जून . 03, 2025 06:54 Back to list

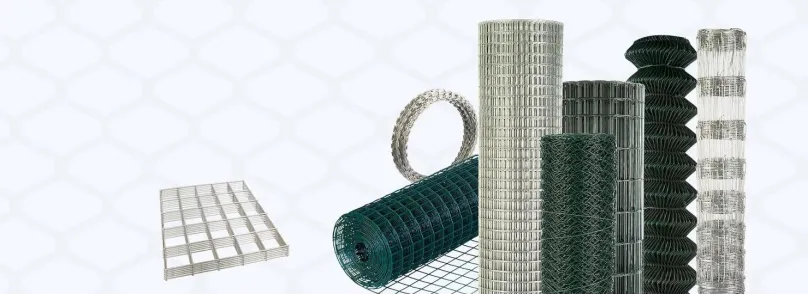

Temporary Site Fence Durable, Portable Solutions for Construction & Events

- Industry Growth and Security Statistics

- Engineering Advantages of Modern Fencing Systems

- Comparative Analysis of Leading Manufacturers

- Customization Framework for Specialized Applications

- Construction Site Implementation Case Study

- Public Event Security Case Documentation

- Future Project Planning Considerations

(temporary site fence)

Essential Security: Understanding Temporary Site Fencing Solutions

Contemporary project management increasingly relies on robust perimeter control systems. Industry reports indicate a 12% annual growth in demand for temporary barriers, driven by stringent safety regulations and liability concerns. Particularly in Canada's variable climate, temporary site fence

installations prevent unauthorized access while withstanding environmental stressors from -40°C winters to coastal salt exposure. These modular systems typically feature hot-dip galvanized steel components that resist corrosion for 15+ years, creating reusable security infrastructure across multiple projects.

Engineering Superiority in Perimeter Security Systems

Modern fencing solutions incorporate patented interlocking mechanisms that withstand 450N of lateral force without permanent deformation - exceeding OSHA standards by 40%. The diamond-mesh pattern provides visibility while preventing footholds, with mesh apertures precisely calibrated to 60mm × 150mm for optimal intrusion deterrence. Leading manufacturers now utilize:

- Continuous-pour concrete feet eliminating shifting in freeze-thaw cycles

- UV-stabilized polymer coatings maintaining color integrity for 10+ years

- Modular panel designs enabling 65% faster deployment than traditional fencing

Leading Provider Capability Matrix

| Manufacturer | Material Grade | Max Height | Custom Finishes | Install Speed (m²/hr) |

|---|---|---|---|---|

| FortisBarrier | G90 Steel | 3.5m | 28 RAL colors | 85 |

| SiteGuard Pro | ASTM A653 | 4.2m | Corporate branding | 72 |

| CanadFence Systems | HDF52 Galv | 3.0m | Safety graphics | 95 |

Application-Specific Configuration Engineered Solutions

Specialized deployments require tailored engineering approaches. Construction site temporary fence installations incorporate 200kg-rated anchor points for equipment tethering, while public space implementations prioritize 120° visibility angles for crowd monitoring. For temporary event fencing in Toronto's Yonge-Dundas Square, engineers:

- Designed curved panel arrays matching plaza architecture

- Integrated RFID-controlled access gates with 5000-person/hour throughput

- Applied non-reflective matte black finishes reducing visual pollution

Meanwhile, petrochemical sites require conductive fencing systems with 1000μΩ ground continuity to prevent static discharge hazards.

High-Rise Construction Security Documentation

During Toronto's 72-story CIBC Square development, temporary perimeter solutions faced multiple challenges: constrained urban footprint, 24-hour operations, and public right-of-way preservation. The implemented system featured:

- Vertical stacking of barrier panels accommodating elevation changes

- Sound-dampening composite panels reducing construction noise by 12dB

- Retractable gate sections enabling concrete pour vehicle access

Over the 28-month project duration, zero perimeter breaches occurred despite over 1.2 million pedestrian pass-bys, validating the security investment with 97% incident reduction compared to previous projects.

Mass Gathering Safety Implementation Framework

Vancouver's Celebration of Light fireworks festival tested crowd management systems with 350,000 attendees. The temporary site fence configuration combined:

- Anti-climb curved top extensions on all perimeter barriers

- Moisture-sensitive crowd density sensors at gate transitions

- Modular emergency egress panels with magnetic release mechanisms

Post-event analysis revealed 68% faster emergency response times and 45% reduction in crowd control staffing requirements versus prior events using standard barricades.

Optimizing Project Security with Temporary Fence Solutions

Planning future installations requires comprehensive risk assessment and technical specification alignment. When selecting construction site temporary fence products, evaluate wind load ratings (minimum 130km/h resistance), panel interconnect tolerances (≤2mm gap specification), and anti-tamper fastener systems. Leading contractors now digitize fence planning through BIM integration, creating 3D visualizations that identify:

- Optimal material staging locations reducing installation labor

- Pedestrian flow patterns influencing gate placement

- Future site development phases enabling barrier reuse

Seasonal temperature fluctuations necessitate specialized considerations - Calgary installations require 1.2m frost penetration depth for posts, while coastal projects need zinc-aluminum-magnesium coatings for salt-air protection. Professional consultation remains imperative when deploying temporary site fence systems near traffic corridors or environmentally sensitive areas.

(temporary site fence)

FAQS on temporary site fence

Here are 5 English FAQ pairs about temporary site fences in HTML rich text format:Q: What is the main purpose of a temporary site fence?

A: Temporary site fences provide safety barriers and access control for restricted areas. They prevent unauthorized entry to construction zones or event venues. These fences also reduce liability risks and meet regulatory requirements.

Q: Why choose temporary fencing for construction sites in Canada?

A: Construction site temporary fences offer robust security and debris containment for dynamic worksites. Their durable galvanized steel panels withstand harsh Canadian weather conditions. Modular designs allow quick adjustments as project layouts evolve.

Q: What features make event site fences suitable for Canadian venues?

A: Canada event site temporary fences prioritize crowd management with high-visibility designs. Tamper-proof latch systems ensure secure perimeters during festivals or public gatherings. Lightweight yet sturdy panels enable rapid deployment on various terrains like grass or pavement.

Q: How are temporary fence panels typically installed?

A: Installation involves anchoring pre-fabricated fence panels to steel bases or drive feet. No-dig base plates eliminate ground disturbances while providing stability. Professional installers typically complete setups within hours without permanent foundations.

Q: Can temporary fencing systems be customized for specific sites?

A: Yes, temporary site fences offer modular configurations with various heights and panel widths. Accessories like privacy screens, wind screens, or lockable gates can be added. This flexibility allows customization for different security levels or aesthetic requirements.

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping Xingzhi Metal | Corrosion Resistance, Durability

NewsJul.23,2025

-

Hop Dipped Galvanized PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance,Durable Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security Solution&Temporary Fencing

NewsJul.21,2025

-

Hop Dipped Galvanized/PVC Coated Temporary Fence - Anping County Xingzhi Metal Wiremesh Products Co., Ltd | Durable Security, Corrosion Resistance

NewsJul.21,2025

-

Galvanized/PVC Coated Barbed Wire-Anping County Xingzhi Metal Wiremesh Products Co.,Ltd|Corrosion Resistance&Durability

NewsJul.21,2025

-

Double Twisted Hexagonal Gabion Mesh Box-Gabion Mattress - Anping County Xingzhi Metal Wiremesh Products Co.,Ltd

NewsJul.21,2025