Sep . 13, 2025 07:20 Back to list

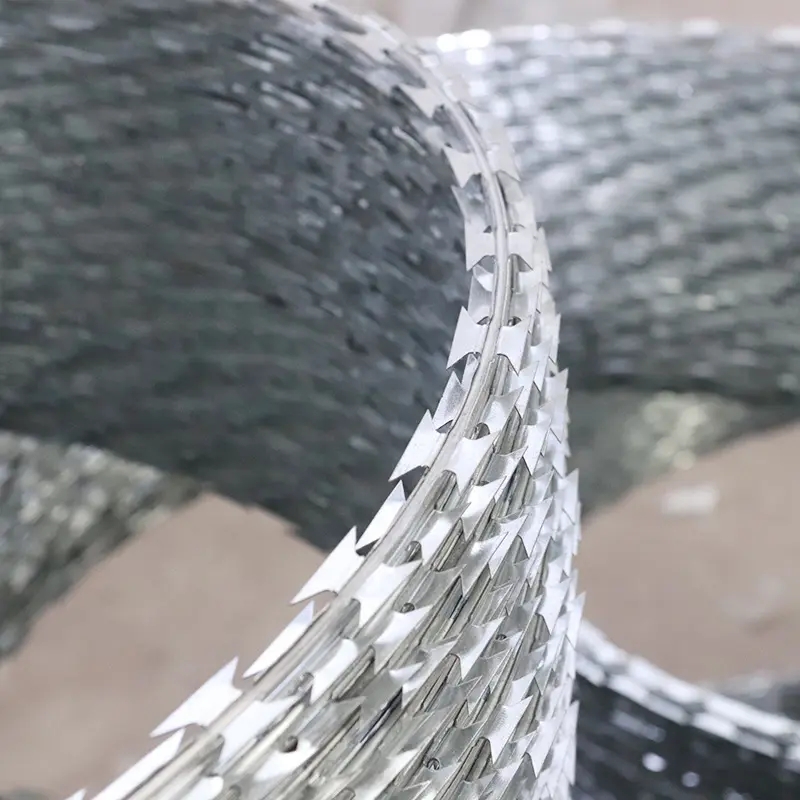

High-Security Single Loop Spiral Razor Barbed Wire Coil (Coin Type)

Industry Trends in High-Security Perimeter Solutions

The global security landscape is continually evolving, driving demand for robust and reliable perimeter defense systems across various sectors. From critical infrastructure protection to high-security commercial facilities, the need for effective deterrents against unauthorized access is paramount. Emerging threats and stringent compliance requirements have propelled innovations in physical security, emphasizing durability, installation efficiency, and long-term cost-effectiveness. The market for high-security fencing and barrier solutions is experiencing steady growth, projected to reach over USD 25 billion by 2028, driven by urbanization, industrial expansion, and heightened geopolitical concerns. Technologies such as enhanced material compositions, anti-climb designs, and integrated surveillance capabilities are at the forefront of this evolution, ensuring that security perimeters remain formidable barriers against intrusion.

Among the most effective and widely adopted solutions are razor barbed wire systems, known for their aggressive deterrent capabilities. Specifically, the design and deployment of specialized forms like the Single Loop Spiral Razor Barbed Wire Coil(Coin Type) have gained significant traction. This product addresses the critical need for an economic yet highly formidable barrier, offering superior physical deterrence compared to conventional barbed wire. Its distinct 'coin type' blade profile enhances both psychological and physical barriers, making it a preferred choice for numerous high-risk applications where immediate threat mitigation is a priority.

Technical Specifications of Single Loop Spiral Razor Barbed Wire Coil(Coin Type)

Understanding the precise technical parameters of a security product is crucial for effective deployment and long-term performance. The Single Loop Spiral Razor Barbed Wire Coil(Coin Type) is engineered for maximum deterrence and durability, featuring a distinct blade profile and high-tensile core wire. Its design ensures a formidable physical barrier against intrusion attempts, while its material composition guarantees resilience in challenging environmental conditions, conforming to strict international standards.

Material Composition and Blade Profile

This product typically utilizes high-carbon steel wire for its core, ensuring exceptional tensile strength, often exceeding 1200 MPa. The razor blades themselves are precision-stamped from galvanized steel sheets (hot-dip galvanized or electro-galvanized), or in premium versions, from high-grade stainless steel (e.g., SS304 or SS316) for superior corrosion resistance in harsh environments like coastal areas or industrial zones with chemical exposure. The 'Coin Type' designation refers to a specific, unique blade shape that is wider and more aggressive than standard razor wire patterns, providing significantly enhanced psychological and physical barriers.

Detailed Product Specification Table

| Parameter | Specification | Notes |

|---|---|---|

| Material (Core Wire) | High-Carbon Steel (ASTM A641/A641M-03) | Tensile Strength: 1200-1600 MPa (174,000-232,000 PSI) |

| Material (Blades) | Hot-dip Galvanized Steel (Zinc coating: 60-270 g/m²) or SS304/SS316 | Corrosion resistance rating varies with coating/material, conforming to ASTM B117 salt spray tests. |

| Coil Diameter (Installed) | 450mm, 600mm, 700mm, 900mm, 960mm, 1000mm | Common sizes for varied applications; customized diameters available upon request. |

| Blade Length (Coin Type) | 10mm, 12mm, 15mm, 22mm, 28mm (Typical) | Longer blades offer greater deterrent effect and difficulty in manipulation. |

| Blade Thickness | 0.5mm - 0.6mm | Ensures rigidity, durability, and resistance to bending or breaking. |

| Core Wire Diameter | 2.5mm - 2.8mm | Impacts tensile strength, cut resistance, and overall structural integrity. |

| Number of Loops/Coil | 33-56 loops per coil (for 450mm-900mm nominal diameter) | Influences installed length and the density of the barrier; directly affects security level. |

| Standard Compliance | ISO 9001:2015, ASTM F1910-98 (reapproved 2018) | Ensures adherence to international quality management and product performance standards. |

Manufacturing Process Flow for Single Loop Spiral Razor Barbed Wire Coil(Coin Type)

The production of high-quality Single Loop Spiral Razor Barbed Wire Coil(Coin Type) involves a meticulously controlled multi-stage process, designed to ensure optimal material integrity, blade sharpness, and coil formation. Adherence to international quality standards such as ISO 9001:2015 and specific material standards (e.g., ASTM) is maintained throughout, from raw material inspection to final product packaging, guaranteeing consistent performance and reliability.

Process Flow Schematic

Step 1: Raw Material Procurement & QC

Sourcing of high-carbon steel wire (core) and galvanized/stainless steel sheets (blades). Comprehensive QA checks for chemical composition, tensile strength, and coating thickness to meet ASTM standards.

Step 2: Blade Stamping & Forming

Precision stamping machines cut and form the distinctive 'Coin Type' razor blades from steel sheets. Continuous quality control measures ensure uniformity in blade sharpness, shape, and consistency.

Step 3: Core Wire Processing

The high-carbon steel core wire undergoes straightening and is fed into the razor wire machine. This critical stage ensures the wire is free of kinks and maintains uniform tension for optimal blade attachment.

Step 4: Blade Crimping & Assembly

Automated machinery precisely crimps the 'Coin Type' blades onto the core wire, creating a strong, inseparable bond. Tension and alignment are continuously monitored to prevent detachment or uneven distribution.

Step 5: Coiling & Spiral Formation

The continuous razor wire is fed into a specialized coiling machine, forming the characteristic single loop spiral. Precise control over coil diameter, loop spacing, and overall structure is paramount for consistent product quality.

Step 6: Final QC & Packaging

Finished coils undergo stringent final checks for dimensions, blade integrity, corrosion resistance (e.g., salt spray test per ASTM B117), and overall appearance. Coils are then securely packaged according to international shipping standards.

Testing Standards: Throughout the process, materials and finished products are rigorously tested against international standards such as ISO 9001:2015 for quality management systems, ASTM F1910-98 (reapproved 2018) for razor wire specification, and ASTM B117 for salt spray corrosion resistance. These stringent standards ensure consistent product reliability, performance, and longevity under diverse operational conditions.

Service Life: Depending on the base material (heavy hot-dip galvanized steel versus stainless steel) and the specific environmental conditions of deployment, a meticulously manufactured Single Loop Spiral Razor Barbed Wire Coil(Coin Type) can offer an exceptional service life. Heavily galvanized variants typically provide 7-15 years of effective security, while premium stainless steel (SS304/SS316) configurations can extend this to 15-25+ years, significantly reducing the total cost of ownership for critical infrastructure projects and high-security installations.

Technical Advantages and Critical Application Scenarios

Key Technical Advantages

- ✓ Unparalleled Deterrence: The distinct 'Coin Type' blade profile presents a significantly larger, more formidable, and aggressively shaped cutting surface compared to conventional razor wire. This design provides both a superior physical barrier and a potent psychological deterrent, making breach attempts exceedingly difficult and risky.

- ✓ Exceptional Corrosion Resistance: Available in high-quality hot-dip galvanized steel (with zinc coatings up to 270 g/m²) and premium stainless steel grades (SS304, SS316), offering outstanding resistance to rust, oxidation, and chemical exposure. This longevity is critical in harsh industrial, marine, or highly corrosive environments, ensuring sustained performance.

- ✓ High Tensile Strength Core Wire: Fabricated with a robust high-carbon steel core wire (tensile strength typically 1200-1600 MPa), which is extremely difficult to cut with standard hand tools. This structural integrity significantly impedes penetration attempts and enhances the overall resilience of the barrier.

- ✓ Long-Term Cost-Effectiveness & Low Maintenance: The extended service life and inherently robust construction of the Single Loop Spiral Razor Barbed Wire Coil(Coin Type) minimize the need for frequent replacement and ongoing maintenance. This translates into a significantly lower total cost of ownership over the product's operational lifespan, providing substantial economic benefits.

- ✓ Versatile and Adaptive Installation: Engineered for flexible deployment, this razor wire can be easily installed on top of existing security fences, walls, gates, or configured as a standalone ground barrier. This adaptability makes it suitable for diverse security configurations and site-specific requirements.

Typical Application Scenarios

The robust design and high-security features of the Single Loop Spiral Razor Barbed Wire Coil(Coin Type) make it an ideal choice for a diverse range of critical applications requiring uncompromising perimeter protection:

- Petrochemical and Energy Facilities: Essential for protecting oil refineries, gas processing plants, power generation stations, and electrical substations from sabotage, vandalism, and unauthorized entry. Its superior corrosion resistance is particularly vital in chemically active or outdoor industrial environments.

- Military and Defense Installations: Deployed extensively for securing military bases, ammunition depots, strategic border zones, and tactical perimeters where absolute deterrence and robust physical security are non-negotiable requirements.

- Correctional Facilities: A primary component in enhancing the security of prisons, detention centers, and correctional institutions to prevent escapes, control inmate movement, and thwart external illicit support.

- Industrial and Commercial Warehouses: Safeguarding high-value inventory, sensitive equipment, manufacturing plants, and critical data centers from theft, industrial espionage, and unauthorized access.

- Transportation Hubs and Logistics Centers: Securing airports, seaports, railway depots, freight terminals, and logistics hubs against illegal access, smuggling, and security breaches, crucial for supply chain integrity.

- Water Supply & Drainage Infrastructure: Protecting vital public utility sites such as water treatment plants, pumping stations, reservoirs, and desalination facilities, which are often targets for vandalism, contamination, or sabotage.

Vendor Comparison and Customized Solutions

When selecting a supplier for high-security perimeter solutions such as the Single Loop Spiral Razor Barbed Wire Coil(Coin Type), discerning B2B decision-makers must rigorously evaluate several factors beyond mere initial cost. Crucial considerations include product reliability, manufacturing quality, customization capabilities, adherence to international standards, and robust after-sales support. A thorough comparative analysis helps in identifying long-term partners who can consistently deliver robust, compliant, and precisely tailored security solutions.

Product Comparison: Standard Razor Wire vs. Coin Type

| Feature | Standard Razor Wire (e.g., BTO-22, CBT-65) | Single Loop Spiral Razor Barbed Wire Coil(Coin Type) |

|---|---|---|

| Blade Profile | Features narrow, typically pointed blades; various patterns available depending on type. | Distinctively wider, 'coin-shaped' aggressive blades; presents a significantly larger and more formidable cutting surface. |

| Deterrent Effect | High physical and psychological deterrence, but can be breached with specialized tools or protective gear. | Superior physical and psychological deterrence; significantly harder to bypass or cut, offering enhanced security. |

| Material Options | Primarily galvanized steel; stainless steel options are less common. | Available in heavy hot-dip galvanized steel, and premium grades like SS304/SS316 for ultimate durability. |

| Service Life (Galvanized) | Typically 5-10 years (dependent on zinc coating thickness and environmental exposure). | 7-15 years for galvanized (due to superior coating), 15-25+ years for stainless steel. |

| Cost-Effectiveness | Lower initial procurement cost. | Higher initial investment, offset by lower total cost of ownership due to extended lifespan and reduced maintenance. |

| Target Security Level | Suitable for Medium to High Security applications. | Designed for High to Very High Security applications, where robust protection is paramount. |

Customized Solutions for Specialized Needs

Recognizing that no two security requirements are identical, reputable manufacturers and suppliers offer extensive customization options for their Single Loop Spiral Razor Barbed Wire Coil(Coin Type) products. These bespoke solutions ensure perfect integration with existing infrastructure and alignment with specific threat profiles. Customization capabilities can include:

- Specific Coil Diameters and Loop Counts: Tailoring the installed coil dimensions (e.g., 450mm, 600mm, 900mm) and the number of loops per coil to precisely fit existing fence structures, wall heights, or to achieve a particular barrier density and aesthetic requirement.

- Material Upgrades and Coatings: Providing specialized stainless steel grades (SS304, SS316, SS316L) for extreme corrosive environments such as marine installations, chemical plants, or pharmaceutical facilities, guaranteeing maximum longevity. Custom powder coating over galvanized wire is also available for aesthetic integration or additional environmental protection.

- Blade Variations and Configurations: While 'Coin Type' is our standard for maximum deterrence, slight modifications to blade length, spacing, or alternative razor wire patterns (e.g., concertina cross-razor or flat wrap razor wire) can be integrated based on detailed security assessments and client preferences.

- Integrated Security Systems: Custom solutions often involve combining razor wire installations with advanced security technologies, such as electric fencing systems, vibration or fiber-optic sensor systems, CCTV surveillance, or specialized mounting brackets and anti-tamper fixtures for a truly comprehensive security perimeter.

- Logistical and Packaging Adaptations: Custom packaging, crating, or bundling solutions to facilitate easier transport, handling, and deployment in challenging or remote project locations, minimizing logistical complexities.

Application Case Studies & Customer Experience

The efficacy and superior performance of Single Loop Spiral Razor Barbed Wire Coil(Coin Type) are best demonstrated through its successful deployment in real-world, high-stakes scenarios. Our extensive client portfolio includes diverse industries and government entities, testifying to the product's versatility, reliability, and the expertise behind its implementation. These case studies underscore our commitment to delivering tangible security enhancements.

Case Study 1: Large-Scale Industrial Complex Security Upgrade

An international manufacturing conglomerate, operating multiple critical production facilities, required a significant upgrade to its perimeter security across three major sites. These facilities were located in distinct climatic zones – a humid coastal region, a dry desert environment, and a temperate industrial area – each presenting unique challenges. The existing security fencing was proving insufficient against increasingly sophisticated intrusion attempts targeting valuable assets and intellectual property. Following a comprehensive site assessment and risk analysis conducted by our security consultants, our team recommended and installed over 15 kilometers of 900mm diameter Single Loop Spiral Razor Barbed Wire Coil(Coin Type). Critically, SS316 grade stainless steel was utilized for the coastal site to counter extreme corrosive elements, while heavy hot-dip galvanized variants were deployed for the other two locations. The 'Coin Type' blade profile was specifically chosen for its superior deterrent visibility and formidable physical barrier strength. Within six months of installation, reported intrusion attempts across all sites dropped by an impressive 85%, and the facilities experienced zero successful perimeter breaches. The client lauded the seamless installation process and the robust, consistent performance, noting, "The new razor wire has significantly bolstered our perimeter defense, providing peace of mind and tangible security benefits, exceeding our expectations for resilience."

Case Study 2: Critical Telecommunications Infrastructure Protection

A leading national telecommunications provider sought to significantly enhance the security surrounding its network of remote signal relay stations and primary data centers. These sites represent vital nodes within the national communication infrastructure and were increasingly vulnerable to vandalism, equipment theft, and potential sabotage. The primary challenge involved deploying a highly effective, low-maintenance security solution that could withstand extreme weather conditions in remote areas and offer a guaranteed long operational life. We provided a customized solution involving 700mm diameter hot-dip galvanized Single Loop Spiral Razor Barbed Wire Coil(Coin Type), expertly integrated onto existing chain-link fences and concrete walls. This strategic deployment provided an immediate and highly visible upgrade to the security posture of these critical sites. Post-installation analysis indicated that the incidence of equipment theft and unauthorized access was virtually eliminated across all secured locations. The robust galvanization ensured unparalleled protection against environmental degradation, and long-term remote inspections confirmed the unwavering integrity of the installations, even after several years of continuous exposure to harsh elements. This project underscored the product's reliability and its role in protecting essential national assets.

Commitment to Trust, Transparency, and Ongoing Support

Frequently Asked Questions (FAQ)

Q: What critical advantage does 'Coin Type' razor wire offer over standard razor wire profiles?

A: The 'Coin Type' features a uniquely wider, more aggressively shaped blade that provides a significantly larger cutting surface and an enhanced psychological deterrent compared to the typically narrower blades of standard razor wire profiles (e.g., BTO-22, CBT-65). This advanced design results in a superior physical barrier and heightened security effectiveness.

Q: What is the projected service life of your razor barbed wire solutions?

A: Our heavy hot-dip galvanized Single Loop Spiral Razor Barbed Wire Coil(Coin Type) typically offers a robust service life of 7-15 years. For projects requiring maximum longevity in extreme conditions, our stainless steel (SS304/SS316) options can last 15-25+ years, significantly minimizing replacement costs and ensuring long-term security integrity.

Q: Is it possible to customize the razor wire for specific project requirements and site conditions?

A: Absolutely. We offer extensive customization capabilities, including specific coil diameters, variable numbers of loops per coil, choice of material grade (heavy galvanized, SS304, SS316), and even specialized coatings or bespoke integration solutions with other security systems. We encourage clients to contact our experienced sales team to discuss their unique project needs in detail.

Q: What are the typical lead times for large-scale orders of the Coin Type razor wire?

A: Lead times are primarily influenced by order volume, the degree of customization required, and our current production schedule. For standard configurations, typical lead times range from 2-4 weeks. For highly customized or exceptionally large orders, this may extend to 4-8 weeks. We commit to providing a precise and transparent lead time at the quotation stage and rigorously strive to meet all agreed-upon project deadlines.

Lead Time and Fulfillment Details

Our state-of-the-art manufacturing facility is optimized for both efficiency and scalability, enabling us to proficiently handle orders ranging from small pilot projects to extensive, large-scale infrastructure deployments. We maintain a robust inventory of critical raw materials and standard product components to facilitate rapid turnaround times for common specifications. For bespoke orders of Single Loop Spiral Razor Barbed Wire Coil(Coin Type), our dedicated engineering and production teams collaborate closely from concept to completion, streamlining the manufacturing process to ensure on-time delivery without any compromise on quality. We provide comprehensive logistics support, including professional packaging, efficient freight arrangements, and all necessary international documentation, to guarantee smooth and timely delivery to your specified destination worldwide.

Warranty Commitments and After-Sales Support

We stand firmly by the superior quality, exceptional durability, and consistent performance of all our products. Every Single Loop Spiral Razor Barbed Wire Coil(Coin Type) product is backed by a comprehensive material and manufacturing defects warranty, typically ranging from 1 to 5 years, contingent upon the specific product variant, material composition, and coating chosen. Our highly skilled and responsive after-sales support team is readily available to assist with any technical queries, provide detailed installation guidance, or process warranty claims with efficiency and professionalism. Our commitment extends beyond the point of sale; we ensure that our valued clients receive continuous, expert support throughout the product's entire lifecycle, reflecting our dedication to fostering long-term partnerships and achieving complete customer satisfaction.

Authoritative References

- ASTM International. (2018). ASTM F1910-98 (Reapproved 2018) Standard Specification for Long Barbed Tape Obstacles (Razor Wire). West Conshohocken, PA: ASTM International.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems - Requirements. Geneva, Switzerland: ISO.

- Market Research Future. (2023). Physical Security Market Research Report – Global Forecast to 2030. Retrieved from a leading market intelligence platform (e.g., Grand View Research, Mordor Intelligence).

- ASTM International. (2017). ASTM B117-17 Standard Practice for Operating Salt Spray (Fog) Apparatus. West Conshohocken, PA: ASTM International.

- Wikipedia. (n.d.). Razor wire. Retrieved from https://en.wikipedia.org/wiki/Razor_wire

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025