Oct . 22, 2025 12:15 Back to list

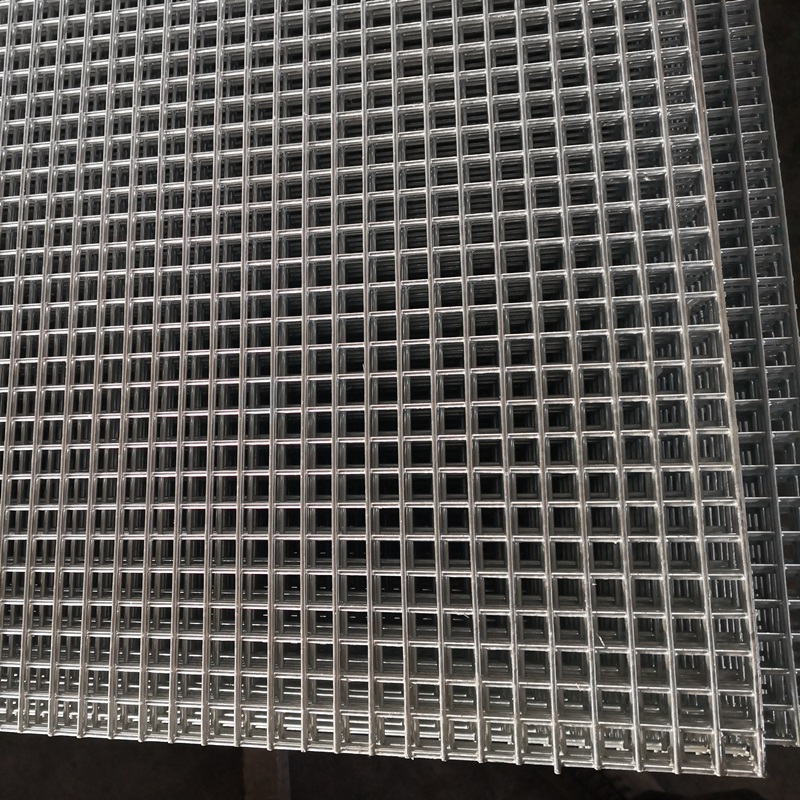

Welded Wire Mesh Panels and Rolls - Galvanized, Custom Sizes

Report from the field: why Welded Wire Mesh Panels And Rolls are quietly winning projects

I’ve been walking job sites from Hebei to Houston, and the conversation keeps circling back to welded mesh. To be honest, it’s not glamorous—wire, welds, coatings—but contractors love gear that shows up square, flat, and consistent. At XZ Metal’s works just 200 meters north of Huangcheng Village, Anping (Hebei, China), you can feel the rhythm: coil in, mesh out, trucks loaded by dusk. The demand is real.

What’s driving the trend

Two things: predictable tolerances and flexible formats. Panels for rigid installs; rolls for long runs and curves. Actually, the mix has shifted—more PVC-coated fences for residential and logistics parks, and a spike in welded gabion cages for faster retaining walls. Many customers say the biggest surprise is reduced rework: straight lines, tight apertures, fewer on-site fixes.

Key specifications (real-world ranges)

| Parameter | Panels (typical) | Rolls (typical) |

|---|---|---|

| Material | Q195/Q235 low-carbon steel | Q195/Q235 low-carbon steel |

| Wire diameter | ≈ 2.0–6.0 mm | ≈ 1.2–3.5 mm |

| Mesh opening | 25×25 to 200×200 mm | 12.5×12.5 to 100×100 mm |

| Sizes | 1×2 m, 1.2×2.4 m, custom | H 0.9–1.8 m, L 25–30 m |

| Coatings | Electro-Galv, Hot-Dip Galv, PVC, painting | Same options |

| Zinc mass | EG ≈ 20–35 g/m²; HDG ≈ 50–275 g/m² | Similar range |

| PVC thickness | ≈ 0.4–1.0 mm (RAL colors) | ≈ 0.3–0.8 mm |

Mechanical baselines: Q195 tensile ≈ 315–430 MPa; Q235 ≈ 375–500 MPa. Weld shear acceptance often targets ≥70% of wire tensile (per industry practice drawn from ASTM A185/A497). Real-world use may vary with aperture and heat input.

Process flow, testing, and service life

Wire drawing → straightening & cutting → automatic resistance welding → galvanizing or PVC coating → trimming & flattening → inspection → palletizing. Tests we’ve seen on shop floors: - Aperture tolerance: typically ±2–3 mm. - Zinc thickness verification to ISO 1461 or EN 10244-2. - Salt-spray to ASTM B117: EG ≈ 72–120 h, HDG ≈ 240–500 h, PVC over galv often > 500 h (indicative). - Cross-hatch adhesion (PVC) per ISO 2409.

Service life (ballpark): rural 10–20 years for hot-dip; industrial/coastal 5–12 years; PVC-coated can extend life, especially where abrasion is low. Not a promise—just field averages.

Applications and advantages

Use cases pop up everywhere: construction reinforcement, perimeter fences, animal cages, welded gabion boxes, vineyard trellis, HVAC guards, storage cages, even temporary site panels. Advantages? Fast install, consistent geometry, predictable coating performance, and simple spares. It seems that the fewer surprises, the better the margins.

Customization

Aperture, wire dia, panel size, roll length, coating type, and color (RAL 6005, 7016, 9005 are popular). Private-label packaging and barcodes on request. Certificates: ISO 9001. Origin stamped: Anping, Hebei, China.

Vendor landscape (quick comparison)

| Vendor type | Origin | Certs | Lead time | Coatings | QC docs |

|---|---|---|---|---|---|

| Manufacturer (Anping) | Hebei, China | ISO 9001 | ≈ 7–20 days | EG / HDG / PVC / paint | Mill & test reports |

| Trading house | Mixed | Varies | ≈ 15–35 days | Depends on source | On request |

| Local fabricator | Your region | Shop-level | Short for small lots | Limited | Basic |

Field notes and mini case studies

- Logistics park fence: 2.5 mm wire, 50×200 mm panels, PVC RAL 6005. Installers said flatness cut labor by ~12%.

- Retaining wall (welded gabions): HDG 4.0 mm, 100×100 mm. Faster than stone masonry—contractor wrapped in 9 days, not 12.

- Poultry farm rollout: 1.6 mm roll mesh, EG, 25×25 mm. Customer feedback: “Clean welds, no sharp burrs.” Simple, but it matters.

If you’re weighing Welded Wire Mesh Panels And Rolls versus chain-link or expanded metal, the calculus is straightforward: where geometry and rigidity matter, welded mesh usually wins. Where the terrain is wild or budgets ultra-tight, chain-link still has a say. I guess that’s the honest take.

Standards and references

- ASTM A185/A185M – Standard Specification for Steel Welded Wire Reinforcement, Plain.

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel articles.

- EN 10244-2 – Steel wire and wire products—Non-ferrous metallic coatings on steel wire.

- ISO 9001 – Quality management systems—Requirements.

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025