- Awherika

- Albanian

- Amharic

- Arapi

- Arameina

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosniana

- Bulgarian

- Katarana

- Cebuano

- Haina

- Haina (Taiwan)

- Korihika

- Koroatiana

- Czech

- Teniana

- Tatimana

- Ingarihi

- Esperanto

- Estonian

- Finnish

- Wīwī

- Frisian

- Kariri

- Georgian

- Tiamana

- Kariki

- Gujarati

- Haiti Creole

- hausa

- hawaii

- Hiperu

- Kao

- Miao

- Hungarian

- Tiorangi

- igbo

- Initonia

- Irish

- Itariana

- Hapanihi

- Hawaana

- Kannada

- Kazakh

- Khmer

- Rwandan

- Koreana

- Kurdish

- Kyrgyz

- Reipa

- Latina

- Latvian

- Lithuania

- Luxembourgish

- Makeronia

- Malgashi

- Malay

- Malayalam

- Marite

- Maori

- Mareti

- Mongolian

- Myanmar

- Nepali

- Norewai

- Norewai

- Occitan

- Pashto

- Pahia

- Porohia

- Potiti

- Punjabi

- Romanian

- Ruhia

- Hamoa

- Scottish Gaelic

- Serbian

- Ingarihi

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Paniora

- Hatana

- Swahili

- Huitene

- Tagalog

- Tajik

- Tamil

- Tatara

- Telugu

- Thai

- Turiki

- Turkmen

- Iukereiniana

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Awhina

- Yiddish

- Yoruba

- Zulu

Jun . 26, 2025 16:55 Hoki ki te rarangi

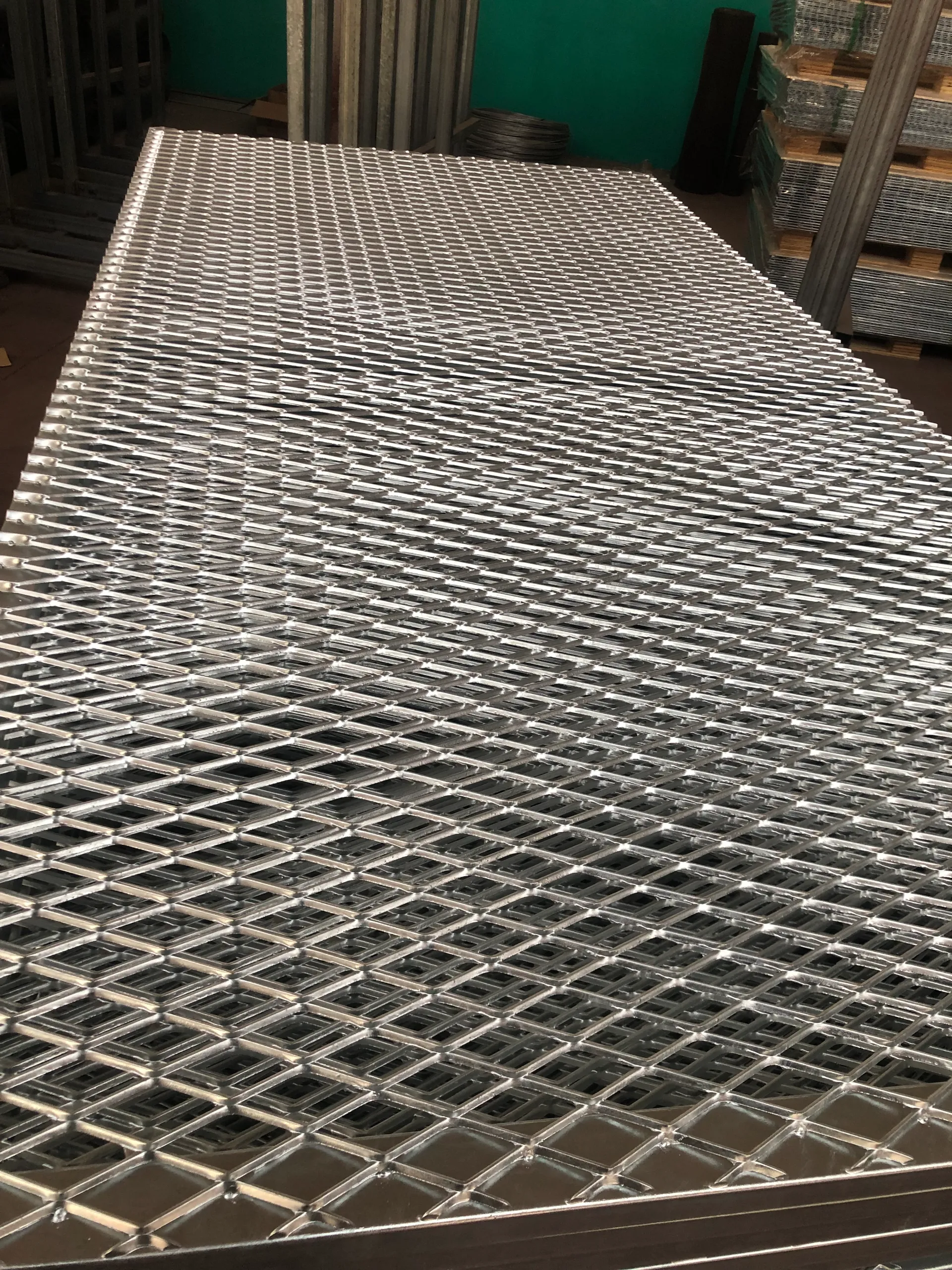

Choose Galvanized Expanded Metal Mesh

When it comes to multi-functional materials that balance strength, flexibility, and corrosion resistance, galvanized expanded metal mesh stands out as a top choice. Crafted from high-quality steel and coated with a protective layer of zinc, this mesh offers excellent performance in both structural and aesthetic applications. The galvanization process prevents rust, making it ideal for indoor and outdoor use—even in harsh or moisture-prone environments.

What makes galvanized expanded metal mesh unique is its manufacturing process: a single sheet of metal is slit and stretched to form a mesh-like pattern. This results in a material that is lighter than solid steel but retains incredible structural integrity. The openings also allow for airflow, drainage, and light filtration—making it a preferred material in fencing, enclosures, partitions, catwalks, shelving, and even architectural facades.

In addition to functionality, galvanized expanded metal mesh is environmentally friendly. Since it’s made from a single sheet without any welding or waste, it's a sustainable solution that meets both performance and ecological goals. Whether you're an industrial builder, contractor, or homeowner with a DIY project, this material offers unmatched reliability and adaptability.

Find the Right Fit with Galvanized Expanded Metal Sheet Sizes and Grades

Selecting the right galvanized expanded metal sheet involves understanding the different mesh sizes, strand widths, and sheet thicknesses available. Mesh size refers to the size of the diamond or hexagonal openings, and this determines the balance between strength and visibility. Smaller mesh openings are often used for security or screening, while larger openings provide better airflow and reduced weight for structural applications.

Galvanized expanded metal sheet is available in a range of gauges—from light-duty 20-gauge sheets used in cabinetry to heavy-duty 9-gauge sheets used in security fencing and industrial platforms. These sheets also come in standard sizes, such as 4’ x 8’, 5’ x 10’, or custom-cut formats for specialized applications.

One of the biggest benefits of galvanized expanded metal sheet is its longevity. The zinc coating resists corrosion for decades, even under UV exposure, rain, or chemical splash. This makes it a cost-effective alternative to aluminum or stainless steel while still offering robust durability. Additionally, its rough surface offers better grip in walkways or safety platforms, reducing the risk of slips and falls.

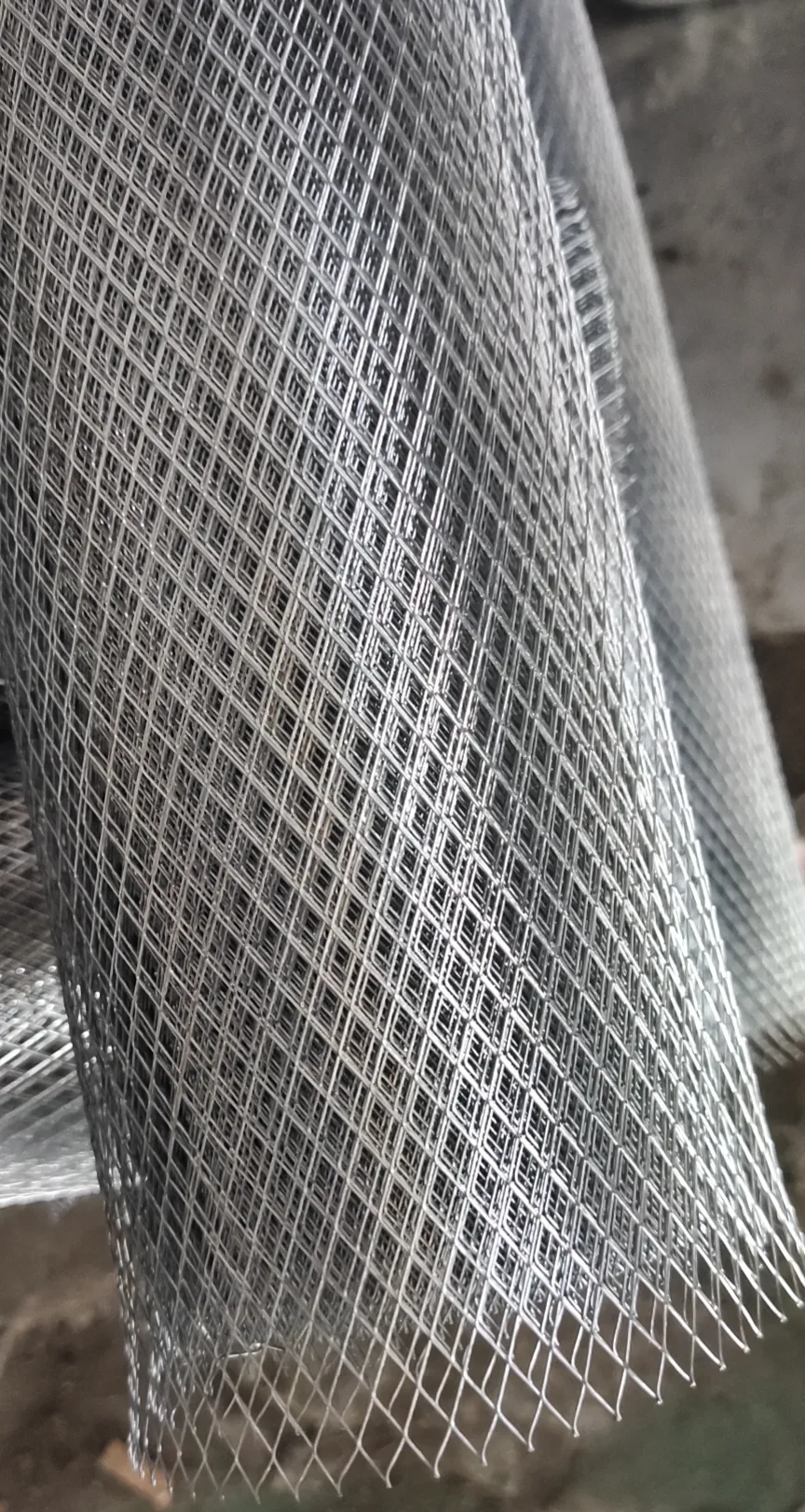

Expanded Metal Mesh Roll: Flexible, Lightweight, and Easy to Handle

For projects that require long lengths of mesh or involve irregular surfaces, expanded metal mesh roll is a practical solution. These rolls are manufactured from galvanized steel and offer all the benefits of traditional metal mesh with added flexibility and convenience. They are especially popular for lightweight fencing, animal enclosures, plaster reinforcement, and construction scaffolding.

Unlike flat sheets, expanded metal mesh roll is easier to transport, store, and manipulate on-site. Contractors often prefer rolls because they allow for seamless coverage over large or curved areas without joints or seams. The roll format reduces waste and labor costs while speeding up the installation process.

Expanded metal mesh roll is also suitable for temporary structures or quick installations. Whether you need a barrier for a construction site or reinforcement for a concrete pour, these rolls offer just the right blend of strength, formability, and corrosion resistance. And because they come pre-galvanized, they’re ready for immediate use—no additional surface treatment required.

Benefits of Galvanized Expanded Metal Mesh Across Industries

The versatility of galvanized expanded metal mesh extends to virtually every industry, including construction, transportation, agriculture, energy, and interior design. In construction, it's used for scaffolding platforms, lath for plaster or stucco, and ventilation panels. In agriculture, it's ideal for animal pens, feed hoppers, and fencing that needs to endure both impact and weather.

For architectural purposes, galvanized expanded metal sheet provides a modern, industrial look while maintaining airflow and light transmission. It can be used as sunshades, privacy screens, or decorative panels. In manufacturing, it’s commonly found in machine guards, filters, and shelving where visibility and ventilation are needed.

The lightweight nature of expanded metal mesh roll makes it ideal for automotive and aerospace applications where weight savings are crucial. Moreover, because the material doesn’t unravel or fray, it maintains its integrity even when cut to shape or size. That’s why this material continues to gain popularity in modern design and infrastructure projects around the world.

How to Maintain and Install Galvanized Expanded Metal Mesh Properly

Proper maintenance and installation can extend the life of galvanized expanded metal mesh and preserve its visual and structural integrity. Fortunately, thanks to the protective zinc coating, maintenance requirements are minimal. Occasional cleaning with water and mild detergent will remove dust or debris buildup, especially in environments with high pollution or chemical exposure.

Installation varies based on use. For fencing or barriers, galvanized expanded metal sheet can be welded, bolted, or fastened to metal posts or frames. For walkways or decking, sheets should be secured with anti-slip treads and load-bearing supports. Always ensure proper tension and alignment to avoid warping or uneven wear.

When working with expanded metal mesh roll, it’s important to unroll and flatten the material before cutting or mounting. Safety gloves and eye protection should be worn during cutting, as the edges may be sharp. Cut edges can be treated with cold galvanizing spray to restore corrosion protection. With proper handling, your expanded mesh will last for years—even in tough operating conditions.

Galvanized expanded metal mesh FAQs

What are the primary uses of galvanized expanded metal mesh?

Galvanized expanded metal mesh is widely used in construction for walkways, fences, security screens, lath support, and building facades. Its corrosion-resistant properties make it ideal for both indoor and outdoor applications. Additionally, it's used in agricultural fencing, industrial partitions, filtration systems, and even as design elements in architecture.

How does galvanized expanded metal sheet differ from stainless steel sheets?

While both offer corrosion resistance, galvanized expanded metal sheet is more affordable and suitable for general-purpose applications. Stainless steel provides higher resistance to extreme environments and chemicals, but galvanized steel offers an excellent balance of performance and cost. Galvanization also gives the sheet a rugged texture that’s useful for anti-slip surfaces.

Can I cut expanded metal mesh roll to custom sizes?

Yes, expanded metal mesh roll can be easily cut to size using tin snips, angle grinders, or industrial shears. Unlike woven wire mesh, expanded mesh doesn't unravel when cut, maintaining its structure and strength. Custom sizing is useful for fitting mesh into irregular spaces or creating tailored enclosures.

How long does galvanized expanded metal mesh last outdoors?

With proper installation and minimal maintenance, galvanized expanded metal mesh can last 20–30 years outdoors. The zinc coating resists rust and oxidation, even in coastal or industrial environments. Longevity may vary depending on exposure to salt, chemicals, and physical abrasion, but overall, it's one of the most durable mesh types available.

Is galvanized expanded metal mesh suitable for decorative use?

Absolutely. Galvanized expanded metal mesh is increasingly used in architecture and interior design for its modern, geometric look. It serves as cladding, ceiling panels, privacy screens, and light diffusers. Its ability to combine structural strength with visual appeal makes it ideal for creative and functional installations.

-

Durable River Bank Gabion Mesh Solutions for Protection

RongorongoNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

RongorongoNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

RongorongoNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

RongorongoNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

RongorongoNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

RongorongoNov.17,2025