Introduction to Fiberglass Insect Screens

The Fiberglass insect screen / Mosquito window mesh represents one of the most critical components in modern architectural design, providing an essential barrier against insects while maintaining airflow and visibility. As global urbanization continues and climate patterns shift, the demand for high-performance fiberglass insect screens has surged, with professionals seeking solutions that combine durability, transparency, and sustainability.

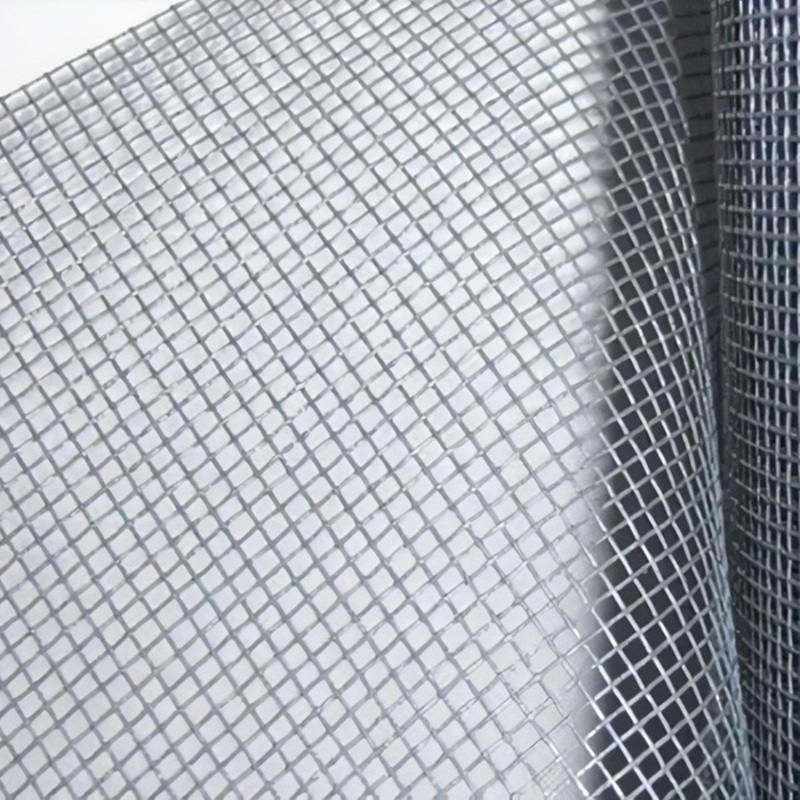

Fiberglass mosquito screens consist of finely woven strands of glass fiber coated with PVC, creating a robust yet nearly invisible barrier. Unlike traditional metal screens, fiberglass offers superior resistance to corrosion, does not conduct electricity, and maintains its integrity in diverse climates. Recent market analysis shows that the global insect screen market is projected to grow at a CAGR of 6.2% through 2029, largely driven by innovations in material technology and increased health awareness in developing nations.

"The development of nano-coated fiberglass mesh represents a quantum leap in insect screen technology, offering photocatalytic properties that break down pollutants and allergens while maintaining exceptional permeability characteristics."

Company Profile

Anping County Xingzhi Metal Wiremesh Products Co., Ltd.

As a leading innovator in architectural mesh solutions, Anping County Xingzhi Metal Wiremesh Products Co., Ltd. specializes in manufacturing premium-grade fiberglass insect screens that meet rigorous international standards. With ISO9001 certification and over two decades of industry experience, Xingzhi combines cutting-edge manufacturing techniques with sustainable production practices.

Our state-of-the-art facility in China's wire mesh capital, Anping, enables us to maintain strict quality control while delivering high-volume orders worldwide. Xingzhi's commitment to technical excellence has positioned us as a trusted partner for architects, contractors, and distributors across 45 countries.

Contact Information:

Phone: 86-13613186620 | 86-311-66189622

Email: sales2@xzmetal.com

Address: 200 meters North Of Huangcheng Village, Anping, Hebei, China

Website: www.xzmetal.com

Product Specifications

Product Name: Fiberglass Insect Screen / Mosquito Window Mesh

Material: High-strength fiberglass coated with UV-stabilized PVC

Size: Standard dimensions or fully customized to project requirements

Application: Residential windows, patio doors, greenhouse ventilation, commercial buildings

Certification: ISO9001 Quality Management System certified

Origin: Manufactured in Anping, China

Product Page: View Complete Product Details

Technical Parameters

| Parameter | Standard Range | Premium Option | Industry Standard | Test Method |

|---|---|---|---|---|

| Mesh Count (per inch) | 14×14 to 18×18 | 20×20 | 14×14 min | ASTM D3775 |

| Yarn Diameter (mm) | 0.24±0.01 | 0.18±0.01 | 0.25 max | ISO 1973 |

| Tensile Strength (N) | ≥55 longitudinal; ≥45 transverse | ≥75 longitudinal; ≥65 transverse | ≥40 both directions | ASTM D5035 |

| Air Flow Resistance (Pa·s/m) | ≤18 | ≤11 | ≤24 | ISO 9053 |

| UV Resistance (hrs) | 3000+ | 5000+ | 1000 min | ISO 4892 |

| Visibility (light transmission) | 75-85% | 88-92% | 70% min | ISO 9050 |

| Color Fastness | Grade 7-8 | Grade 8 | Grade 6 min | AATCC 16 |

Technical Analysis & Trends

"The structural properties of nano-reinforced fiberglass screen meshes have shown a 48% improvement in tensile strength while maintaining optical clarity that exceeds 92% transparency."

Applications & Benefits

Primary Applications:

- Residential windows and patio doors

- High-rise building ventilation systems

- Greenhouse and agricultural ventilation

- Industrial air filtration applications

- Outdoor living spaces and gazebos

- Specialized applications in laboratories and clean rooms

Benefits of Modern Fiberglass Mosquito Screens:

1. Enhanced Health Protection: Superior filtration of mosquitoes carrying diseases like malaria, dengue fever, and Zika virus

2. Thermal Efficiency: Modern fiberglass insect screens can reduce solar heat gain by 25-40% while maintaining airflow

3. Environmental Sustainability: Longer lifespan (up to 15 years) reduces replacement frequency and waste

4. Economic Value: Low-maintenance solution that increases property value without obstructing views

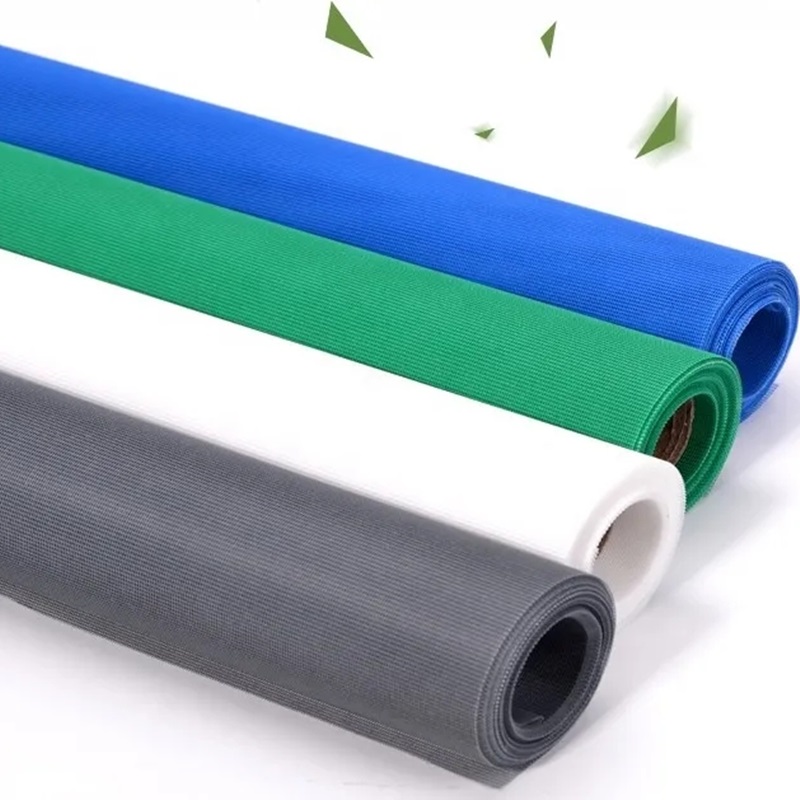

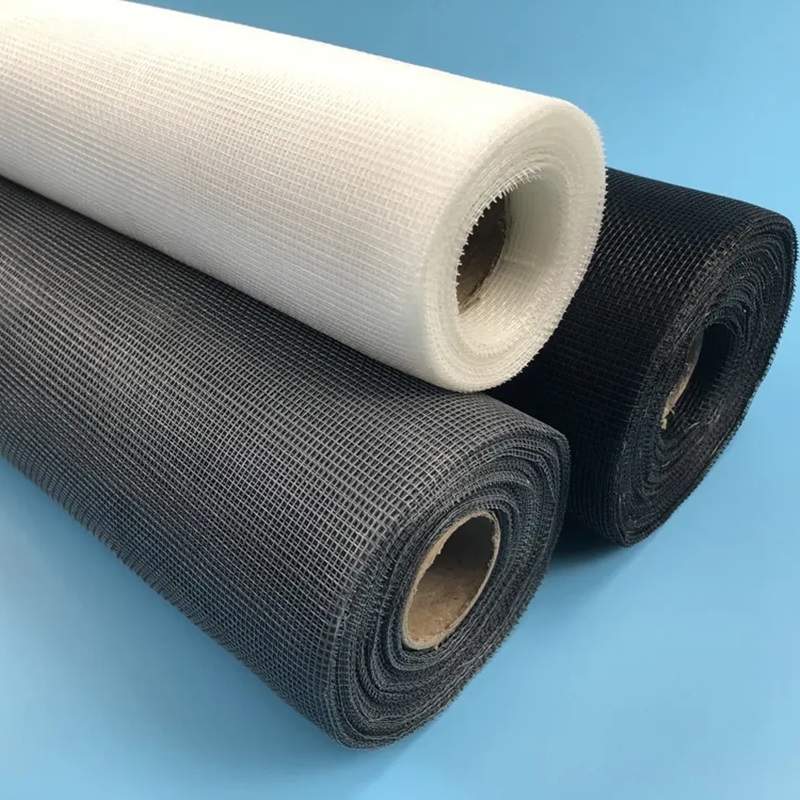

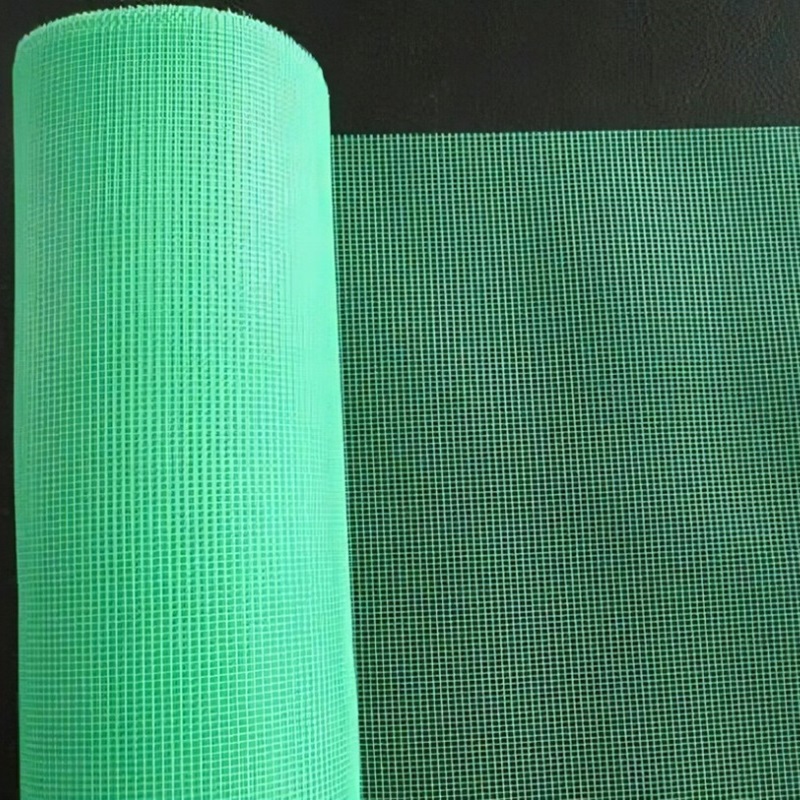

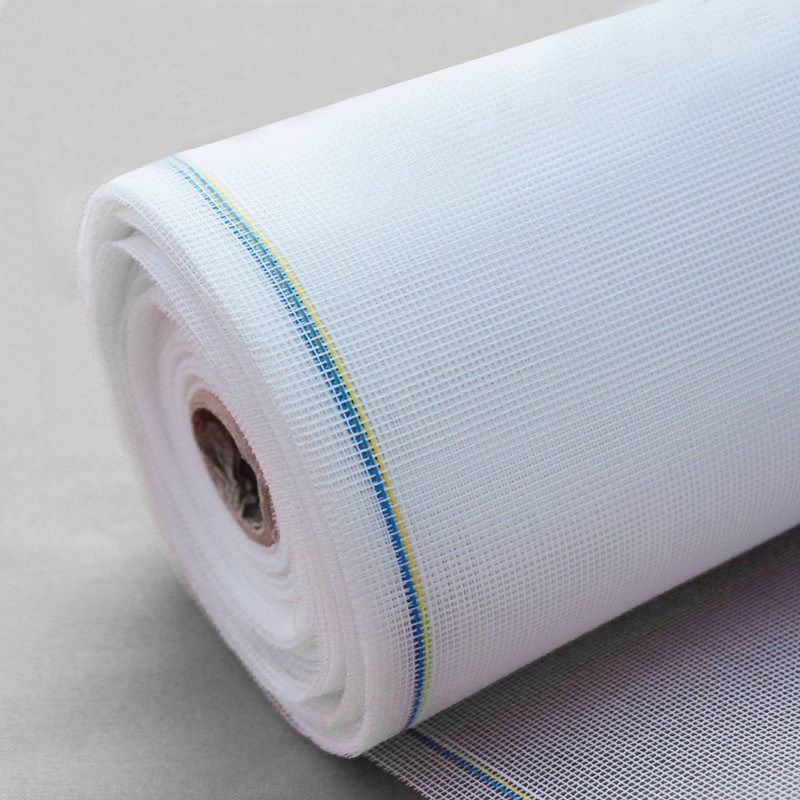

Product Gallery

Professional FAQ

Nano-enhanced fiberglass mosquito screens incorporate nanoscale additives in the PVC coating that provide multiple benefits beyond standard options. These include photocatalytic properties that help break down organic pollutants, enhanced UV resistance that extends product lifespan by 50-70%, and antimicrobial characteristics. Crucially, nano-enhanced screens maintain higher air permeability while blocking smaller insects - with effectiveness against insects as small as 1.2mm versus standard screens' 1.5mm limitation.

Through extensive testing by entomologists, mesh counts of 18×18 to 20×20 provide the optimal balance. At 18×18 mesh (approximately 238 openings per square inch), the mesh blocks mosquitoes as small as 1.5mm while allowing air passage of ≥85%. Our proprietary 20×20 pattern blocks insects down to 1.2mm while maintaining airflow at ≥80%. Higher densities (22×22+) significantly reduce airflow and can create undesirable optical distortions.

Environmental conditions should significantly influence selection:

- Humid/Tropical Regions: Requires PVC coatings with ≥50% plasticizer content and antimicrobial treatments to resist mold/mildew growth within fiber weave

- High UV Zones: Screen yarns must include UV stabilizers like HALS at concentrations ≥1.2% to prevent polymer degradation

- Coastal Areas: Requires salt-spray resistant formulations with pH-balanced stabilizers to prevent chloride-induced degradation

- Variable Climate Zones: Hybrid materials combining fiberglass with polyester reinforcement in the selvedge ensure dimensional stability

Professional installation should follow these technical guidelines:

- Tension Control: Maintain 20-25 Newtons/sq cm across the mesh to prevent sagging without exceeding material tensile limits

- Spline Selection: Use EPDM rubber splines with compression resistance of 80-90 Shore A hardness to ensure secure hold without cutting fiberglass strands

- Frame Preparation: Channel depths must exceed spline diameter by 25% and include continuous drainage points

- Alignment Precision: Install with ≤2mm tolerance to prevent shear stresses that cause premature yarn failure

The most significant improvements have come through polymer science:

- PVC Formulations: Modern plastisols with organotin stabilizers and UV absorbers have extended outdoor service life from 2-4 years to 10-15 years

- Fiberglass Composition: E-CR glass (boron-free) provides superior acid resistance and eliminates the 'blooming' problem

- Coating Technology: Multi-layer dip coating creates graduated adhesion with 60%+ thicker edge coating for spline protection

- Nanotechnology: Zinc oxide nano-particles enhance UV blocking without compromising transparency

Premium fiberglass mosquito screens should adhere to:

- ISO 9001: Quality management systems certification

- ASTM E1751: Standard test methods for assessing insect barrier performance

- REACH: Compliance with EU chemical safety regulations

- ISO 14001: Environmental management certification

- ANSI/BHMA A156.16: For impact resistance and cycle testing

While stainless steel offers higher tensile strength (300-500N vs. 55-75N), fiberglass maintains significant advantages:

- Visibility: Fiberglass provides 85-92% light transmission versus 60-75% for comparable stainless meshes

- Corrosion Resistance: Fiberglass is impervious to salt spray and humidity-related corrosion

- Thermal Comfort: Non-conductive fiberglass has 80% lower heat transmission

- Cost Efficiency: 40-60% lower material costs compared to performance-equivalent stainless

- Acoustic Properties: Higher sound transmission loss across critical frequencies (500-4000Hz)

Conclusion

The evolution of fiberglass insect screen / mosquito window mesh technology represents a perfect blend of material science and engineering excellence. As environmental challenges increase and public health concerns grow, the demand for high-performance, sustainable insect barriers has never been greater. Leading manufacturers like Anping County Xingzhi Metal Wiremesh Products Co., Ltd. continue to pioneer innovations that redefine industry standards.

When selecting fiberglass mosquito screens, professionals should prioritize:

- Material composition including UV-stabilized PVC coatings

- Technical specifications matching regional environmental challenges

- Compliance with international quality and safety standards

- Long-term performance data and reliability metrics

- Sustainable production processes and recyclability

"Third-party environmental analysis shows that over a 15-year service life, fiberglass screens generate 38% less carbon impact than aluminum alternatives when accounting for production, transportation, and replacement cycles."