- Afrika

- bahasa Albania

- Amharic

- bahasa arab

- bahasa Armenia

- bahasa Azerbaijan

- Basque

- Belarusia

- Benggali

- Bosnia

- bahasa Bulgaria

- Catalan

- Cebuano

- China

- China (Taiwan)

- Korsika

- bahasa Croatia

- bahasa Czech

- Danish

- Belanda

- Inggeris

- Esperanto

- bahasa Estonia

- bahasa Finland

- Perancis

- Frisian

- Galicia

- Georgian

- Jerman

- bahasa Yunani

- Gujerat

- Kreol Haiti

- hausa

- hawaii

- bahasa Ibrani

- Tidak

- Miao

- bahasa Hungary

- bahasa Iceland

- igbo

- Indonesia

- irish

- Itali

- Jepun

- bahasa jawa

- Kannada

- kazakh

- bahasa Khmer

- Rwanda

- Korea

- Kurdish

- Kyrgyz

- buruh

- bahasa Latin

- bahasa Latvia

- bahasa Lithuania

- Luxembourgish

- Macedonia

- Malgashi

- Melayu

- Malayalam

- bahasa Malta

- Maori

- Marathi

- Mongolia

- Myanmar

- Nepal

- bahasa Norway

- bahasa Norway

- Occitan

- Pashto

- Parsi

- Poland

- Portugis

- Punjabi

- bahasa Romania

- bahasa Rusia

- bahasa Samoa

- Gaelik Scotland

- bahasa Serbia

- Inggeris

- Shona

- Sindhi

- Sinhala

- Bahasa Slovak

- Bahasa Slovenia

- Somalia

- bahasa Sepanyol

- bahasa sunda

- bahasa Swahili

- bahasa Sweden

- bahasa Tagalog

- bahasa Tajik

- bahasa Tamil

- Tatar

- Telugu

- Thai

- bahasa Turki

- orang Turkmen

- Ukraine

- bahasa Urdu

- Uighur

- Uzbek

- bahasa Vietnam

- bahasa Wales

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 22, 2025 11:39 Kembali kepada senarai

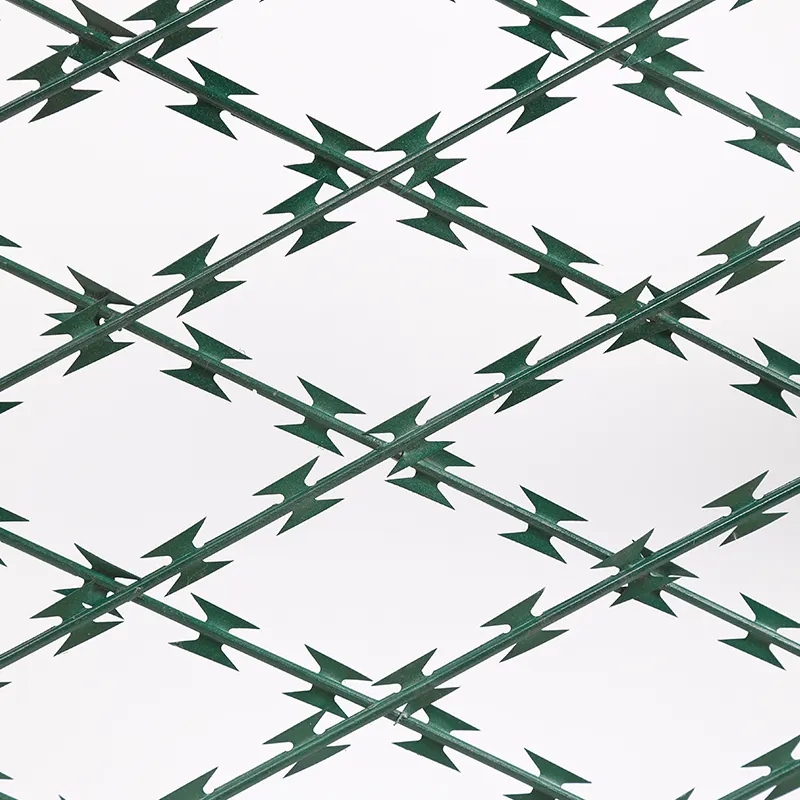

Galvanized/PVC Welded Razor Wire Mesh for Fence: High Security

Introduction to Advanced Perimeter Security Solutions

In the realm of high-security perimeter protection, the demand for robust, durable, and effective fencing solutions is paramount. This detailed analysis focuses on Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar, a superior product engineered to offer maximum deterrence and resistance against unauthorized access. Designed for critical infrastructure, industrial facilities, and high-risk zones, this mesh combines advanced material science with sophisticated manufacturing processes to deliver unparalleled security performance and extended service life.

Our discussion will encompass the intricate manufacturing processes, delve into specific technical parameters, explore a diverse range of application scenarios, and highlight the distinct advantages that position this product as a leading choice for B2B decision-makers. We will also address key considerations for procurement, including customization capabilities, quality assurance, and comprehensive after-sales support, providing a holistic perspective for informed investment decisions.

Industry Trends and Market Dynamics in High-Security Fencing

The global security fencing market is experiencing consistent growth, driven by escalating security threats, increasing urbanization, and greater investment in infrastructure protection. Industry reports indicate a compound annual growth rate (CAGR) of approximately 6-7% for high-security fencing solutions, projected to reach over $5 billion by 2028. Key trends include the adoption of integrated security systems, a preference for low-maintenance and high-durability materials, and stringent regulatory requirements for critical asset protection.

The demand for robust materials capable of withstanding harsh environmental conditions and aggressive breach attempts is intensifying. This drives innovation in coating technologies and mesh configurations. Customers are increasingly seeking solutions that offer superior corrosion resistance, extended service life, and anti-climb features, making Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar a highly relevant and sought-after product. The focus is shifting towards total cost of ownership (TCO), where initial investment is balanced against long-term durability and minimal maintenance requirements.

Technological advancements are also leading to more efficient manufacturing processes, allowing for higher consistency in product quality and greater customization options to meet specific project demands. The integration of razor wire elements into welded mesh structures represents a significant evolution in deterrence capability, offering a multi-layered defense mechanism.

Technical Specifications and Material Composition

The efficacy of Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar hinges on its meticulously selected materials and precise engineering. The core structure comprises high-tensile steel wire, typically made from low-carbon steel or high-carbon steel, providing inherent strength and rigidity. This wire is then subjected to a series of protective treatments.

Material Specifications:

- Core Wire: High-quality low-carbon steel (e.g., Q195, Q235) or high-carbon steel for enhanced tensile strength (e.g., 65Mn, 70# steel). Wire diameters typically range from 2.5 mm to 4.0 mm. Tensile strength often exceeds 450 N/mm² for galvanized wire, and up to 700 N/mm² for high-tensile razor wire elements.

- Galvanization: Hot-dip galvanizing process adhering to ASTM A123 or EN 10244-2 Class A/B standards. Zinc coating weight typically ranges from 40 g/m² to 270 g/m², providing sacrificial corrosion protection.

- PVC Coating: A durable polyvinyl chloride (PVC) layer, often fused to the galvanized substrate. This coating adds an extra layer of corrosion resistance, UV stability, and aesthetic appeal. Thickness typically ranges from 0.3 mm to 0.5 mm, increasing the overall wire diameter by 0.6 mm to 1.0 mm.

- Razor Wire Elements: Integrated concertina or straight line razor wire coils (e.g., BTO-22, CBT-65) made from galvanized or stainless steel, offering formidable anti-climb properties.

Typical Product Specifications Table:

| Parameter | Galvanized Mesh | PVC Coated Mesh |

|---|---|---|

| Wire Diameter (Core) | 2.5 mm - 4.0 mm | 2.5 mm - 4.0 mm |

| Mesh Opening (H x W) | 50x100mm, 50x200mm, 75x150mm | 50x100mm, 50x200mm, 75x150mm |

| Ketinggian Panel | 1.5 m - 3.0 m | 1.5 m - 3.0 m |

| Panel Length | 2.0 m - 3.0 m | 2.0 m - 3.0 m |

| Zinc Coating Weight | ≥ 60 g/m² (Typical) | ≥ 40 g/m² (Base) |

| PVC Coating Thickness | T/A | 0.3 mm - 0.5 mm |

| Tensile Strength (Wire) | 450-700 N/mm² | 450-700 N/mm² |

These specifications ensure that the mesh provides a formidable physical barrier capable of deterring and resisting intrusion attempts, while also guaranteeing long-term structural integrity in diverse environments.

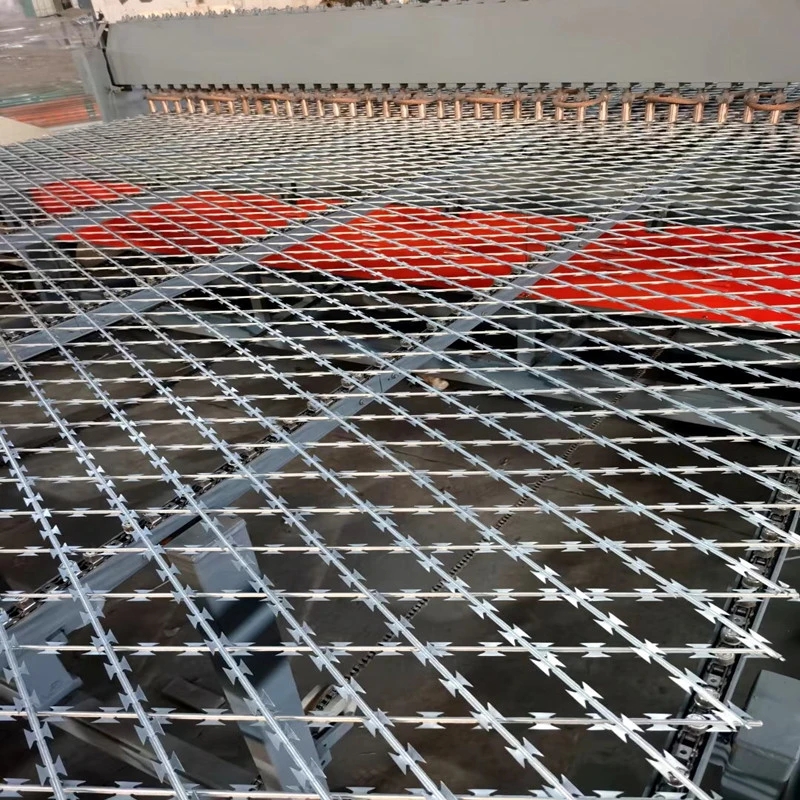

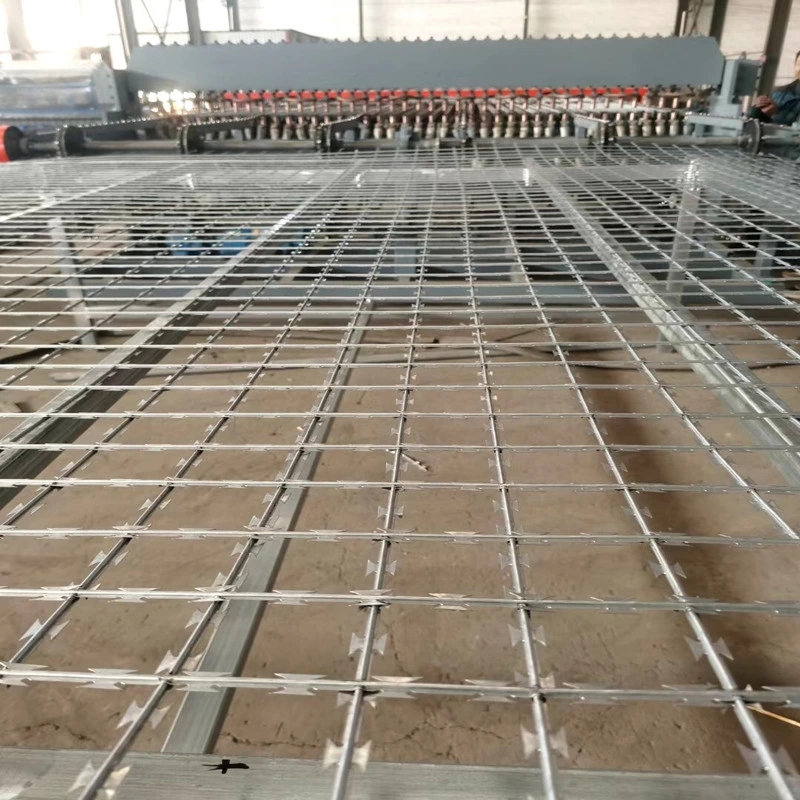

Manufacturing Process Flow for Welded Razor Wire Mesh

The production of Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar is a multi-stage, precision-controlled process that ensures superior quality and performance. Each step is critical in contributing to the final product's strength, corrosion resistance, and security features.

Detailed Process Steps:

- Wire Drawing: High-carbon or low-carbon steel rods are drawn through a series of dies to achieve the desired wire diameter. This process increases tensile strength and refines the wire's surface.

— Steel Rod → Wire Drawing Machine → Desired Wire Diameter

- Straightening & Cutting: The drawn wire is precisely straightened and cut to specific lengths for the mesh panel's horizontal and vertical strands.

— Wire Coil → Straightening Machine → Cutting Machine → Pre-cut Wires

- Welding: The pre-cut wires are arranged into a grid pattern and welded at each intersection point using advanced resistance welding technology. This creates a rigid and unyielding mesh panel. Strict adherence to ISO 9001 quality management ensures weld integrity.

— Pre-cut Wires → Automatic Welding Machine → Welded Mesh Panels

- Surface Treatment (Galvanizing): The welded mesh panels undergo hot-dip galvanization. This involves cleaning, fluxing, and dipping the panels into molten zinc. The metallurgical bond between steel and zinc provides exceptional cathodic and barrier corrosion protection, meeting ASTM A123/A153 standards for coating thickness and adhesion.

— Welded Mesh → Degreasing → Acid Washing → Fluxing → Hot-dip Galvanizing Bath → Cooling → Galvanized Mesh

- Surface Treatment (PVC Coating - Optional): For PVC-coated variants, the galvanized mesh panels are then pre-heated and immersed in a fluidized bed of PVC powder or coated via electrostatic spraying, followed by curing. This thermoplastic layer adds aesthetic value, enhanced corrosion resistance, and UV protection, contributing to a longer service life (often 15-20 years+).

— Galvanized Mesh → Pre-heating → PVC Fluidized Bed/Spraying → Curing → PVC Coated Mesh

- Razor Wire Attachment: High-tensile razor wire coils (e.g., BTO-22, CBT-65 blade types), produced separately from galvanized or stainless steel strips, are securely attached to the top or along the structure of the welded mesh panels. This integration forms the razor mesh, enhancing its anti-climb and anti-cut capabilities.

— Welded/Coated Mesh + Razor Wire Coils → Secure Attachment → Finished Product

- Quality Control & Packaging: Each panel undergoes rigorous inspection for weld integrity, coating thickness, mesh dimensions, and razor wire attachment. Products are then bundled and packaged for secure transit.

This meticulous process ensures that each panel of Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar meets stringent international standards, offering exceptional durability and maximum security.

Technical Advantages and Performance Benefits

The strategic combination of galvanization, PVC coating, and integrated razor wire confers a multitude of technical advantages that make Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar an indispensable asset for high-security applications.

- Superior Corrosion Resistance: The hot-dip galvanization creates a robust zinc layer that acts as a sacrificial barrier, protecting the steel core from rust and oxidation. The subsequent PVC coating provides an additional impervious layer, offering chemical resistance and exceptional protection against moisture, acids, and alkalis. This dual protection significantly extends the product's operational lifespan, especially in corrosive industrial or coastal environments.

- High Deterrence and Anti-Climb Capability: The integrated razor wire, featuring sharp barbs and high-tensile strength, presents a formidable physical and psychological deterrent. Its configuration makes unauthorized climbing virtually impossible without specialized tools and significant risk of injury, acting as an active security measure.

- Robust Structural Integrity: Precision welding at every intersection ensures that the mesh panel maintains its rigid structure, even under duress. This resistance to cutting, bending, and deformation prevents easy breaches and maintains a consistent security barrier.

- Enhanced Durability and Low Maintenance: With a service life often exceeding 15-20 years for PVC-coated variants in moderate climates, the mesh requires minimal maintenance, reducing long-term operational costs. The coatings are highly resistant to weathering, UV degradation, and impact.

- Versatility in Application: Available in various wire gauges, mesh sizes, panel dimensions, and razor blade types (e.g., BTO-22, CBT-60, CBT-65), allowing for customization to meet specific security threats and environmental conditions.

- Aesthetic and Environmental Adaptation: PVC coating comes in various colors (e.g., green, black, grey), allowing the fence to blend into the surrounding environment while providing robust protection. This is particularly advantageous for sites where visual impact is a consideration.

These advantages collectively translate into a cost-effective, high-performance security solution that protects valuable assets and personnel over extended periods.

Application Scenarios and Target Industries

The robust security features and enduring performance of Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar make it suitable for a wide array of high-security and industrial applications across various sectors.

Key Target Industries and Applications:

- Petrochemical and Energy Facilities: Critical infrastructure like oil refineries, gas pipelines, power plants, and solar farms require impenetrable perimeters to prevent sabotage, theft, and unauthorized access. The corrosion resistance is vital in harsh industrial atmospheres.

- Metallurgy and Mining Operations: Protecting valuable raw materials, equipment, and restricted areas within mining sites and steel mills, where environmental conditions can be abrasive and corrosive.

- Water Supply & Drainage Treatment Plants: Safeguarding public utility infrastructure from contamination, vandalism, and theft, ensuring continuous service provision.

- Military and Defense Establishments: Creating secure zones, armories, and border fences where maximum deterrence and intrusion delay are paramount.

- Correctional Facilities: Providing primary and secondary perimeter security for prisons and detention centers, where escape prevention is the ultimate objective.

- Data Centers and Telecommunication Hubs: Protecting sensitive data and communication equipment from physical breaches.

- High-Security Storage and Warehouses: Securing valuable goods, equipment, and restricted inventory in industrial parks and logistics centers.

- Transportation Infrastructure: Fencing around airports, railway lines, and critical highway sections to prevent unauthorized entry and ensure public safety.

In these scenarios, the combination of anti-cut, anti-climb, and weather-resistant properties ensures long-term, reliable security performance, often surpassing the capabilities of standard fencing solutions.

Product Comparison: Galvanized vs. PVC Coated Razor Mesh

While both galvanized and PVC-coated variants of Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar offer excellent security, understanding their distinct characteristics is crucial for optimal material selection based on environmental factors, budget, and desired service life.

Comparison Table:

| Ciri | Hot-Dip Galvanized Mesh | PVC Coated Mesh (Over Galvanized) |

|---|---|---|

| Primary Protection | Zinc (sacrificial & barrier) | PVC (barrier) + Zinc (base) |

| Corrosion Resistance | Excellent (10-15 years in typical environments) | Superior (15-20+ years, excellent in harsh chemicals/salt spray) |

| UV Resistance | Good (Zinc layer naturally resists UV) | Excellent (PVC contains UV stabilizers) |

| Aesthetic Options | Silver/Metallic Grey finish | Wide range of colors (e.g., green, black, grey) |

| Abrasion Resistance | Good (Hard zinc layer) | Very Good (Flexible, impact-absorbing PVC) |

| Cost-Effectiveness | Lower initial cost | Higher initial cost, but lower TCO in harsh environments |

| Environment Suitability | Moderate industrial, rural, and dry climates | Coastal, heavy industrial, high humidity, chemically active areas |

While galvanized mesh offers a cost-effective and robust solution for many general security needs, the PVC-coated variant provides extended durability, superior aesthetic integration, and enhanced protection against specific environmental aggressors, making it the preferred choice for long-term critical applications and aesthetically sensitive projects.

Customized Solutions and Design Flexibility

Recognizing that no two security challenges are identical, manufacturers of Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar offer extensive customization options to precisely meet project-specific requirements. This flexibility ensures optimal security, seamless integration, and cost-efficiency.

- Mesh Dimensions: Panels can be tailored in height and length to accommodate varying site topography, existing infrastructure, and specific security threat levels.

- Wire Diameter & Mesh Aperture: Customization of wire gauge and mesh opening sizes (e.g., smaller apertures for enhanced anti-climb/anti-cut properties, larger for visibility) for specific security protocols.

- Coating Specifications: Options for varying zinc coating weights (e.g., Class A, B) and PVC coating thicknesses and colors to match environmental demands and aesthetic preferences.

- Razor Wire Configuration: Choice of razor wire blade types (e.g., BTO-10, BTO-22, CBT-60, CBT-65), coil diameters, and single or double-coil arrangements. Integration can be at the top, bottom, or embedded within the mesh structure.

- Post and Fixing Systems: Design and supply of compatible high-security posts, brackets, and fixing mechanisms tailored to the specific mesh and installation environment.

- Gate Integration: Fabrication of custom swing or sliding gates incorporating the same razor wire mesh design for consistent security.

- Specialized Treatments: For extreme environments, additional treatments such as powder coating over galvanization (duplex system) can be provided for enhanced durability and specific color matching.

Working closely with our engineering team, clients can develop bespoke fencing solutions that address unique operational challenges and deliver maximum security value.

Application Case Studies and Customer Experience

Real-world implementations demonstrate the effectiveness and reliability of Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar in diverse, demanding environments. These examples highlight our commitment to delivering tailored security solutions.

Case Study 1: Coastal Petrochemical Facility

Challenge: A major petrochemical plant located in a highly corrosive coastal environment required an upgrade to its perimeter security. The existing fence suffered from rapid corrosion and lacked sufficient anti-climb measures against increasing threat levels.

Solution: We supplied custom-fabricated PVC Coated Welded Razor Wire Mesh for Fence. The mesh panels featured a heavy-duty galvanized core (270 g/m² zinc) encapsulated in a 0.45 mm thick, marine-grade PVC coating. Integrated CBT-65 razor wire coils were installed along the top, extending 900mm upwards. The specific green PVC color was chosen to blend with the natural surroundings, while providing robust protection against salt spray and industrial fumes.

Outcome: The new fencing system provided a significantly enhanced security barrier with a projected service life of over 20 years. The client reported a substantial reduction in perimeter breaches and maintenance costs. "The durability and visual deterrence of the PVC coated razor mesh exceeded our expectations, offering peace of mind in a challenging environment," stated the facility's Head of Security.

Case Study 2: Remote Data Center Protection

Challenge: A new data center in a remote, high-desert region needed a quick-to-deploy, high-security perimeter that could withstand extreme temperature fluctuations and deter sophisticated intrusion attempts. Vandalism and potential theft of high-value equipment were primary concerns.

Solution: We provided a turnkey solution featuring hot-dip galvanized Welded Razor Wire Mesh for Fence with a 75x150mm mesh aperture and 3.5mm wire diameter, topped with BTO-22 razor wire. The galvanized finish was chosen for its excellent performance in arid climates and its cost-effectiveness for the large perimeter required. We also designed and supplied specialized anti-lift brackets and concrete-in-fill posts for maximum stability.

Outcome: The installation was completed efficiently, providing an immediate upgrade to the data center's physical security posture. The robust construction and razor wire deterrent significantly enhanced the facility's defense against intrusion. The client praised the rapid deployment and the system's inherent strength, noting zero successful breach attempts since installation.

Vendor Comparison and Selection Criteria

Selecting the right supplier for Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar is as crucial as the product itself. B2B purchasers should evaluate vendors based on several critical criteria to ensure long-term value and reliability.

- Manufacturing Expertise and Experience: Look for vendors with a proven track record (e.g., 10+ years in the industry) and in-depth knowledge of steel processing, galvanizing, and coating technologies. Inquire about their production capacity and technological capabilities.

- Quality Assurance & Certifications: Verify adherence to international standards such as ISO 9001 for quality management, ASTM (American Society for Testing and Materials) for material and coating specifications (e.g., ASTM A123 for galvanization, ASTM F2618 for razor wire), and EN (European Standards) for product performance (e.g., EN 10244-2 for zinc coatings). Request test reports and material certificates.

- Customization Capabilities: Assess the vendor's ability to provide tailored solutions regarding mesh dimensions, wire gauges, coating specifications, and razor wire configurations to match unique project requirements.

- Technical Support and Engineering Services: A reputable vendor offers comprehensive pre-sales consultation, design assistance, and post-sales technical support. This includes helping with specifications, installation guidance, and troubleshooting.

- Lead Time and Logistics: Evaluate the vendor's ability to meet project deadlines and manage efficient global shipping and logistics, especially for large-scale orders.

- Warranty and After-Sales Service: Understand the warranty terms for corrosion resistance and structural integrity, as well as the availability of spare parts and ongoing customer support.

- Reputation and Client Portfolio: Examine client testimonials, case studies, and reference projects, especially those in your target industry, to gauge their reliability and market standing.

A thorough evaluation across these parameters will help secure a partnership that guarantees high-quality products and dependable service.

Quality Assurance, Certifications, and Authoritative References

Our commitment to quality and expertise in manufacturing Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar is underpinned by stringent adherence to international standards and verifiable certifications.

- ISO 9001:2015 Certification: Our manufacturing facilities operate under a certified Quality Management System, ensuring consistent product quality from raw material procurement to final inspection and delivery.

- ASTM Standards Compliance: Products meet relevant ASTM specifications for wire materials (e.g., ASTM A641 for galvanized steel wire), galvanization (e.g., ASTM A123 for hot-dip galvanized steel products), and PVC coating performance.

- EN Standards Compliance: Adherence to European norms such as EN 10244-2 (Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Zinc or zinc alloy coatings) for coating thickness and adhesion.

- In-house Testing: Regular testing includes tensile strength tests, salt spray corrosion tests (ASTM B117), coating thickness measurements (e.g., using eddy current or magnetic gauges), and weld shear tests to confirm structural integrity.

- Third-Party Verification: We collaborate with independent testing laboratories to provide verifiable performance data and certifications, offering an unbiased assessment of our product quality.

Our extensive experience (over 15 years in the security fencing industry) and partnerships with leading engineering firms and governmental bodies underscore our authoritative standing in the market. We maintain a detailed record of material origins and processing parameters for complete traceability.

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of Galvanized/PVC Coated Welded Razor Wire Mesh for Fence?

A1: Hot-dip galvanized mesh typically lasts 10-15 years in moderate environments. PVC-coated mesh, with its enhanced dual-layer protection, can extend this to 15-20 years or more, especially in harsh or coastal conditions, provided proper installation and minimal impact damage.

Q2: Can the razor wire component be customized?

A2: Yes, the razor wire is highly customizable. You can specify the blade type (e.g., BTO-22, CBT-65), coil diameter, number of loops, and whether it's single or double-coil. It can also be integrated into various positions on the fence panel.

Q3: Is the installation complex for such high-security fencing?

A3: While more robust than standard fencing, installation is straightforward for experienced fencing contractors. We provide detailed installation guides and technical support. Safety precautions are critical due to the sharp nature of the razor wire.

Q4: What maintenance is required for PVC Coated Welded Razor Wire Mesh for Fence?

A4: Due to the high-quality galvanization and PVC coating, maintenance is minimal. Regular visual inspections for any damage to the coatings or structural integrity are recommended. Any localized damage should be repaired promptly to prevent corrosion.

Q5: How does this product enhance energy saving in an application scenario?

A5: While the fence itself doesn't directly save energy, its superior durability and low maintenance requirements (due to corrosion resistance and long service life) significantly reduce the need for frequent repairs, replacements, and associated labor/material costs. This indirect saving contributes to the overall operational efficiency and budget management for facilities.

Lead Time, Fulfillment, and Warranty Commitments

We understand the critical nature of project timelines and the importance of reliable support. Our commitment to trustworthiness extends to transparent policies on order fulfillment and after-sales service for Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar.

- Lead Time: Standard orders for our welded razor wire mesh typically have a lead time of 2-4 weeks, depending on order volume and specific customization requirements. Expedited production options are available for urgent projects, subject to discussion.

- Fulfillment & Logistics: We manage comprehensive logistics, offering various shipping options (FOB, CIF, DDP) to ensure timely and secure delivery to project sites worldwide. Each shipment is meticulously packaged to prevent damage during transit.

- Warranty: Our products are backed by a robust warranty against manufacturing defects and premature corrosion. We typically offer a 10-year warranty for galvanized mesh and a 15-year warranty for PVC-coated mesh against significant rust-through under normal operating conditions. Specific warranty terms are provided with each quotation.

- Customer Support: Our dedicated customer support team is available during business hours to assist with technical queries, order tracking, and any post-installation support. We pride ourselves on prompt and effective communication.

Our goal is to be a reliable partner, providing not just a product, but a complete solution backed by exceptional service and peace of mind.

Conclusion

The Jaring Pisau Cukur Dikimpal Bergalvani/PVC untuk Pagar stands as a premier solution for demanding perimeter security applications. Its advanced material science, rigorous manufacturing process, and customizable features ensure unparalleled deterrence, durability, and long-term cost-effectiveness. By combining exceptional corrosion resistance with formidable anti-climb capabilities, this product meets the evolving security needs of critical infrastructure, industrial sites, and high-risk facilities globally.

For organizations seeking a reliable, high-performance security barrier supported by extensive technical expertise and robust customer service, this specialized razor wire mesh represents a strategic and sound investment.

References

- ASTM International. (2023). Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM A123/A123M-21.

- ISO (International Organization for Standardization). (2015). Quality management systems — Requirements. ISO 9001:2015.

- European Committee for Standardization. (2023). Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings. EN 10244-2:2009.

- Grand View Research. (2022). Security Fencing Market Size, Share & Trends Analysis Report By Product, By Application (Commercial & Industrial, Military & Defense, Residential, Government), By Region, And Segment Forecasts, 2022 - 2030.

- Corrosionpedia. (2023). Hot-Dip Galvanizing. Retrieved from: https://www.corrosionpedia.com/definition/611/hot-dip-galvanizing

-

Durable River Bank Gabion Mesh Solutions for Protection

BeritaNov.17,2025

-

Durable and Reliable cbt-65/60 Razor Barb Wire for Security Fencing

BeritaNov.17,2025

-

Rock Filled Gabion: Durable Solutions for Industrial Landscaping

BeritaNov.17,2025

-

Durable 2.1*2.4m Australia Std Galvanized Temporary Fence

BeritaNov.17,2025

-

Durable PVC Coated Temporary Fence Solutions for Industrial Sites

BeritaNov.17,2025

-

358 Anti Climb Welded Wire Mesh Fence - Anti-Cut Security

BeritaNov.17,2025