- африкалык

- Албанча

- Амхарча

- Арабча

- Армянча

- азербайжан

- Баскча

- Беларусча

- Бенгалча

- Бошнакча

- Болгарча

- Каталанча

- Себуано

- Кытай

- Кытай (Тайвань)

- Корсикче

- Хорватча

- Чехче

- Датча

- Нидерландча

- Англисче

- Эсперанто

- Эстончо

- Финче

- Франсузча

- фриз

- Галицияча

- Грузинче

- Немисче

- Грекче

- Гужаратиче

- Гаити креол

- Хаусача

- Гавайча

- Еврейче

- Жок

- Miao

- Венгерче

- Исландияча

- игбо

- Индонезияча

- Ирландча

- Итальянча

- Жапончо

- Жанавизче

- Каннадача

- Казакча

- кхмер

- Руанда

- Корейче

- күрд

- Кыргызча

- Эмгек

- Латынча

- Латвияча

- Литвача

- Люксембургча

- Македонияча

- Малгаши

- Малайча

- Малаяламча

- Малтизче

- Маориче

- Маратиче

- Монголчо

- Мьянма

- Непаличе

- Норвежче

- Норвежче

- Occitan

- Пуштунча

- Парсча

- Полякча

- Португалча

- Пунжабиче

- Румынча

- Орусча

- самоа

- Шотландиялык галец

- Сербче

- Англисче

- Shona

- Синдиче

- Sinhala

- Словакча

- Словенияча

- Сомаличе

- Испанча

- сундан

- Свахиличе

- Шведче

- Тагалогчо

- тажик

- Тамилче

- татар

- Телугуча

- Тайча

- Түркчө

- Түркмөнчө

- Украинче

- Урдуча

- уйгур

- Өзбекче

- Вьетнамча

- Валлийче

- Жардам

- Идишче

- Йорубача

- Зулуча

Sep . 08, 2025 14:35 Тизмеге кайтуу

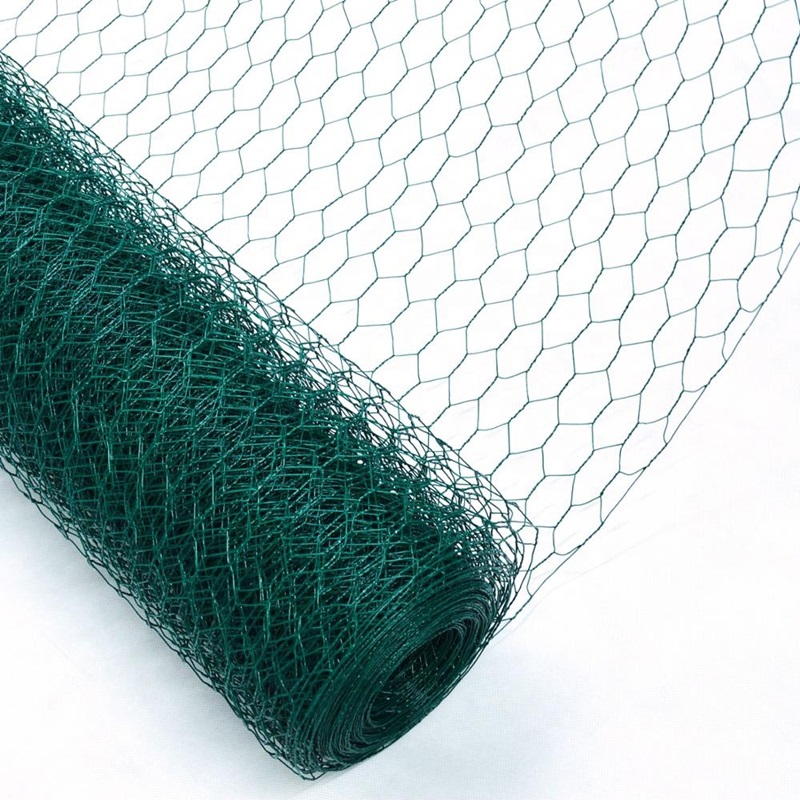

Durable Galvanized Hexagonal Poultry Wire Mesh for Secure Enclosures

Introduction to Galvanized Hexagonal Poultry Wire Mesh

In the agricultural and industrial sectors, selecting the appropriate fencing and containment materials is paramount for operational efficiency, biosecurity, and long-term durability. Among the various solutions available, Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор stands out as a highly versatile and cost-effective material. Commonly known as chicken wire, this product is engineered from low-carbon steel wire that is then twisted into a hexagonal pattern and subsequently galvanized to enhance its resistance to corrosion. Its inherent flexibility, light weight, and structural integrity make it an indispensable choice for a broad spectrum of applications, ranging from animal enclosures and garden protection to light construction and craft projects. This comprehensive overview delves into the technical specifications, manufacturing processes, application advantages, and market dynamics surrounding this essential material, providing B2B decision-makers with the insights necessary to make informed procurement choices.

Industry Trends and Market Dynamics for Wire Mesh Solutions

The market for wire mesh products, including Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор, is experiencing sustained growth, driven by several key factors. Globally, increased demand for sustainable agriculture and enhanced biosecurity measures in livestock farming is propelling the adoption of robust, long-lasting containment solutions. Modern poultry operations, for instance, are prioritizing materials that can withstand harsh environmental conditions while ensuring the safety and welfare of poultry, thereby minimizing disease transmission risks.

Technological advancements in galvanization processes, such as improved zinc coating adhesion and uniformity, contribute significantly to extended product lifespans and reduced maintenance costs. Furthermore, the construction industry continues to be a major consumer, utilizing hexagonal mesh for plastering reinforcement, insulation, and light-duty fencing. Emerging trends include a focus on environmentally friendly manufacturing practices and the development of specialized coatings for niche applications requiring enhanced chemical resistance or aesthetic appeal. Regulatory landscapes, particularly concerning animal welfare and construction safety, increasingly influence product specifications, pushing manufacturers towards higher quality and compliant materials. The market is also seeing a rise in demand for customized solutions, tailored to specific project requirements regarding mesh size, wire gauge, and roll dimensions.

Detailed Manufacturing Process Flow of Galvanized Hexagonal Wire Mesh

The production of Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор is a multi-stage process that prioritizes material integrity and corrosion protection. Understanding this process is crucial for appreciating the product's performance characteristics and ensuring procurement aligns with specific application requirements.

1. Wire Rod Sourcing and Drawing

The process begins with high-quality low-carbon steel wire rod, typically conforming to standards like ASTM A510. This rod undergoes a drawing process where it is pulled through a series of dies to reduce its diameter to the desired wire gauge, enhancing its tensile strength and uniformity.

2. Hexagonal Weaving/Twisting

The drawn wires are then fed into specialized weaving machines. Unlike welded mesh, hexagonal mesh is created by continuously twisting adjacent wires together to form hexagonal openings. This double or triple twist mechanism provides inherent flexibility and prevents unraveling if a single wire is cut, a key advantage for containing active animals. The precision of this twisting process dictates the uniformity of the mesh size and overall structural stability.

3. Galvanization Process

After weaving, the steel mesh undergoes galvanization, which is critical for corrosion resistance and extended service life. Two primary methods are employed:

- Electro-galvanization: In this process, zinc is electrolytically deposited onto the wire surface. It typically results in a thinner, more uniform coating and a bright, shiny finish, suitable for less corrosive environments or aesthetic applications.

- Hot-dip Galvanization (after weaving): This method involves immersing the entire woven mesh in a bath of molten zinc. This creates a thicker, more robust zinc coating that metallurgical bonds with the steel, offering superior corrosion protection, especially in harsh or outdoor conditions. This is the preferred method for high-durability applications. The zinc coating adheres to standards such as ASTM A90/A90M (Standard Test Method for Weight of Coating on Zinc-Coated (Galvanized) Iron or Steel Articles).

4. Quality Control and Finishing

Throughout the manufacturing process, stringent quality control measures are implemented. This includes checking wire gauge consistency, mesh opening accuracy, zinc coating thickness and adhesion, and overall roll dimensions. Products typically adhere to international quality management standards like ISO 9001, ensuring consistent product performance. The mesh is then cut to specified lengths and rolled for packaging and distribution.

The typical service life of hot-dip Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор can range from 10 to 20 years or more, depending on environmental factors like humidity, salt exposure, and abrasion. For target industries such as agriculture, light construction, and environmental protection (e.g., erosion control), the corrosion resistance of the galvanized coating offers significant advantages, reducing replacement frequency and maintenance costs compared to non-galvanized alternatives.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор is essential for ensuring its suitability for specific applications and for verifying compliance with project requirements. Key parameters include wire gauge, mesh opening size, roll dimensions, and zinc coating characteristics.

Key Parameters Explained:

- Wire Gauge (BWG): This refers to the diameter of the steel wire used. A lower BWG number indicates a thicker wire, offering greater strength and durability. Common gauges for poultry wire range from 18 BWG (1.2mm) to 22 BWG (0.7mm).

- Mesh Opening Size: Measured between parallel twists, this determines the size of the hexagonal holes. Typical sizes include ½ inch (13mm), ¾ inch (19mm), 1 inch (25mm), 1.5 inch (38mm), and 2 inches (50mm). The choice depends on the size of the animals to be contained or the application's required barrier level.

- Roll Dimensions: Available in various widths (e.g., 0.5m, 1.0m, 1.2m, 1.5m, 2.0m) and lengths (e.g., 25m, 30m, 45m, 50m) to accommodate diverse project scales and reduce wastage.

- Zinc Coating Thickness: Critical for corrosion resistance. Hot-dip galvanized coatings typically offer a minimum of 200-300 g/m² (grams per square meter), providing robust protection against environmental degradation. Electro-galvanized coatings are generally thinner, ranging from 10-30 g/m².

- Tensile Strength: The maximum stress the wire can withstand before breaking. For low-carbon steel wire used in this mesh, typical tensile strength ranges from 350-550 MPa, ensuring structural integrity under moderate loads.

- Elongation: The measure of ductility, or how much the wire can stretch before fracturing. Adequate elongation ensures the mesh can absorb impacts and conform to irregular surfaces without breaking.

Typical Product Specification Table:

| Parameter | Specification Range | Typical Value (Hot-Dip Galvanized) |

|---|---|---|

| Wire Gauge (BWG) | 18 BWG to 22 BWG (1.2mm to 0.7mm) | 19 BWG (1.0mm) |

| Mesh Opening Size | 0.5 inch to 2 inch (13mm to 50mm) | 1 inch (25mm) |

| Roll Width | 0.5m to 2.0m (19.7" to 78.7") | 1.0m (39.4") |

| Roll Length | 25m to 50m (82ft to 164ft) | 45m (147.6ft) |

| Zinc Coating Weight | Electro: 10-30 g/m²; Hot-dip: 200-300 g/m² | 250 g/m² (Hot-dip) |

| Тартуу күчү | 350-550 MPa | 450 MPa |

Key Technical Advantages of Galvanized Hexagonal Poultry Wire Mesh

The design and material composition of Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор provide several distinct technical and operational advantages for B2B applications, making it a preferred choice over other mesh types in many scenarios.

- Superior Corrosion Resistance: The primary advantage stems from the galvanization process. The zinc coating acts as a sacrificial layer, protecting the underlying steel from rust and environmental degradation. Hot-dip galvanization, in particular, ensures a thick, durable coating that significantly extends the mesh's service life, even in humid or agricultural environments where exposure to animal waste or chemicals is common. This translates to reduced replacement costs and lower lifecycle expenses.

- Exceptional Flexibility and Formability: The twisted hexagonal pattern imparts remarkable flexibility to the mesh. This allows it to be easily shaped, cut, and installed around irregular contours, making it highly adaptable for various fencing, caging, and support applications. Its flexibility simplifies installation, reducing labor time and specialized tooling requirements.

- Enhanced Structural Integrity (Non-Raveling Design): Unlike welded mesh, where a single broken weld can compromise a larger section, the twisted hexagonal structure ensures that if one wire breaks, the adjacent twists hold the mesh together, preventing unraveling. This "non-raveling" characteristic is crucial for security and containment, particularly in animal enclosures, where maintaining an intact barrier is vital.

- Lightweight yet Durable: Despite its robustness and protective coating, hexagonal wire mesh is relatively lightweight, simplifying transport, handling, and installation. This balance of weight and durability makes it an efficient material for large-scale projects without compromising on long-term performance.

- Cost-Effectiveness: When considering its longevity, ease of installation, and low maintenance, galvanized hexagonal mesh offers a highly competitive total cost of ownership compared to alternative fencing or reinforcement materials, providing significant economic benefits over its lifespan.

Application Scenarios and Target Industries

The versatility of Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор extends its utility across numerous sectors. Its unique combination of flexibility, strength, and corrosion resistance makes it ideal for a wide array of applications.

1. Agriculture and Animal Husbandry:

- Poultry Enclosures: This is its most recognized application. The mesh effectively contains chickens, ducks, geese, and other fowl, preventing escapes while protecting them from predators. Its flexibility allows for easy construction of custom-sized coops and runs, enhancing biosecurity by minimizing contact with wild animals.

- Small Animal Pens: Ideal for rabbits, guinea pigs, and other small livestock, offering secure yet visible containment.

- Garden Fencing: Protects vegetable gardens and flowerbeds from pests like rabbits, deer, and rodents without blocking sunlight or air circulation.

2. Construction and Infrastructure:

- Plastering and Stucco Reinforcement: Often used as a substrate for plaster, stucco, and cement applications. The mesh provides an excellent key for bonding, enhancing the structural integrity and crack resistance of walls and ceilings.

- Insulation Support: Used to hold insulation materials, such as mineral wool or fiberglass, in place within walls, ceilings, and underfloor spaces, particularly in industrial buildings or large cold storage facilities.

- Light-Duty Fencing and Barriers: For temporary construction sites, demarcation, or light perimeter security.

3. Environmental and Erosion Control:

- Gabion Baskets (light duty): While heavier gauge mesh is typically used for full-scale gabions, hexagonal mesh can be used for smaller, temporary erosion control measures or to retain soil in specific landscaping applications.

- Slope Stabilization: Applied to slopes to help anchor vegetation and prevent soil erosion, especially during the establishment phase of plant growth.

4. Industrial and Commercial Uses:

- Machinery Guards: Provides lightweight yet effective protection around moving parts of machinery in industrial settings, enhancing worker safety.

- Storage and Shelving: Used to create cost-effective, breathable storage solutions or as backings for shelves in warehouses and retail environments.

Vendor Comparison for Galvanized Hexagonal Poultry Wire Mesh

Selecting the right supplier for Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор is crucial for ensuring product quality, consistent supply, and competitive pricing. A comprehensive evaluation of potential vendors should extend beyond initial cost to encompass a range of factors influencing long-term value and operational efficiency.

Key Comparison Criteria:

- Product Quality and Compliance: Verify adherence to international standards (e.g., ISO 9001 for manufacturing, ASTM for materials and galvanization). Assess wire gauge consistency, mesh opening accuracy, and zinc coating thickness/uniformity. Higher quality correlates with longer service life and better performance.

- Customization Capabilities: Evaluate if the vendor can meet specific requirements for wire gauge, mesh size, roll dimensions, or even specialized coatings beyond standard galvanization.

- Lead Times and Logistics: Assess the vendor's capacity for timely delivery, especially for large orders or recurring supply. Evaluate their logistics network and ability to handle international shipping efficiently.

- Pricing and Payment Terms: While not the sole factor, competitive pricing coupled with flexible payment terms is important. Transparency in pricing (including shipping and duties) is key.

- After-Sales Support and Warranty: Understand the vendor's policy on product returns, defect resolution, and warranty coverage for manufacturing defects or premature corrosion.

- Certifications and Reputation: Look for certifications (e.g., ISO, CE) and review client testimonials or case studies to gauge reliability and industry standing.

Vendor Comparison Table (Illustrative):

| Feature/Criterion | Vendor A (Premium) | Vendor B (Standard) | Vendor C (Economy) |

|---|---|---|---|

| Zinc Coating (g/m²) | Hot-dip, 250-300+ | Hot-dip, 180-220 | Electro-galv, 10-20 |

| Wire Gauge Consistency | Excellent (±0.02mm) | Good (±0.05mm) | Acceptable (±0.1mm) |

| Customization | Full range, flexible MOQ | Limited options, higher MOQ | Standard sizes only |

| Certifications | ISO 9001, ASTM, CE | ISO 9001 | Internal QC |

| Typical Lead Time | 2-3 weeks | 3-5 weeks | 4-6 weeks |

| Warranty | 5-10 years on coating | 1-3 years on coating | Limited |

This table serves as a general guide. Actual specifications and offerings vary by manufacturer. A thorough vetting process, including material samples and factory audits, is recommended for major procurement decisions.

Customized Solutions for Galvanized Hexagonal Wire Mesh

While standard sizes and specifications of Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор meet a wide range of needs, many industrial and commercial applications benefit significantly from customized solutions. Tailored mesh can optimize performance, reduce waste, and provide a perfect fit for unique project requirements.

Customization Options Include:

- Wire Gauge: Custom wire diameters can be specified for applications requiring enhanced strength (thicker wire) or greater flexibility/lighter weight (thinner wire).

- Mesh Opening Size: Tailored hexagonal opening sizes can be produced to meet precise containment needs (e.g., smaller openings for pest control, larger for ventilation).

- Roll Dimensions: Custom widths and lengths can minimize cutting and splicing, saving labor and material costs on large-scale projects.

- Galvanization Type and Thickness: While hot-dip is standard for durability, specific environments might require a higher zinc mass coating or specialized post-treatment coatings (e.g., PVC coating for added aesthetic appeal and extreme corrosion resistance).

- Material Grade: While low-carbon steel is typical, specific chemical resistance or strength requirements might warrant consideration of other steel alloys if galvanization alone isn't sufficient.

The Customization Process:

Engaging with a manufacturer for customized mesh typically involves:

- Consultation: Discussing project specifics, environmental conditions, and performance expectations with expert engineers.

- Design and Specification: Developing detailed technical drawings and specifications based on the consultation.

- Sampling and Prototyping: For complex requirements, a prototype or sample run might be conducted for approval.

- Production and Quality Assurance: Manufacturing the custom mesh under strict quality control, ensuring it meets all agreed-upon parameters.

This tailored approach ensures that the end product delivers optimal functionality and cost-efficiency for even the most demanding applications.

Real-World Application Case Studies

The practical utility and enduring performance of Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор are best illustrated through its successful deployment in diverse operational environments. Here are a few representative case studies:

Case Study 1: Large-Scale Commercial Poultry Farm Biosecurity Enhancement

A major commercial poultry farm in the Midwestern United States faced challenges with wild bird ingress and opportunistic predators, compromising flock health and biosecurity. Existing fencing was insufficient. The solution involved installing 1.5-inch mesh, 19 BWG, hot-dip Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор to create comprehensive perimeter fencing around all rearing houses and free-range areas. The mesh's flexibility allowed for easy adaptation to uneven terrain, while its non-raveling twisted structure ensured a continuous, robust barrier. The thick zinc coating offered superior resistance to the humid conditions and occasional chemical exposure from cleaning agents. Post-installation data showed a significant reduction (over 85%) in wild bird incursions and predator-related losses within the first year, leading to improved flock health metrics and a notable decrease in biosecurity incidents.

Case Study 2: Erosion Control on a Residential Hillside Development

A new residential development constructed on a moderate hillside in a high-rainfall region required effective erosion control during the landscaping phase. Steep slopes were prone to soil washout before vegetation could fully establish. Engineers specified 2-inch mesh, 18 BWG Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор laid directly over the newly graded soil and anchored. Its pliable nature allowed it to conform intimately to the contours of the slope. Grass seeds and small plants were then sown through the mesh. The mesh provided immediate mechanical stabilization, preventing topsoil runoff during heavy rains. The galvanization ensured the mesh would not degrade prematurely, providing support for the crucial first few years until the vegetative cover fully matured and established a natural erosion barrier. This saved considerable costs compared to traditional retaining structures and promoted rapid greening of the area.

Case Study 3: Industrial Insulation Jacketing in a Petrochemical Plant

In a petrochemical processing plant, extensive pipework and vessels required insulation to maintain process temperatures and ensure energy efficiency. The insulation material needed a lightweight yet durable mesh to hold it securely in place before outer cladding was applied. Standard 1-inch mesh, 20 BWG Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор was selected. Its flexibility made it easy to wrap around complex pipe configurations and spherical vessels, minimizing gaps and ensuring full insulation coverage. The galvanized coating was vital for resisting the mildly corrosive industrial atmosphere, preventing rust that could stain or compromise the insulation. The mesh proved to be an efficient and cost-effective solution for large-scale insulation support, contributing to significant energy savings and operational safety.

Quality Assurance, Certifications, and Trustworthiness

Establishing trust and ensuring reliability in B2B transactions for materials like Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор requires robust quality assurance protocols and transparent operational practices. Our commitment to excellence is underpinned by comprehensive certifications and customer-focused services.

Quality Assurance & Certifications:

- ISO 9001:2015 Certified: Our manufacturing facilities adhere strictly to ISO 9001:2015 Quality Management System standards, ensuring consistent product quality from raw material sourcing to final packaging. This certification signifies our commitment to continuous improvement and customer satisfaction.

- ASTM Compliance: Our galvanized products meet or exceed relevant ASTM International standards, such as ASTM A90/A90M for zinc coating weight and ASTM A641/A641M for zinc-coated (galvanized) carbon steel wire, ensuring verifiable product performance.

- Rigorous Internal Quality Control: Each production batch undergoes multi-stage inspections, including raw material inspection, in-process checks for wire gauge and mesh formation, and post-galvanization testing for coating thickness, adhesion, and uniformity using non-destructive methods.

- Traceability: All products are traceable to their raw material origins and production parameters, allowing for detailed quality audits and transparency.

Frequently Asked Questions (FAQ):

- Q: What is the typical lead time for a standard order?

A: For standard product sizes and quantities, the lead time typically ranges from 2-4 weeks, depending on current production schedules and shipping destination. Large custom orders may require additional time for planning and production. - Q: What warranty is offered on your galvanized hexagonal poultry wire mesh?

A: We offer a 5-year limited warranty on our hot-dip galvanized mesh against manufacturing defects and premature coating failure under normal use conditions. Specific terms and conditions apply and are available upon request. - Q: Can you provide custom sizes or wire gauges?

A: Yes, we specialize in customized solutions. Please provide your specific requirements, including mesh size, wire gauge, roll dimensions, and intended application, and our technical team will work with you to develop a tailored solution. Minimum Order Quantities (MOQs) may apply for custom specifications. - Q: How is the mesh packaged for shipping?

A: Rolls are typically wrapped in waterproof paper and then often palletized and secured with steel strapping for secure transportation, preventing damage during transit. Custom packaging options are available upon request.

Lead Time & Fulfillment:

Our streamlined production and logistics ensure efficient order processing. Standard orders are typically fulfilled within 2-4 weeks. For urgent requirements or large-volume contracts, we collaborate closely with clients to optimize production and shipping schedules. We leverage a robust global logistics network to ensure timely and secure delivery to your designated location.

Customer Support & Engagement:

Our commitment extends beyond product delivery. We provide comprehensive after-sales support, including technical assistance, installation guidance, and prompt resolution of any product-related inquiries. Our dedicated customer service team is available via phone and email to ensure seamless communication and client satisfaction throughout the product lifecycle. We pride ourselves on building long-term partnerships based on trust and mutual success.

Conclusion

Гальванизацияланган алты бурчтуу канаттуулар үчүн зым тор represents a foundational material with broad applicability across agriculture, construction, and various industrial sectors. Its inherent advantages—superior corrosion resistance through galvanization, exceptional flexibility, and a robust non-raveling structure—underscore its value proposition as a durable, reliable, and cost-effective solution for containment, reinforcement, and protection. From safeguarding poultry in commercial farms to stabilizing critical infrastructure and providing essential support in construction, its versatility is unmatched. By adhering to stringent quality standards, offering extensive customization capabilities, and providing dedicated customer support, we ensure that our products not only meet but exceed the demanding expectations of B2B clients. Partnering with a reputable manufacturer committed to quality and service ensures long-term performance and optimal return on investment for all your mesh requirements.

References

- American Society for Testing and Materials (ASTM). ASTM A90/A90M-13, "Standard Test Method for Weight of Coating on Zinc-Coated (Galvanized) Iron or Steel Articles."

- International Organization for Standardization (ISO). ISO 9001:2015, "Quality management systems – Requirements."

- The Galvanizers Association. "Corrosion Resistance of Galvanized Steel."

- USDA National Agricultural Library. "Biosecurity for the Birds."

- Construction Materials Journal. "Mesh Reinforcement in Stucco and Plaster Applications."

-

Durable River Bank Gabion Mesh Solutions for Protection

ЖаңылыктарNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

ЖаңылыктарNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

ЖаңылыктарNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

ЖаңылыктарNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

ЖаңылыктарNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

ЖаңылыктарNov.17,2025