- Afrika

- bahasa Albania

- Amharik

- Arab

- Armenia

- Azerbaijan

- Basque

- Belarusia

- Benggala

- Bosnia

- Bulgaria

- Katalan

- Cebuano

- Cina

- Tiongkok (Taiwan)

- Korsika

- Kroasia

- Ceko

- Orang Denmark

- Belanda

- Bahasa inggris

- Esperanto

- Estonia

- Finlandia

- Perancis

- Frisia

- Galisia

- Georgia

- Jerman

- Orang yunani

- Gujarati

- Kreol Haiti

- hausa

- hawaii

- Ibrani

- Tidak

- Miao

- Hongaria

- Islandia

- igbo

- bahasa Indonesia

- orang Irlandia

- Italia

- Jepang

- Jawa

- Kannada

- kazakh

- Khmer

- Rwanda

- Korea

- Kurdi

- Kirgistan

- Tenaga kerja

- Latin

- Latvia

- Lithuania

- Luksemburg

- Makedonia

- Malgashi

- Melayu

- Malayalam

- Malta

- Maori

- Marathi

- Mongolia

- Myanmar

- Nepal

- Norwegia

- Norwegia

- Occitan

- Pashto

- Orang Persia

- Polandia

- Portugis

- Punjabi

- Rumania

- Rusia

- Samoa

- Gaelik Skotlandia

- Orang Serbia

- Bahasa inggris

- Shona

- Sindhi

- Sinhala

- Orang Slovakia

- Slovenia

- Somalia

- Orang Spanyol

- Sunda

- Swahili

- Orang Swedia

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turki

- Turkmenistan

- Orang Ukraina

- Urdu

- Uighur

- Uzbek

- Orang Vietnam

- Welsh

- Membantu

- Yiddi

- Yoruba

- Zulu

Okt . 31, 2024 15:45 Kembali ke daftar

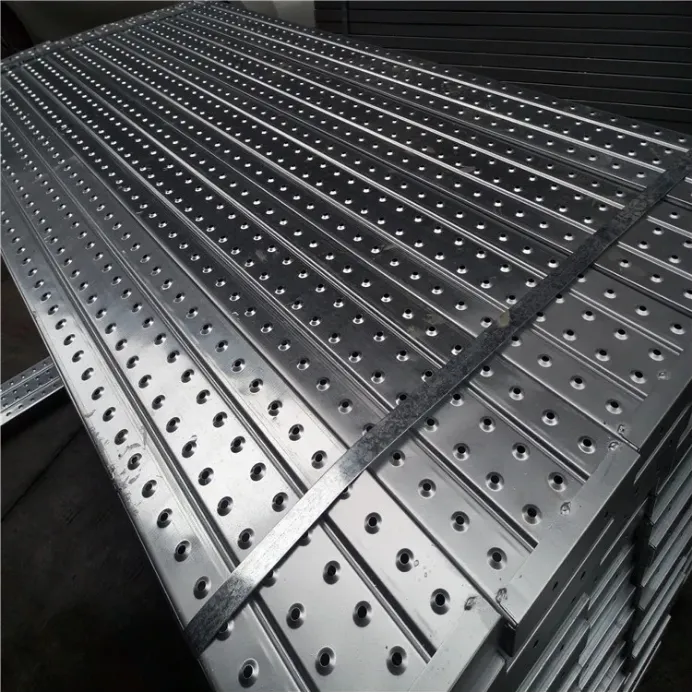

Characteristics and Manufacturing Process of Galvanized Steel Plank

Galvanized steel plank is an alloy material coated with a layer of zinc on the surface of the steel sheet, which has been widely used in various fields due to its unique performance characteristics. The following is an explanation of the characteristics and manufacturing process of galvanized steel plank.

1、 Characteristics of Galvanized Steel Plank

Excellent corrosion resistance: The surface of galvanized steel plank is coated with a layer of zinc, which serves as an electrochemical protective layer, effectively preventing oxidation and corrosion of the steel plate and extending its service life.

High strength: Galvanized steel plank maintains the original high strength characteristics of steel, can withstand large external impacts, and is not easily deformed or broken.

Aesthetics: The surface of galvanized steel plank is smooth, shiny, and has a metallic luster, suitable for occasions with certain requirements for aesthetics.

Good processability: Galvanized steel plank are easy to cut, bend, and weld, and can be processed into various shapes and sizes to meet different application needs.

Wide application fields: Galvanized steel plank has a wide range of applications in various fields such as construction, automobile manufacturing, home appliances, and furniture manufacturing due to its unique performance characteristics.

2、 The Production Process of Galvanized Steel Plank

The production process of galvanized steel plank mainly includes two methods: hot-dip galvanizing and electroplating galvanizing:

Hot dip galvanizing: Hot dip galvanizing is the process of completely immersing a steel plate in molten zinc solution, leaving a zinc layer on top of the product. The zinc layer formed by this method is relatively thick, usually between 30-50 microns, and has excellent corrosion resistance. The process of hot-dip galvanizing includes pretreatment, hot-dip plating, and cooling steps, among which pretreatment is a key link, including steps such as oil removal, rust removal, and acid washing, to ensure that the surface of the steel plate is clean and free of impurities, and to improve the adhesion and corrosion resistance of the zinc layer.

Electrogalvanizing: Electrogalvanizing is the process of depositing a layer of zinc on the surface of a steel plate through electrolysis. The zinc layer formed by this method is relatively thin, but has good uniformity and glossiness. The process of electroplating zinc includes pretreatment, electroplating, and post-treatment steps, among which electroplating is a key link that requires controlling parameters such as current density, electroplating time, and temperature to achieve the desired zinc layer thickness and performance.

In summary, galvanized steel plank have been widely used in various fields due to their excellent corrosion resistance, high strength, aesthetic appeal, and good processability. The production process includes two methods: hot-dip galvanizing and electroplating galvanizing, each with its own advantages and disadvantages. The selection should be based on specific application needs and cost-effectiveness.

As a company special in metal wire mesh products, our business scope is very broad . We have wire mesh products , construction material products, types of barbed wire , gabion box and metal wire fence . About the construction material products ,we have different type of it .Such as galvanized steel plank , hot dip galvanized grating and steel bar welded wire mesh. Itu galvanized steel plank price in our company are reasonable . If you are interesting in our product welcome to contact us!

-

Durable River Bank Gabion Mesh Solutions for Protection

BeritaNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

BeritaNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

BeritaNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

BeritaNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

BeritaNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

BeritaNov.17,2025

Okt . 24, 2024 12:19 Kembali ke daftar

Characteristics and Manufacturing Process of Galvanized Steel Plank

Galvanized steel plank is an alloy material coated with a layer of zinc on the surface of the steel sheet, which has been widely used in various fields due to its unique performance characteristics. The following is an explanation of the characteristics and manufacturing process of galvanized steel plank.

Characteristics of Galvanized Steel Plank

Excellent corrosion resistance: The surface of galvanized steel plank is coated with a layer of zinc, which serves as an electrochemical protective layer, effectively preventing oxidation and corrosion of the steel plate and extending its service life.

High strength: Galvanized steel plank maintains the original high strength characteristics of steel, can withstand large external impacts, and is not easily deformed or broken.

Aesthetics: The surface of galvanized steel plank is smooth, shiny, and has a metallic luster, suitable for occasions with certain requirements for aesthetics.

Good processability: Galvanized steel plank are easy to cut, bend, and weld, and can be processed into various shapes and sizes to meet different application needs.

Wide application fields: Galvanized steel plank has a wide range of applications in various fields such as construction, automobile manufacturing, home appliances, and furniture manufacturing due to its unique performance characteristics.

The Production Process of Galvanized Steel Plank

The production process of galvanized steel plank mainly includes two methods: hot-dip galvanizing and electroplating galvanizing:

Hot dip galvanizing: Hot dip galvanizing is the process of completely immersing a steel plate in molten zinc solution, leaving a zinc layer on top of the product. The zinc layer formed by this method is relatively thick, usually between 30-50 microns, and has excellent corrosion resistance. The process of hot-dip galvanizing includes pretreatment, hot-dip plating, and cooling steps, among which pretreatment is a key link, including steps such as oil removal, rust removal, and acid washing, to ensure that the surface of the steel plate is clean and free of impurities, and to improve the adhesion and corrosion resistance of the zinc layer.

Electrogalvanizing: Electrogalvanizing is the process of depositing a layer of zinc on the surface of a steel plate through electrolysis. The zinc layer formed by this method is relatively thin, but has good uniformity and glossiness. The process of electroplating zinc includes pretreatment, electroplating, and post-treatment steps, among which electroplating is a key link that requires controlling parameters such as current density, electroplating time, and temperature to achieve the desired zinc layer thickness and performance.

In summary, galvanized steel plank have been widely used in various fields due to their excellent corrosion resistance, high strength, aesthetic appeal, and good processability. The production process includes two methods: hot-dip galvanizing and electroplating galvanizing, each with its own advantages and disadvantages. The selection should be based on specific application needs and cost-effectiveness.

As a company special in metal wire mesh products, our business scope is very broad . We have wire mesh products , construction material products, types of barbed wire , gabion box and metal wire fence . About the construction material products ,we have different type of it .Such as galvanized steel plank , hot dip galvanized grating and steel bar welded wire mesh. Itu galvanized steel plank price in our company are reasonable . If you are interesting in our product welcome to contact us!

-

Durable River Bank Gabion Mesh Solutions for Protection

BeritaNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

BeritaNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

BeritaNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

BeritaNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

BeritaNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

BeritaNov.17,2025

Okt . 24, 2024 12:07 Kembali ke daftar

Characteristics and Manufacturing Process of Galvanized Steel Plank

Galvanized steel plank is an alloy material coated with a layer of zinc on the surface of the steel sheet, which has been widely used in various fields due to its unique performance characteristics. The following is an explanation of the characteristics and manufacturing process of galvanized steel plank.

Characteristics of Galvanized Steel Plank

Excellent corrosion resistance: The surface of galvanized steel plank is coated with a layer of zinc, which serves as an electrochemical protective layer, effectively preventing oxidation and corrosion of the steel plate and extending its service life.

High strength: Galvanized steel plank maintains the original high strength characteristics of steel, can withstand large external impacts, and is not easily deformed or broken.

Aesthetics: The surface of galvanized steel plank is smooth, shiny, and has a metallic luster, suitable for occasions with certain requirements for aesthetics.

Good processability: Galvanized steel plank are easy to cut, bend, and weld, and can be processed into various shapes and sizes to meet different application needs.

Wide application fields: Galvanized steel plank has a wide range of applications in various fields such as construction, automobile manufacturing, home appliances, and furniture manufacturing due to its unique performance characteristics.

The Production Process of Galvanized Steel Plank

The production process of galvanized steel plank mainly includes two methods: hot-dip galvanizing and electroplating galvanizing:

Hot dip galvanizing: Hot dip galvanizing is the process of completely immersing a steel plate in molten zinc solution, leaving a zinc layer on top of the product. The zinc layer formed by this method is relatively thick, usually between 30-50 microns, and has excellent corrosion resistance. The process of hot-dip galvanizing includes pretreatment, hot-dip plating, and cooling steps, among which pretreatment is a key link, including steps such as oil removal, rust removal, and acid washing, to ensure that the surface of the steel plate is clean and free of impurities, and to improve the adhesion and corrosion resistance of the zinc layer.

Electrogalvanizing: Electrogalvanizing is the process of depositing a layer of zinc on the surface of a steel plate through electrolysis. The zinc layer formed by this method is relatively thin, but has good uniformity and glossiness. The process of electroplating zinc includes pretreatment, electroplating, and post-treatment steps, among which electroplating is a key link that requires controlling parameters such as current density, electroplating time, and temperature to achieve the desired zinc layer thickness and performance.

In summary, galvanized steel plank have been widely used in various fields due to their excellent corrosion resistance, high strength, aesthetic appeal, and good processability. The production process includes two methods: hot-dip galvanizing and electroplating galvanizing, each with its own advantages and disadvantages. The selection should be based on specific application needs and cost-effectiveness.

As a company special in metal wire mesh products, our business scope is very broad . We have wire mesh products , construction material products, types of barbed wire , gabion box and metal wire fence . About the construction material products ,we have different type of it .Such as galvanized steel plank , hot dip galvanized grating and steel bar welded wire mesh. Itu galvanized steel plank price in our company are reasonable . If you are interesting in our product welcome to contact us!