- Afrika

- basa Albania

- Amharic

- Arab

- wong Armenia

- basa Azerbaijan

- Basque

- Belarusia

- Bengali

- Bosnia

- basa Bulgaria

- Katalan

- Cebuano

- Cina

- China (Taiwan)

- Korsika

- basa Kroasia

- Ceko

- Danish

- Walanda

- Inggris

- Esperanto

- basa Estonia

- basa Finlandia

- Prancis

- Frisian

- Galician

- Georgian

- Jerman

- Yunani

- Gujarati

- Kreol Haiti

- hausa

- hawaiian

- basa Ibrani

- Ora

- Miao

- Hungaria

- basa Islandia

- igbo

- basa Indonesia

- irlandia

- basa Italia

- Jepang

- basa jawa

- Kannada

- kazakh

- Khmer

- wong Rwanda

- Korea

- Kurdi

- Kyrgyz

- Buruh

- latin

- Latvia

- Lithuania

- Luksemburg

- Makedonia

- Malgashi

- Melayu

- Malayalam

- wong Malta

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- basa Norwegia

- basa Norwegia

- Occitan

- Pashto

- Persia

- Polandia

- Portugis

- Punjabi

- basa Rumania

- Rusian

- Samoan

- Gaelik Skotlandia

- basa Serbia

- Inggris

- Shona

- Sindhi

- Sinhala

- basa Slowakia

- basa Slovenia

- Somali

- Spanyol

- Sundha

- Swahili

- Swedia

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- basa Turki

- Turkmen

- Ukrainia

- Basa Urdu

- Uighur

- Uzbek

- Vietnam

- Welsh

- Pitulung

- Yiddish

- Yoruba

- Zulu

Sep . 04, 2025 14:22 Bali menyang dhaptar

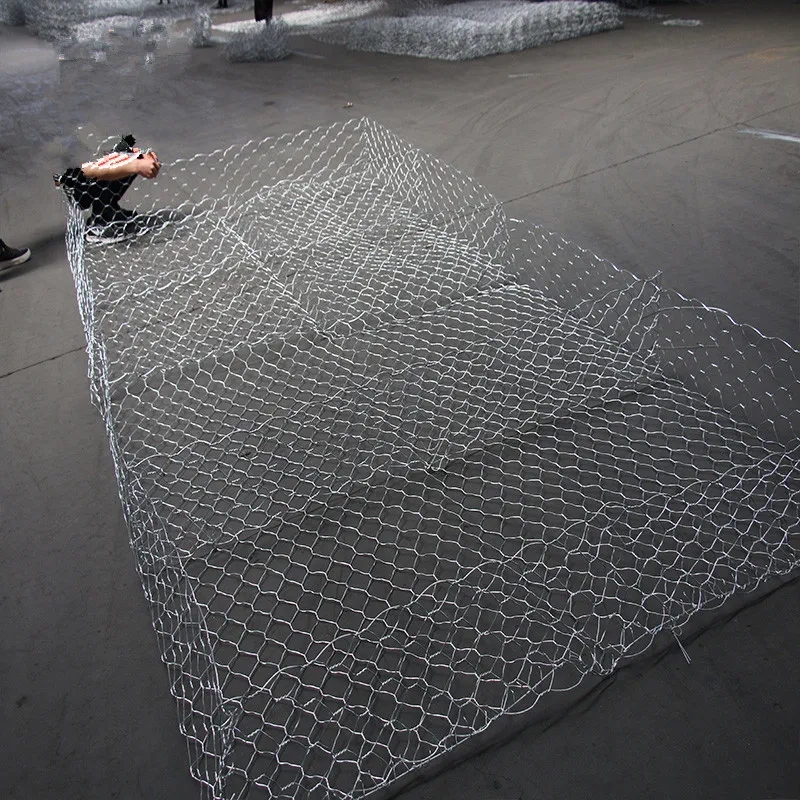

Double Twisted Hexagonal Gabion Mesh Box & Mattress | Erosion Control

Understanding Double Twisted Hexagonal Gabion Mesh Box/Gabion Mattress: Industry Trends and Innovations

In modern civil engineering, environmental protection, and infrastructure development, the demand for resilient, sustainable, and adaptable construction materials is paramount. One such cornerstone product is the Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion. This engineered solution plays a critical role in erosion control, soil stabilization, and hydraulic works, offering a blend of flexibility, permeability, and structural integrity. Current industry trends emphasize eco-friendly solutions, cost-effectiveness, and ease of installation, all of which are inherently characteristic of gabion structures. The shift towards sustainable infrastructure projects, coupled with the increasing frequency of extreme weather events, has amplified the need for robust, flexible, and environmentally harmonious geotechnical materials. Our commitment to innovation ensures that our gabion products not only meet but exceed these evolving industry demands, providing reliable performance in even the most challenging environments.

Technical Specifications and Parameters

The performance and longevity of a gabion structure are directly dependent on its precise technical specifications. Our Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion products are manufactured to stringent international standards, ensuring optimal mechanical properties and resistance to environmental degradation. Key parameters include wire diameter, mesh opening size, coating type, and dimensional accuracy, all of which contribute to the structural integrity and service life of the finished product. We offer a range of specifications to suit diverse project requirements, emphasizing material quality and manufacturing precision.

Product Specification Table

| Parameter | Katrangan | Standard Range |

|---|---|---|

| Wire Material | Low carbon steel wire (ASTM A975) | Galvanized, Galfan (Zn-Al alloy), PVC Coated |

| Wire Diameter (Mesh) | Diameter of wire forming the mesh | 2.0mm - 4.0mm |

| Wire Diameter (Selvedge) | Diameter of edge wire, typically thicker | 3.0mm - 5.0mm |

| Mesh Opening Size (HxW) | Hexagonal opening dimension | 60x80mm, 80x100mm, 100x120mm, 120x150mm |

| Coating Thickness (Zinc) | Minimum zinc mass per unit area | ≥ 245 g/m² (for Galvanized) |

| Kekuwatan Tensile | Wire breaking strength | 350-550 MPa |

| Gabion Box Dimensions (LxWxH) | Standard unit sizes | 1x1x1m, 2x1x1m, 3x1x1m, 4x1x1m (customizable) |

| Gabion Mattress Dimensions (LxWxH) | Standard unit sizes (thinner profile) | 3x2x0.3m, 4x2x0.3m, 6x2x0.3m (customizable) |

Diverse Application Scenarios

The versatility of the Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion makes it an indispensable component across numerous target industries, including petrochemical, metallurgy, water supply & drainage, civil infrastructure, and environmental protection. Its robust design and inherent flexibility allow it to adapt to ground movements without structural failure, a critical advantage in unstable terrains.

- River Bank and Channel Protection: Gabions provide effective erosion control for riverbanks, preventing scour and maintaining channel stability. Their permeable nature allows for natural drainage, reducing hydrostatic pressure.

- Retaining Walls: Utilized in gravity-type retaining structures for highways, railways, and industrial sites, gabion walls offer a cost-effective and aesthetically pleasing alternative to traditional concrete structures.

- Erosion Control Structures: From coastal protection to slope stabilization in mountainous regions, gabion mattresses are deployed to dissipate energy from water flow and trap sediment, fostering vegetation growth.

- Bridge Abutment and Culvert Protection: Protecting critical infrastructure from scour and undermining, gabions ensure the long-term integrity of bridges and culverts.

- Sound Barriers: Filled with sound-absorbing materials, gabion structures can also function as effective noise reduction barriers along busy transportation corridors.

- Landscaping and Architectural Features: Beyond their functional role, gabions are increasingly integrated into modern landscape design for decorative walls, garden features, and terracing due to their natural aesthetic.

The adaptability of these structures, often becoming integrated with the local flora over time, makes them an environmentally conscious choice for diverse engineering challenges.

Technical Advantages and Performance Benefits

Our Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion offers a compelling suite of technical advantages that set it apart in geotechnical and hydraulic engineering applications. These benefits translate directly into enhanced project performance, longevity, and overall value.

- Superior Corrosion Resistance: Employing advanced galvanization processes (e.g., hot-dip galvanizing, Galfan coating) and optional PVC coating ensures exceptional resistance to rust and environmental stressors, extending service life in harsh conditions like marine environments or industrial runoff. Typically, our gabion products offer a service life exceeding 50 years when properly installed and maintained, far surpassing many conventional materials.

- Exceptional Flexibility and Adaptability: The double-twisted hexagonal mesh structure provides inherent flexibility, allowing the gabion to accommodate differential settlement and ground movement without fracturing. This makes it ideal for unstable slopes and dynamic hydrological environments.

- High Permeability for Hydrostatic Pressure Relief: Gabions are naturally permeable, allowing water to pass through freely. This prevents the buildup of hydrostatic pressure behind retaining structures, which is a major cause of failure in impermeable walls. This characteristic also contributes to energy saving by requiring less complex drainage systems.

- Environmental Friendliness: Gabions use locally sourced fill material (stones), minimizing transportation costs and carbon footprint. They integrate naturally into the landscape, promoting vegetation growth over time and enhancing ecological diversity. This aligns with modern sustainability goals.

- Cost-Effectiveness: Reduced material costs (due to local fill), simpler installation procedures, and minimal maintenance requirements contribute to significant cost savings over the project lifecycle compared to rigid structures.

- Robust Structure: The double-twist weave prevents unraveling in case of wire damage, ensuring the integrity of the mesh even under localized stress. This robust construction is crucial for long-term stability.

These combined advantages make our gabion solutions a technically sound and economically viable choice for critical infrastructure projects, delivering reliable performance and long-term value.

Detailed Manufacturing Process Flow

The manufacturing of our Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion involves a meticulously controlled process to ensure product quality and consistency. Adherence to international standards such as ISO 9001 for quality management and ASTM A975 for metallic-coated steel wire gabions is fundamental to our production.

- 1. Material Selection: High-quality low carbon steel wire, typically with a tensile strength ranging from 350 to 550 MPa, is carefully selected. The wire must meet precise chemical composition and mechanical property requirements.

- 2. Wire Galvanization/Coating: The selected wire undergoes a thorough cleaning process before being hot-dip galvanized to apply a protective zinc coating. For enhanced corrosion resistance, a Galfan (Zn-5%Al-MM) alloy coating or an additional PVC coating (typically 0.5mm thick) can be applied. Coating thickness and adherence are rigorously tested to ISO 7989, ASTM A90, and ASTM A641 standards.

- 3. Double Twisting Weaving: Specialized CNC weaving machines precisely interlock the galvanized/coated wires into a double-twisted hexagonal mesh pattern. This double-twist mechanism ensures that if one wire breaks, the integrity of the mesh is maintained, preventing unraveling. Mesh opening sizes (e.g., 60x80mm, 80x100mm, 100x120mm) are strictly controlled.

- 4. Panel Cutting and Selvedge Wiring: The continuous mesh is cut into specific panel dimensions for gabion boxes and mattresses. Thicker selvedge wires are then mechanically twisted or woven along the edges of the panels to reinforce the structure, providing increased strength and integrity during assembly and filling.

- 5. Panel Assembly and Folding: The mesh panels (base, front, back, sides, diaphragms for gabion boxes) are assembled and secured using lacing wire or C-rings to form the box or mattress shape. The units are then flattened and folded for efficient transportation.

- 6. Quality Control and Testing: Throughout the entire process, multiple quality control checks are performed. This includes visual inspection, measurement of wire diameters, mesh sizes, coating thickness, and tensile strength tests (to ISO 6892-1 or ASTM E8) on wire samples. Finished products undergo final dimensional checks to ensure they conform to client specifications and relevant industry standards.

- 7. Packaging and Dispatch: The folded gabion units are bundled, often strapped onto pallets, and carefully packaged to prevent damage during transit, ready for global dispatch.

This meticulous process guarantees a high-quality, durable, and reliable product for all geotechnical and hydraulic engineering requirements.

Vendor Comparison: Choosing the Right Partner

Selecting the right supplier for Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion is crucial for project success. While many vendors offer gabion solutions, critical differentiators often lie in material quality, manufacturing precision, coating technology, and technical support. Our company prides itself on adhering to the highest standards, offering superior products compared to generic market offerings.

Gabion Product Comparison

| Feature/Parameter | Our Gabion Solutions | Generic Market Offering |

|---|---|---|

| Wire Material Quality | Virgin low carbon steel, certified to ASTM A975. Consistent tensile strength (380-500 MPa). | Often recycled or lower-grade steel. Variable strength, prone to premature failure. |

| Proteksi Korosi | Hot-dip galvanized (≥245g/m² zinc), optional Galfan (Zn-5%Al) or PVC coating (0.5mm minimum). Superior adhesion, tested to ISO 7989. | Light galvanization ( |

| Mesh Consistency | Precision CNC double-twisted hexagonal mesh. Uniform opening size, exact wire spacing. | Manual or semi-automatic weaving, inconsistent mesh openings, potential for wire deformation. |

| Selvedge Wire | Significantly thicker (e.g., 1.0mm-1.5mm thicker than mesh wire), robustly woven/twisted. | Same or marginally thicker than mesh wire, often loosely attached, leading to edge failure. |

| Certification & Standards | ISO 9001 certified, products meet ASTM A975, EN 10223-3, BS 1052. Full test reports available. | Limited or no verifiable certifications. "Meets standards" without proof. |

| Customization Options | Extensive options for dimensions, wire gauge, coating types, diaphragm placement. | Limited standard sizes only, difficult to accommodate unique project needs. |

| Technical Support | Dedicated engineering support, installation guides, post-sales assistance. | Basic product information, minimal or no technical consulting. |

Our unwavering commitment to quality, backed by rigorous testing and certifications, ensures that our clients receive a superior product that delivers reliable performance and long-term value, mitigating project risks associated with substandard materials.

Customized Solutions for Unique Project Demands

Recognizing that every engineering project presents its unique set of challenges and specific requirements, we offer comprehensive customized solutions for our Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion products. Our engineering team collaborates closely with clients to design gabion structures that perfectly align with site-specific conditions, geotechnical parameters, and project objectives.

Customization options include:

- Tailored Dimensions: Gabion boxes and mattresses can be manufactured to specific lengths, widths, and heights, optimizing material usage and construction efficiency for non-standard applications.

- Variable Wire Gauges: Depending on the anticipated loads, environmental exposure, and desired service life, we can adjust the wire diameter of both the mesh and selvedge wires to meet precise structural requirements.

- Specialized Coatings: Beyond standard galvanization, we offer advanced Galfan (zinc-aluminum alloy) coatings for superior corrosion resistance in aggressive environments, and heavy-duty PVC coatings for maximum protection against chemical attack or abrasion.

- Internal Diaphragm Configuration: For larger gabion units, the placement and number of internal diaphragms can be customized to enhance stability, prevent stone migration, and facilitate filling.

- Integrated Geotextile Solutions: For projects requiring enhanced filtration or separation, gabion units can be designed for seamless integration with geotextile fabrics, providing a complete erosion control system.

Our expertise in geotechnical design and material science ensures that every customized solution is engineered for optimal performance and compliance with relevant industry standards.

Application Case Studies and Customer Feedback

Our extensive experience and portfolio of successful projects underscore our authoritative position in the industry. We have partnered with leading construction firms and government agencies worldwide, demonstrating consistent excellence in delivering reliable gabion solutions.

Case Study 1: River Bank Stabilization Project, Southeast Asia

A major infrastructure project required urgent stabilization of a highly erodible riverbank stretching over 5 kilometers. Traditional concrete solutions were deemed too costly and environmentally intrusive. Our team supplied Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion units (4x2x0.3m, PVC coated, 80x100mm mesh) which were filled with local river stones. The project, completed within an aggressive timeline, effectively mitigated erosion, protected adjacent farmlands, and allowed for natural revegetation. Local engineers praised the ease of installation and the gabions' ability to withstand seasonal flood events without structural degradation.

— Project Manager, Leading Civil Engineering Firm

Case Study 2: Highway Embankment Retaining Wall, European Alps

To support a new mountain highway section, a series of flexible retaining walls were necessary to cope with potential seismic activity and seasonal ground movements. Our galvanized Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion (2x1x1m units, 100x120mm mesh) were chosen for their robust flexibility and permeability. Over five years post-installation, the structures have performed flawlessly, showing no signs of distress, even after minor tremors and significant freeze-thaw cycles. The client noted the significant cost savings and reduced environmental impact compared to pre-cast concrete alternatives.

— Chief Engineer, Regional Transport Authority

Trustworthiness: FAQ, Lead Time, Warranty & Support

Our commitment to our clients extends beyond delivering high-quality products. We prioritize transparency, reliability, and comprehensive support to ensure complete satisfaction and project success.

Frequently Asked Questions (FAQ)

- Q: What is the typical service life of your gabions?

A: Our heavily galvanized gabions typically have a service life of 25-30 years. With Galfan (Zn-5%Al) coating, this extends to 40-50 years, and with additional PVC coating, it can exceed 50-70 years, depending on environmental conditions. - Q: Are your gabions environmentally friendly?

A: Yes, gabions are considered highly sustainable. They use natural fill materials, minimize concrete usage, allow for vegetation growth, and promote natural drainage, integrating seamlessly with the ecosystem. - Q: Do you provide installation guidance?

A: Absolutely. We offer detailed installation manuals, technical drawings, and can provide on-site technical assistance or training for larger projects, ensuring proper assembly and deployment. - Q: What is the minimum order quantity (MOQ)?

A: Our MOQ is generally 500-1000 square meters, but this can be flexible depending on the specific product and customization requirements. Please contact our sales team for project-specific details.

Lead Time and Fulfillment

Our state-of-the-art manufacturing facilities and optimized logistics ensure efficient order fulfillment.

- Standard Orders: Typically 15-20 business days from order confirmation for standard specifications and quantities.

- Customized Solutions: Lead times for custom orders may vary based on complexity and volume, usually ranging from 20-35 business days. We provide clear timelines at the quotation stage.

- Shipping: We facilitate global shipping through trusted logistics partners, offering various options (FOB, CIF, DDP) to meet your project's delivery schedule and budget.

Warranty Commitments

We stand behind the quality of our products with robust warranty provisions. All our Double Twisted Hexagonal Gabion Mesh Box / Kasur Gabion products come with a material and workmanship warranty of 10 years for standard galvanized products and up to 25 years for Galfan or PVC-coated products, provided they are installed and maintained according to our guidelines and industry best practices.

Customer Support Information

Our dedicated customer support team is available to assist you at every stage of your project.

- Technical Consultation: Our engineers provide expert advice on product selection, design optimization, and application.

- Sales Inquiries: For quotations, orders, and product information, please contact our sales department.

- After-Sales Service: We offer comprehensive after-sales support, addressing any queries related to installation, performance, or warranty claims promptly and efficiently.

We are committed to building long-term partnerships based on trust, quality, and mutual success.

References

- ASTM International. (2011). ASTM A975-11: Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With PVC Coating) for Soil Stabilization, Erosion Control, and Structural Fill. West Conshohocken, PA: ASTM International.

- EN 10223-3:2013. (2013). Steel wire and wire products for fencing and netting - Part 3: Steel wire mesh products for gabions and mattresses. Brussels: European Committee for Standardization.

- Maccaferri. (2018). Gabion and Reno Mattress System: Technical Guide. Retrieved from maccaferri.com.

- FHWA (Federal Highway Administration). (2015). Design and Construction of Geosynthetic-Reinforced Soil Structures. Publication No. FHWA-HRT-14-094. Washington, D.C.: U.S. Department of Transportation.

-

Durable River Bank Gabion Mesh Solutions for Protection

KabarNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

KabarNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

KabarNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

KabarNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

KabarNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

KabarNov.17,2025