- Affricanaidd

- Albaneg

- Amhareg

- Arabeg

- Armenaidd

- Azerbaijani

- Basgeg

- Belarwseg

- Bengali

- Bosnieg

- Bwlgareg

- Catalaneg

- Cebuano

- Tsieina

- Tsieina (Taiwan)

- Corseg

- Croateg

- Tsiec

- Daneg

- Iseldireg

- Saesneg

- Esperanto

- Estoneg

- Ffinneg

- Ffrangeg

- Ffriseg

- Galiseg

- Sioraidd

- Almaeneg

- Groeg

- Gwjarati

- Creol Haitaidd

- hausa

- hawaiian

- Hebraeg

- Naddo

- Miao

- Hwngareg

- Islandeg

- igbo

- Indoneseg

- gwyddelig

- Eidaleg

- Japaneaidd

- Jafaneg

- Kannada

- kazakh

- Khmer

- Rwanda

- Corëeg

- Cwrdaidd

- Kyrgyz

- Llafur

- Lladin

- Latfieg

- Lithwaneg

- Lwcsembwrgaidd

- Macedoneg

- Malgashi

- Maleieg

- Malayalam

- Malteg

- Maori

- Marathi

- Mongoleg

- Myanmar

- Nepali

- Norwyaidd

- Norwyaidd

- Ocsitaneg

- Pashto

- Perseg

- Pwyleg

- Portiwgaleg

- Pwnjabi

- Rwmania

- Rwsieg

- Samoaidd

- Gaeleg yr Alban

- Serbeg

- Saesneg

- Shona

- Sindhi

- Sinhala

- Slofaceg

- Slofeneg

- Somalïaidd

- Sbaeneg

- Sundanaidd

- Swahili

- Swedeg

- Tagalog

- Tajiceg

- Tamil

- Tatar

- Telugu

- Thai

- Twrceg

- Tyrcmeniaid

- Wcrain

- Wrdw

- Uighur

- Wsbeceg

- Fietnameg

- Cymraeg

- Help

- Iddeweg

- Iorwba

- Zwlw

Medi . 09, 2025 09:25 Yn ôl i'r rhestr

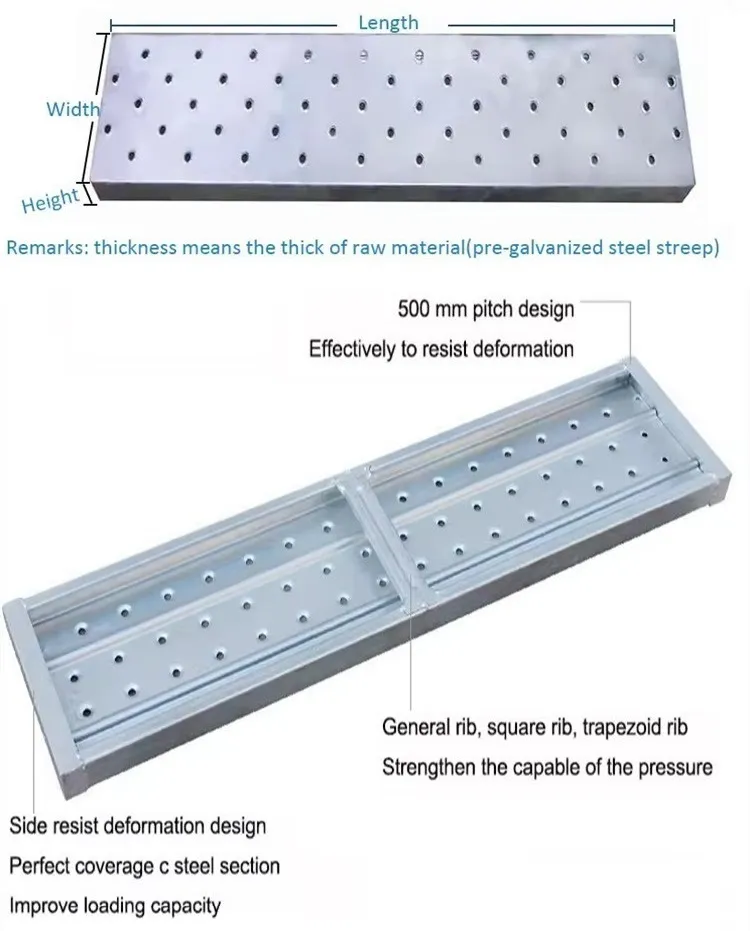

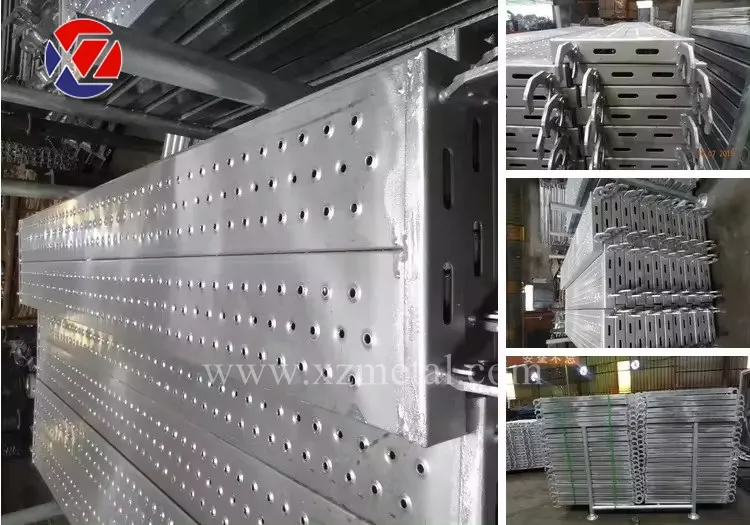

The Role of Metal Scaffold Boards in Modern High-Rise Projects

High-rise construction demands robust, reliable, and safe working platforms that can withstand heavy loads and harsh conditions. Metal scaffold boards, including galvanized steel plank and galvanized scaffold planks, have become indispensable in modern skyscraper projects due to their superior durability, safety, and cost-effectiveness. This article explores how scaffolding steel plank systems enhance construction efficiency while meeting stringent safety standards, and why Anping Xingzhi stands out as a premier supplier of galvanized plank solutions.

Why Metal Scaffold Boards Are Essential for High-Rise Construction

Traditional wooden planks are increasingly being replaced by galvanized scaffold planks due to their unmatched advantages:

Superior Load-Bearing Capacity – Scaffolding steel plank can support up to 750 lbs per square foot, far exceeding wooden alternatives.

Fire Resistance – Unlike wood, metal scaffold boards do not burn, reducing fire hazards on construction sites.

Weather Resistance – Galvanized steel plank resists rust, moisture, and UV degradation, ensuring longevity.

Non-Slip Surface – Perforated or ribbed designs enhance worker safety in wet conditions.

Cost-Effective – Although the initial investment for metal scaffold boards may be higher, their extended lifespan and reduced maintenance costs make them more economical in the long run compared to wooden planks, which require frequent replacement due to wear and tear.

Environmentally Friendly – The use of galvanized steel planks contributes to sustainability efforts by reducing the demand for timber, thus preserving forests and reducing carbon footprints.

Ease of Installation and Handling – Metal scaffold boards are lightweight yet sturdy, facilitating quick and easy installation and handling on construction sites, enhancing overall productivity and efficiency.

Irreconcilability – At the end of their extended service life, galvanized scaffold planks can be recycled, further contributing to their environmental benefits and reducing waste in landfills. This circular economy approach aligns well with modern sustainable construction practices.

Versatility in Applications – Beyond traditional scaffolding use, galvanized scaffold planks can also be adapted for various applications such as temporary flooring, staging, and access platforms, making them a versatile tool in various construction and event scenarios.

Uniform Strength and Consistency – Each metal scaffold plank is manufactured to strict specifications, ensuring a consistent level of strength and reliability across all units. This uniformity minimizes the risk of weak spots or inconsistencies that might be found in wooden planks due to natural variations in wood grain and quality.

Improved Aesthetics – The sleek, modern appearance of galvanized scaffold planks can enhance the visual appeal of a construction site, presenting a more professional image to clients, stakeholders, and the public. This aesthetic advantage can be particularly beneficial in high-profile or urban development projects where appearance is a key consideration.

|

Nodwedd |

Metal Scaffold Boards |

Wooden Planks |

|

Max Load Capacity |

750 lbs/sq ft |

250 lbs/sq ft |

|

Lifespan |

5–8 years |

1–2 years |

|

Fire Resistance |

Excellent |

Poor |

|

Maintenance Required |

Minimal |

Frequent |

Metal Scaffold Boards Key Applications in High-Rise Projects

Galvanized scaffold planks are used in multiple phases of high-rise construction:

Exterior Work – Provides stable platforms for facade installation and window fitting.

Concrete Pouring – Supports heavy equipment and workers during slab construction.

Interior Finishing – Ensures safe access for electrical, plumbing, and drywall installation.

Maintenance & Repairs – Used long-term for building upkeep due to their durability.

Anping Xingzhi’s galvanized plank solutions are customization for any project requirement, from lightweight aluminum options to heavy-duty steel variants.

Metal Scaffold Boards Advantages of Galvanized Steel Planks

Corrosion Resistance – Hot-dip galvanization protects against rust, even in coastal environments.

Lightweight Yet Strong – High-strength Q235 steel ensures durability without excessive weight.

Modular Design – Interlocking scaffolding steel plank systems allow quick assembly and reconfiguration.

Cost-Effective – Longer lifespan reduces replacement costs compared to wood or plastic.

Our metal scaffold boards comply with ISO9001 standards, guaranteeing quality and safety for high-risk construction environments.

Why Choose Anping Xingzhi for Metal Scaffold Boards Planks?

We specialize in manufacturing premium galvanized steel plank products with:

Custom sizes (0.5m–4m lengths, 210mm–250mm widths)

Multiple thickness options (1.2mm–1.8mm)

Anti-slip perforations for enhanced safety

Bulk order discounts for contractors and wholesalers

Metal Scaffold Boards FAQs

How much weight can galvanized metal scaffold boards planks support?

Our scaffolding steel plank supports up to 750 lbs/sq ft, depending on thickness and span.

Are metal scaffold boards slippery in rain?

No, perforated or ribbed galvanized plank designs provide excellent grip even in wet conditions.

How long do galvanized steel planks, used as metal scaffold boards, last?

With proper care, they last 5–8 years, significantly longer than wooden alternatives.

Can metal scaffold boards be used in marine environments?

Yes, hot-dip galvanized scaffold planks resist saltwater corrosion, making them ideal for coastal projects.

Where can I buy bulk metal scaffold boards?

Anping Xingzhi supplies high-quality galvanized steel plank globally, with customization options for large orders.Upgrade your construction safety with Anping Xingzhi’s metal scaffold boards—durable, compliant, and cost-effective. Contact us today for wholesale inquiries!

-

Durable River Bank Gabion Mesh Solutions for Protection

NewyddionNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

NewyddionNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

NewyddionNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

NewyddionNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

NewyddionNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

NewyddionNov.17,2025