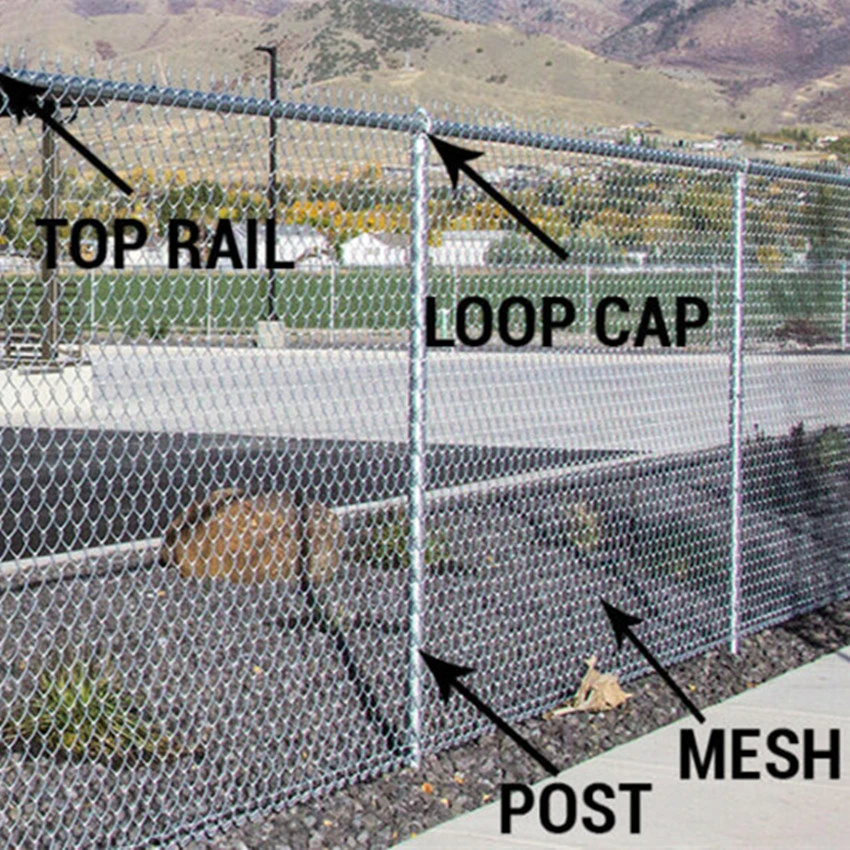

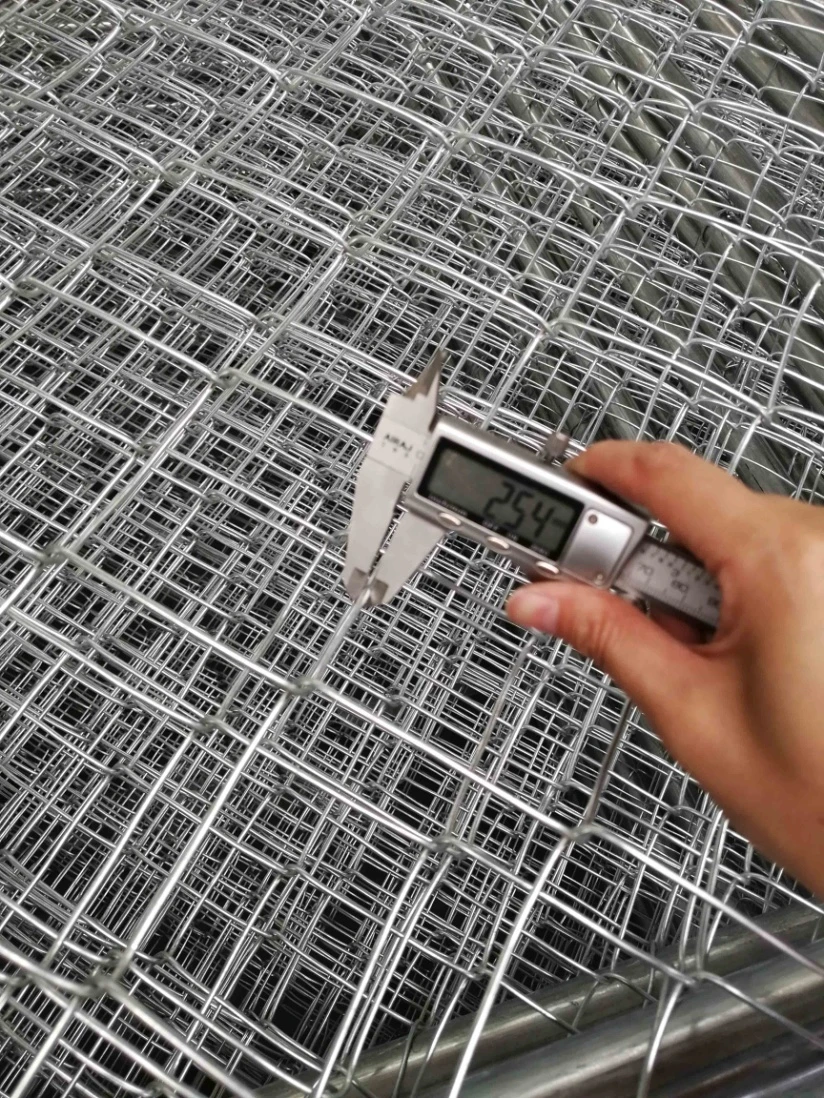

Why a Chain Link Wire Mesh Fence Is the Ultimate Choice for Security and Durability

When it comes to securing your property, ensuring long-term protection, and maintaining durability in various environmental conditions, a chain link wire mesh fence stands out as one of the most practical and reliable choices.Přečtěte si více -

Ensure Security and Durability with Chain Link Wire Mesh Fence: Your Ultimate Solution

When it comes to securing your property, no material is as reliable, versatile, and cost-effective as a chain link wire mesh fence.Přečtěte si více -

Elevate Your Property’s Security and Aesthetics with a Chain Link Wire Mesh Fence

When it comes to choosing a fence that offers both functionality and durability, few options compare to a chain link wire mesh fence.Přečtěte si více -

Discover the Versatility of Chain Link Wire Mesh Fence: Ideal for Every Need

A chain link wire mesh fence offers unparalleled flexibility, strength, and durability, making it one of the most popular fencing options worldwide.Přečtěte si více -

Discover the Strength and Versatility of Chain Link Wire Mesh Fencing

When it comes to securing your property, ensuring privacy, or even managing your industrial or agricultural spaces, chain link wire mesh fence is a top choice.Přečtěte si více -

Choosing the Best Chain Link Wire Mesh Fence for Your Property

When securing your property, selecting the right chain link wire mesh fence can make all the difference.Přečtěte si více -

The Durability and Appeal of Chain Link Wire Mesh Fence: A Long-Lasting Solution for Your Property

When it comes to securing properties and defining boundaries, few solutions are as reliable and affordable as chain link wire mesh fences.Přečtěte si více