Sep . 23, 2025 09:00 Back to list

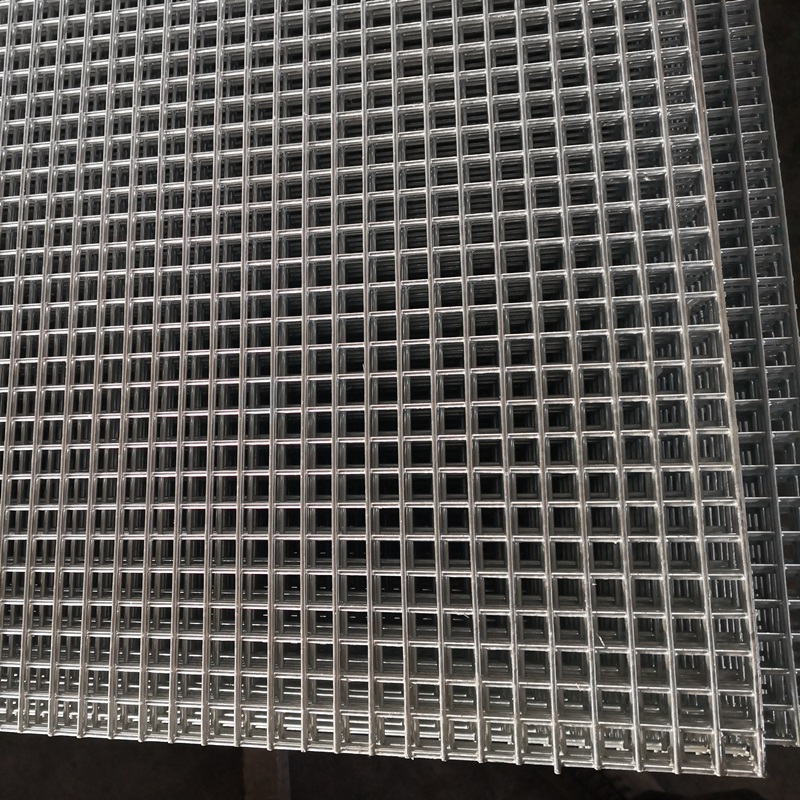

Welded Wire Mesh Panels & Rolls | Strong, Durable, Versatile

Introduction to Welded Wire Mesh Solutions

In demanding industrial and commercial applications, the structural integrity and reliability of containment and reinforcement materials are paramount. This article delves into the critical role and technical intricacies of .Welded wire mesh panels and rolls., a versatile product essential for sectors ranging from construction and infrastructure to security and agriculture. Manufactured through a precise resistance welding process, these products offer exceptional strength, rigidity, and consistency, making them a preferred choice over traditional fencing or reinforcement methods. Their modularity, available in both rigid panels and flexible rolls, allows for tailored applications, optimizing material usage and installation efficiency across diverse projects. Understanding the manufacturing nuances, technical specifications, and application advantages is crucial for B2B decision-makers seeking durable and cost-effective solutions.

Industry Trends and Market Dynamics

The global market for .Welded wire mesh panels and rolls. is experiencing robust growth, driven by an accelerating pace of urbanization, infrastructural development, and increased demand for enhanced security measures. Key trends include a heightened focus on sustainable and recycled materials, the integration of advanced anti-corrosion coatings, and a move towards automated manufacturing processes that ensure superior product consistency and cost efficiency. Furthermore, demand for bespoke mesh configurations is on the rise, necessitating greater flexibility in production capabilities. Industry reports indicate a compound annual growth rate (CAGR) of approximately 5-7% for wire mesh products, primarily fueled by applications in construction reinforcement, agricultural enclosures, and perimeter security. Innovations in material science, particularly in high-strength alloys and composite materials, are also shaping future product development, promising lighter yet more durable solutions.

Technological advancements in welding automation, such as multi-point spot welding machines, contribute to higher production speeds and reduced error rates, delivering a more uniform and reliable product. This translates into tangible benefits for end-users, including faster project completion and reduced material waste. The push for compliance with stringent international quality standards, such as ISO 9001 and ASTM, also underscores the industry's commitment to delivering high-performance materials.

Manufacturing Process: From Raw Material to Finished Product

The production of high-quality .Welded wire mesh panels and rolls. is a meticulously controlled multi-stage process, ensuring structural integrity and precise dimensions.

Detailed Process Flow:

- Material Selection: The foundation of superior mesh lies in the raw material. Typically, high-quality low carbon steel wire, stainless steel (e.g., 304, 316 grades for corrosion resistance), or galvanized wire is selected based on application requirements. These materials undergo rigorous checks to meet chemical composition and mechanical property standards (e.g., tensile strength, yield strength, elongation) as per ASTM A82 or equivalent.

- Wire Drawing: Raw steel rods are drawn through a series of dies to achieve the precise wire diameter required for the specific mesh configuration. This process enhances the wire's tensile strength and surface finish.

- Automated Resistance Welding: Longitudinal and transverse wires are fed into an automated welding machine. At each intersection, an electric current is passed through the wires, creating a localized heat that fuses them together through resistance welding. This process is precisely controlled (current, pressure, time) to ensure consistent, strong, and clean weld points. Modern CNC-controlled welding machines guarantee high accuracy in mesh spacing.

- Cutting and Forming: For panels, the continuous mesh is cut to specified dimensions. For rolls, the mesh is wound onto spools. Specialized machinery handles accurate cutting and edge finishing, ensuring uniform panel sizes and clean edges.

- Surface Treatment (Post-Welding):

- Hot-Dip Galvanizing: For enhanced corrosion resistance, especially in outdoor or humid environments, welded mesh can be hot-dip galvanized after welding. This process involves immersing the mesh in molten zinc, creating a metallurgical bond that provides superior protection and extends service life significantly (up to 50 years in suitable environments).

- PVC Coating: A layer of PVC powder is applied electrostatically and then heat-treated, forming a durable, protective, and often aesthetically pleasing coating. This adds an extra layer of corrosion protection and UV resistance.

- Quality Control and Testing: Each batch undergoes rigorous testing. This includes visual inspection for weld defects, mesh regularity, and surface finish. Mechanical tests involve pull-off tests for weld strength (e.g., meeting ISO 13918 standards for stud welding), tensile tests of wires, and dimensional checks. Conformance to standards like ISO 9001 for quality management and specific product standards (e.g., ASTM A185/A185M for concrete reinforcement) is mandatory. The average service life for galvanized mesh typically exceeds 20 years, while stainless steel variants can last for several decades with minimal maintenance.

These precise manufacturing steps ensure that the final .Welded wire mesh panels and rolls. exhibit consistent quality, strength, and durability, critical for their demanding target industries such as petrochemical, metallurgy, and water supply & drainage. The emphasis on corrosion resistance, particularly through galvanization or stainless steel usage, demonstrably leads to energy savings by reducing maintenance cycles and the need for frequent replacements.

Technical Specifications and Parameters

The technical specifications of .Welded wire mesh panels and rolls. are critical for engineers and procurement specialists to ensure optimal performance for specific applications. These parameters directly influence the mesh's strength, durability, and suitability for various environmental conditions.

Typical Product Specification Table:

| Parameter | Range/Option | Standard Conformance |

|---|---|---|

| Material Grade | Low Carbon Steel (Q195/Q235), Stainless Steel (304, 316), Galvanized Steel | ASTM A82, EN 10025, ISO 16120 |

| Wire Diameter | 0.5 mm to 12 mm | ASTM A82 |

| Mesh Opening (Aperture) | 6 mm x 6 mm up to 200 mm x 200 mm (Square/Rectangular) | ISO 9044 |

| Panel Width | 0.5 m to 3.0 m | Customizable |

| Panel Length | 1.0 m to 6.0 m | Customizable |

| Roll Width | 0.5 m to 2.5 m | Customizable |

| Roll Length | 10 m to 100 m | Customizable |

| Surface Treatment | Electro Galvanized, Hot-Dip Galvanized, PVC Coated | ASTM A123, ISO 1461 |

| Tensile Strength | Typically 450-550 MPa (for low carbon steel) | ASTM A82 |

These specifications are crucial for ensuring compliance with engineering blueprints and regulatory requirements. For example, in structural reinforcement, the choice of wire diameter and mesh opening directly impacts the load-bearing capacity and crack control characteristics of concrete elements. Stainless steel variants, while initially more expensive, offer superior resistance to aggressive chemical environments, extending the life cycle of structures in petrochemical or wastewater treatment plants, thus providing long-term value.

Advantages and Performance Characteristics

The inherent design and manufacturing precision of .Welded wire mesh panels and rolls. confer several key advantages that make them indispensable across various industrial applications:

- Superior Strength-to-Weight Ratio: Welded mesh provides high tensile strength with relatively low material volume, making it an efficient reinforcement or barrier solution. This optimized material usage contributes to reduced overall project costs and easier handling.

- Consistent Mesh Aperture: Unlike woven mesh, welded mesh maintains precise and uniform openings due to the fixed weld points. This is crucial for applications requiring exact filtration, sieving, or controlled passage, such as in conveyor systems or industrial filters.

- Enhanced Durability and Longevity: With options like hot-dip galvanization or stainless steel, the mesh exhibits exceptional resistance to rust, corrosion, and environmental degradation. This extended service life minimizes maintenance costs and replacement frequency, contributing to operational efficiency and indirect energy savings over the product lifecycle.

- Versatility in Application: Available in both rigid panels and flexible rolls, welded wire mesh adapts to a wide array of project requirements, from flat concrete slabs to curved architectural elements or expansive perimeter fencing.

- Ease of Installation: Panels can be cut and shaped on-site with relative ease, facilitating quicker installation compared to traditional rebar grids or custom-fabricated barriers. Rolls offer efficiency for large-area coverage.

- Cost-Effectiveness: While initial material costs might vary, the long-term benefits of reduced maintenance, extended service life, and efficient installation often translate into significant cost savings for large-scale industrial projects.

These advantages are particularly pronounced in scenarios requiring robust, long-lasting structures, such as animal enclosures in agriculture where product longevity is critical, or in high-security fencing where strength and resistance to tampering are paramount. The ability of the mesh to withstand harsh weather and corrosive agents ensures minimal environmental impact and consistent performance.

Application Scenarios Across Key Industries

The adaptability and durability of .Welded wire mesh panels and rolls. make them invaluable across a broad spectrum of industries:

- Construction and Infrastructure: As concrete reinforcement (rebar mesh) in foundations, slabs, roads, and precast concrete elements. Its consistent grid pattern ensures even stress distribution, mitigating crack formation and enhancing structural integrity. Also used for temporary fencing, scaffolding screens, and gabions for erosion control.

- Petrochemical and Energy: Used in grating, platforms, protective cages around machinery, and as support for insulation in pipelines and tanks where high temperature and corrosion resistance are critical. Stainless steel variants are particularly favored here.

- Metallurgy and Mining: Screens for ore separation, safety barriers, machine guards, and reinforcement for rockfall protection in mining operations due to its robust nature.

- Water Supply & Drainage: Filtration systems, screens for intake pipes, and reinforcement in concrete structures like reservoirs and wastewater treatment plants, where exposure to water and chemicals necessitates corrosion-resistant materials.

- Agriculture: Animal enclosures (cages for poultry, rabbits, etc.), fencing for livestock, plant supports, and protective barriers against pests. The galvanized and PVC-coated options provide excellent outdoor performance.

- Security and Fencing: High-security fencing for industrial sites, prisons, airports, and public facilities. Its rigid construction and small mesh sizes deter climbing and cutting, enhancing perimeter protection.

- Automotive and Manufacturing: Machine guards, shelving, and components in production lines.

These diverse applications underscore the product's versatility and the industry's reliance on its specific attributes, from precise filtration in water treatment to robust reinforcement in civil engineering projects.

Customized Solutions and Fabrication

Recognizing that standard products may not always meet unique project demands, manufacturers of .Welded wire mesh panels and rolls. increasingly offer bespoke solutions. Customization capabilities are crucial for optimizing material use, reducing installation time, and achieving specific aesthetic or functional requirements.

- Tailored Dimensions: Exact panel widths, lengths, and roll sizes can be manufactured to minimize on-site cutting and waste, accelerating project timelines.

- Variable Mesh Openings and Wire Gauges: Specific mesh patterns, varying aperture sizes within a single panel, or custom wire diameters can be produced to meet precise structural, security, or filtration needs.

- Specialized Materials and Coatings: Beyond standard galvanized or stainless steel, options include specialized alloys for extreme environments, or custom powder coating colors for architectural integration and enhanced protection.

- Pre-fabricated Shapes: Complex shapes, bent panels, or mesh components with cut-outs can be pre-fabricated, simplifying complex installations and reducing labor costs on site.

- Integrated Fixing Systems: Custom edge treatments, pre-drilled holes, or integrated mounting brackets can be incorporated during manufacturing for seamless integration with existing structures.

Working with a vendor capable of comprehensive custom fabrication ensures that the mesh solution is perfectly aligned with project specifications, optimizing performance and cost-efficiency. This service often involves close collaboration between the client's engineering team and the manufacturer's technical experts from initial design to final delivery.

Vendor Comparison and Selection Criteria

Selecting the right supplier for .Welded wire mesh panels and rolls. is paramount for project success, long-term performance, and cost optimization. Key criteria for vendor evaluation include:

- Quality Certifications: Look for ISO 9001 certified manufacturers who adhere to international standards like ASTM, ANSI, or relevant regional codes. This indicates a commitment to consistent quality control.

- Material Traceability: Ensure the vendor can provide full material traceability reports, confirming the origin and specifications of raw materials.

- Production Capabilities: Assess their capacity for both standard and customized orders, including specific wire diameters, mesh sizes, and surface treatments.

- Technical Support and Expertise: A knowledgeable technical team capable of assisting with material selection, design optimization, and installation guidance is invaluable.

- Lead Times and Logistics: Evaluate their ability to meet project deadlines and provide efficient, reliable global shipping solutions.

- Warranty and After-Sales Service: Clear warranty statements and responsive after-sales support are indicators of a trustworthy partner.

- Reputation and Experience: Longevity in the industry, positive customer feedback, and a portfolio of successful projects are strong indicators of reliability.

Comparison of Mesh Types for Specific Applications:

| Feature | Hot-Dip Galvanized Mesh | Stainless Steel Mesh (e.g., 304/316) | PVC Coated Mesh |

|---|---|---|---|

| Corrosion Resistance | Excellent (thick zinc layer) | Superior (inherent alloy properties) | Very Good (barrier protection) |

| Durability | High, long service life | Extremely High, minimal maintenance | Good, UV resistant |

| Cost Efficiency | Medium (excellent value for lifespan) | High (premium investment) | Medium-Low (good balance) |

| Aesthetic Appeal | Industrial silver-grey | Bright, clean finish | Various colors available |

| Typical Applications | General construction, fencing, agricultural | Chemical, marine, food processing, architectural | Residential/commercial fencing, decorative panels |

This comparative analysis helps in making an informed decision, balancing initial investment with long-term performance and specific environmental challenges.

Real-World Application Case Studies

Case Study 1: Large-Scale Industrial Perimeter Security

A major logistics hub required a high-security perimeter fence spanning 5 kilometers. Traditional chain-link fencing was deemed insufficient against determined intrusion attempts. The solution involved implementing .Welded wire mesh panels and rolls. with a small 50x50mm aperture and 4mm wire diameter, hot-dip galvanized for extreme weather resistance. The rigid panel structure, combined with anti-climb features, provided superior deterrence and physical security. The project saw a 30% reduction in installation time compared to rebar-based security walls, primarily due to the modularity and consistent dimensions of the panels. Post-installation, the facility reported zero successful perimeter breaches over a five-year period, significantly enhancing asset protection and operational continuity. Customer feedback highlighted the ease of integration with surveillance systems and the minimal maintenance required.

Case Study 2: Wastewater Treatment Plant Filtration

For a municipal wastewater treatment plant, fine screening of incoming effluent was crucial to protect downstream machinery. Custom-fabricated stainless steel (316 grade) welded wire mesh panels were engineered with a precise 6x6mm aperture. The inherent corrosion resistance of 316 stainless steel ensured the screens withstood continuous exposure to aggressive chemicals and organic matter without degradation, a critical factor for maintaining operational efficiency and reducing downtime. The uniform mesh openings guaranteed consistent filtration performance, meeting strict environmental discharge regulations. This application demonstrated the material's longevity and reliability in highly corrosive, continuously wet environments, contributing to more sustainable water management practices.

Quality Assurance, Certifications, and Client Partnerships

Our commitment to delivering superior .Welded wire mesh panels and rolls. is underpinned by rigorous quality assurance protocols and adherence to international standards. We are an ISO 9001:2015 certified manufacturer, ensuring that every stage of our production process, from raw material sourcing to final inspection, meets the highest quality management benchmarks. Our products regularly undergo third-party testing to verify compliance with ASTM, ANSI, and local regulatory requirements for material composition, weld strength, and dimensional accuracy. We maintain comprehensive material traceability records for every batch, providing clients with complete transparency and confidence in our product's integrity.

With over two decades of specialized experience in the metal fabrication industry, we have cultivated enduring partnerships with leading enterprises across petrochemical, construction, agriculture, and municipal sectors globally. Our extensive client portfolio includes long-term collaborations with major infrastructure developers and industrial operators who trust our consistent product quality and reliable supply chain. These partnerships are built on a foundation of mutual trust, consistent performance, and dedicated technical support, reflecting our position as an authoritative and experienced vendor in the market.

Logistics, Lead Times, and After-Sales Support

Understanding the time-sensitive nature of B2B projects, we prioritize efficient logistics and transparent communication regarding lead times. Our streamlined production process, combined with robust inventory management for common specifications, enables us to offer competitive lead times. For standard .Welded wire mesh panels and rolls., typical lead times range from 7-14 business days, while customized orders may range from 3-5 weeks depending on complexity and volume. We provide global shipping solutions, leveraging established partnerships with freight forwarders to ensure timely and secure delivery to project sites worldwide.

Our commitment extends beyond product delivery with comprehensive after-sales support. All our products come with a standard 5-year warranty against manufacturing defects, providing peace of mind and demonstrating our confidence in product durability. Our dedicated technical support team is available to assist with any post-purchase inquiries, installation guidance, or troubleshooting. We offer remote and, where necessary, on-site assistance to ensure optimal performance and client satisfaction throughout the product's operational life. Detailed documentation, including installation guides and maintenance recommendations, is provided with every order.

Frequently Asked Questions (FAQ)

- Q: What is the primary difference between welded wire mesh panels and rolls?

- A: Panels are rigid, pre-cut sheets, ideal for structural reinforcement, security fencing, or applications requiring flat, stable sections. Rolls are flexible and suitable for longer runs, temporary fencing, animal enclosures, or applications where the mesh needs to conform to contours, offering versatility in installation.

- Q: How do I choose the correct wire diameter and mesh opening?

- A: The choice depends on the application's specific requirements. Thicker wires provide greater strength and durability (e.g., for heavy-duty fencing or concrete reinforcement). Smaller mesh openings offer enhanced security, finer filtration, or containment of smaller objects/animals. Consult with our technical team to determine optimal specifications for your project.

- Q: What surface treatments are available and which is best for my needs?

- A: Common treatments include Electro Galvanized, Hot-Dip Galvanized, and PVC Coated. Hot-dip galvanization offers superior long-term corrosion resistance for harsh outdoor environments. Stainless steel provides inherent corrosion resistance without additional coating. PVC coating adds an extra layer of protection, UV resistance, and aesthetic appeal, available in various colors. The best choice depends on environmental exposure, desired lifespan, and budget.

- Q: Can your welded wire mesh products be customized?

- A: Yes, we offer extensive customization options including specific dimensions, wire gauges, mesh patterns, material grades, and surface finishes. Our engineering team works closely with clients to design and produce mesh solutions tailored to unique project requirements.

- Q: What are the typical lead times for large orders?

- A: Lead times vary based on the order volume, product complexity, and current production schedule. For standard products, it typically ranges from 7-14 business days. For large, customized orders, it can be 3-5 weeks. We strive for efficient order fulfillment and will provide a precise estimate upon quotation.

Conclusion

The versatility, strength, and durability of .Welded wire mesh panels and rolls. underscore their indispensable role across modern industries. From reinforcing critical infrastructure to securing high-value assets and supporting sustainable agricultural practices, these products offer a robust, cost-effective, and adaptable solution. By focusing on precision manufacturing, adherence to stringent quality standards, and offering comprehensive customization options, manufacturers ensure that these mesh products continue to meet the evolving demands of B2B clients. Partnering with a reliable and experienced vendor who prioritizes quality, technical support, and efficient logistics is crucial for leveraging the full benefits of welded wire mesh in any industrial application.

References

- International Organization for Standardization (ISO). ISO 9001:2015 - Quality management systems - Requirements.

- ASTM International. ASTM A82/A82M-05(2018) Standard Specification for Steel Wire, Plain, for Concrete Reinforcement.

- Galvanizers Association. The Corrosion Resistance of Galvanizing.

- European Committee for Standardization (CEN). EN 10025-2:2004 Hot rolled products of structural steels - Part 2: Technical delivery conditions for non-alloy structural steels.

- American National Standards Institute (ANSI). Standards for Metal and Related Products.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025