Říj . 11, 2024 19:24 Back to list

custom steel welded wire mesh panels for construction

Custom Steel Welded Wire Mesh Panels for Construction

In the ever-evolving landscape of construction, the demand for durable, versatile, and cost-effective materials has led to the increased use of custom steel welded wire mesh panels. These panels are essential in a variety of applications, from structural reinforcement to safety and security installations. Understanding their advantages, manufacturing process, and applications can provide valuable insights for builders and designers alike.

What are Custom Steel Welded Wire Mesh Panels?

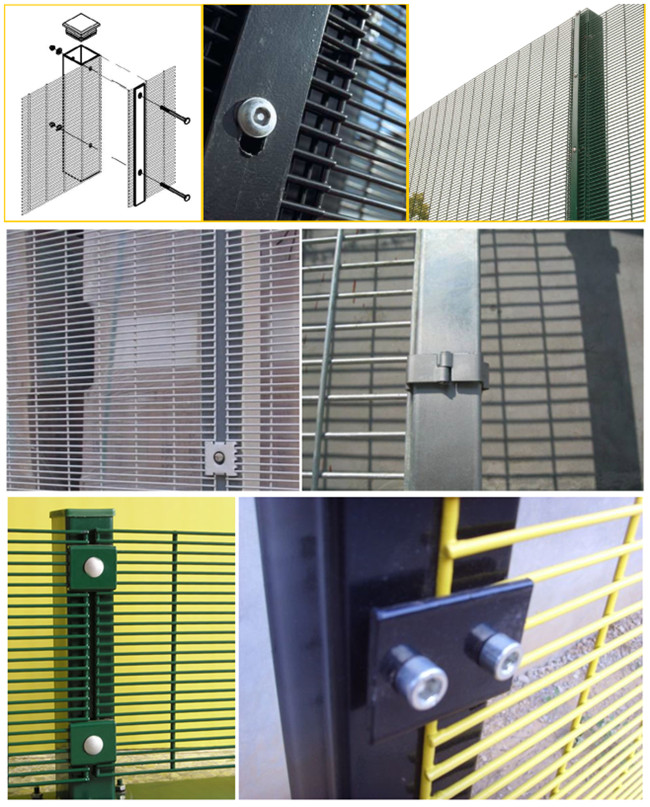

Custom steel welded wire mesh panels are made by interweaving horizontal and vertical steel wires. These wires are welded at each intersection, creating a sturdy grid-like structure. The versatility of steel allows these panels to be customized in terms of size, wire gauge, and spacing according to specific project needs. These panels are lightweight yet exceptionally strong, making them ideal for various construction applications.

Advantages of Steel Welded Wire Mesh Panels

1. Durability Steel is known for its strength and longevity. Welded wire mesh panels resist corrosion, especially when galvanized, ensuring that they can withstand harsh weather conditions and maintain their integrity over time.

2. Versatility Customization options enable engineers and architects to design panels that meet the specific needs of their projects. Whether reinforcing concrete, creating enclosures, or providing safety barriers, custom panels can be tailored for optimal performance.

3. Cost-Effectiveness The efficient manufacturing process of welded wire mesh panels leads to cost savings. They require less material compared to solid barriers while providing equal or greater structural support.

4. Enhanced Safety In construction sites, safety is paramount. Welded wire mesh can be used to create secure fencing and barriers to protect both workers and surrounding properties from potential hazards.

5. Ease of Installation These panels are lightweight and can be easily handled and installed. This reduces labor costs and time on the job site, allowing for a faster project completion.

Manufacturing Process

custom steel welded wire mesh panels for construction

The manufacturing of custom steel welded wire mesh panels involves several steps

1. Wire Selection High-quality steel wire is chosen based on the required strength and application.

2. Welding The wires are arranged into a grid and welded at each intersection using automated machines. This ensures consistent quality and strength across the entire panel.

3. Finishing Once welded, the panels undergo processes such as galvanization or powder coating to enhance their resistance to rust and environmental damage. This is a crucial step to increase their lifespan and performance.

4. Customization Panels can then be cut to size and configured based on the specific needs of the construction project. Custom sizes and unique specifications can be accommodated easily during this stage.

Applications in Construction

Custom steel welded wire mesh panels find extensive use across various sectors in construction. They are commonly employed in

- Reinforcement of Concrete In slabs and walls, mesh panels provide critical support, distributing loads evenly and reinforcing structural integrity. - Fencing and Barriers They are widely used for site fencing, security barriers, and safety netting around construction sites.

- Architectural Features Decorative applications, such as façade elements or landscaping features, can also utilize welded wire mesh panels for aesthetic value.

- HVAC and Electrical Systems The panels can serve as protective grilles or enclosures that safeguard vital systems.

In conclusion, custom steel welded wire mesh panels are an indispensable asset in modern construction practices, combining strength, durability, and versatility. Their ability to be custom-manufactured for specific applications ensures that they meet the unique demands of any construction project. As sustainability and efficiency continue to drive the industry, these panels are poised to play a critical role in shaping future developments.

-

High Quality 9 Gauge Expanded Metal Mesh & Chain Link Wire Mesh Fence Manufacturer

NewsJun.10,2025

-

Barbed Wire Roll Price - Wholesale Exporters & Reliable Factories Supply

NewsJun.10,2025

-

High-Quality Temporary Mesh Fence Panels for Sale Durable Temporary Fence Panels Supplier

NewsJun.10,2025

-

Welded Wire Fence Mesh Exporters Custom Sizes & Competitive Pricing

NewsJun.10,2025

-

Durable China Expanded Metal Security Mesh High-Security & Affordable

NewsJun.10,2025

-

White Expanded Metal Mesh Durable for Temp Fencing & Plaster

NewsJun.10,2025