Jul . 25, 2025 12:01 Back to list

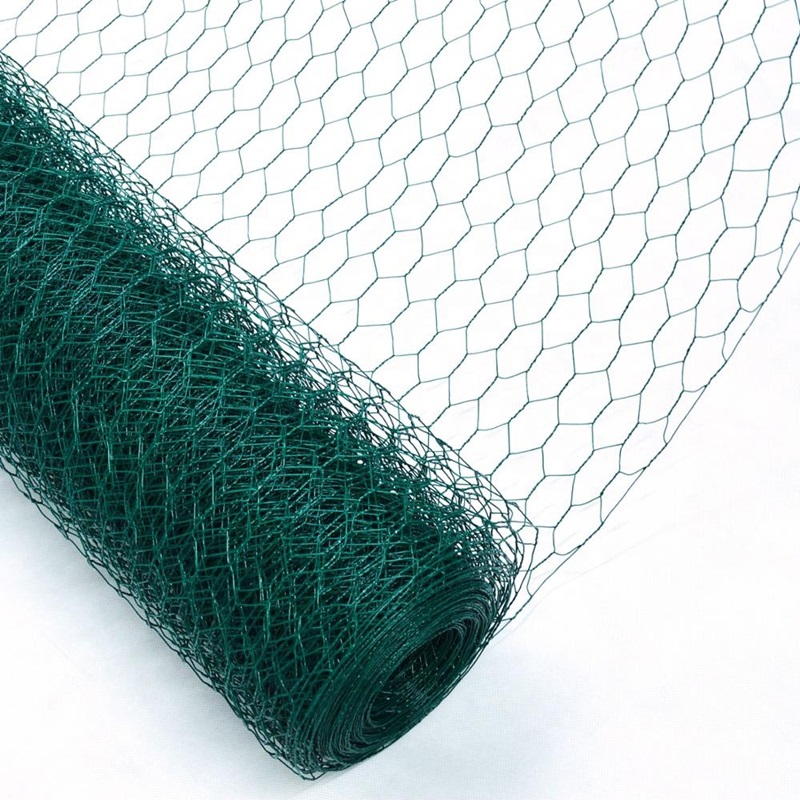

Galvanized Hexagonal Poultry Wire Mesh Durable Corrosion-Resistant

Introduction to Galvanized Hexagonal Poultry Wire Mesh

In the agricultural and poultry industry, the quality of containment systems is critical for animal welfare and operational efficiency. Galvanized Hexagonal poultry wire mesh, also known as chicken wire, plays a pivotal role in modern farming practices. This versatile mesh structure combines flexibility with durability, making it ideal for constructing chicken coops, rabbit cages, and various agricultural enclosures.

The unique hexagonal pattern provides an optimal balance of strength, cost-effectiveness, and containment capabilities. When galvanized for corrosion resistance, this mesh becomes an indispensable solution for poultry farmers worldwide. With decades of development and innovation, the industry has refined galvanized hexagonal poultry wire mesh to meet increasingly stringent animal welfare and safety requirements.

For poultry farmers and livestock managers, understanding the technical specifications, material properties, and appropriate applications of galvanized hexagonal poultry wire mesh is essential for selecting the right product for specific agricultural needs. This comprehensive guide will explore the manufacturing processes, material science, industry standards, and practical applications that define modern galvanized wire mesh products.

85%

Commercial poultry farms utilizing galvanized wire systems

25+ Years

Lifespan of hot-dip galvanized mesh

$2.5B

Global poultry mesh market value (2023)

95%

Satisfied farmers reporting reduced animal injuries

Xingzhi Metal Wiremesh Products Co., Ltd.

Anping County Xingzhi Metal Wiremesh Products Co., Ltd. is a trusted industry leader in the manufacturing of high-quality galvanized hexagonal poultry wire mesh. With ISO 9001 certification and decades of expertise, Xingzhi delivers premium wire mesh solutions that meet international agricultural standards. Their commitment to quality control, material excellence, and customer service has established them as a preferred supplier for poultry farms worldwide.

Visit Official WebsiteTechnical Specifications of Galvanized Hexagonal Poultry Wire Mesh

The performance of galvanized hexagonal poultry wire mesh depends on several technical factors that farmers should understand when selecting materials. These specifications directly impact durability, safety, and animal containment effectiveness.

Key Technical Parameters

| Parameter | Standard Specifications | Special Options | Significance |

|---|---|---|---|

| Material | Q195, Q235 low carbon steel | Stainless steel, High-zinc coating | Determines strength and corrosion resistance |

| Wire Diameter | 0.6mm - 2.5mm | Custom diameters available | Affects mesh strength and weight-bearing capacity |

| Mesh Size | 1/2", 1", 2" (12-50mm) | Rectangular openings | Determines animal containment capability |

| Zinc Coating | 30-200 g/m² | Galfan alloy coating | Corrosion protection level |

| Tensile Strength | 350-550 MPa | High-tensile options | Mechanical durability |

| Roll Dimensions | Width: 0.5-2m, Length: 15-30m | Custom cutting available | Installation flexibility |

For precise specifications tailored to specific poultry requirements, consult the galvanized hexagonal poultry wire mesh product page to review available configurations.

Material Science Behind Poultry Wire Mesh

The fundamental material used in quality galvanized hexagonal poultry wire mesh is low-carbon steel wire, designated as Q195 or Q235 under Chinese standards. This material offers the optimal balance between formability, strength, and weldability required for hexagonal mesh formation. The steel composition includes controlled levels of carbon (0.06-0.22%) and manganese (0.25-1.20%), providing the base material characteristics necessary for wire drawing and subsequent galvanizing processes.

Featured Product: Xingzhi Galvanized Hexagonal Poultry Wire Mesh

Material: Premium Q195/Q235 Steel

Specifications: Custom sizes available

Surface Treatment: Hot-dip galvanized or PVC coated

Applications: Chicken cages, rabbit enclosures, poultry fencing

Certifications: ISO9001 Quality Management System

Product Origin: Anping, Hebei, China

View Product Details

Manufacturing Process Excellence

The production of premium galvanized hexagonal poultry wire mesh follows a sophisticated manufacturing protocol that combines traditional techniques with modern quality control:

At Xingzhi Metal, the manufacturing process begins with high-quality steel rod selection. Through multiple cold-drawing processes, the rods are transformed into wire of precise diameters with smooth surfaces optimized for galvanizing. The wire then undergoes a continuous annealing process to restore ductility before being fed into automatic twisting machines that form the characteristic hexagonal patterns.

The galvanizing phase employs hot-dip technology where the woven mesh is immersed in molten zinc at temperatures between 440-460°C. This creates a metallurgical bond between steel and zinc, with the resulting alloy layers providing superior corrosion protection. Advanced quality control systems continuously monitor coating uniformity and thickness to ensure every batch meets specifications.

Industry Applications and Use Cases

Galvanized hexagonal poultry wire mesh serves multiple functions in modern agriculture beyond its traditional role in poultry cages. The versatility of this material stems from its unique combination of strength, flexibility, and corrosion resistance.

Primary Applications:

Poultry Housing Systems: The predominant application remains in constructing chicken coops, broiler houses, and layer cages. The hexagonal pattern prevents injuries to birds' feet and beaks, especially important for poultry welfare certification programs. The flexibility allows shaping to various configurations while maintaining structural integrity when using proper wire diameters and spacing.

Small Animal Enclosures: Beyond poultry, this mesh serves excellently in rabbit hutches, quail pens, and pheasant enclosures. The galvanized finish is non-toxic to animals while resisting corrosive effects of urine and feces. Smaller mesh variants prevent predator access while ensuring adequate ventilation.

Specialized Applications

Modern adaptations include garden fencing against small pests, compost bin construction, tree guards for young saplings, and aquaculture pond protection. The corrosion resistance makes it suitable for hydroponic system components and erosion control structures.

Quality Standards and Certifications

Premium galvanized hexagonal poultry wire mesh must adhere to strict international quality standards that ensure product consistency and safety. Xingzhi Metal's ISO 9001 certification reflects their commitment to quality management systems throughout the manufacturing process.

Key international standards include:

ASTM A641: Standard specification for zinc-coated carbon steel wire

ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles

EN 10223-3: European standard for fencing materials

GB/T 343: Chinese standard for galvanized hexagonal wire netting

Agricultural applications may require additional compliance with animal welfare standards such as the UK's RSPCA welfare standards and EU directives on cage-free poultry systems.

Professional FAQ: Galvanized Poultry Wire Mesh

What distinguishes hot-dip galvanizing from electro-galvanizing for poultry mesh?

Hot-dip galvanizing creates a metallurgical bond between zinc and steel through immersion in molten zinc, resulting in coating thicknesses of 30-200 g/m² that provide superior corrosion protection lasting 25+ years. Electro-galvanizing applies a thinner zinc coating through electrochemical deposition that typically lasts 5-8 years in agricultural environments.

How does mesh opening size affect poultry containment?

Mesh geometry is critical for animal safety. For chicks (0-3 weeks), 1/2" mesh prevents escape. Grower facilities typically use 1" mesh, while 2" mesh suits mature layers. Proper sizing prevents foot injuries, reduces feed waste, and contains birds effectively. Xingzhi offers guidance on mesh specifications for all poultry life stages.

What are the differences between Q195 and Q235 steel in wire mesh?

Q195 steel has slightly lower carbon content (0.06-0.12%) and tensile strength (315-430 MPa) compared to Q235 (0.14-0.22% carbon, 375-500 MPa). Q235 offers greater strength for larger enclosures while Q195 provides superior flexibility and is more economical for standard applications. Both undergo identical galvanizing processes.

How should PVC-coated poultry mesh be maintained differently than galvanized?

PVC-coated poultry mesh requires specialized cleaning solutions that avoid solvents that might degrade the polymer coating. Gentle, non-abrasive cleaners at moderate temperatures preserve PVC integrity. Galvanized mesh withstands stronger alkaline cleaners but requires inspection for white rust formation if stored improperly.

What innovations have recently emerged in poultry wire mesh technology?

Recent advancements include Galfan coatings (95% zinc + 5% aluminum alloy) offering 1.5-2x longer corrosion resistance than conventional zinc coatings. Antimicrobial powder coatings are being introduced to reduce pathogen transmission, while high-tensile steel formulations allow thinner wire diameters without compromising strength.

How do international standards affect cage-free poultry system designs?

Modern cage-free systems increasingly utilize galvanized hexagonal mesh for vertical partitions and platforms. The 2023 EU directive requires a minimum of 9cm mesh opening height per bird with sufficient structural support to prevent deformation. Galvanizing thickness requirements have also increased to 120g/m² for these applications.

What are the key considerations when installing poultry netting in humid climates?

In high-humidity environments, galvanized mesh with zinc coatings exceeding 150g/m² is recommended. Mesh should be tensioned properly to prevent sagging that collects moisture, and installation should provide adequate clearance from soil contact. Regular cleaning to remove corrosive organic matter is essential for longevity.

EEAT Validation: Expert Perspectives

The following citations provide authoritative perspectives on poultry enclosure materials:

"Modern poultry farming has adopted galvanized hexagonal wire as the standard containment solution due to its combination of safety, durability, and cost-effectiveness. The specialized manufacturing processes have evolved significantly to meet stricter animal welfare requirements."

Poultry Science Review - Material Innovations in Agriculture Series

https://academic.oup.com/ps

"Our comparative analysis demonstrated that properly galvanized hexagonal poultry mesh significantly outlasted alternative materials in accelerated corrosion tests simulating poultry house environments."

Journal of Agricultural Engineering Vol. 47 (2023)

https://www.tandfonline.com/toc/taec20/current

"Quality galvanized wire is essential for cage-free poultry systems that meet international welfare standards. Proper mesh size selection prevents injuries while enabling natural behaviors."

World Poultry Science Association Technical Bulletin #47

https://www.wpsa.com

Contact Xingzhi Metal Wiremesh Products

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025