Sveiki atvykę į mūsų svetaines!

- Afrikos

- albanų

- amharų

- arabiškas

- armėnų

- Azerbaidžaniečių

- baskų

- baltarusių

- bengalų

- bosnių

- bulgarų

- katalonų

- Cebuano

- Kinija

- Kinija (Taivanas)

- Korsikos

- kroatų

- čekų

- danų

- olandų

- Anglų

- Esperanto

- Estų

- suomių

- Prancūzų kalba

- fryzų

- Galisų

- gruzinų

- vokiečių

- graikų

- gudžaratų

- Haičio kreolų

- hausa

- havajietis

- hebrajų

- Ne

- Miao

- vengrų

- islandų

- igbo

- Indoneziečių

- airių

- italų

- japonų

- javiečių

- kanada

- kazachų

- khmerų

- Ruandos

- korėjiečių

- kurdų

- Kirgizų

- Darbo

- lotynų kalba

- latvių

- lietuvių

- liuksemburgiečių

- Makedonietis

- Malgashi

- malajiečių

- malajalių

- maltiečių

- maorių

- marati

- mongolų

- Mianmaras

- Nepaliečių

- norvegų

- norvegų

- oksitanų

- puštūnų

- persų

- lenkas

- portugalų

- Pandžabų

- rumunų

- rusų

- samoiečių

- škotų gėlų

- serbų

- Anglų

- Šona

- Sindų

- Sinhala

- slovakų

- slovėnų

- Somalis

- ispanų

- Sundanai

- suahilių

- Švedijos

- tagalogų

- tadžikų

- tamilų

- totorių

- telugų

- tajų

- turkų

- turkmėnų

- ukrainiečių

- urdu

- Uigūras

- uzbekas

- vietnamiečių

- valų

- Pagalba

- jidiš

- Joruba

- Zulu

Rgs . 04, 2025 14:35 Grįžti į sąrašą

Hot Dipped Galvanized Steel Grating | Durable Bar Grating Solutions

Karštai panardinto cinkuoto plieno grotelės / strypinės grotelės is a key solution in the manufacturing industry, specifically within Fabricated metal products and Metal structure manufacturing. This article explores how Anping County Xingzhi Metal Wiremesh Products Co.,Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Hot Dipped Galvanized Steel Grating/Bar Grating Overview

- Benefits & Use Cases of Hot Dipped Galvanized Steel Grating/Bar Grating in Metal structure manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

Hot Dipped Galvanized Steel Grating/Bar Grating Overview

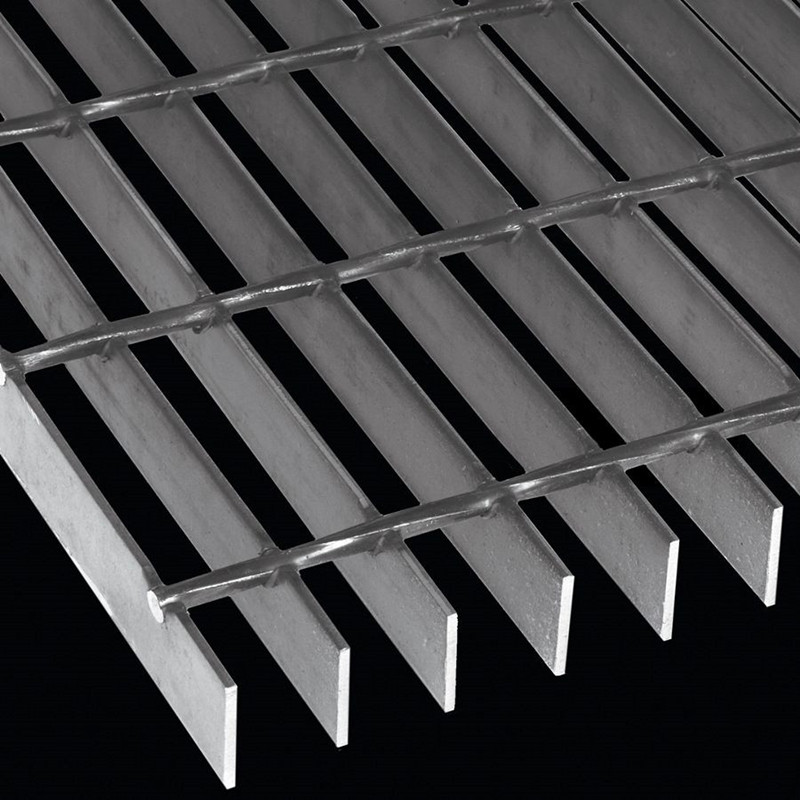

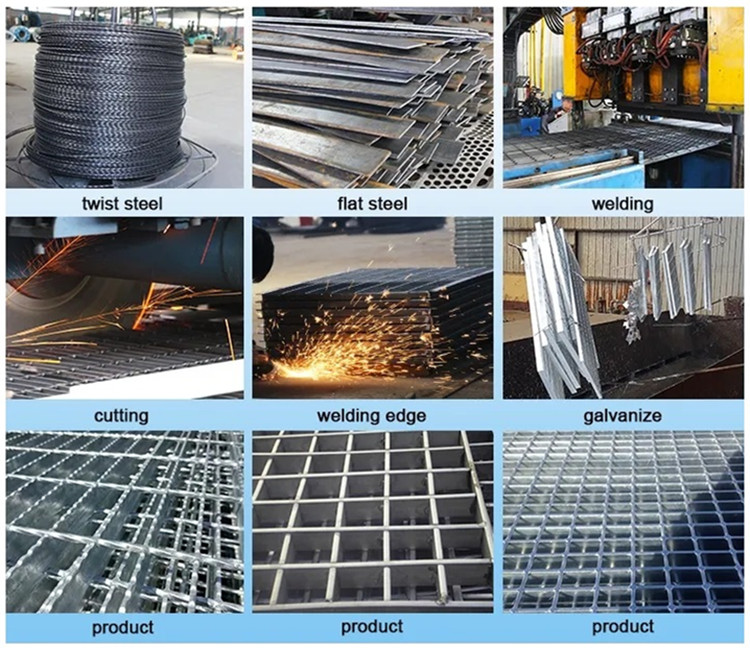

In the demanding world of manufacturing, especially within Fabricated metal products and Metal structure manufacturing, the choice of materials directly impacts safety, longevity, and operational efficiency. This is where Karštai panardinto cinkuoto plieno grotelės / strypinės grotelės emerges as an indispensable solution. Essentially, this product comprises a series of bearing bars and cross bars, typically welded or locked together, which are then immersed in a bath of molten zinc. This galvanization process creates a metallurgically bonded coating that offers superior corrosion resistance compared to other surface treatments. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd specializes in manufacturing high-quality Hot Dipped Galvanized Steel Grating/Bar Grating that meets stringent industrial standards. Our gratings are vital for various applications, including industrial flooring, elevated platforms, walkways, stair treads, and drainage covers. The robust nature of galvanized steel ensures exceptional load-bearing capacity, while the open mesh design allows for excellent ventilation, light penetration, and debris shedding. Our commitment to precision engineering and quality materials makes us a reliable partner for businesses requiring durable and safe structural components in their fabricated metal products.

Benefits & Use Cases of Hot Dipped Galvanized Steel Grating/Bar Grating in Metal structure manufacturing

For B2B decision-makers in Metal structure manufacturing, integrating Karštai panardinto cinkuoto plieno grotelės / strypinės grotelės offers a multitude of benefits and extensive application possibilities. These gratings are widely utilized in constructing mezzanines, catwalks, equipment platforms, and trench covers in harsh industrial environments such as power plants, chemical processing facilities, and offshore oil rigs. Their inherent strength and exceptional durability make them ideal for areas subjected to heavy foot traffic, dynamic loads, and corrosive agents. A key competitive advantage of our Hot Dipped Galvanized Steel Grating/Bar Grating lies in its unparalleled corrosion resistance, which is critical for long-term structural integrity. The zinc coating provides both a barrier and cathodic protection, effectively preventing rust and extending the product's lifespan significantly. Furthermore, options like serrated bar grating offer enhanced slip resistance, bolstering safety in wet or oily conditions. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd leverages its extensive expertise in this sector to produce custom-fabricated gratings that precisely match project specifications, ensuring optimal performance and compliance with relevant safety standards, thereby providing a superior solution for any complex metal structure manufacturing requirement.Cost, Maintenance & User Experience

When evaluating long-term investments in the Fabricated metal products sector, the total cost of ownership for Karštai panardinto cinkuoto plieno grotelės / strypinės grotelės presents a compelling argument. While the initial investment might be slightly higher than untreated steel options, the remarkable durability and minimal maintenance requirements translate into substantial cost savings over the product's lifespan. Our gratings boast an impressive ROI by significantly reducing the need for frequent repairs, repainting, or premature replacement, even in the most aggressive industrial settings. The metallurgical bond of the hot-dip galvanizing process ensures the coating remains intact and protective for decades, preventing costly downtime associated with rust treatment or structural failures. Feedback from our customers in the Fabricated metal products sector consistently highlights the superior user experience offered by our Hot Dipped Galvanized Steel Grating/Bar Grating. Its robust construction can withstand heavy loads and impact, while the effective drainage and light-penetrating design enhance workplace safety and visibility. Installation is straightforward, allowing for quick deployment and reduced labor costs. The low maintenance profile – often requiring just occasional cleaning – frees up valuable resources, letting operations focus on core manufacturing activities rather than ongoing structural upkeep. This blend of durability, safety, and ease of maintenance makes our gratings a preferred choice for pragmatic decision-makers.

Sustainability & Market Trends in manufacturing

In today's evolving manufacturing landscape, sustainability is no longer an option but a necessity. The use of Karštai panardinto cinkuoto plieno grotelės / strypinės grotelės aligns perfectly with eco-conscious industrial practices. Steel itself is one of the world's most recycled materials, and the galvanization process further enhances its sustainability by significantly extending its service life. This longevity reduces the frequency of replacement, thereby conserving raw materials and energy associated with new production. Zinc, the primary component of the coating, is also a natural and recyclable element, further contributing to a circular economy model. Choosing galvanized grating minimizes the environmental impact by reducing waste and the need for frequent application of corrosive-resistant paints. Current market trends in manufacturing point towards an increasing demand for materials that offer both high performance and environmental responsibility. Regulatory bodies are also tightening standards for workplace safety and material specifications. Anping County Xingzhi Metal Wiremesh Products Co.,Ltd is committed to staying ahead of these trends. We ensure our Hot Dipped Galvanized Steel Grating/Bar Grating products meet stringent international environmental and safety standards. By employing efficient manufacturing processes and offering highly durable solutions, we position ourselves as a forward-thinking, eco-conscious supplier, helping our B2B partners achieve their operational goals while contributing to a greener future.Conclusion on Hot Dipped Galvanized Steel Grating/Bar Grating from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

In conclusion, for B2B decision-makers across manufacturing, Fabricated metal products, and Metal structure manufacturing, investing in Karštai panardinto cinkuoto plieno grotelės / strypinės grotelės from Anping County Xingzhi Metal Wiremesh Products Co.,Ltd is a strategic decision that prioritizes durability, safety, and long-term cost efficiency. Our gratings provide exceptional corrosion resistance, superior load-bearing capabilities, and minimal maintenance requirements, delivering a robust and reliable solution for even the most challenging industrial environments. We are dedicated to delivering products that not only meet but exceed industry standards, ensuring enhanced operational performance and a significant return on investment for our clients. Trust Anping County Xingzhi Metal Wiremesh Products Co.,Ltd for your critical infrastructure needs. Contact us today to learn how our Hot Dipped Galvanized Steel Grating/Bar Grating can elevate your next project. Email: sales2@xzmetal.com Visit our website: https://www.xzmetal.comDalintis

Naujausios naujienos

-

Durable River Bank Gabion Mesh Solutions for Protection

žiniosNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

žiniosNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

žiniosNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

žiniosNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

žiniosNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

žiniosNov.17,2025