Aug . 03, 2025 00:20 Back to list

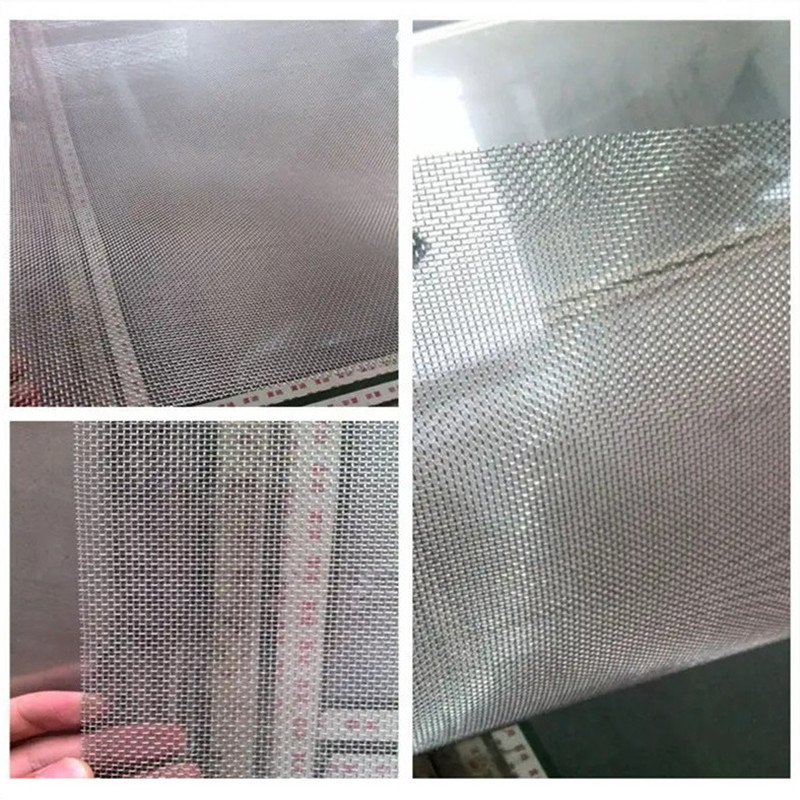

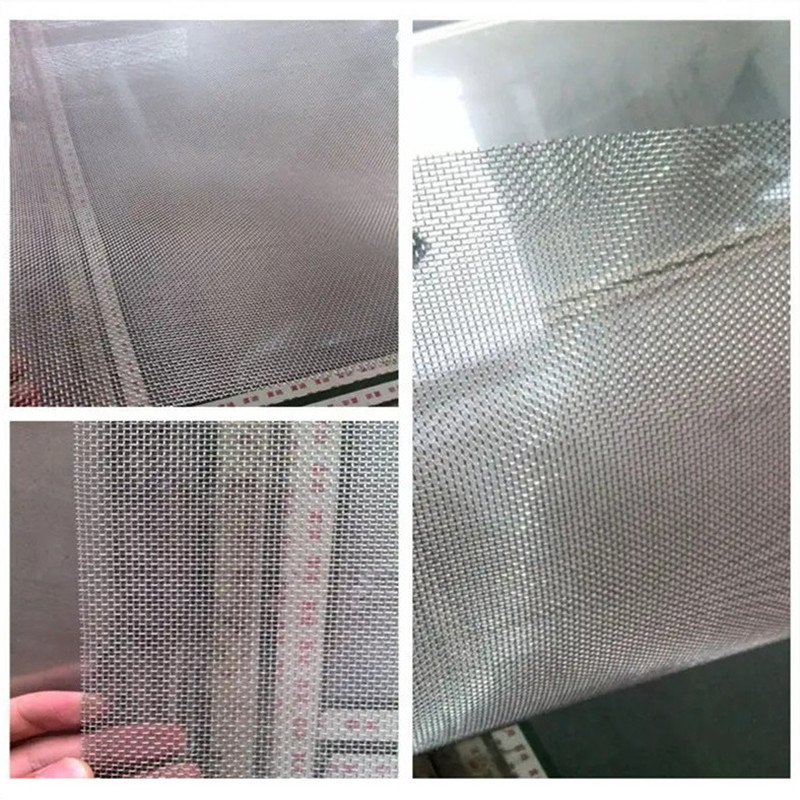

Galvanized Iron Wire Anti Mosquito Window Screen Net | Durable

As the demand for advanced Galvanized Iron Wire Anti Insect & Mosquito Mesh Window Screen Net solutions grows worldwide, industrial standards elevate product performance, safety, and durability. This article offers a comprehensive analysis of galvanized wire mesh trends, technical details, manufacturing processes, and customized deployment strategies for diverse environments. Readers will gain a professional perspective, backed with real industry data, certifications, specification tables, visual charts, and customer application cases.

Industry Trend Analysis

The global window screening market is experiencing significant growth, with increased emphasis on sustainable building materials, long-lasting corrosion resistance, and public health measures against mosquitoes and disease-vectors.

According to ResearchAndMarkets.com, the wire window screen segment is forecast to exceed $2.3 billion USD by 2028, with galvanized iron wire accounting for nearly 38% of professional installations due to:

- Superior anti-insect performance and safety

- Prolonged lifespan in challenging environments

- Cost-effective customized production

- Advanced compliance for commercial, petrochemical, and residential sectors

Technical Parameters & Industry Comparison

Primary Specification Table

| Specification | Parameter Range | Industry Standard | Remarks |

|---|---|---|---|

| Wire Material | Low Carbon Galvanized Iron (Q195/Q235) | GB/T 343, ASTM A641 | High malleability, corrosion-resistant zinc layer |

| Mesh Size | 14x14 to 18x18 mesh/inch (common: 16x16) | ISO 9044 | Optimized anti-mosquito weave |

| Wire Diameter | 0.17–0.28 mm | ANSI/ASTM E2016 | Precision-controlled, low tolerance (<0.01mm) |

| Galvanized Coating | 20–30 g/m² | ISO 1461 | Double-sided hot-dip zinc layer |

| Width Range | 0.6 m – 1.8 m | Customizable | Flexible to project needs |

| Roll Length | 10–30 meters | Project-based | Easy bulk supply |

| Service Life | >15 Years (Lab-simulated exposure) | ISO 9227 | Passed 720h salt spray test |

Galvanized Iron Wire Mesh: Key Performance Statistics (2023 Market Data)

- Market share (window screen sector): 38.6% (APAC & Europe leading regions)

- Defect rate (per 10,000 sqm):

- Average mesh warranty provided: 8–15 years per installation

- CO2 saving (vs. aluminum): Up to 14% lower embedded emission during the fabrication process

Manufacturing Process Flow & Quality Control

ISO 1461-compliant, min. 20g/m2

Quality Certifications & Global Standards: Products undergo regular inspections under ISO 9001:2015 (Quality Management), ISO 1461 (Hot-dip Galvanization), and meet ANSI/ASTM E2016 mesh uniformity standards.

Application Scenarios & Technical Advantages

Typical Use Cases Across Industries

| Industry | Scenario | Customer Requirement | Key Benefit |

|---|---|---|---|

| Petrochemical/Refinery | Process building filtered air intakes | Severe corrosion, insect vector control | High zinc coating, anti-acid/alkali resistance |

| Water Treatment | Pumping station window screens | Humidity, biofouling | Galvanized mesh retards rust, easy cleaning |

| Residential/Commercial | Windows, doors, ventilations | Aesthetic, airflow, mosquito/dust block | Exact mesh aperture and surface finish |

| Food Industry | Kitchens, food processing windows | Sanitary, anti-insect, safe material | Meets FDA/ISO food safety guidance |

| Agriculture | Greenhouse and crop protection | Durable, UV refrain, pest repelling | Long service life, environmental resistivity |

Technical Advantages

- Superior Corrosion Resistance: Zinc coatings passed 720h neutral salt spray test (>5x standard requirement; ISO 9227)

- Optimal Light and Airflow: Mesh aperture scientifically designed at 16x16–18x18 for best comfort/ventilation effect while blocking vector insects

- Eco-friendly & Recyclable: Fully recyclable iron base; production emits up to 14% less CO2 vs aluminum alternatives

- Strength-to-weight ratio: Thinner wire achieves same insect protection as thicker-fiber glass at half the mass

- Ultra-low Maintenance: Zinc passivation layer ensures minimal sticky buildup; just periodic water wash

Manufacturer Comparison Table

| Manufacturer | Certifications | Material Source | Minimum Order (sqm) | Lead Time | Warranty |

|---|---|---|---|---|---|

| XZ Metal (China) | ISO 9001, ISO 1461 | Q195/Q235, Baosteel | 500 | 10–18 days | 15 years |

| MET-Guard (India) | ISO 9044 | IS2062 local | 1000 | 20–25 days | 12 years |

| SCREENeco (EU) | EN 10025, REACH | C45, SSAB | 300 | 14–22 days | 9 years |

| RoyalMesh (US) | ASTM A641, ANSI QC | US Steel | 600 | 21–29 days | 10 years |

Custom Solutions & Case Studies

Our team offers tailored Galvanized Iron Wire Anti Insect & Mosquito Mesh Window Screen Net solutions for unique project requirements:

- Custom Mesh Size: From 10x10 to 20x20, based on client vector protection needs or airflow requirements.

- Variable Galvanization: Higher coating for tropical/coastal corrosion zones

- Special Colors: Grey, black, green powder finishes for architectural harmony

- Pre-formed Frames: Ready-to-install screens for high-rise, hospitality buildings

- OEM branding: Custom tags, box logos, barcoding as per distributor/EPC orders

Recent Project Showcase:

2023 Malaysia Petrochemical Export – Over 100,000 sqm of galvanized mesh supplied, with custom 22g/m2 coating for humid salt-heavy zone. Feedback: “After 15 months of monsoon rains, mesh shows zero sign of corrosion or clog.”

2022 Europe Nursing Home Chain – Deployed 16x16 grey-finished mesh for 6800 windows, achieving mosquito-free living while maintaining natural light, with 5-year onsite audit confirming full mesh integrity.

Professional FAQ

- Q1: What is the main wire material used? A: High-purity low-carbon iron (Q195/Q235), optionally further specified under GB/T 343 or ASTM A641, ensuring ductility and superior zinc adhesion.

- Q2: What mesh sizes are commonly available? A: Standard sizes are 14x14, 16x16, 18x18 apertures/inch. 16x16 offers optimal compromise between insect control and airflow.

- Q3: How is the galvanized coating thickness verified? A: All mesh is tested via magnetic and gravimetric methods to ISO 1461 or ASTM A641 requirements before shipment.

- Q4: Is the mesh suitable for food or hospital use? A: Yes, there are FDA- and ISO 22000-compliant variants; zinc coating has no harmful leaching, verified by SGS reports.

- Q5: What installation standards are followed? A: Mesh frames comply with ASTM E2112 (window installation), and can be pre-formed to architectural window profiles for rapid on-site fitting.

- Q6: What is the typical lead time and warranty? A: For custom orders, dispatch in 10–22 days, subject to order size, with warranty from 8–15 years against rust (>5x industry minimum).

- Q7: How is quality and traceability assured? A: Each roll is tracked via batch lot number, with third-party SGS/BV certificates and photos of salt spray/lab test records before shipment.

After-sales Service, Lead Time, and Warranty Commitment

Warranty Program: 5–15 years anti-corrosion guarantee, backed by ISO 9001 management and formal contracts.

Support Services: 24/7 technical support (EN/CN), video installation guidance, claim response Documented Quality: Each shipment includes factory test certificates, batch records, and installation instruction sheets.

Conclusion: Trusted Choice for Modern Projects

Driven by compliance with ISO, ANSI, FDA and enhanced customization, Galvanized Iron Wire Anti Insect & Mosquito Mesh Window Screen Net continues to outperform traditional screening solutions across multiple industries. Whether for petrochem, HVAC, hospital, or residential builds, its cost, reliability, and technical adaptability remain unmatched.

- Galvanized iron wire mesh properties and built environment applications — ResearchGate

- ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles — ISO Standards

- Wire mesh selection for corrosion and insect exclusion — Eng-Tips Forum

- ANSI/ASTM E2016: Industrial Wire Cloth Standard — ASTM International

-

Razor Barbed Wire: The Modern Solution for Industrial & Humanitarian Security

NewsNov.24,2025

-

Understanding Gabion Cost: A Practical Guide to Budgeting Durable Infrastructure

NewsNov.23,2025

-

Durable Gabion Mattress Mesh for Erosion Control & Infrastructure Resilience

NewsNov.22,2025

-

2x1x1 Gabion Box – Durable, Sustainable Modular Erosion Control Solution

NewsNov.21,2025

-

4x1x1 Gabion Box – Durable & Sustainable Modular Construction Solutions

NewsNov.21,2025

-

Durable Galvanized Steel Gabion Nets from Top Factories | Global Uses & Advantages

NewsNov.20,2025