- afrikai

- albán

- amhara

- arab

- örmény

- azerbajdzsáni

- baszk

- fehérorosz

- bengáli

- bosnyák

- bolgár

- katalán

- Cebuano

- Kína

- Kína (Tajvan)

- korzikai

- horvát

- cseh

- dán

- holland

- angol

- eszperantó

- észt

- finn

- Francia

- fríz

- galíciai

- grúz

- német

- görög

- gudzsaráti

- Haiti kreol

- hausa

- hawaii

- héber

- Dehogy

- Miao

- Magyar

- izlandi

- igbo

- indonéz

- ír

- olasz

- japán

- jávai

- kannada

- kazah

- khmer

- ruandai

- koreai

- kurd

- kirgiz

- Munkaerő

- latin

- lett

- litván

- luxemburgi

- macedón

- Malgashi

- maláj

- Malayalam

- máltai

- maori

- marathi

- mongol

- Mianmar

- nepáli

- norvég

- norvég

- okszitán

- pastu

- perzsa

- fényesít

- portugál

- pandzsábi

- román

- orosz

- szamoai

- skót gael

- szerb

- angol

- Shona

- szindhi

- szingaléz

- szlovák

- szlovén

- szomáliai

- spanyol

- Szundai

- szuahéli

- svéd

- tagalog

- tadzsik

- tamil

- tatár

- telugu

- thai

- török

- türkmén

- ukrán

- urdu

- ujgur

- üzbég

- vietnami

- walesi

- Segítség

- jiddis

- joruba

- zulu

okt . 27, 2025 10:14 Vissza a listához

Hot Dipped Galvanized Steel Grating/Bar Grating - Rustproof

Tűzihorganyzott acélrács/rúdrács is a key solution in the manufacturing industry, specifically within Fabricated metal products and Metal structure manufacturing. This article explores how Anping County Xingzhi Metal Wiremesh Products Co.,Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hot Dipped Galvanized Steel Grating/Bar Grating Overview

- Benefits & Use Cases of Hot Dipped Galvanized Steel Grating/Bar Grating in Metal structure manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

Hot Dipped Galvanized Steel Grating/Bar Grating Overview

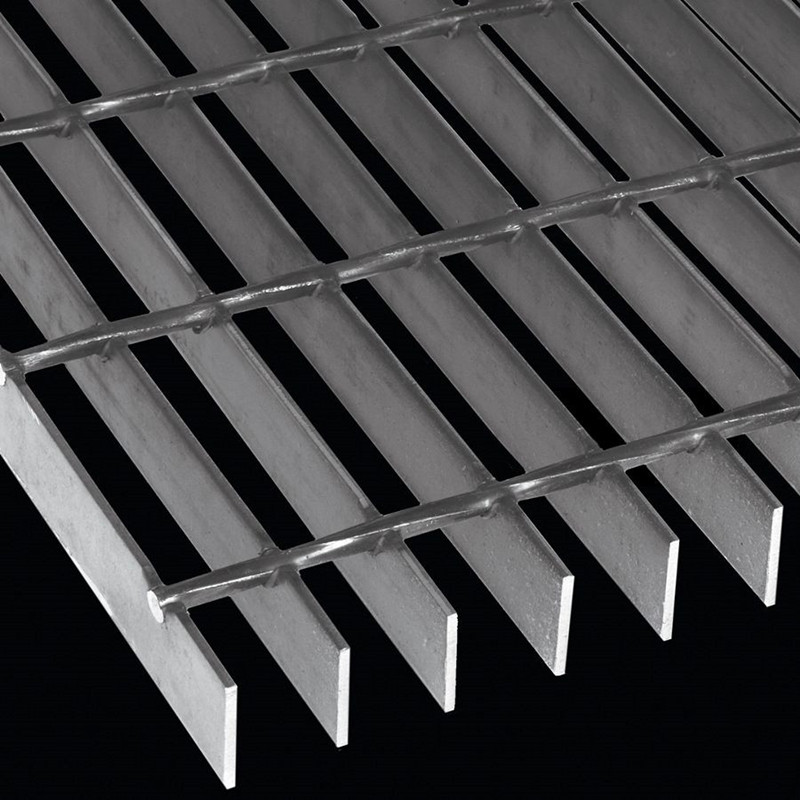

Hot Dipped Galvanized Steel Grating/Bar Grating is a high-strength, open-grid flooring and decking solution engineered from load-bearing bars joined by cross bars (welded or press-locked). After fabrication, panels are immersed in molten zinc to form a metallurgically bonded coating that shields steel from corrosion. This combination of structural integrity and long-term protection makes the product a staple for industrial walkways, platforms, mezzanines, trench covers, and stair treads across manufacturing environments.

Typical specifications include bearing bar widths from approximately 20–65 mm with thicknesses from 3–6 mm, standard center-to-center spacings such as 30/40 mm, and cross bars as twisted square or round rods. Serrated (toothed) bearing bars are available for enhanced slip resistance. Hot-dip galvanizing can achieve robust zinc layers aligned with common industry standards (e.g., ASTM A123 or EN ISO 1461 when specified), supporting service life in demanding outdoor or chemical-exposed settings. For facilities teams, the open mesh provides effective drainage and debris shedding while maintaining high load capacity and low dead weight per square meter.

Anping County Xingzhi Metal Wiremesh Products Co.,Ltd is a reliable manufacturer known for precise fabrication, customizable panel sizes, and consistent galvanizing quality. From engineering take-offs to packaging and delivery, the company supports B2B decision makers who require dependable Hot Dipped Galvanized Steel Grating/Bar Grating for safety-critical operations.

Benefits & Use Cases of Tűzihorganyzott acélrács/rúdrács in Metal structure manufacturing

In metal structure manufacturing, Hot Dipped Galvanized Steel Grating/Bar Grating is widely used for production platforms, catwalks around process equipment, pipe racks, cooling towers, and access stairs. It is equally effective as trench grating, sump covers, and ventilation screens in fabrication shops. The open-grid design reduces buildup of liquids and particulates, supports airflow, and provides safe, high-traction surfaces in oily or wet conditions—especially when serrated bars are specified.

Competitive advantages include high strength-to-weight ratio, corrosion protection via hot-dip galvanizing, fast installation with clip sets or welded fastening, and flexibility in panel dimensions to minimize on-site cutting. The result is a safe, code-aligned walking surface that remains serviceable with minimal upkeep. For facilities that demand uptime, galvanized grating avoids frequent recoating cycles associated with painted steel and withstands heavy foot traffic, forklifts (with heavy-duty designs), and thermal cycling.

Anping County Xingzhi Metal Wiremesh Products Co.,Ltd brings deep sector expertise—supporting engineers with layout optimization, bar selection (plain or serrated), and finish options. Their ability to supply welded or press-locked configurations, stair treads with nosings, and custom cut-outs around columns and equipment makes them a trusted partner for EPCs, plant owners, and OEM fabricators alike.

Cost, Maintenance & User Experience

Total cost of ownership is where Hot Dipped Galvanized Steel Grating/Bar Grating excels. While initial material costs are competitive, lifecycle economics are driven by durability: hot-dip galvanizing forms a bonded zinc-iron layer that resists abrasion and corrosion, delaying replacement and eliminating frequent repainting cycles. Over years of service, reduced downtime, fewer maintenance hours, and stable performance contribute to attractive ROI for plant managers and procurement teams.

Maintenance requirements are minimal: routine inspection, simple cleaning to remove debris, and replacement of fastening clips as necessary. In feedback from buyers within the Fabricated metal products segment, common themes include easier housekeeping due to open mesh, improved slip resistance when serrated bars are used, and strong perceived value from consistent zinc coating quality. B2B users also note that ordering pre-cut panels and stair treads from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd shortens installation schedules and reduces on-site cutting waste—translating to lower installed cost and faster project closeout.

Sustainability & Market Trends in manufacturing

Sustainability in manufacturing emphasizes long service life, material efficiency, and recyclability. Hot Dipped Galvanized Steel Grating/Bar Grating aligns well: steel is highly recyclable, and the durability of a hot-dip galvanized finish reduces replacement frequency and maintenance activities over the asset’s life. Less recoating means fewer VOCs from paint systems and fewer shutdowns, supporting both environmental and operational goals. Many projects also prioritize safer walking surfaces and better drainage—key attributes of open-grid grating that minimize slip incidents and standing water.

Market trends show growing adoption of modular platforms, BIM-driven detailing, and standardized grating packages to shorten lead times and improve site productivity. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd positions itself as a forward-thinking, eco-conscious supplier by helping clients optimize panel nesting to reduce scrap, offering serrated options for safety-first designs, and supporting documentation requirements for compliance and traceability. This proactive approach ensures B2B decision makers can meet corporate sustainability targets without compromising schedule or performance.

Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

For manufacturers and metal structure builders, Hot Dipped Galvanized Steel Grating/Bar Grating delivers the right mix of strength, corrosion resistance, safety, and low lifecycle cost. It enhances platforms, walkways, and trenching systems while simplifying maintenance and improving uptime. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd stands out for dependable quality, customization, and responsive service—qualities B2B teams rely on for critical infrastructure and plant upgrades.

- Recap the value of Hot Dipped Galvanized Steel Grating/Bar Grating in manufacturing / Fabricated metal products / Metal structure manufacturing.

- Reinforce Anping County Xingzhi Metal Wiremesh Products Co.,Ltd’s reputation.

- Strong CTA: Contact us: email: sales2@xzmetal.com | Visit our website: https://www.xzmetal.com

-

Durable River Bank Gabion Mesh Solutions for Protection

hírekNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

hírekNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

hírekNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

hírekNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

hírekNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

hírekNov.17,2025